how 20hp mud pump works manufacturer

15 kW vertical mud pump with thickened pump body and holder. The thickened holder makes the heavy bearing strong. Sewage treatment plant and bog can be used this mud pump.

Pump body thick. The pump body is made of high quality pig iron, durable and equipped with a thickened base. Thickened impeller, wear-resistant and dry rotating.

(Place the vertical mud pump upright or tilted in the liquid. Make sure the pump case is completely submerged in water. In addition, the motor part can not be immersed in water.)

A mud pump is a reciprocating pump used to circulate fluid (mud) through a well during drilling. The reason for circulating fluid through the well is to carry the cuttings from the drilling process back up to the surface. The mud pump is used in oil and gas drilling operations as well as water drilling.

Mud pump, refers to the drilling process to the drilling mud or water and other washing liquid machinery. The main components are volute, impeller, pump seat, pump case, support cylinder, motor seat, motor and other components. Impeller nut is cast iron, so corrosion resistance is good, and convenient processing technology. Pump seat is equipped with four skeleton oil seal and shaft sleeve, prevent shaft wear, prolong the service life of the shaft.

ATO offers high quality vertical mud pumps with thick, solid shaft and copper motor. Various models are available, such as 2 inch mud pump, 3 inch mud pump, 4 inch mud pump and 6 inch mud pump.

Vertical mud pump is used as suction and pouring of river mud, suitable for oil refining, construction, printing and dyeing, chemical industry and other industries.

A: In the order period, we will list our vulnerable parts and their quantities to our customer, and sold at competitive price,then ship together with pumps if customer needs.

The 80mm BW200 mud pump is mainly used to supply flushing fluid for drilling in geology, geothermal, water source, shallow oil and coalbed methane. The medium can be mud, clean water, etc. it can also be used as the above infusion pump.

80mm BW200 Mud pump is a kind of machinery that transports mud or water and other flushing fluid to the borehole during drilling, which is an important part of drilling equipment.

The commonly used mud pump is piston type or plunger type. The power engine drives the crankshaft of the pump to rotate, and the crankshaft drives the piston or plunger to do reciprocating motion in the pump cylinder through the crosshead. Under the alternate action of suction and discharge valves, the purpose of pressing and circulating flushing liquid is realized.

The structure is firm, compact, small in volume and good in performance. It can meet the requirements of high pump pressure and large displacement drilling technology.

Long stroke, keep in a low number of strokes. It can effectively improve the water feeding performance of mud pump and prolong the life of vulnerable parts. The structure of the suction air case is advanced and reliable, which can buffer the suction pipeline.

Bw-200 mud pump is a horizontal double cylinder reciprocating piston pump, which is mainly used to supply flushing fluid to drilling in core drilling. Compared with the same type of pump, the pump has smaller volume and lighter weight, and is more suitable for geological exploration.

In order to meet the needs of diamond drilling, bw-200 mud pump is equipped with cylinder liners of two diameters, φ 80 cylinder liner can be used for 600m drilling rig, φ 65 cylinder liner can be used for 1000m drilling rig.

2. Check the parallelism of the engine, or intermediate shaft and mud pump pulley, and the position of the drive belt, so that they are on the same plane.

The Ingersoll Rand 15T bare compressor pump is commonly paired with the IR 15hp and 20hp air compressor models. This is within their T30 series of models. The 15T utilizes a durable 100% cast iron design with finned cylinders for improved cooling. The V-shape design allows for air to flow around each section of the cylinder walls. This bare pump utilizes two low pressure intake cylinders for maximum airflow. These cylinders and pistons then send the air to a single high pressure cylinder to compress the air to 175psi. This is a two stage pump.

Ingersoll Rand utilizes finned style intercoolers between the two low pressure cylinders and the high pressure cylinder, reducing the operating temperature of the air between the first stage and second stage of the pump. The cast iron fan type flywheel forces a “cyclone” air blast to provide even more cooling for the deep finned cylinders and multi-finned copper tube intercooler. The flywheel is balanced to keep vibration to a minimum. Reliable stainless steel reed valves optimized for increased volumetric efficiency and precision-balanced overhung crankshaft runs smoothly and quietly.

Our Vaxil PUMPS (5x4 Centrifugal Pump) For Bentonite Circulation are basically designed for Construction Industry, for use in hire diameter pilling work. The Pump is high capacity mud pump design, Top Suction, Cantilever Type of Bearing Housings, while the drive motor is located at the top. The design of the pump is such that it mixes as well as it pumps the Bentonite slurry, thus giving the effect of churning the Bentonite Slurry in the tank. It is 20 HP pump Quality efficient.

Engine or motor is attached as a power sourceIt is tested on various quality parameters that assure our clients of the superior quality of the product. It is tested in various parameters and it is capable of handling high load capacity. These heavy duties vaxil pumps are widely appreciated by our clients for high service life.

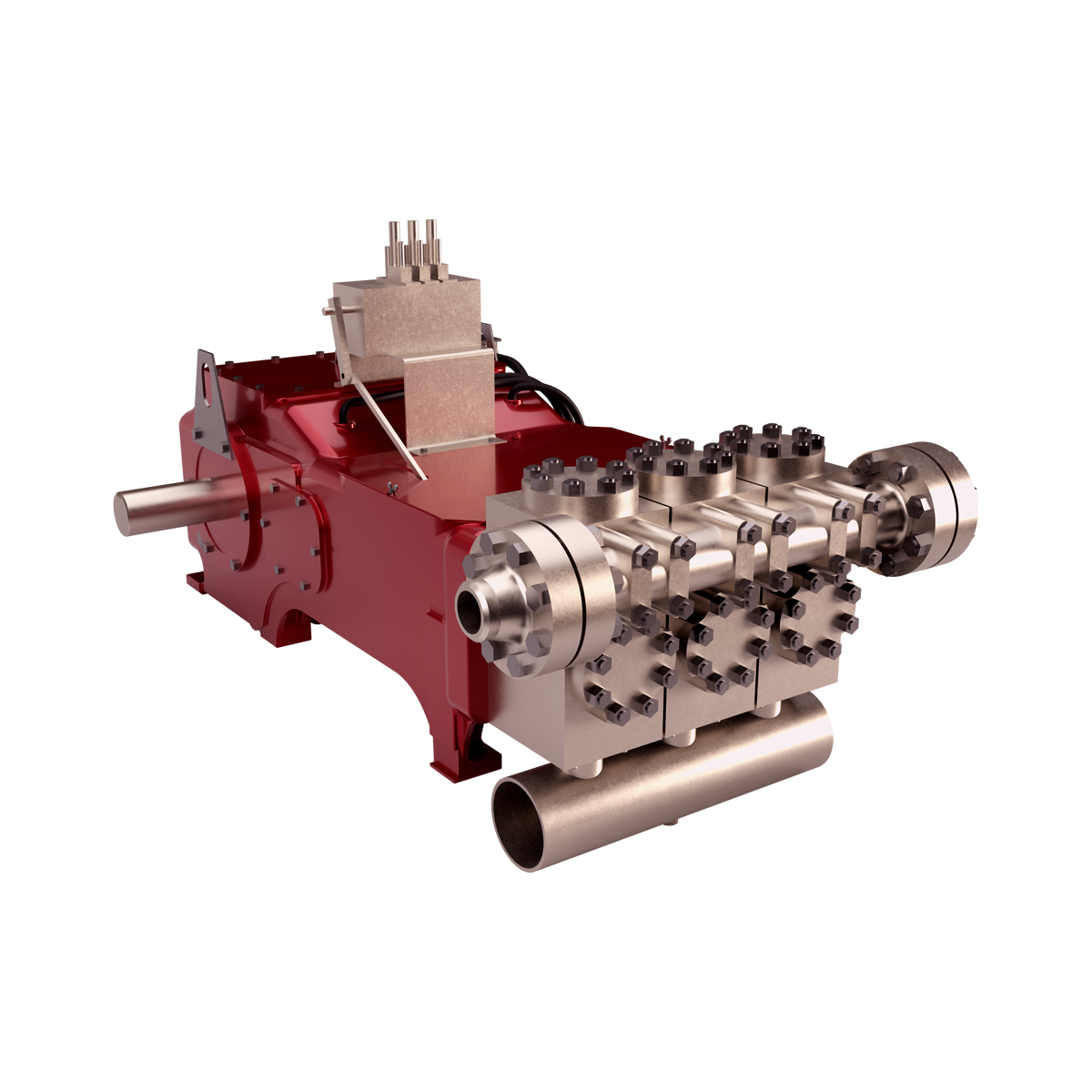

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.

The DAE Pumps Submersible Drainage Pumps support a variety of dewatering applications. Their robust design provides the highest level of performance, reliability, and ease of use. The submersible drainage pumps offer a range of sizes up to 10-inches with over 80 HP and a volume capability of pumping as much as 6100 GPM.

Submersible Sludge Pumps are peak performers in pumping thick mud, clay, and waste. These energy-efficient pumps run at low horsepower, pumping as much as 420 GPM. Available in 3-inch and 4-inch sizes, the heavy-duty DAE Pumps Submersible Sludge Pumps are capable of moving abrasive solids as large as 2-inches. Our Submersible Sludge Pumps provide the support you need for for your toughest jobs.

The DAE Pumps Submersible Slurry Pumps are the toughest and most durable submersible pump. Built for pumping the worst slurry and materials, these pumps have the highest rating in ruggedness. Our Submersible Slurry Pumps are made for dredging the most abrasive media with high solid content in quarries and mining operations. With up to 102 horsepower, these powerful unit are capable of moving 2112 GPM of solids as large as 2.5-inches, and are available in 3-inch, 4-inch, 6-inch, and 8-inch sizes.

The DAE Pumps Payload Electric Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Payload Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

The DAE Pumps Hydraulic Submersible Slurry Pumps are the industry’s best-performing hydraulic submersible pumps. Capable of pumping up to 1325 GPM our hydraulic pumps provide the reliability you need. Because these 3-inch and 4-inch pumps are compact, their lightweight design makes them necessary tools for all site operations. They are non-clogging and are also available in a high head performance of up to 350 feet

The DAE Pumps Hauler Hydraulic Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Hauler Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

DAE Pumps is committed to providing you with the highest quality of pumps at affordable prices. We build our submersible pumps with you in mind. We use the strongest material inside and out to withstand the harshest conditions for getting the job done. Over the years, we built a modular platform of submersible pump that allows us to provide the highest performing pump with the same durability and reliability from one size and power to the next. This means you get the best pump each time.

Our low-cost submersible pump lines are an extension of our commitment to affordably priced pumps. These pumps are built with the same types of metal inside and out as our modular lines, but use a different technology design that brings the performance of these pumps close to those of the other models. We offer these pumps with a lower guarantee so you can get very high-grade pumps at the best prices.

Submersible pumps are the industry’s most durable pumps for underwater operations moving solids and liquids. They can withstanding everyday use of processing water, rocks, sand, mud, sludge, slurry, and other abrasive materials. DAE Pumps provides a variety of submersible pumps for mining, dredging, minerals processing, ash pumping, wastewater, dewatering, and pumping chemicals, oil, sludge, paste, and many other applications. We offer light-duty to heavy-duty submersible drainage pumps, submersible sludge pumps, and submersible slurry pumps.

The submersible drainage pump is built for general dewatering, groundwater, raw water, and construction site use. Construction companies and various municipalities use drainage pumps for removing water from heavily flooded areas and as sump pumps when rainwater or groundwater collects in low-lying and below ground work areas.

DAE Pumps drainage pumps are designed for flexibility and ease of use. Capable of pumping solids up to .5-inches, the durable design is made to move large amounts of water. DAE Pumps drainage pumps handle clean and dirty water with the best performance and efficiency on the market. Our drainage pumps provide powerful performance with minimal maintenance, and their durable body ensures continued use in harsh environments. We offer a variety of drainage pumps in 3-inch, 4-inch, 6-inch, and 10-inch discharge outlets with a horsepower of over 80 HP, and capable of pumping up to 6100 GPM.

Made to pump thick mud and other similarly viscous mixtures of liquids and solids, submersible sludge pumps are used for moving sludge or light slurry, tank clean-outs, trench and pond cleaning, mining dewatering operations, and various other applications. The sludge pump moves the material that can clog ordinary drainage pumps.

DAE Pumps heavy-duty sludge pumps can move water, but they are made for moving solid material and are built with a high wear resistance inside and out. The high-chrome (55HRC) impellers and base of the pump ensures stability while allowing the passage of large solids. The high-quality components for the mechanical seal guarantees a watertight seal and trouble-free operation. Our submersible sludge pumps move up to 420 GPM and come in multiple sizes and power options. These sturdy sludge pumps provide the reliability you need and the performance you can trust for your dewatering, cleaning, and transferring needs.

The submersible slurry pump is the catch-all of submersibles. Capable of pumping the most abrasive media with high solids content, the slurry pump is the workhorse for quarries and settling pond operations. These ultimate pumps are used for everything from dewatering to dredging.

DAE Pumps non-clogging submersible slurry pumps provide the ultimate in toughness.They have the largest apertures to facilitate the handling of slurry with the most challenging solids and the high-efficiency high chrome agitator can lift settled solids up to 2.5-inches. The robust design uses heavy-duty bearings to withstand shocks and overloads and a double silicon carbide mechanical seal for duty application. Our slurry pumps are available in 3-inch, 4-inch, and 6-inch models, with the ability to move up to 2112 GPM.

Sand is one of the most abrasive materials for any type of pump to manage. The beating of sand on the impeller, volute, and even the hose cause extreme wear and tear on pump components. Thesubmersible sand pump is designed to minimize the effects of blasting sand. However, over a period of extended time, the submersible sand pumps will show signs of wear on these parts from the constant pounding of sand and will require replacement.

Our submersible sand pump wear components are built with a high chromium iron, an extremely strong alloy that is mainly used in mining, milling, earth-handling, and manufacturing industries which require materials with exceptional wear and corrosion resistance. The exceptional wear resistance of high chromium cast iron is due to the high volume fraction of hard chromium carbides. The toughness of the matrix also contributes to the wear resistance and makesit very suitable for pumping sand.

DAE Pumps non-clogging submersible sand pumps provide the ultimate in toughness and sand pumping capabilities. Ourpumps move up to 1664 gallons per minute of material and are available in 3-inch, 4-inch, and 6-inch models.

Of all the high pressure engino pumps ofthis class, it ensurosthe highest lift and is a must for sprinklers or for water deliveryto high and distant places.The entire unit is protected by a sturdy rollover pipe frame.

8613371530291

8613371530291