how triplex mud pump works quotation

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes, and why it is important? In order to understand that, you’ll need to know some basic information about mud pumps.

Knowing how a mud pump functions is important in understanding the role a pump stroke counter plays in rig operations. Mud pumps act as the heart of the drilling rig, similar to how our heart works. Just as our heart circulates blood throughout our bodies, a mud pump circulates essential drilling mud down the hole and back up to the surface. Mud tanks house drilling mud, and a mud pump draws the fluid from the mud pump. A piston draws mud in on the backstroke through the open intake valve and pushes mud through the discharge valve and sends it towards the rig. By circulating fluid, the mud pump ensures that the drill bit is cool and lubricated and that cuttings are flushed from the hole. The two main kinds of pumps used are duplex and triplex pumps, where the duplex pump has two pistons and the triplex pump has three. Whether the rig is using a duplex or triplex pump, it is important to know how many strokes per second the pistons are moving. The driller monitors strokes per minute to determine how much costly, yet essential, mud is being pumped into the system with the use of a mud pump stroke counter system. Now, that you know about mud pumps, you’ll need to know what’s in a stroke counter system.

Stroke Counter — The stroke counter stainless steel box is mounted on the driller’s console and is either square or rectangular in shape, depending on the number of pumps it is monitoring. Stroke counters will show strokes per minute and total strokes, and when a particular mud pump is operating the strokes/minute and total strokes will be displayed. Power is supplied by a 3.6 volt lithium battery, and the counter contains a crystal-controlled real time clock with 100 parts per million accuracy or better. Each counter is mounted to the console with 1/4” stainless steel hex head bolts, lock washers and nuts.

Micro Limit Switch — The micro switch is connected to a c clamp near the mud pump piston. The micro switch stainless steel rod (sometimes called a whisker) sticks out in the piston housing near the piston. As the piston passes the rod, it moves the rod and the switch sends an electronic signal back to the counter. The counter increases by one each time the piston moves the rod, counting the mud pump’s strokes. The switch’s signal is then transmitted to the stroke counter. These micro switches are built to stand up to demanding outdoor conditions. They can withstand shock, equipment vibration, extreme temperatures, water and dust.

Cable and Junction Box – A cable is connected to the back of the pump stroke counter and then to the junction box. From the junction box, the cables travel to the limit switches.

Pump Stroke Counters are like a blood pressure machine. Each time our heart pumps, a blood pressure machine reads our systolic and diastolic blood pressure by way of our pulse. A mud pump stroke counter functions in much the same way. Just as a blood pressure machine detects our pulse so too does a limit switch rod detect the movement of the piston. When the stainless steel rod is moved, the micro limit switch detects the movement. The signal is sensed as a contact closure, and it is transmitted to the stroke counter where the contact closure is converted to a logic pulse. The pulse feeds two separate circuits. The total strokes circuit reads and displays the closures one at a time, totaling them up to reveal the total strokes in the LED window. The second pulse is sent along a separate circuit which is a rate circuit. This rate circuit will average the closures against the real time clock. The result is displayed as the total strokes per minute.

Pump stroke counters are essential to drilling rig operations because they measure the efficiency of mud pumps. Knowing strokes per minute and total strokes of the pistons helps the driller to determine if the correct amount of mud is going down hole. Having this information aids in running a drilling rig at peak efficiency, assists in extending drill bit life, and avoids costly overuse of drilling rig mud. Unsure which pump stroke counter is right for your application? Give our friendly, knowledgeable staff a call or email. We’ll keep you turning right.

Positive displacements pumps are generally used on drilling rigs to pump high pressure and high volume of drilling fluids throughout a drilling system. There are several reasons why the positive displacement mud pumps are used on the rigs.

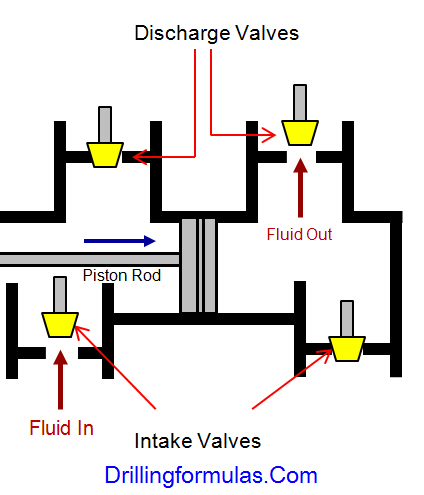

The duplex pumps (Figure 1) have two cylinders with double acting. It means that pistons move back and take in drilling mud through open intake valve and other sides of the same pistons, the pistons push mud out through the discharge valves.

When the piston rod is moved forward, one of intake valves is lift to allow fluid to come in and one of the discharge valve is pushed up therefore the drilling mud is pumped out of the pump (Figure 2).

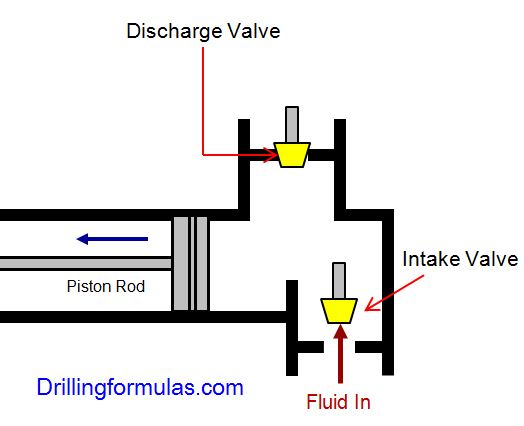

On the other hand, when the piston rod is moved backward drilling fluid is still pumped. The other intake and discharge valve will be opened (Figure 3).

The triplex pumps have three cylinders with single acting. The pistons are moved back and pull in drilling mud through open intake valves. When the pistons are moved forward and the drilling fluid is pushed out through open discharge valves.

On the contrary when the piston rods are moved backward, the intake valve are opened allowing drilling fluid coming into the pump (Figure 6). This video below shows how a triplex mud pump works.

Because each pump has power rating limit as 1600 hp, this will limit capability of pump. It means that you cannot pump at high rate and high pressure over what the pump can do. Use of a small liner will increase discharge pressure however the flow rate is reduces. Conversely, if a bigger liner is used to deliver more flow rate, maximum pump pressure will decrease.

As you can see, you can have 7500 psi with 4.5” liner but the maximum flow rate is only 297 GPM. If the biggest size of liner (7.25”) is used, the pump pressure is only 3200 psi.

Finally, we hope that this article would give you more understanding about the general idea of drilling mud pumps. Please feel free to add more comments.

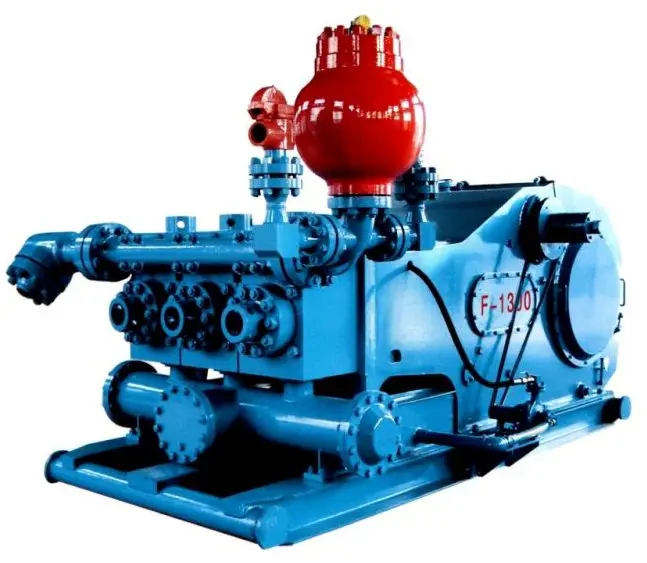

The effectiveness of triplex mud pumps for sale determines the success of drilling operations in rigs. Circulation of the drilling fluid or mud is a continuous process that calls for uninterrupted operations of the mud pumps. Finicky about how our equipment work, we at ShalePumps, go to extreme lengths before engineering modern beasts for continuous drilling operations in rigs.

Our state of the art Houston facility develops high performing mud pumps for drillings rigs by a combination of the best materials, and structural dynamics to put together some of the best equipment. Designed to be adapted for various drilling applications in rigs through designs that incorporate various liner sizes, the triplex mud pumps for sale that leave the assembly line at ShalePumps are mean and mighty workhorses. The triplex mud pumps feature high performance steel power ends, balanced forged steel crankshaft, steel herringbone gears and anti-friction roller bearings. Striking the right balance between weight and performance, the triplex mud pumps for sale we make are best for drilling operations in rigs.

The triplex mud pumps manufactured at ShalePumps have extended continuous duty cycles, and foolproof lubrication systems for smooth drilling operations in rigs. With mud pumps from ShalePumps the drilling operations in rigs will never be the weak link, but a pivot that spells success.

ShalePumps, LLC is proud to introduce the SP-1614 1600 HP Continuous Duty Triplex Drilling Pump. Engineering and rated for 1600 horse power at 110 strokes per minute with a 14” stroke capable of 7500 PSI. Manufactured in our Houston Texas facility, this pump defines longevity, quality and capability. The SP-1614 is designed to incorporate minimum weight and maximum performance using a high performance steel power end, a balanced forged steel crank shaft, steel herringbone gears and anti friction roller bearing throughout. Multiple liner sizes are available to allow variance in pressure and output volume for a variety of drilling applications. Download the performance chart for more detailed information.

The Hex Pump is an axial piston mud pump with six vertical pistons driven by two AC motors via a gear and a specially profiled cam. In contrast to crankshaft-driven triplex pumps, the Hex pump delivers a nearly pulsation free flow. Consequently, there is no need for pulsation dampeners on either the suction or discharge side when running this pump. Other major advantages are compactness (reduced weight and footprint) and no need for replacing liner sizes to achieve high pressure or flow. The Hex 240 version with 4 1/2" liners has a rated capacity of 2540 HP, a maximum rated pressure of 7500 PSI and a maximum flow capacity of 1034 GPM.

The Hex Pump has substantially less weight than a comparable Triplex pump, and this results in increased variable deck load capacity on drilling units. The potential cost savings related to increased variable deck load capacity both on new builds and on existing rigs will be discussed in this paper. Also, the potential steel weight reduction in the substructure on drilling units will be discussed.

The Hex Pump creates a clean standpipe pressure with much lower pressure fluctuation levels than triplex pumps. Due to this, there are no need for pulsation dampeners when running the Hex Pump. This additionally leads to much better and cleaner MWD-signals for the directional driller. As a consequence, this will contribute to faster and more accurate drilling in long and complicated directional wells.

The design and development of the Hex Pump is described in SPE paper 79831, ref /1/; "Development and Performance Testing of the Hex Mud Pump", but for the understanding of this paper it is important to understand the functionality of the Hex Pump design. Some of the main items are therefore repeated in this paper. SPE paper 92507, ref. /2/, "Operational experience with use of a Hex Pump on a land rig" focuses on the improved MWD-measurements related to use of Hex Pump compared to triplex pumps. Some of the main items discussed there will also be repeated in this paper.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

The policy set forth below outlines the personal data that Power Zone Equipment may collect, how Power Zone Equipment uses and safeguards that data, and with whom we may share it. This policy is intended to provide notice to individuals regarding personal data in an effort to be compliant with the data privacy laws and regulations of the jurisdictions in which Power Zone Equipment operates.

If you have a comment, question, or complaint about how Power Zone Equipment is handling your personal data, we invite you to contact us in order to allow us to resolve the matter. In addition, individuals located in the EU may submit a complaint regarding the processing of their personal data to the EU data protection authorities (DPAs). The following link may assist you in finding the appropriate DPA:http://ec.europa.eu/justice/data-protection/bodies/authorities/index_en.htm.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

abstractNote = {Triplex piston pump performance is optimized by adding a centrifugal auxiliary charge pump to the suction system. Due to its inherent flexibility, the centrifugal prevents hydraulic knock in the triplex cylinders and provides several other advantages all at a relatively low cost. A guide to charge pump selection, installation and operation is provided.},

You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex Mud Pumps for sale by Pickett Oilfield, LLC. These National 12-P-160 Mud Pumps are Rebuilt and Ready to go to work.

Some refurbishments include: Fully reconditioned mud pump assembly. Pinion shaft assembly complete with new SKF bearings and new seals. Pump internals painted with Oil Resistant 2 Part epoxy Jotun Tank guard. MPI inspection of all critical areas of pump frame. MPI of all load path components of Crankshaft and Pinion shaft assemblies, and all new Southwest Premium “L” Shape 6,000 psi Fluid End Modules. A full Data Pack with all dimensional control & MPI reports will be furnished.

Warranty on National 12-P-160 Triplex Mud Pumps: All new parts fitted come with a 12 month warranty or such as offered by the part manufacturer; The refurbished GE-752 traction motors come with an 18 month warranty.

Pickett Oilfield, LLC offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Drilling Equipment at competitive prices, including Triplex Mud pumps.

Request A Quote National Oilwell 12-P-160 Triplex Mud Pump Refurbished National 12-P-160 Mud Pumps You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex ...

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

ALCO F-Series Triplex Mud Pump features reasonable design and unique substructure, resulting in compact size and light weight for the best yet in portability and convenient placement and removal, plus less wearable parts as another advantage. It is very practical, as it works under various conditions, service well work, wells of different depth, land operation and drilling or service platform offshore.

8613371530291

8613371530291