hex 240 mud pump for sale

A mud pump is a reciprocating piston device designed to circulate drilling fluid under high pressure. RS-240 triplex single-acting piston pump is a horizontal, triplex, single acting reciprocation piston pump which is reliable, agile and simple for operation. It can be driven by diesel engine, electric motor or hydraulic motor. RS-240 triplex single-acting piston pump is characterized by compact structure, smooth running, large-scale variable rates of flow, high output pressure, long service life and so on.

As a well-known global mud pump manufacturer, we provide all kinds of mud pump to meet the needs of different construction demands. RS-240 triplex single-acting piston pump provides 4 different discharge pressure, and it is mainly used to match horizontal directional pipe laying drilling machine. The pump can meet the needs of construction for water well and earth heat, superficial layer oil drilling and mine drainage.

Our pump stroke counter systems (CPS101 Series) measure the stroke rate and number of strokes on mud pumps. The oilfield pump stroke system is user-friendly and reliable and is configurable to measure up to three mud pumps at once. Our digital pump stroke counter systems are manufactured here in the U.S. by Crown Oilfield Instrumentation, and Crown’s Pump Stroke Counter provides easy monitoring of strokes per minute on multiple mud pumps. Each mud pumps’s stroke rate can be selected individually and the display is updated regularly for accurate monitoring. LCD displays indicate both pumps strokes per minute and the total number of strokes. Located at the bottom of the panel, push buttons provide easy operation and reseting of each pump. When you need to accurately monitor and maintain the amount of mud being pumped, you can trust Crown’s oilfield stroke counters.

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex:Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well"s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

15 Models below. Made in USA. Gas, Diesel or Electric diaphragm pump, or mud / sludge pump. Easily maneuverable, the gas diaphragm pump is built for performance; Ideal for seepage dewatering, high suction lift, cleaning septic tanks, pumping industrial waste and marine tanks, small wellpoint systems and dewatering in sandy, muddy waters. Honda or Briggs gasoline engine or Electric diaphragm pump with motor.

Durable design with enclosed gears in oil bath, self cleaning flow path, dry run without damage, auto priming. Built in polyurethane flapper / check valve assures self-priming to 20 feet. This unit has steel suction strainer, two NPT hex nipples and wheel kit with 10" semi-pneumatic transport wheels for portability.

Diaphragm Mud pump Suction & discharge port size cannot be reduced. Cast aluminum construction with thermoplastic rubber diaphragm. Also called a mudhog. 90 degree rotatable base on all models to fit through narrow gates. As a alternate in a centrifugal pump dredge pump design see 316F-95 2" mud pumps. Trash pumps, centrifugal Dredge Pump. Hoses and accessories.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

An integral part of onshore and offshore drilling, mud pumps circulate the drilling fluids used to facilitate drilling oil and natural gas wells. Used to stabilize pressure and support the well during the drilling process, drilling fluids also provide friction reduction and a means to remove cuttings.

While drilling with some type of fluid has been in practice for centuries, the term "drilling mud" was coined when a herd of cattle was driven through a wet field near Spindletop, and the resulting mud was used to lubricate the drillstring and drill bit. Drilling fluids have come a long way since those early days of drilling, and offshore mud pumps are constantly taxed to help operators find and develop hydrocarbons in harsher, deeper and more difficult locations.

"A mud pump delivers drilling fluid from the mud tanks, through the top drive, down the drill string and through the bit," explained Juan Lerma, Mud Pumps Product Line Manager at National Oilwell Varco. "When the mud exits the bit, it travels back to the surface carrying the cuttings made by the bit where it flows over a shale-shaker removing the cuttings, cleaning the mud and returning it to the tanks, where it"s used over and over again."

"A mud pump is one of the critical and required pieces of equipment for a drilling rig whether on land or offshore," Lerma stated. "Offshore, where real estate is at a premium, mud pumps are configured with a compact top-mounted drive system, reducing the overall length with a smaller package and strategically placing it in the pump room for permanent installation."

"Jackups semis and drillships all use the same mud pumps; however, the number of pumps installed in the pump rooms changes from rig to rig depending on the drilling specifications," explained Lerma.

Additionally, the rock formations and pressure encountered when drilling may vary; HT/HP and environmental conditions also may affect the drilling process, as well as the drilling fluids chosen and mud pumps required.

"As the drilling programs require higher flows and higher pressures, it is necessary to increase pressure ratings and either increase the number of mud pumps required or utilize larger capacity mud pumps," Lerma continued. "Most early jackups utilized two mud pumps and piping systems rated for 5000 psi work pressures and 1600 horsepower, while most of today"s jackups have 7500 psi working pressure and up to four 2200 HP pumps piping systems."

According to information gathered by premium rig data service RigLogix, National Oilwell Varco leads the pack in providing mud pumps to offshore oil rigs. Of the top six brands of mud pumps, NOV supplies four of them, garnering more than 70% of the offshore mud pump market.

Those leading NOV brands include National Oilwell, Continental Emsco (which was acquired by NOV in 1999), National and NOV. The other leading mud pump system is provided by Gardner Denver and is the third most popular type of system offshore. Additionally, Lewco, a division of Rowan, has about 4% of the offshore mud pump market, putting it fifth on the list of leading suppliers.

With more than four decades of experience providing the offshore industry with mud pumps, Lerma revealed that the company has been able to sustain such a high market share by constantly transforming the product to meet the needs of the industry. As offshore drilling programs have required higher flows and pressures, the company has strived to provide the best quality equipment, while maintaining the lowest cost of ownership.

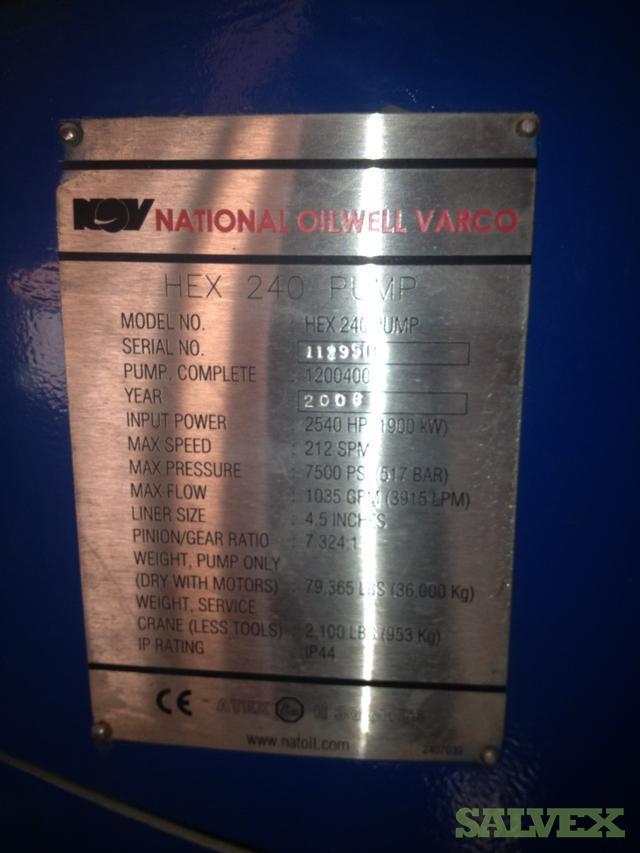

To better serve its offshore clients, the company developed the Hex Pump in the last several years, and this new line of mud pumps has proven a success in offshore waters worldwide. Boasting 2400 HP, the Hex pump is capable of delivering up to 1,034 gallons of drilling fluids per minute, making it one of the most powerful mud pumps on the market today.

In 2004, the first two Hex Pumps were deployed on a Global Santa Fe rig working offshore West Africa, and in 2005, both the Noble Max Smith and the Noble All While started using the Hex Pump as well. In fact, the Noble Al White, working in the harsh conditions of the North Sea, was the first rig to be solely dependent on the Hex Pumps with two of them located in its pump room, and the rig now has more than 8,000 hours of successful drilling operations using the system.

"The first drillship to use the system, Transocean"s Discoverer Clear Leader just started drilling in the Gulf of Mexico with five Hex Pump systems," said Lerma. "Additionally, the soon-to-start-drilling Discoverer Americas houses four Hex Pumps, and the soon-to-be-delivered Discoverer Inspiration will have five."

- The pump skid weighs only 2450 kg (wet) and only covers an area of 2.4 m x 1.92 m making it very easy to move into restricted areas due to its compact abilities.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

8613371530291

8613371530291