high-pressure mud pump manufacturers pricelist

Explore a wide variety of mud pump price list on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump price list are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump price list is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump price list for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump price list to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

The crank gear and connecting rods drive a rotary movement that is transferred by the motor transmission. The pressure is produced by the piston in the cylinder due to which the mud is sucked. Following the operation, the suction valve is closed when it moves to left. As the pressure increase in the pipeline, the valve is forced to open and mud is released.

In accordance with the operating liquid displacer type being incorporated, the pumps are subdivided into piston units and plunger-type units. The liquid discharge uniformity is independent of head. The pumping plants are used actively for the processes with the liquids containing solid inclusions in high amounts. Incorporating the self-suction function in piston unit, the liquid is sucked and discharged twice in mud pumps during the single shaft turn, making themselves the double-action pumps whereas, the mud plunger pumps are single-action pumps where the liquid is sucked and discharged only once during a shaft turn.

The single direct-action three-piston pumps prove to be better than other types of drilling. These pumps demonstrate much more uniformity in mud delivery, lesser weight, and easy mounting when compared with two-cylinder units.

Depending on the number of cylinders, the pumping plants are classified into the following categories, single-cylinder, double-cylinder, three-cylinder and multi-cylinder pumping plants. These cylinders may be vertical or horizontal. Comparatively, the multi-cylinder pumping plants will cost higher but don’t feature any significant advantages other than the single-cylinder.

When drilling, there might occur the necessity of mud pumping out- and flushing-out, so there are various types of pumps available for such operations which are required to be installed on drilling rigs.

Sucker-rod pumps: In sucker-rod pumps, the pumpjack is a driver. This pump is installed at the bottom of the well. The reciprocating movements of the pumpjack are converted into liquid flow by the pump, which results in delivery of liquid on the surface. These pumps move oil with various admixtures demonstrating high level of capacity.

Screw pumps:The screw pumps are small-sized and are generally used to deliver mud into a centrifuge. These pumps have the rotor and stator as the major structural components and the material used to manufacture these components suit right for smooth pumping of liquids with solid inclusions and high level of viscosity. The pumped liquid flows with stable pressure, shaft slowly and the flow is free of vortexes. These pumps comparatively require minimum service.

Well pumps: These pumps are submerged into wells. The ground part of the plant is a transformer substation equipped for start and adjustment. The pump has a vertical structure, with a fixed cylinder and single-action. A plunger and valve are moving parts. The pumped liquid may contain water content of up to 99% at the temperature as high as 130ºC.

All the mud pumps have few general advantages that include the capability to process liquids and substances with high level of viscosity and with admixtures. Also, enabling the smooth flow of substances, free of pulsations or suspensions mixing are counted under the major advantages of incorporating mud pumps. The pumps have high suction power and small weight, easing out the transportation and installation at remote oil fields. They are highly reliable and also affordable.

There are various types of mud pumps available for different purposes. So, it is important to incorporate the right one for your purpose. A Professional help in getting the right mud pump would be a good and safe option.

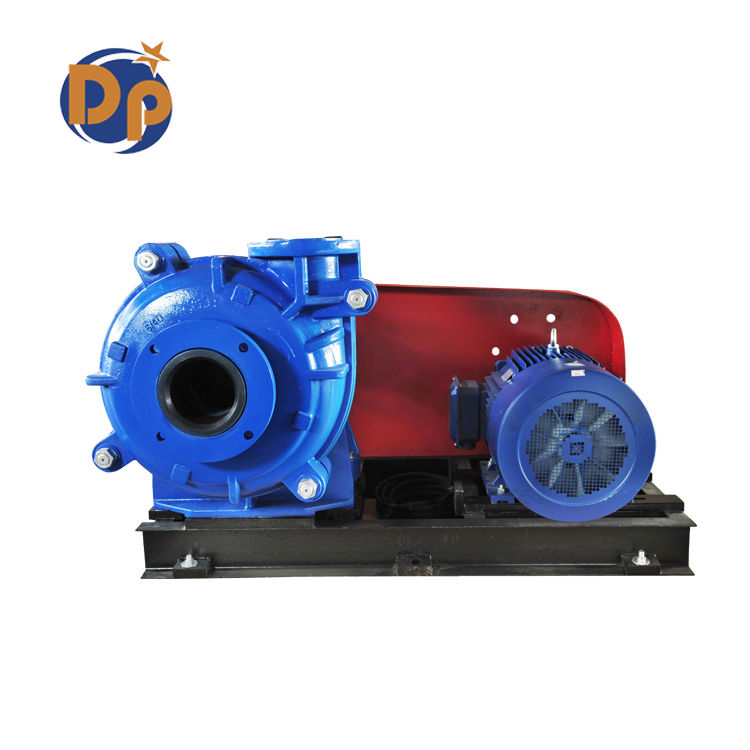

Mud pump, refers to the drilling process to the drilling mud or water and other washing liquid machinery. The main components are volute, impeller, pump seat, pump case, support cylinder, motor seat, motor and other components. Impeller nut is cast iron, so corrosion resistance is good, and convenient processing technology. Pump seat is equipped with four skeleton oil seal and shaft sleeve, prevent shaft wear, prolong the service life of the shaft.

High quality vertical mud pumps with thick, solid shaft and copper motor can be provided in ATO shop. Various models are available, such as 2 inch mud pump, 3 inch mud pump, 4 inch mud pump and 6 inch mud pump. Here is the price list of vertical mud pump.

Sewage mud pump is used in mining, papermaking, printing and dyeing, environmental protection, ceramics, refining, petroleum, chemical industry, farm, dyeing, brewing, food, construction, gold mine, mud, quicksand, mud pond, sewage pond, turbid fluid to send suction thick liquid, loading and suspended matter sewage operation, can also be used for mine drainage and fluid containing mud blocks.

If the mud pump and high-pressure water pump, water gun with the composition of hydraulic mechanized earthwork unit, can be used for land leveling, river and pond dredging, digging and other small water conservancy projects, as well as urban air defense engineering, underground engineering.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

High pressure water pumps from PumpBiz cover the full spectrum of applications. From the top manufactures, our high pressure pump inventory includes engine driven and electric motor driven, and centrifugal as well as diaphragm pumps.

We sell high pressure pumps from the most reliable manufacturers in the country. While we have a large selection of high pressure pumps for sale, we want to be sure you purchase the right pump for your needs. If you are not sure which pump is best, please give us a call. While we are always happy to sell pumps to you, we want to be sure it is the right pump for your needs.

For most applications, electric water pumps are very common. From high pressure pumps for irrigation to small pumps for ice machines, the primary power is provided by electric motors. If you have a relatively stationary need with reliable electric power, the high pressure electric pumps are your best choice.

Gorman-Rupp and AMT are among the most popular brands for engine driven high pressure pumps. Their gas or diesel powered pump engines provide high pressure pumping capabilities that are portable and reliable. For high pressure fire pumps, we provided LP conversion kits as well.

We carry pumps from the top pump manufacturers in the United States. Some of more popular high pressure pump manufacturers are All-Flo, Lanaster, Gorman-Rupp, Berkeley, AMT, MTH, Myers, Sta-Rite, Oberdorfer, Pedrollo, Flotech, Webtrol, and Pumptech. While not an exhaustive list of our high pressure pump manufacturers, it should give you an idea of the breadth of pumps available from PumpBiz.

High pressure water pump prices vary widely. You can obtain pumps from $75 - $5,000 or more. The real question about pricing starts with your application. How much do high pressure pumps cost that are designed for your specifications and needs. On the left side of the page are price ranges. If you have a sense of the range of prices your needs fall, you can filler our pumps by price. If you’re not sure, give us a call and we’ll help you find the right price range, and the right pump.

The HMI HM-1 hydraulic mudjacking pump was the first concrete raising product engineered and manufactured by HMI, just over 40 years ago. It’s reliability and superior engineering maintains its place in the market, but has also acted as the springboard for other, more advanced models / options which offer various options of engine horsepower, hopper size, pumping pressure, and so much more.

Our largest, self-propelled, multi-functional pump. This rugged and durable pump is the top-of-the-line mudjacking unit. With the highest available pumping pressure, largest material hopper, most horsepower and versatility.

Our most popular model, the self-propelled, hydraulic mudjacking pump drives circles around the competition. Affordable and durable, the Power Pump is a great way to start-up or add to a concrete raising business.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

A wide variety of impellers and shaft seals provide a prefect fit for a wide range applications. The DE-PUMP ®slurrypumpprovidesexcellentwearlifewhilemaintaining efficiencyduringthewearcycleprovidingthebesttotaloperatingcost.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Hangzhou Qinjie Electromechanical Co.,ltd is a branch company established by Feili Pump in 2015. Because Hangzhou is a big city with developed economy and trade and talents gathering.

Our goal is providing high-quality, cost-effective solar water pumps to customers around the world, so that people can use green and energy-saving products, no longer worry about shortage of water.

The company introduces the ISO9001 quality system, strictly controls the quality and stability of raw materials, and pushes high-end products to the global market. We have a 9,000 square meter workshop and two assembly lines with the ability to produce motors, assemble pumps, test and develop. Currently has 5 utility model patents.

At present, our pumps have obtained relevant export certificates such as CE SGS CB, and the products have certain market share and brand recognition in Southeast Asia, Africa and North America.

Ideco is one of the parts of a mud pump that is complete with high quality parts. This is a name that is a leading manufacturer of high quality parts of the fluid end such as the following:Modules

The Ideco pumps allow an addition in the quality trading of the replacements parts of the mud pumps and their parts that also take into account the following varieties such as:Centrifugal pumps

All of the above mentioned ingredients are found in the market and are available for better oil drilling and extraction. There are more than 1000000 varieties of inter changeable mud pump constituents and all the previously mentioned types like centrifugal pumps, parts of a rig and swivel components for the majority of the manufacturers and this includes Ideco. Their components include:Duplex pump spares

Parts of Ideco are provided with a full series of pistons for the triplex as well as duplex mud pumps. This is done for ensuring their popularity among the customers. All the manufacturers of the mud pumps and their parts make sure or try to make sure that their products and constituents are made under the certification of the American Petroleum Institute, the API. Some of them include:Bonded rubber pistons

The Bonded premium urethane piston is a single piece bonded constructed piston that does not have any joints which guarantees the prevention of leaking. The Ideco components like these eliminate the possibility of the abrasive fluids to accumulate between the liner and the piston. The expanded lip of the fluid is not damaged by faster strokes of the pump or high pressure actions. It is a fail proof piston that seals off to increased diameters as the liner keep wearing.

Parts of the mud pump like the pistons with replacement rubbers are currently running for drilling mud in the highest of pressures. It has a bonded construction as well as build without using leakage and joints. The longer size of the piston helps in guaranteeing the longevity of the equipment. The Ideco component helps the piston to function in higher pressure for ensuring a faster stroke. It is additionally resistant to the mud of the oil base as well as other additives that are put to use.

Pistons with replacement rubbers are actually the premium Ideco pistons or mud pump parts that have been serving the industry for a number of years with excellent and unparalleled performance records to suit extreme drilling conditions. This is a single piece bonded unit that has a number of benefits as it is impermeable to different kinds of chemicals as well as other kinds of oil.

Piston pumps can be used for low viscosity and medium-flow media (in the range of 80 m³/h). Additionally, pumping solid particles is impossible with this type of equipment because the pump can ensure proper operation only if the seal between the cylinder and the piston is perfect.

For high-pressure uses, you can opt for a plunger pump, they differ from piston pumps in that the seal does not move with the piston, it is fixed and therefore able to withstand...

The 3-diaphragms pump ZETA 70 produces a flow of 71 l/min and operates at a maximum pressure of 20 bar. It is available with single or double splined/cylindrical shaft.

Electric motors, motor pumps and high pressure pumps take part from the wide range of products made by Mazzoni srl. Made from robust and high-quality ...

DA Pumps are manual grease and oil, double-action piston high pressure pumps. For bearings that require an application of lubricant infrequently, the manually-operated ...

... are balanced type pumps of single vane that have fixed displacement. It has been designed for higher operation of pressure and more flow having the same size of housing.

The Osna VKI is an array of high-pressure multi-stage vertical pumps for pumping clear and slightly contaminated liquids in pressure boosting plants, cold and hot water ...

GARBARINO manufactures multistage pumps which have been widely tested in applications with pressures up to 40 bar. The newly developed GH pumps have pressures up to 85 ...

Also known as BCPs or BWCPs (Boiling Water Circulating Pumps), these sealless pumps with an integrated fluid-filled motor eliminate the need for a mechanical ...

CBF-F Series high pressure gear pump is the power component of hydraulic system. It adopts intensity Al-alloy shell,DU bearing with high loading capacity ...

Alemite H Pumps are designed for intermittent use in medium or high pressure industrial applications. Double acting H Pumps handle lightweight and fibrous lubricants.

The OSIP AS 50 is a high pressure industrial electronic pump. This device is made up of brass and is equipped with a vertical submerged stem that provides the circulation of liquid coolants ...

8613371530291

8613371530291