kirloskar mud pump made in china

THF6B-1 single stage horizontal centrifugal pump ◊ Application Applied to pumping such liquid which is clean, no solid matter or frictional matter, low viscous, noncorrosive, non-crystallizable, chemically neutral and close to water. Such as: 1. Tank filling 2. Domestic water supply 3. Water transfer 4. Pressure boosting 5. Irrigation ◊ Features 1. 100% copper wire , and automatic wiring. 8. 30 years experience, 1 year warranty ◊ Technical data 1. Suction lift up to 8 m 2. Liquid temperature up to +35°C 3. Ambient temperature up to +40°C 4. Max.

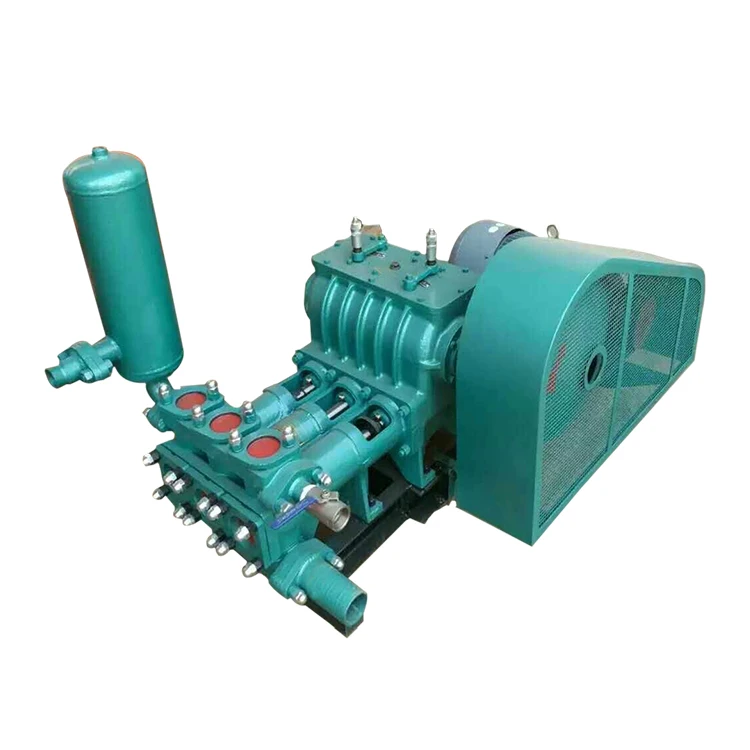

2.BW mud pump have four gear shifts.Output and drilling depth are adjustable,so it can be used to grout cement slurry or equipped with drilling machine.

3.BW mud pump is widely used in railway, hydraulic engineering, metallurgical engineering, building construction, geological exploration, engineering exploration.

kirloskar mud pumps is used for pumping light chemicals, effluents, sewage, ash-water, public utilities, de-watering from basements, multi storeys, shopping malls, godowns etc

We have attained huge reputation as prominent manufacturer and supplier of Portable Dewatering Submersible Pumps. These pumps are well accepted in the market for their light weight, robust construction and excellent functional accuracy. We design these pumps by utilizing latest tools and techniques as per latest industrial norms with quality tested raw materials. We supply these machines in wide specifications at affordable price range to our customers.

• Portable submersible pumps are one of its kinds. We have a wide range of selection within the same Horse Power rating for these pumps. Our construction is robust compared to other make pumps and has proved its self in the market with its trouble free Operation

• Motor – submersible pumps are available in Single phase and three-phase squirrel cage induction dry motor with ‘F" class insulation and IP 68 protection

• We provide pumps with Aluminum MOC, which will make the pump very light and will be extremely handy for the operator. Trolley mounted construction is also an available option

With a back pull out design these pumps are gland packed or mechanically sealed and are used for air conditioning, booster service, fire fighting and sprinkler system. Delivery size varies from 32 mm to 150 mm

Kirloskar "SP" Series Pumps are of non clog and self priming type. They are used in various marine, industrial, civil construction, mobile machinery and public utilities applications.

Established in 1888 and incorporated in 1920, The core businesses of KBL are large infrastructure projects (Water Supply, Power Plants, and Irrigation), Project and Engineered Pumps, Industrial Pumps, Agriculture and Domestic Pumps, Valves, Motors and Hydro turbines.

Pumps Parts.Pump Liners Colin supplies all kinds of liners for those of the following model mud pumps: China F series Mud Pumps (made by BOMCO, RG, RONGLI, RONGSHENG, HONGHUA), China 3NB series Mud Pumps (made by Lanzhou, Qingzhou), EMSCO, GARDNER DENVER, NATIONAL, OILWELL, IDECO, WIRTH, OPI, ELLIS WILLIAMS, WHITE STAR etc. China F series Mud Pump: F-500, F-8001000, F-13001600 China 3NB series Mud Pump: 3NB-350, 3NB-500, 3NB-600, 3NB-800, 3NB-1000, 3NB-1300, 3NB-1600 EMSCO: F-350, F-500, F-650, F-800, F-1000, FA-1300, FB-1300, FA-1600, FB-1600 GARDNER DENVER: PZ-7, PZ-89, PZ-1011, FK-FXK, FY-FXD, FD-FXX, FG-GXG, FG-FXG, KG-KXG, FQ-FXQ, FF-FXF, FF-FXP NATIONAL: 7P50, 8P80, 9P100, 10P130, 12P160, N1300, C-250, 14-P-220, E-700G-1000, K-500, K-380, K-500A700A, C-250350, JWS-400 OILWELL: A-560600-PT, A-850-PTA-1100-PT, A-1700-PTA-1400-PT IDECO: T-500, T-800, T-1000, T-1300, T-1600 Mud Pump Liner Types: There are four main mud pump lines, like high frequency quenching liners, chromium-plated liners, ceramic liners, and bi-metal liners.

Kirloskar Bros Pump Dealers are one of the leading authorized dealers of the industry providing the best and effective pumping solutions. It has been engaged since many years in marketing industrial pumps, motors, valves and many more industrial products with the best possible services and are the leaders in the respective product line. Their team is having decades of experience in dealing with this products.

Kirloskar Bros Pump Dealers enterprise is backed by its own team of pre and post sales services and it is managed by highly qualified factory trained engineers. It has also been selected as the member of the top dealing market club due to its consequent recognition of performance.

Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford

Prominent & Leading Manufacturer from Rajkot, we offer high head water pump, portable water cooled diesel engine pump set, horizontal aircool diesel engine pump set, diesel water pump, 5hp diesel engine water pump set anil brand and diesel engine pump sets 20 hp.

Engine Horsepower12.5hpPREM Brand High Head Diesel Water Pump, 12.5hp/1500rpm Watercooled Diesel Engine Coupled With 3"x3" High Head Direct Coupled Pump,Mounted on MS Base Frame 4 Wheel Trolley. Pump Details: 32mtrs Head, 22Lps.

Model NumberPVP-50APREM Brand - PVP-50A Portable - 5 HP 1800 RPM {85mm Bore x 80mm Stroke} Water Cooled Diesel Engine coupled with 3” x 2.5” Centrifugal Pump mounted on M. S. Fabricated 4 Rubber Wheel Trolley with standard accessories.

Automation GradeManualPREM Brand - Horizontal Aircool Diesel Engine Pump Set - 5hp/2600rpm Aircooled Engine Coupled With 3"x3" Centrifugal Pump Mounted on MS Base Frame 4 Wheel Trolley Set.

Country of OriginMade in Indiawe "Prem Engineering Pvt Ltd" are engaged in Manufacturer, Supplier, Exporter and Trader reliable gamut of High Spped Diesel Engine ,Diesel Engine Pump Set, Centrifugal Pumps, Water Hand Pump, Air Cooled Diesel Engine, Water Cooled Diesel Engine etc.

The mud pumps market size is expected to grow at a significant rate during the forecast period. A mud pump is a large, high-pressure (up to 7500 psi), single-acting triplex reciprocating pump used to circulate mud in a well at a specific flow rate (between 100 and 1300 gallons per minute). Instead of a triplex reciprocating pump, a double-acting two-cylinder reciprocating pump is occasionally utilized as a mud pump. Typically, a rig operator keeps two or three mud pumps on hand, one of which is active and the others on standby in case of an emergency. Mud is gathered up with the use of mud pumps, which use suction to circulate the mud from the wellbore to the surface during the drilling process.

Increased demand for directional and horizontal drilling, higher pressure handling capabilities, and some new oil discoveries are the main drivers of this market"s growth. Mud pumps are specialized pumps that are used to transport and circulate drilling fluids and other related fluids in a variety of industries, including mining and onshore and offshore oil and gas. The global energy demand is boosting the market for mud pumps. However, high drilling costs, environmental concerns, and shifting government energy and power laws may stymie industry growth.

Innovation in technology is the key for further growth for example, MTeq uses Energy Recovery’s Pressure exchanger technology in the drilling industry, as the ultimate engineered solution to increase productivity and reduce operating costs in pumping process by rerouting rough fluids away from high-pressure pumps, which helps reduce the cost of maintenance for operators.

The major key player in global mud pumps market are Flowserve (U.S.), Grundfos (Denmark), Halliburton (U.S.), Sulzer (Switzerland), KSB Group (Germany), Ebara Corporation (Japan), Weir Group (U.K), and SRS Crisafulli, Inc (U.S.). Tsurumi Pump (Japan), Shijiazhuang Industrial Pump Factory Co. Ltd (China), Excellence Pump Industry Co.Ltd (China), Kirloskar Ebara Pumps Limited (India), Xylem Inc (U.S.), and Goulds Pumps (U.S.) are among others.

In the drilling business, MTeq uses Energy Recovery"s Pressure exchanger technology as the ultimate engineering solution to boost productivity and lower operating costs in the pumping process by rerouting abrasive fluids away from high-pressure pumps, which helps operators save money on maintenance. The latest trend reveals that regulatory agencies are persuading manufacturers and consumers to choose electric mud pumps over fuel engine mud pumps to reduce the environmental impact of fuel engine mud pumps.

The global mud pumps market is segmented on the basis of type (duplex pump, triplex pump, and others), component (fluid end and power end), application (oil & gas industry and building industry), and Region (North America, Europe, Asia Pacific, and Rest of the World).

Based on type, mud pumps can be segmented as duplex and triplex pumps. Triplex pumps are expected to progress because of the ~30.0% lesser weight than duplex pumps offering similar efficiency. The pump transfers the fluids with the help of mechanical movements.

Based on application, mud pumps market can be segmented as oil & gas industry and building industry. As oil and gas fields going mature, operators must drill wells with large offset, high laterals, widening their applicability by using mud motors, and high-pressure pumps. To fulfill the demand drilling companies increase their mud pumping installation capacity, with higher flexibility. For instance, LEWCO has developed W-3000 mud pump model for oil drilling, which can handle power up to 3000 HP.

Based on region, North America is predominant because of tight oil and shale gas sources, followed by Asia-Pacific due to the increased number of wells in the regions, especially in countries such as China and India due to the rapid urbanization and industrialization. Authorities in countries such as India, China are working on enhancing their production capacities for reducing the import bills, which ultimately help in the growth of mud pumps market.

This market is broadly driven by oil and gas industry as mud pumps are used to move massive amount of sludge and mud at the time of drilling. Countries such as China, Russia, Saudi Arabia, and the U.S. have the largest number of oil wells. The demand for mud pumps will increase with the number of oil wells, across the globe.

8613371530291

8613371530291