hhf-1600 mud pump manual in stock

‘ancl then locked down to avoid the preset pressure changing.‘Upon builtin installation of the lube oif pump, as shown item 9 in Figure 13, the pump mast be

1 The cylinder (block) (fluid end) of HHF-1300/1600 and FB-1300/1600 can be interchanged, but the start place of screw hole of 12x1-14UNS-2B is different (place for wear ring connection),, 2 The clamp assembly of piston rod of FB-1300/1600mud pump can be used for HHF-1300/1600mud pump, contrarily, The clamp assembly of piston rod of HHF-1300/1600 mud pump can not be used for FB-1300/1600mud pump. (because the clamp assembly of HHF-1300/1600 has no thread to connect spray line

Suction Damperis a part of mud pump, used as pressure balance on mud pump. rubber suction bladder is the main parts for drilling mud discharged assembly.it is made of rubber vulcanization, to meet the needs of high pressure jet...

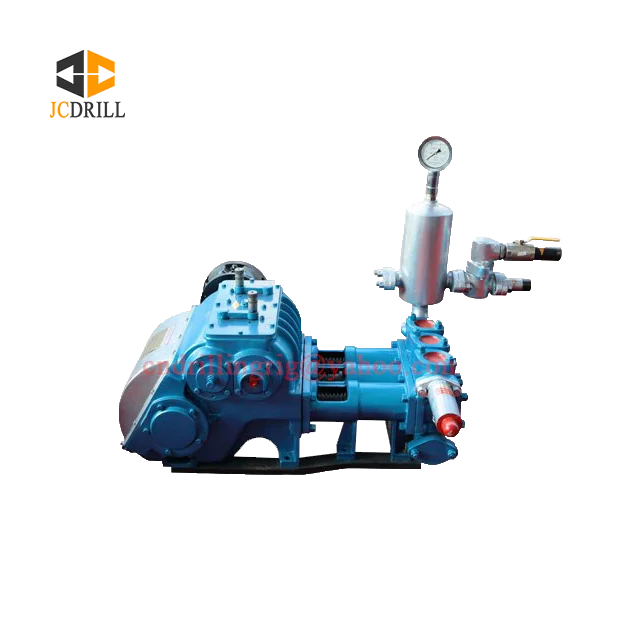

The mud pump is horizontal tri-cylinder dual role penthouse Detroit piston pump. It is mainly used to supply flushing fluid to the drilling well in core drilling or hole drilling. The pump can discharge not only clear water, but also thick mud. And for the specialty of small external dimension, light weight, the pump is suitable for transportation in mountain.

BW450/5 type mud pump is a horizontal triplex single acting reciprocating piston pump, which has three bore and four gear speed. Displacement and hole depth can be adjusted according to the application, the deepest can be adjusted to the application,the deepest can be used with 1800meters driling rig,it also can be used cement perfusion.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

BW450/5 Mud Pumps is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1500 meter.

We have specilized in research, development and produce of rock blasting drilling rig, water well drilling rig, diamond core drilling rig, anchor drilling rig,Mud pump and relative accessories & drilling services. constantly provide professional drilling solutions for all customers with our advanced technology, excellent equipment, strict testing means and perfect service network, which establish our brand "JINCHENG" a good image of market, now,we products account for 50% of domestic market and have been export to more than 40 countries, and we awarded ISO9001: 2000 in November, 2002.

A: Normally mud pump products will take about 3-15 days to produce the ordered machines. Most of the time, we can have an immediate delivery of our regular machines in 15 days.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

Mud pump liner is an important and easily worn part of the mud pump fluid end, so the service life of mud pump liner directly affects the service life of the mud pump. The liner must not only have sufficient strength and rigidity but also must be resistant to high temperature, corrosion, and wear.

Hy-Chrome liner is one of the mud pump fluid end parts used most widely and largest at currently. Our production Hy-Chrome liner is a combination of hot forging high wear coat and the advantages of high chrome wear-resisting corrosion inner sleeve. The outer sleeve is made of quality carbon steel hot-pressing time forming, an inner sleeve made from high chromium cast iron centrifugal casting. And the tensile strength of the outer sleeve is higher than 900000 psi, the hardness of the inner sleeve after heat treatment is greater than HRC62 and can bear the mud pressure of 7000 psi, it"s surface smooth as a mirror, inner hole size tolerance strictly, the normal service life is up to 800 hours.

8613371530291

8613371530291