horizontal mud pump quotes in stock

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

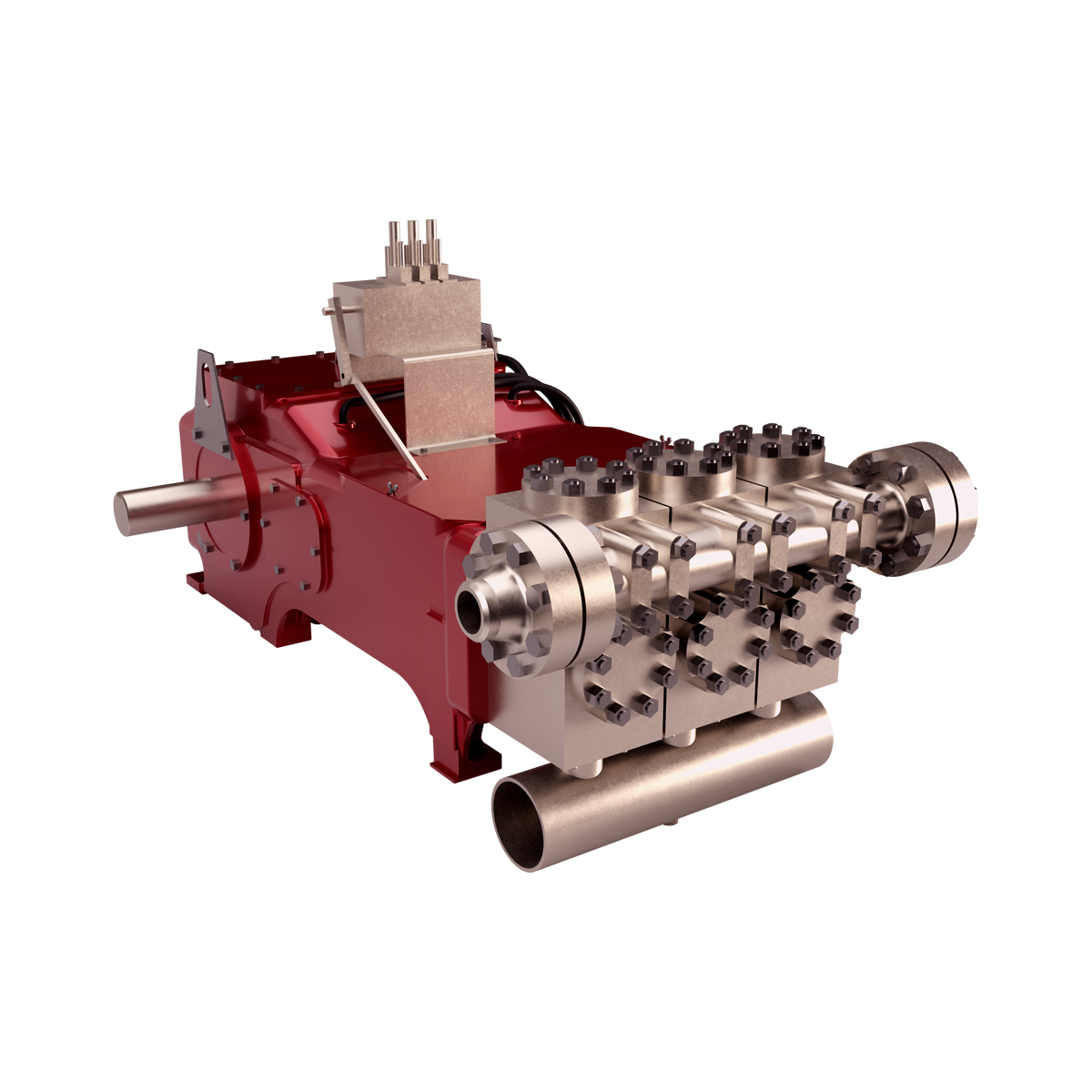

The PZ 2400 features a Y-shaped module design, meaning less stress is placed on the pumps internal components and higher flow rates can be achieved with improved fatigue life.

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

A centrifugal pump is a dynamic device that brings fluid into the center of the “impeller”, the impeller slings it outward and forces it into a diverging section called a diffuser or volute chamber.

Single Stage Horizontal Mud Pump is a device that helps join systems or mechanisms together by preventing leakage, containing pressure, or excluding contamination. It is used in public health department, large housing colonies, chemical and pharma company. We manufacture this pump using high quality cast iron and alloy steel. It is also used for Mobile machinery-cooling water for marine engines and shovels. Single Stage Horizontal Mud Pump can also be utilized in civil construction-dewatering foundations and public utilities. It"s back pull-out design enables easier removal for inspection and maintenance. Clients can avail our pump in different power ratings as per their requirements.

BW400/10 mud pump is a horizontal three cylinder reciprocating single acting piston pump.Advanced product design, reasonable structure, high pressure, flow, multi-file variable, energy saving, light volume, efficiency, plant life, safe operation, easy maintenance.

BW series mud pump is widely used in mining, drilling, coal, railway, highway, water conservancy and hydropower, bridges, high-rise buildings, foundation reinforcement works.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

Specifically designed for the horizontal-drilling market, our THE pump is an upgraded, 215 BHP version of the TEE and features a cast-through stud fluid end with piston and liner sizes up to 5.5 in. for high flow rates.

After using several of the “Big Name” pumps I was sure there wasn’t a product on the market that could move our drilling mud. I was having to use an excavator and two dump trucks to move the mud. We found Gator Pumps and purchased a 12″ PTO driven pump. We were able to move our mud in half the time with less effort. What used to require three pieces of machinery and three operators now requires one tractor and one worker checking on the pump periodically. We also use our Gator Pump to pump rain water off our pits. The pumps are almost maintenance free and absolute workhorses. Save yourself the frustration of trying to find the right pump for your operation. Just call Dale and the guys at Gator. They’ll fix you up and you won’t be disappointed.

Estimated to surpass the valuation of US$ 800 Mn, the market is pegged for over 4% year on year revenue growth in 2019. Onshore applications of mud pumps hold clear dominance over offshore, and accounts for over 70% share of the mud pumps market revenue.

Growing oilfield explorations and land drilling activities will continue to encourage mud pumps demand, according to Persistence Market Research. In its recently released intelligence study, PMR offers exclusive insights on the competition landscape of global mud pumps market. The study analyses the market performance over an eight-year projection period, i.e. 2018-2026.

A senior research analyst refers to the global market for mud pumps as a moderately consolidated landscape, around 55% of which belongs to the top 10 performers.

The analyst explains, "Tier 1 manufacturers of mud pumps account for an average 40% value share in market, whereas over 50% share is contributed by Tier 2 companies. While market leaders are zooming in on NPD for R&D investments, innovation and direct distribution are also the most commonly used differentiating strategies". Elaborating further on competition tracking, the analysts says, "Key market players are concentrating more on strengthening their regional footprint and entering new territories. They are thus prominently opting for strategic collaborations and joint ventures with leading regional players, in addition to frequent M&A of regionally active distributors".

On the backdrop of towering oil & gas prices due to lowering production, a recent appeal by IEA (International Energy Agency) asks the OPEC and non-OPEC countries to up their oil & gas production output. The demand for new oil wells is thus likely to create a plethora of growth opportunities for manufacturers of mud pumps and other drilling equipment.

As oil well explorations at remote sites is constantly on the rise, manufacturers of mud pumps are innovating their existing product lines to cater to demands of remote sites such as efficient operability in a wide range of environmental conditions. Regional oil & gas industry players are focusing on strategically acquiring specialized contractors for remote site projects.

Mud Pumps Market Segmentation by Key Players National Oilwell Varco, Gardner Denver, Schlumberger Limited (Cameron International), WeatherFord International plc, Flowserve Corporation, CNPC Baoji Oilfield Machinery Co., Ltd., Honghua Group Ltd., MHWirthTrevi Group (Drillmec), Bentec GmbH Drilling & Oilfield Systems:https://www.persistencemarketresearch.com/market-research/mud-pumps-market.asp

Although triplex mud pumps have been holding the lion"s share of over 65% in the global market revenue primarily due to their lightweight and cost effective attributes, the consistent quest for advanced technological features and superior performance has been introducing a number of innovative mud pumps in the market. The most recent of these innovations include hexa mud pumps, quintuplex mud pumps, and quadraplex mud pumps.

For advanced technology drilling rigs, a majority of manufacturers are prioritizing development of quintuplex mud pumps owing to their ability to deliver a significantly improved flow rate that eventually curtails overall operational costs. PMR projects that the revenue growth of quintuplex mud pumps will reach its peak in 2019, i.e. above 4%.

Sustained activities for hydrocarbon exploration, coupled with strong presence of a majority of mud pumps manufacturers, enable North America to secure the top market position in terms of mud pumps demand. Onshore applications are likely to witness around 5% year on year revenue growth in the next couple of years, which is clearly due to ever-increasing hydraulic fracturing and shale gas exploration activities in the region.

On the other side, Chinese market for mud pumps is slated for considerable expansion owing to the discovery of new oil reservoirs within Western China, according to Persistence Market Research.

We provide a qualitative range of Mud Monoblock Pumps, which are immensely used in construction, agriculture, waste water management and many other industries

A.Our production is strictly according to ISO 9001 standard and factory was established in 1980, have over 30 years experience in slurry pumps and parts.

A.Customers could send us application data, we will select suitable pump and seal types, or client could send us drawings, We are well in OEM and ODM.

With our many years of practical experience in Horizontal Directional Drilling mix, pump, and recycle mud systems, we can empathize with the needs and wishes of you as our customer for each HDD mud system.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

The EDDY Pump is excellent at moving heavy materials through long pipelines. The EDDY Pump creates a turbulent flow that helps keep the heavier and abrasive materials in suspension. Maintaining suspension assists the material in moving along the pipeline downstream of the pump due to less settling inside of the piping.

Centrifugal pumps create a laminar flow which allows the material to settle at the bottom of the piping. Material settling at the bottom of the piping can interfere with the effective flow of the fluid and also cause greater wear inside the bottom portion of the piping.

EDDY Pump’s Performance does not rely on maintaining critical tolerances between the rotor and the volute. With the proper choice of materials for the pump case and rotor, the EDDY Pump is the perfect solution for pumping abrasive and corrosive material that often cause significant issues for other pumps.

Centrifugal pumps are designed with critical tight tolerances that must be maintained if consistent flow rate and efficiency is desired. When pumping abrasive fluids these tight tolerances can diminish due to wear at the impeller. When pumping corrosive material, increased wear due to the corrosive nature of the fluid can also be experienced. This wear can increase the spacing between the impeller and the inside of the pump casing which creates slip, reduces pump efficiency, and begins to reduce the flow rate.

When choosing an EDDY non-clog pump for your abrasive and corrosive applications, you can experience less clogging, increased uptime, lower maintenance costs, and greater production.

The EDDY Pump Corporation is a premier manufacturer of pumping and dredging equipment. If you are pumping or dredging slurry, high solids, extremely viscous material, paste, high abrasives (sand & gravel) and material filled with solids, then you found the best suited product for the job.Go to:https://eddypump.com/or Call Us!

Mining, Fly Ash, Coal Ash, Oil, Fracking, Gas, Wastewater, Pulp and Paper, Chemical, Energy, Water Municipalities, Irrigation, and Dredging Companies. For Access to Complete Product Line Go to: https://eddypump.com/products/

8613371530291

8613371530291