how to use a mud pump brands

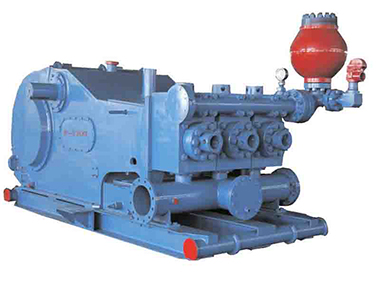

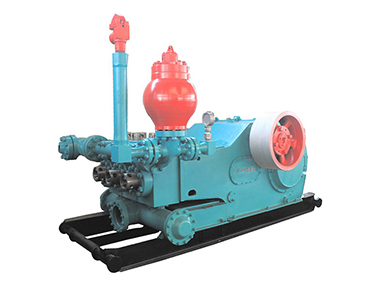

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

Mud pumps are essential equipment for any oil or gas well. They are used to move drilling mud and other fluids needed during the drilling process. To select the right mud pump for your well, you need to understand the different types available and what each one can do.

In this article, we will take a comprehensive look at mud pumps and provide you with all the information you need to make an informed purchase. We will also discuss how mud pumps are used in drilling operations and highlight some of their key features. By the end of this article, you will clearly understand what mud pumps are and what they can do for your well.

A mud pump is a type of reciprocating positive displacement pump that is specifically designed for use in drilling operations. It helps to circulate the drilling fluid (or “mud”) through the drill bit and back up to the surface. The mud pump also provides pressure to keep the drill bit from becoming plugged.

The pump creates suction that pulls the drilling fluid from the pit and then uses its piston to push the fluid back up the well. This action not only circulates the fluid but also helps to remove any cuttings or debris that may have been generated during the drilling process. Mud pumps are an essential part of the drilling process and are typically used in conjunction with other pumps, such as centrifugal pumps, to create a complete pumping system. Without a mud pump, drilling would not be possible.

There are many different types of mud pumps, each with its own advantages and disadvantages. However, pump experts generally understand the requirement and then suggest which type of pump design would be more efficient. Here are five of the most popular types:

Piston mud pumps are the most common type of mud pump. They use a piston to draw mud from the pit and then force it to the drill bit through the hose. Piston mud pumps are very durable and can handle a lot of pressure. However, they are also very loud and can be challenging to operate.

Plunger mud pumps work similarly to piston mud pumps, but they use a plunger instead of a piston. As a result, plunger mud pumps are quieter than piston mud pumps and are easier to operate. However, plunger mud pumps are not as durable and can only handle a limited amount of pressure.

Hydraulic mud pumps use hydraulic power to draw mud from the pit. They are very powerful and can handle a lot of pressure. However, these types of pumps are generally costly and can be challenging to operate.

Diaphragm mud pumps use a diaphragm to draw mud from the pit. They are less powerful than hydraulic mud pumps but are much cheaper. They are also easier to operate. These merits make such pumps more used in small scale operations.

Peristaltic mud pumps use peristaltic action to draw mud from the pit. They are the most expensive type of mud pump but are also the most powerful. Unfortunately, they are also the most difficult to operate. But given their operational power, they are used in large-scale mining and drilling operations.

Even though mud pumps are very lucrative for mining and drilling purposes, they exhibit many more merits, making them useful in other industries. Following are some of the main advantages of mud pumps:

Mud pumps help to increase the efficiency of drilling operations by allowing for fluid circulation and cooling of the drill bit. This results in faster drilling and less wear on the equipment.

Mud pumps also help to improve safety during drilling operations by providing a means to circulate and cool the drill bit, which reduces the risk of overheating and fire.

Mud pumps can also help to improve the accuracy of drilling operations by preventing the drill bit from wandering off course due to excessive heat build-up.

The use of mud pumps can also help to reduce the costs associated with drilling operations by reducing the need for frequent replacement of drill bits and other worn items.

The use of mud pumps can also help to increase the productivity of drilling operations by reducing the downtime associated with the frequent replacement of drill bits and other worn items.

Mud pumps are an essential part of the oil and gas industry, as they are used to pump drilling fluid (mud) into the drill hole. There are many different mud pumps, each with its own unique set of features and applications. A reliable pump expert will help you choose which pump to use where. Here are 10 of the most common applications for mud pumps:

Mud pumps are extensively used to circulate drilling fluid during the drilling process. This helps to cool and lubricate the drill bit and remove cuttings from the hole.

Mud pumps are also used in hydraulic fracturing operations, where high-pressure fluid is injected into the rock formation to create fractures. The pump helps to circulate the fracturing fluid and keep the pressure at the desired level.

Mud pumps are sometimes used in geothermal operations to circulate water or other fluids through the drilled well. This helps extract heat from the rock and bring it to the surface.

In coal seam gas extraction, mud pumps are used to circulate water and chemicals through the coal seam to dissolve the methane gas and make it easier to extract.

In potash mining, mud pumps are used to circulate brine solution through the ore body to dissolve the potassium chloride (potash) and pump it out of the mine.

Mud pumps are often used in water well drilling operations to circulate water through the drill hole and help flush out any cuttings or debris. Pump experts can customize mud pumps to suit this application.

In tunnelling operations, mud pumps can circulate a slurry of water and clay through the drilling area. This helps to stabilize the walls of the tunnel and prevent collapse.

Mud pumps are sometimes used in pipeline operations to help clean and inspect the inside of the pipe. The pump circulates water or other fluids through the pipe to remove any build-up or debris.

In environmental remediation projects, mud pumps can circulate water or chemicals through contaminated soil or groundwater. This helps to break down contaminants and make them easier to remove.

Mud pumps can also be used in construction projects to help remove water from the site or stabilize the ground. For this application, they are extensively used in large construction sites.

Mud pumps are an essential part of many different industries and have various applications. If you need a mud pump for your next project, be sure to consult with a pump expert to find the right pump for your needs.

When choosing a size and type of mud pump for your drilling project, there are several factors to consider. These would include not only cost and size of pump that best fits your drilling rig, but also the diameter, depth and hole conditions you are drilling through. I know that this sounds like a lot to consider, but if you are set up the right way before the job starts, you will thank me later.

Recommended practice is to maintain a minimum of 100 to 150 feet per minute of uphole velocity for drill cuttings. Larger diameter wells for irrigation, agriculture or municipalities may violate this rule, because it may not be economically feasible to pump this much mud for the job. Uphole velocity is determined by the flow rate of the mud system, diameter of the borehole and the diameter of the drill pipe. There are many tools, including handbooks, rule of thumb, slide rule calculators and now apps on your handheld device, to calculate velocity. It is always good to remember the time it takes to get the cuttings off the bottom of the well. If you are drilling at 200 feet, then a 100-foot-per-minute velocity means that it would take two minutes to get the cuttings out of the hole. This is always a good reminder of what you are drilling through and how long ago it was that you drilled it. Ground conditions and rock formations are ever changing as you go deeper. Wouldn’t it be nice if they all remained the same?

Centrifugal-style mud pumps are very popular in our industry due to their size and weight, as well as flow rate capacity for an affordable price. There are many models and brands out there, and most of them are very good value. How does a centrifugal mud pump work? The rotation of the impeller accelerates the fluid into the volute or diffuser chamber. The added energy from the acceleration increases the velocity and pressure of the fluid. These pumps are known to be very inefficient. This means that it takes more energy to increase the flow and pressure of the fluid when compared to a piston-style pump. However, you have a significant advantage in flow rates from a centrifugal pump versus a piston pump. If you are drilling deeper wells with heavier cuttings, you will be forced at some point to use a piston-style mud pump. They have much higher efficiencies in transferring the input energy into flow and pressure, therefore resulting in much higher pressure capabilities.

Piston-style mud pumps utilize a piston or plunger that travels back and forth in a chamber known as a cylinder. These pumps are also called “positive displacement” pumps because they literally push the fluid forward. This fluid builds up pressure and forces a spring-loaded valve to open and allow the fluid to escape into the discharge piping of the pump and then down the borehole. Since the expansion process is much smaller (almost insignificant) compared to a centrifugal pump, there is much lower energy loss. Plunger-style pumps can develop upwards of 15,000 psi for well treatments and hydraulic fracturing. Centrifugal pumps, in comparison, usually operate below 300 psi. If you are comparing most drilling pumps, centrifugal pumps operate from 60 to 125 psi and piston pumps operate around 150 to 300 psi. There are many exceptions and special applications for drilling, but these numbers should cover 80 percent of all equipment operating out there.

The restriction of putting a piston-style mud pump onto drilling rigs has always been the physical size and weight to provide adequate flow and pressure to your drilling fluid. Because of this, the industry needed a new solution to this age-old issue.

Enter Cory Miller of Centerline Manufacturing, who I recently recommended for recognition by the National Ground Water Association (NGWA) for significant contributions to the industry.

As the senior design engineer for Ingersoll-Rand’s Deephole Drilling Business Unit, I had the distinct pleasure of working with him and incorporating his Centerline Mud Pump into our drilling rig platforms.

In the late ’90s — and perhaps even earlier — Ingersoll-Rand had tried several times to develop a hydraulic-driven mud pump that would last an acceptable life- and duty-cycle for a well drilling contractor. With all of our resources and design wisdom, we were unable to solve this problem. Not only did Miller provide a solution, thus saving the size and weight of a typical gear-driven mud pump, he also provided a new offering — a mono-cylinder mud pump. This double-acting piston pump provided as much mud flow and pressure as a standard 5 X 6 duplex pump with incredible size and weight savings.

The true innovation was providing the well driller a solution for their mud pump requirements that was the right size and weight to integrate into both existing and new drilling rigs. Regardless of drill rig manufacturer and hydraulic system design, Centerline has provided a mud pump integration on hundreds of customer’s drilling rigs. Both mono-cylinder and duplex-cylinder pumps can fit nicely on the deck, across the frame or even be configured for under-deck mounting. This would not be possible with conventional mud pump designs.

Centerline stuck with their original design through all of the typical trials and tribulations that come with a new product integration. Over the course of the first several years, Miller found out that even the best of the highest quality hydraulic cylinders, valves and seals were not truly what they were represented to be. He then set off on an endeavor to bring everything in-house and began manufacturing all of his own components, including hydraulic valves. This gave him complete control over the quality of components that go into the finished product.

The second generation design for the Centerline Mud Pump is expected later this year, and I believe it will be a true game changer for this industry. It also will open up the application to many other industries that require a heavier-duty cycle for a piston pump application.

Many things go into getting the most life out of your mud pump and its components — all important to extend the usage of this vital piece of equipment on an HDD jobsite. Some of the most important key points are covered below.

The most important thing you can do is service your pump, per the manufacturer’s requirements. We get plenty of pumps in the shop for service work that look like they have been abused for years without having basic maintenance, such as regular oil changes. You wouldn’t dream of treating your personal vehicle like that, so why would you treat your pump like that.

Check the oil daily and change the oil regularly. If you find water or drilling mud contamination in the oil, change the oil as soon as possible. Failure to do so will most likely leave you a substantial bill to rebuild the gear end, which could have been avoided if proper maintenance procedures would have been followed. Water in the oil does not allow the oil to perform correctly, which will burn up your gear end. Drilling mud in your gear end will act as a lapping compound and will wear out all of the bearing surfaces in your pump. Either way it will be costly. The main reasons for having water or drilling mud in the gear end of your pump is because your pony rod packing is failing and/or you have let your liners and pistons get severely worn. Indication of this is fluid that should be contained inside the fluid end of your pump is now moving past your piston and spraying into the cradle of the pump, which forces its way past the pony rod packing. Pony rod packing is meant to keep the oil in the gear end and the liner wash fluid out of the gear end. Even with brand new packing, you can have water or drilling fluid enter the gear end if it is sprayed with sufficient force, because a piston or liner is worn out.

Monitor your oil and keep your pistons, liners and pony rod packing in good condition. If a liner starts to leak, identify the problem and change it as soon as possible.

There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components.

Liner wash fluid can be comprised of different fluids, but we recommend just using clean water. In extremely cold conditions, you can use RV antifreeze. The liner wash or rod wash system is usually a closed loop type of system, consisting of a tank, a small pump and a spray bar. The pump will move fluid from the tank through the spray bar, and onto the inside of the liner to cool the liner, preventing scorching. The fluid will then collect in the bottom of the cradle of the pump and drain back down into the collection tank below the cradle and repeat the cycle. It is important to have clean fluid no matter what fluid you use. If your liners are leaking and the tank is full of drilling fluid, you will not cool the liners properly — which will just make the situation worse. There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components. Ensure that the water is spraying inside the liner and that any overspray is not traveling out of the pump onto the ground or onto the pony rod packing where it could be pulled into the gear end. If the fluid is spraying out of the cradle area and falling onto the ground, it won’t be long before your liner wash tank is empty. It only takes a minute without the cooling fluid being sprayed before the liners become scorched. You will then need to replace the pistons and liners, which is an avoidable costly repair. Make a point to check the liner wash fluid level several times a day.

Liner wash fluid can be comprised of different fluids, but it is recommended to just using clean water. In extremely cold conditions, you can use RV antifreeze.

Drilling fluid — whether pumping drilling mud, straight water or some combination of fluid — needs to be clean. Clean meaning free of solids. If you are recycling your fluid, make sure you are using a quality mud recycling system and check the solids content often throughout the day to make sure the system is doing its job. A quality mud system being run correctly should be able to keep your solids content down to one quarter of 1 percent or lower. When filling your mud recycling system, be sure to screen the fluid coming into the tanks. If it is a mud recycling system, simply make sure the fluid is going over the scalping shaker with screens in the shaker. If using some other type of tank, use an inline filter or some other method of filtering. Pumping out of creeks, rivers, lakes and ponds can introduce plenty of solids into your tanks if you are not filtering this fluid. When obtaining water out of a fire hydrant, there can be a lot of sand in the line, so don’t assume it’s clean and ensure it’s filtered before use.

Cavitation is a whole other detailed discussion, but all triplex pumps have a minimum amount of suction pressure that is required to run properly. Make sure this suction pressure is maintained at all times or your pump may cavitate. If you run a pump that is cavitating, it will shorten the life of all fluid end expendables and, in severe cases, can lead to gear end and fluid end destruction. If the pump is experiencing cavitation issues, the problem must be identified and corrected immediately.

The long and the short of it is to use clean drilling fluid and you will extend the life of your pumps expendables and downhole tooling, and keep up with your maintenance on the gear end of your pump. Avoid pump cavitation at all times. Taking a few minutes a day to inspect and maintain your pump can save you downtime and costly repair bills.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

A mud pump is a piston driven pump design that can produce high-pressure operations to safely transfer high viscosity fluids over an extended depth. The mud pump has many applications in industrial service, but it has proven to be invaluable in many drilling operations. Let"s take a look at mud pumps and why they are such a good fit for the industries they serve.

A Mud pump is a reciprocal pump design utilizing a piston in a cylinder to transfer fluids under high pressure. A mud pump can generate up to 7,500 psi (52,000 kPa) during normal operations. Mud pumps are a positive displacement design.

Mud pumps are available in a variety of configurations and sizes. However, mud pumps tend to be one of two main types: the duplex and the triplex. The duplex mud pump features two pistons (or plungers) in constant action to move the fluid.

The triplex mud pump has all but replaced the duplex version in most applications, although you will still find the latter in use in some smaller countries. The triplex mud pump features a triple piston (plunger) design that is more efficient than the duplex design.

The latest designs of the mud pump are the quintuplex and hex versions. As the name suggests, these designs feature five or six pistons in a reciprocating design. Although not in widespread use as compared to the triplex design, these mud pumps spread the pumping action across the rotational cycle, creating less mud noise. This allows for better measurements and logging to take place while in operation.

There are two main parts to a mud pump: the fluid end and the power end. The fluid end is where the actual pumping takes place. The components of the fluid end consist of valves, pistons (or plungers), and liners.

Since the fluid end is in constant contact with the material being pumped, most modern designs allow for quick replacement of worn components as needed. This dramatically extends the life of a unit without having to completely replace the pump.

The power end of a mud pump is responsible for taking the input power, typically through a driveshaft, and converting it into the reciprocating motion needed for the pistons. In most mud pump applications, the power end uses a crosshead crankshaft for this conversion.

Rotational power is supplied to the mud pump through an external power source. The power end of the pump converts this rotational energy through a crankshaft to a reciprocating motion that moves the pistons.

The pistons move back and forth in their liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

Due to the pressure and material being pumped, most mud pump applications can create a lot of vibration. To combat this, many mud pump applications incorporate pulsation dampeners. These are typically used on both suction and discharge sides of the pump.

In some cases, a positive displacement pump may pull the fluids at a pressure lower than its vapor pressure. When this happens, damaging cavitation can take place. In these cases, a charge pump might be required at the inlet side to maintain a positive pressure on the suction stream.

When selecting a mud pump, there are two main parameters to be used, pressure and displacement. Pressure is the net pumping pressure that the pump can safely provide. The requirement for pressure increases as the drilling depth and fluid (or slurry) viscosity increases.

Displacement is the volume of fluid that the pump can transfer within a given time period. In most applications, this is rated as discharged liters per minute.

Mud pumps are ideal wherever a lot of fluid needs to be pumped under high pressure. They are considered an essential part of most oil well drilling rigs. Mud pumps can deliver high concentration and high viscosity slurry in a stable flow, making them adaptable to many uses.

Mud pumps are an invaluable tool when high pressure and high viscosity fluids are needing to be transferred. Mader Electric, Inc. specializes in mud pump repair and installation, as well as pump training. Contact us to see how we can help with your pumping needs.

I’ve run into several instances of insufficient suction stabilization on rigs where a “standpipe” is installed off the suction manifold. The thought behind this design was to create a gas-over-fluid column for the reciprocating pump and eliminate cavitation.

When the standpipe is installed on the suction manifold’s deadhead side, there’s little opportunity to get fluid into all the cylinders to prevent cavitation. Also, the reciprocating pump and charge pump are not isolated.

The gas over fluid internal systems has limitations too. The standpipe loses compression due to gas being consumed by the drilling fluid. In the absence of gas, the standpipe becomes virtually defunct because gravity (14.7 psi) is the only force driving the cylinders’ fluid. Also, gas is rarely replenished or charged in the standpipe.

Installing a suction stabilizer from the suction manifold port supports the manifold’s capacity to pull adequate fluid and eliminates the chance of manifold fluid deficiency, which ultimately prevents cavitation.

Another benefit of installing a suction stabilizer is eliminating the negative energies in fluids caused by the water hammer effect from valves quickly closing and opening.

The suction stabilizer’s compressible feature is designed to absorb the negative energies and promote smooth fluid flow. As a result, pump isolation is achieved between the charge pump and the reciprocating pump.

The isolation eliminates pump chatter, and because the reciprocating pump’s negative energies never reach the charge pump, the pump’s expendable life is extended.

Investing in suction stabilizers will ensure your pumps operate consistently and efficiently. They can also prevent most challenges related to pressure surges or pulsations in the most difficult piping environments.

Sigma Drilling Technologies’ Charge Free Suction Stabilizer is recommended for installation. If rigs have gas-charged cartridges installed in the suction stabilizers on the rig, another suggested upgrade is the Charge Free Conversion Kits.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

Mud pumps can be divided into single-acting pump and double-acting pump according to the completion times of the suction and drainage acting in one cycle of the piston"s reciprocating motion.

Mud pumps come in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pump is used. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplexes with five horizontal piston/plungers. The advantages that these new pumps have over convention triplex pumps is a lower mud noise which assists with better measurement while drilling (MWD) and logging while drilling (LWD) decoding.

The fluid end produces the pumping process with valves, pistons, and liners. Because these components are high-wear items, modern pumps are designed to allow quick replacement of these parts.

To reduce severe vibration caused by the pumping process, these pumps incorporate both a suction and discharge pulsation dampener. These are connected to the inlet and outlet of the fluid end.

The power end converts the rotation of the drive shaft to the reciprocating motion of the pistons. In most cases a crosshead crank gear is used for this.

Displacement is calculated as discharged liters per minute. It is related to the drilling hole diameter and the return speed of drilling fluid from the bottom of the hole, i.e. the larger the diameter of drilling hole, the larger the desired displacement. The return speed of drilling fluid should wash away the debris and rock powder cut by the drill from the bottom of the hole in a timely manner, and reliably carry them to the earth"s surface. When drilling geological core, the speed is generally in range of 0.4 to 1.0 m^3/min.

The pressure of the pump depends on the depth of the drilling hole, the resistance of flushing fluid (drilling fluid) through the channel, as well as the nature of the conveying drilling fluid. The deeper the drilling hole and the greater the pipeline resistance, the higher the pressure needed.

With the changes of drilling hole diameter and depth, the displacement of the pump can be adjusted accordingly. In the mud pump mechanism, the gearbox or hydraulic motor is equipped to adjust its speed and displacement. In order to accurately measure the changes in pressure and displacement, a flow meter and pressure gauge are installed in the mud pump.

The construction department should have a special maintenance worker that is responsible for the maintenance and repair of the machine. Mud pumps and other mechanical equipment should be inspected and maintained on a scheduled and timely basis to find and address problems ahead of time, in order to avoid unscheduled shutdown. The worker should attend to the size of the sediment particles; if large particles are found, the mud pump parts should be checked frequently for wear, to see if they need to be repaired or replaced. The wearing parts for mud pumps include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be adopted to increase the service life of the wearing parts, which can reduce the investment cost of the project, and improve production efficiency. At the same time, wearing parts and other mud pump parts should be repaired rather than replaced when possible.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

KATHWADA., Ahmedabad SHREENATH ESTATE, NR.NIKOL-KATHAWADA CROSS ROAD, NR.SP RING ROAD. VISHALA EASTATE ROAD KATHWADA GIDC., KATHWADA., Ahmedabad - 382415, Dist. Ahmedabad, Gujarat

Hatkeshwar, Ahmedabad No. 4, Behind Ramdev Estate, Opposite Baroda Express Highway & Glass CTM, Near Green Market, Hatkeshwar, Ahmedabad - 380026, Dist. Ahmedabad, Gujarat

VATVA GIDC, Ahmedabad 195, Pushpak Industrial Estate, Old Nika Tube Compound Phase I, GIDC, Vatva, VATVA GIDC, Ahmedabad - 382445, Dist. Ahmedabad, Gujarat

Odhav, Ahmedabad 331, Yamuna Park, Opposite Grand Vishala Estate SP Ring Road, Beside Madhav Orchid Bulding, Odhav, Ahmedabad - 382415, Dist. Ahmedabad, Gujarat

Ahmedabad Shed No-08, Block-B, Grand Vishala Industrial Estate, Near Royal Restaurant, Sardar Patel Ring Road, Odhav, Ahmedabad - 382415, Dist. Ahmedabad, Gujarat

Ahmedabad Ground Floor, 122, Hirabaug Society,part-2, Opp. Alkapuri Society, Nr.karmachari School, Ghatlodiya, Ahmedabad - 380061, Dist. Ahmedabad, Gujarat

Near Chhotalal Cross Road, Odhav, Ahmedabad 6, Agrasen Estate Opposite LIG Quarters, D 44 Road, Near Chhotalal Cross Road, Odhav, Ahmedabad - 382415, Dist. Ahmedabad, Gujarat

Odhav, Ahmedabad 11, Karma Industrial Park, Kathwada, Odhav Ring Road Circle, Kathwada Singarva Road GIDC, Odhav, Ahmedabad - 382430, Dist. Ahmedabad, Gujarat

We Propeller Pumps from 2009 are engaged in Manufacturing Wholesaling Exporting and Retailing the Centrifugal Pumps Axial Flow Pumps Chemical Pumps Sump Pumps PP Pumps Pump Accessories Feed Pump Slurry Pump Turbine Pump Impeller Pump Mixed Flow Pump End Suction Pump Self Priming Centripetal Pump

Bapunagar, Ahmedabad 9, Rameshwar Estate, opp. Hirawadi BRTS stop, near axis bank narol-naroda road, Bapunagar, Ahmedabad - 382350, Dist. Ahmedabad, Gujarat

Sarkhe Highway, Ahmedabad No. 19, Ground Floor, Yogeswar Complex, Opposite Sola Overbridge, Near The Fern Hotel Gulab Tower Road, S.G Highway, Thaltej, Sarkhe Highway, Ahmedabad - 380054, Dist. Ahmedabad, Gujarat

Amraiwadi, Ahmedabad No. 16, Bankar Estate, Near Anup Estate, Behind Bharat Party Plot National Highway No. 8, Amraiwadi, Amraiwadi, Ahmedabad - 380026, Dist. Ahmedabad, Gujarat

Ahmedabad Shed No. 222, Ground Floor, Puskpak Industrial Estate, Opp. Mecons Factory, Phase-1, GIDC Estate Vatva, Ahmedabad - 382445, Dist. Ahmedabad, Gujarat

New Naroda, Ahmedabad 16, 4th Floor, Vitthal Plaza, Opposite G.E.B Office, Naroda-Dehgam Road,, New Naroda, Ahmedabad - 382330, Dist. Ahmedabad, Gujarat

Mud pumps for drilling rigs are used in most of the off-shore projects, and it is one of the essential equipment used in these types of projects. The plus point of using the mud pump is that the operation has been appropriately checked and proven in th …

Drilling mud pumps are used on rigs for mud circulation. The pumps suit the best for processing drilling oil wells. Shale Pumps offer different types of used, remanufactured, and new drilling equipment for international and domestic drilling companies. …

When you are using the good frac pump, the success of the oil and gas drilling operations is ensured. The latest equipment that is used is the quintuplex pump. This pump comes with five plungers responsible for pushing the drilling fluid into a drill s …

For the extraction of water, oil, and gas, horizontal directional drilling equipment is used. This equipment is an underground infrastructure. This technique is directed through a curvature or conducted from the surface level as well. This process invo …

Horizontal Directional Drilling Equipment (HDD) is used for installing utilities located underground. We at Shale Pumps use HDD equipment like cables and pipes. 5,000 to 100,000 lbs range of models are available with us. If you want to get well-communi …

Mud pumps are used for drilling operations and they are reciprocating plunging pumps. It works by circulating the drilling fluid or the mud on the drilling rig. Drilling mud pumps are the most important types of equipment used in the oil drilling proce …

The horizontal directional drilling (HDD) technology and pump are used for water, oil, and gas piping, in underground infrastructure. The HDD technique can be directed through a curvature or conducted from the surface level as well. The Horizontal Dire …

The drilling mud pumps are of immense utility to the oil companies, for the purposes related to oil well drilling. The pumps have the reciprocating piston for circulating the drilling fluid. These units work at high pressure and provide for low noise, …

Horizontal directional drilling HDD is one typical method needed for the installation of underground pipelines, service conduit, and cables via trenchless methods. It makes use of horizontal directional drilling machine and other related attachments fo …

Before you directly go to the topic of Drilling Mud Pump Companies in Houston, it is important for us to know about this specific pump. So what exactly is this pump and its role? Well, a mud pump is the one which is basically a reciprocating piston pu …

8613371530291

8613371530291