interchangeable mud pump part quotation

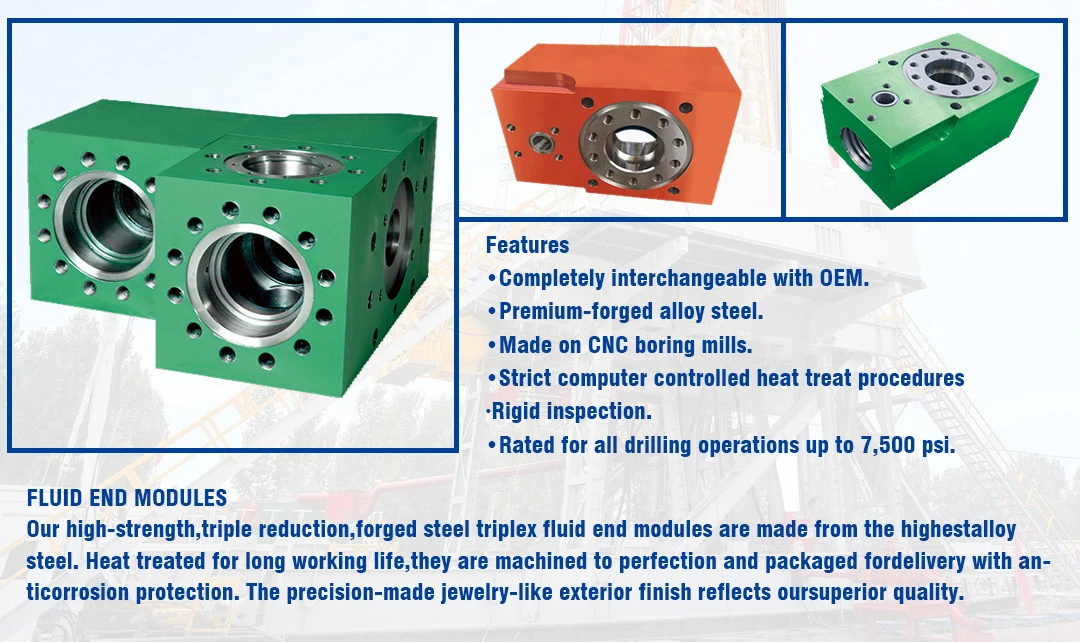

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

Power Frame. High-strength gray iron alloy casting with heavy wall sections, well ribbed to ensure rigid construction and design to fully enclose all working parts.

Lubrication. All power and parts including gears, cross heads, connecting rod bearings, crankshaft bearings and pinion crank shaft bearings, are lubricated by splash system from lubricant in crankcase reservoir.

Power Frame. Alloys stocked are Molybdenumâs cast iron and cast steel. Fluid ounce can be trimmed out for pumping various liquids. Ductile iron can be furnished upon request.

Liners. All pumps are available with interchangeable pipe liners. Standard materials available are Molybdenums alloyed iron, file hard steel and special corrosion resistant liners.

Stuffing Box Lubrication. Furnished by use of regulated flow of oil from a force-feed lubricate or mounted on the pump, with a separate oil line to each stuffing box.

The Weatherford MP Series F & FB style design compatibility means that parts are readily available and fully interchangeable. The MP series mud pumps are based on the industry-recognized, proven and trusted F & FB style mud pump. The MP10 & MP16 Models are always in stock and available for immediate shipment.

The MP Series F style design compatibility means that parts are readily available and fully interchangeable. The MP series mud pumps are based on the industry-recognized, proven and trusted F style mud pump. Any of these parts for the MP Series models below can be purchased from Rig Manufacturing, LLC.

Special design to minimize maintenance and downtime include: cantilever shaft that eliminates troublesome submerged bearings, mechanical or gland-type shaft seals, and packing; double suction thrust-less impeller prevents air locking; pump agitates the sump"s contents reducing the need to hard clean sumps.

Highest quality workmanship and materials, which include cast iron and a wide selection of alloys and elastomer coverings, assure you of a dependable, durable pump built to overcome your pumping problems.

Many operators say these pumps are the only vertical pumps that can be installed on abrasive applications then be forgotten except for routine maintenance.

High chrome sleeve liners, zirconia ceramic liners, urethane bonded pistons with long service life, high temperature urethane bonded pistons, replaceable rubber pistons, rubber bonded pistons, a full range of full open, 3 web, 4 web and plate type design valves and seats available in API 4 thru 8 sizes to fit all major mud pumps, a complete line of interchangeable fluid end modules and accessories, for various OEM"s mud pumps such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell etc.

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

Your search for superb quality oil well Drilling Parts ends at one stop shop that is Vision Auto Industries. Finding multiple applications in various industries, the drilling parts offered by us are appreciated andread more...

We are Authorized dealers for HAINUAO AO brand of mud pump spares which are compatible with mud pumps of EMSCO, GARDNER-DENEVER, NATIONAL OILWEL, IDECO, SKYTOP/BREWSTER, OPI WERTH WILSON and GASO and are an OEM replacement, approved by the API and are designed for the longest service.

Owing to the years of industrial experience, we have been able to serve our esteemed clients with a wide variety of Duplex Mud Pump Part. These parts of pumps are manufactured by our industry-experts using advanced machinery and premium quality material. Further, we check these parts on different parameters previous to theirread more...

Keeping in pace with the specific need of our customers, we are engaged in offering a wide series of Mud Pump Spare Parts. Our offered item is developed under the supervision of our skilled workers using finest quality basic material. This is well regarded among the clients due to its corrosion resistance, fine finish andread more...

Special care is taken for accurate dimensions of Piston hub and formed from high grade steel to ensure very long life. Our Piston assemblies give very long life even under extreme working conditions. Pistons are fully interchangeable with other API standard designed pistons and deliver maximum performance inread more...

We have in store an outstanding gamut of Mud Pumps Modules. Developed in complete adherence with the defined parameters of the industry, these offered products are highly appreciated for their below cited incomparable attributes:

We are instrumental in manufacturing spare parts of Mud Pumps. These spare parts are made using quality raw material like steel & iron and are quality tested on parameters like durability and dimensions. Mud Pumps are an important part of mining and drilling applications. Spare parts offered by us are as per the highread more...

SEPL offers very high quality and precision machined sleeved bi-metallic liners finished to relevant API dimensions. They are available for various pumps, manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others. They are available in different sizes ranging from 5" to 7.1/2"read more...

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

8613371530291

8613371530291