ksb mud pump manufacturer

Founded in 1871 in Frankenthal (Germany), KSB has been one of the leading suppliers of pumps and industrial valves for over 150 years. With more than 15,000 employees worldwide and its own sales and marketing, manufacturing facilities and service operations, KSB develops and produces custom-fit pumps for various applications.

As an experienced pump manufacturer, its product portfolio includes building and industrial technology, water transport, wastewater treatment and power plant processes. Thanks to innovative research and development, KSB can meet the most diverse requirements of customers. Benefit from many years of experience and technical expertise as a renowned pump manufacturer.

Industrial pumps and valves from KSB cover a wide range of applications and are highly energy-efficient. Products convince with the most innovative technology as well as with systems that have been tried and tested for many years - including the Etanorm water pump. Achieving more than 1.5 million sales worldwide, Etanorm is the most successful standard water pump. With KSB spare parts and services.

KSB ensures the operational reliability of its industrial pumps and valves. The KSB success formula for high-performance pumps lies in the technological strength in hydraulics, materials and automation.

The numerous production facilities ensure that KSB as a pump manufacturer can guarantee customer proximity and first-class service. The experienced specialists are certified to ensure excellent quality and extensive experience. KSB Service takes care of the commissioning, inspection, servicing and maintenance of your pumps, valves and complete systems directly on site. KSB also provides you with spare parts quickly. This means you get the best service directly from your pump manufacturer.

With annual sales revenue of almost 2200 million euros, the KSB Group is one of the leading producers of pumps, valves and related systems. Worldwide, KSB employs more than 16,000 people – all committed to maximum customer satisfaction in building services, industry and water utilities, the energy sector and mining. KSB is increasingly a service partner and provides complete hydraulic systems for water supply and drainage.

KSB has been growing continuously since it was founded in 1871. Today the Group has a presence on all continents with its own sales and marketing companies, manufacturing facilities and service operations.

Wet-installed submersible motor pump for installation in discharge tubes, with channel impeller, single-stage, single-entry. ATEX-compliant version available.

Wet-installed submersible motor pump for installation in discharge tubes, with axial propeller in ECB design, single-stage, single-entry. ATEX-compliant version available.

Self-cleaning tank insert for grouted installation in new concrete structures or in concrete structures in need of refurbishment. Designed to prevent soiling of the structure and clogging of the pumps by heavily waste or fibre loaded waste water. Suitable for pump stations emitting unpleasant odours and/or gases.

Protection module for water and waste water products as all-in-one device. Depending on the variant, it can be used for motor temperature measurement, bearing temperature measurement, leakage measurement, vibration measurement, voltage measurement and current measurement as well as for diagnosing a pump, pump system or submersible mixer to ensure trouble-free and reliable operation.

Vertical single-stage fully floodable submersible motor pump in close-coupled design, with integrated level switch for automatic control or optionally for control via external control unit. The maximum immersion depth is 2 metres.

AmaDrainer 4../5..: Vertical single-stage fully floodable submersible motor pump in close-coupled design, IP68, with or without level control, max. immersion depth: 7 m. AmaDrainer 80/100: Vertical single-stage fully floodable submersible motor pump in close-coupled design, IP68, with or without level control, max. immersion depth: 10 m.

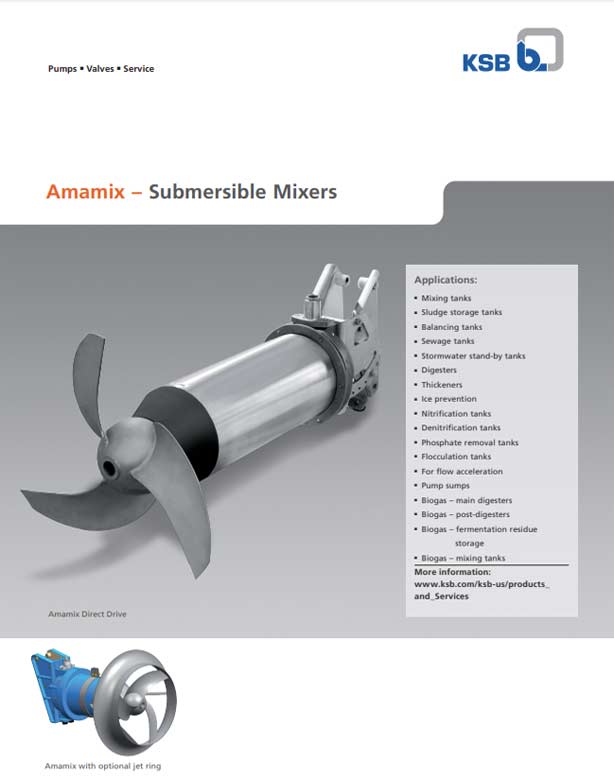

Wet-installed horizontal propeller pump with submersible motor, equipped with direct drive or spur gear, ECB propeller with rigid, fibre-repellent blades, bolt-free connection to the discharge pipe. Explosion-proof version available.

Vertical single-stage submersible motor pump for wet installation, with vortex impeller (F-max) or open dual-vane impeller (D-max), stationary or transportable version. Single-stage, single-entry close-coupled pump sets which are not self-priming. ATEX-compliant version available.

Horizontal or vertical single-stage submersible motor pump in close-coupled design, with various next-generation impeller types, for wet or dry installation, stationary or transportable version, with energy-saving motor and models for use in potentially explosive atmospheres.

Vertical single-stage submersible motor pump for wet installation, with cutter (S), stationary or transportable version. Amarex N pumps are floodable, single-stage, single-entry close-coupled pump sets which are not self-priming. ATEX-compliant version available.

Horizontal self-priming centrifugal pump, open or semi-open impeller, adjusted via wear plate, with mechanical seal, ATEX-compliant version available.

Horizontal self-priming centrifugal pump in close-coupled design, open or semi-open impeller, adjusted via wear plate, with mechanical seal, driven by electric motors or internal combustion engines; ATEX-compliant version available.

Vertical turbine pump conforming to AWWA E101-88 and designed with radially split interchangeable pump bowls, wear rings and impellers; column assembly with interchangeable column bearings and lengths of column pipes for variable immersion depths.

Control valve to DIN/EN based on standard type series BOA-Compact, BOA-SuperCompact, BOA-W, BOA-Compact EKB, BOA-Compact IMS EKB, BOA-Control IMS and BOA-Control IMS EKB, bonnetless pressure-retaining body, soft-seated. Leakage rate selectable from 0.05 % to drop-tight, Kvs values between 6.3 and 700 m³/h and closing pressures of up to 16 bar. With intelligent microprocessor-controlled and pre-set electric actuators providing actuating forces from 1000 N to 14,000 N; electronic configuration of flow characteristic, Kvs value, actuating signal and actuating time using PC tool or manual parameterisation unit. Customised configuration can be implemented at the KSB factory on request.

Maintenance-free high-efficiency flanged or screw-ended glandless pump with high-efficiency electric motor and continuously variable differential pressure control.

Maintenance-free high-efficiency flanged or screw-ended glandless pump with high-efficiency electric motor and continuously variable differential pressure control.

Maintenance-free high-efficiency flanged or screw-ended glandless pump in twin pump design with high-efficiency electric motor and continuously variable differential pressure control.

Maintenance-free high-efficiency screw-ended glandless pump with high-efficiency electric motor and continuously variable differential pressure control.

Maintenance-free high-efficiency flanged or screw-ended glandless pump in twin pump design with high-efficiency electric motor and continuously variable differential pressure control.

Maintenance-free fixed speed glandless drinking water circulator pump, screw-ended, electric motor with multiple fixed speed levels, for use in drinking water supply systems and hot water supply systems.

Horizontal high-pressure barrel-type pumps with radial impellers, single-entry and double-entry, multistage, with flanges or weld end nozzles to DIN and ANSI.

Horizontal high-pressure barrel-type pumps with radial impellers, single-entry and double-entry, multistage, with flanges or weld end nozzles to DIN and ANSI.

Horizontal high-pressure barrel-type pump with radial impellers, single-entry and double-entry, multistage, with flanges or weld end nozzles to DIN, API 610 and ANSI.

Horizontal axially split single-entry multistage between-bearings volute casing pump with single casing and back-to-back impeller arrangement to API 610 (ISO 13709), type BB3. First stage optionally available in double-entry design for low NPSH requirements. ATEX-compliant version available.

Floodable single-pump sewage lifting unit or dual-pump sewage lifting unit for automatic disposal of waste water and faeces in buildings and building sections below the flood level.

Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to ISO 2858 / ISO 5199. Also available as a variant with "wet" shaft, conical seal chamber and/or semi-open impeller. ATEX-compliant version available.

Horizontal volute casing pump in back pull-out design, with semi-open impeller, single-stage, to ISO 2858 / ISO 5199. ATEX-compliant version available.

Fully automatic pressure booster system with two to three (MVP) / four (SVP) vertical high-pressure pumps in two variable speed versions. The MVP and SVP variable speed versions ensure variable speed control of each pump by motor-mounted frequency inverter for asynchronous motors (MVP) or by PumpDrive variable speed system and KSB SuPremE motor (SVP), respectively, providing fully electronic control to ensure the required supply pressure. Equipped with a central fuse box.

Fully automatic package pressure booster system with two to four (F) / six (VC/SVP) vertical high-pressure pumps; available in cascade-controlled and two variable speed designs. Cascade control (F) for ensuring the required supply pressure. The VC and SVP versions ensure variable speed control of each pump by cabinet-mounted frequency inverter (VC) or motor-mounted PumpDrive variable speed system and KSB SuPremE motor (SVP), respectively, providing fully electronic control to ensure the required supply pressure. Automated with KSB BoosterCommand Pro Plus.

Fully automatic package pressure booster system with two to three (VC) / four (F/SVP) vertical high-pressure pumps; available in cascade-controlled and two variable speed designs. Cascade control (F) for ensuring the required supply pressure. The VC and SVP versions ensure variable speed control of each pump by cabinet-mounted frequency inverter (VC) or motor-mounted PumpDrive variable speed system and KSB SuPremE motor (SVP), respectively, providing fully electronic control to ensure the required supply pressure. Automated with KSB BoosterCommand Pro.

Fully automatic single-pump system available in two variable speed versions. The MVP and SVP variable speed versions ensure variable speed control of each pump by motor-mounted frequency inverter for asynchronous motors (MVP) or by PumpDrive variable speed system and KSB SuPremE motor (SVP), respectively, providing fully electronic control to ensure the required supply pressure.

Vertical immersion pump for wet installation, with various impeller types designed to meet specific fluid requirements. Supplied with discharge pipe extending above the cover plate, DN according to nominal flow rate. Sealing by lip seal, single or double cartridge mechanical seal. ATEX-compliant version available.

Single-stage close-coupled volute casing pump, with ratings to EN 733, with replaceable shaft sleeve and casing wear rings, with motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Volute casing pump for horizontal or vertical installation, back pull-out design, single-stage, with ratings to EN 733, radially split volute casing, replaceable casing wear rings, volute casing with integrally cast pump feet, closed radial impeller with multiply curved vanes, single mechanical seal to EN 12756, product-lubricated carbon plain bearing, grease-lubricated radial ball bearing in the motor housing, with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system; ATEX-compliant version available.

Horizontal single-stage close-coupled circular casing pump, with ratings and main dimensions to EN 733, with replaceable casing wear rings and motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Horizontal single-stage circular casing pump, with ratings and main dimensions to EN 733, with replaceable casing wear rings and motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Single-stage volute casing pump in in-line design, with magnetless KSB SuPremE motor of efficiency class IE4/IE5 and PumpDrive variable speed system; pump shaft and motor shaft are rigidly connected. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Single-stage volute casing pump in in-line design, with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system; pump shaft and motor shaft are rigidly connected. ATEX-compliant version available.

Single-stage volute casing pump in in-line design as twin pump, with magnetless KSB SuPremE motor of efficiency class IE4/IE5 and PumpDrive variable speed system; pump shaft and motor shaft are rigidly connected. An M12 module (accessory) enables redundant operation of Etaline Z without the need for a higher-level controller. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Vertical close-coupled pump with volute casing in in-line design with magnet-less KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system.

Horizontal volute casing pump, single-stage, with ratings and main dimensions to EN 733, long-coupled, back pull-out design, with replaceable shaft sleeves / shaft protecting sleeves and casing wear rings, with motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Horizontal volute casing pump in back pull-out design, single-stage, with ratings and dimensions to EN 733, radially split volute casing with integrally cast pump feet, replaceable casing wear rings, closed radial impeller with multiply curved vanes, single mechanical seal to EN 12756, double mechanical seal to EN 12756, drive-end bearings: rolling element bearings, pump-end bearings: plain bearings, with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system; ATEX-compliant version available.

Horizontal volute casing pump in back pull-out design, single-stage, with ratings and dimensions to EN 733, radially split volute casing with integrally cast pump feet, replaceable casing wear rings, closed radial impeller with multiply curved vanes, single mechanical seal to EN 12756, double mechanical seal to EN 12756, drive-end bearings: rolling element bearings, pump-end bearings: plain bearings, with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system; ATEX-compliant version available.

Horizontal self-priming volute casing pump, single-stage, with open multi-vane impeller, close-coupled; pump shaft and motor shaft rigidly connected; ATEX-compliant version available.

Horizontal self-priming volute casing pump, single-stage, with open multi-vane impeller, from size 40-40-140 with bearing bracket, in back pull-out design, ATEX-compliant version available.

Horizontal or vertical seal-less volute casing pump in back pull-out design with fully enclosed canned motor, low noise emission, with radial impeller, single-stage, single-entry, casing connecting dimensions to EN 733, or in in-line design.

High-flow / low-head white cast iron pump with single-wall casing and high-efficiency impeller. Single-piece suction cover with integrated mounting plate.

Horizontal radially split volute casing pump in back pull-out design, with centreline pump feet, with radial impeller, single-entry, single-stage. Optional TRD type testing by TÜV. ATEX-compliant version available.

Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to ISO 2858 / ISO 5199. Optional TRD type testing by TÜV. ATEX-compliant version available.

Horizontal radially split volute casing pump in back pull-out design to ISO 2858 / ISO 5199, single-stage, single-entry, with radial impeller. Equipped with heat barrier, seal chamber air-cooled by integrated fan impeller, no external cooling. ATEX-compliant version available.

A high-efficiency pump that has been specially developed for handling air entrained slurries. The design features a patented impeller and a venting chamber that removes the air contained in the fluid handled from the impeller eye, preventing blockage and reducing downtime. The wetted pump end (casing, impeller and suction plate / liner) is made of white cast iron with a high chromium content. This increases the service life of the components. Urethane is also available as a material. The maximum permissible working pressures are between 8 and 11.5 bar, depending on the pump size. Perfectly suited for transporting fluids containing hardly to slightly abrasive solids. Ideal for sludges, classes 1 to 2.

Fully automatic package dual-pump system consisting of one duty system and one stand-by system to ensure system redundancy. Design and function as per DIN 14462.

Vertical in-line centrifugal pump with closed impeller and mechanical seal. ILNS fitted with an auxiliary vacuum pump, ILNE with ejector. Back pull-out design allows the impeller to be dismantled without removing the piping and the motor. ATEX-compliant version available.

Vertical close-coupled centrifugal pump in in-line design, with electric motor, closed impeller and mechanical seal. ILNCS fitted with an auxiliary vacuum pump, ILNCE with ejector. Standardised IEC frame motor. ATEX-compliant version available.

Vertical immersion pump for wet or dry installation, available with closed or semi-open impeller. Supplied with discharge pipe extending above the baseplate (INVCP) or without discharge pipe (INVCN). ATEX-compliant version available.

Multistage close-coupled centrifugal pump for fully or partly submerged operation (min. immersion depth 0.1 m), with low-level inlet, suction strainer with a max. mesh width of 2.0 mm.

Multistage submersible borehole pump with integrated pressure switch, flow sensor and lift check valve. Electronic dry running protection with four consecutive start-up attempts; integrated capacitor. 15-metre H07 RN-F power cable with shockproof plug included.

The smart and comprehensive monitoring service for pumps and other rotating machinery, available 24/7 and also for non-KSB pumps. Benefit from predictive maintenance with KSB: comprehensive transparency, increased availability, enhanced operating reliability and efficient operation (of fixed-speed pumps). Important operating data such as vibrations, temperature, operating hours and load condition (of fixed-speed pumps) can be accessed via KSB Guard, anytime and from anywhere. In addition, deviations from normal operation trigger immediate notifications via the KSB Guard web portal and/or app. The experts at the KSB Monitoring Centre also provide support in analysing causes.

The KSB Leakage Sensor is an intelligent monitoring system for measuring and displaying mechanical seal leakage on site. It comprises a leakage measuring instrument and a display unit.

Horizontal radially split volute casing pump in back pull-out design, single-stage, single-entry, available with various impeller types: closed multi-channel impeller, open multi-vane impeller and vortex impeller. ATEX-compliant version available.

Horizontal or vertical radially split close-coupled volute casing pump, single-stage, single-entry, available with various impeller types: closed multi-channel impeller, open multi-vane impeller and vortex impeller.

A high-efficiency slurry pump as an ideal solution for heavy-duty applications. The wetted pump end (casing, impeller and suction plate / liner) is made of white cast iron with a large chromium content. The walls of the wetted parts of the LCC-H version are thicker than those of the LCC-M. This increases wear resistance and enables the use in applications with higher pressures. The suction-side wear plate and the suction cover are two separate components, which significantly reduces maintenance costs. All pumps are designed for a maximum permissible working pressure of 16 bar. Perfectly suited for transporting fluids containing hardly to slightly abrasive solids. Ideal for sludges, classes 2 to 3.

A high-efficiency slurry pump with excellent wear properties over a broad operating range. The wetted pump end (casing, impeller and suction cover / liner) is made of white cast iron with a high chromium content. Design optimised for easy dismantling and reassembly for maintenance and inspection work. The maximum permissible working pressures are between 8 and 16 bar, depending on the pump size. Perfectly suited for transporting fluids containing hardly to slightly abrasive solids. Ideal for sludges, classes 1 to 2.

Robust vertical shaft submersible pump in cantilever design with suction from the bottom and bearings arranged outside of the fluid handled. Design with open and closed impeller for best efficiency and maximum free passage. Wear parts of wetted pump components (casing, impeller, suction cover / liner) made of white cast iron with a high chromium content and therefore very wear-resistant. The maximum permissible working pressures are between 7 and 11 bar, depending on the pump size. Perfectly suited for transporting fluids containing hardly to slightly abrasive solids. Ideal for sludges, classes 1 to 2.

Level control unit for controlling and protecting either one or two pumps. DOL starting up to 4 kW, star-delta starting up to 22 kW. Higher ratings on request.

Horizontal volute casing pump for high-volume hydrotransport of solids. For pumping slurries of large and very large particle sizes with a very good suction behaviour and high efficiency. Used in low-pressure applications. Pump components made of white cast iron.

Premium design white cast iron pump for long service life handling severe slurries. The maintenance-friendly single-wall construction and heavy section white cast iron wet end combined with the cartridge bearing assembly provide maximum reliability, a long service life and ease of maintenance.

Vertical spherical casing pump, radial impellers, single-entry, single- to three-stage. Suitable for very high inlet pressures and temperatures. Integrated wet winding motor to VDE. Product-lubricated bearings, no need for oil supply systems. Design to TRD, ASME or IBR.

Vertical pump with integrated motor, single-entry, single- to three-stage. Suitable for very high inlet pressures and temperatures. Integrated wet winding motor to VDE. Product-lubricated bearings, no oil supply systems required. Design to ASME Section 3, KTA, etc.

Horizontal seal-less volute casing pump in back pull-out design, with magnetic drive, to DIN EN ISO 2858 / ISO 5199, with radial impeller, single-entry, single-stage. ATEX-compliant version available.

Horizontal or vertical seal-less volute casing pump in close-coupled design, with magnetic drive, to DIN EN ISO 2858 / ISO 5199, with radial impeller, single-entry, single-stage. ATEX-compliant version available.

Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to DIN EN ISO 2858 / ISO 5199, in a large range of material and seal variants; also available as a variant with "wet" shaft and conical seal chamber. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Horizontal volute casing pump for high-volume hydrotransport of solids. For pumping slurries of large and very large particle sizes with a very good suction behaviour and high efficiency. Pump components made of white cast iron.

The automatic recirculation valve (ARV) is a multifunctional valve whose primary function is to ensure a pre-determined minimum flow through the centrifugal pump at all times.

Floodable single-pump sewage lifting unit or dual-pump sewage lifting unit for automatic disposal of domestic waste water and faeces in building sections below the flood level.

Multistage vertical high-pressure centrifugal pump in ring-section design with suction and discharge nozzles of identical nominal diameters arranged opposite to each other (in-line design), close-coupled. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Multistage horizontal high-pressure centrifugal pump with KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors.

Multistage horizontal or vertical centrifugal pump in ring-section design, long-coupled or close-coupled, with axial or radial suction nozzle, cast radial impellers and motor-mounted variable speed system. ATEX-compliant version available.

Single-stage axially split volute casing pump for horizontal or vertical installation, with double-entry radial impeller, mating flanges to DIN, EN or ASME.

Vertical tubular casing pump with mixed flow propeller, pump intake with inlet nozzle or suction elbow, pull-out design available, discharge nozzle arranged above- or underfloor, flanges to DIN or ANSI standards available.

Vertical tubular casing pump with axial propeller, single-stage, with maintenance-free Residur bearings, discharge nozzle arranged above or below floor level.

Vertical tubular casing pump with axial propeller, pump intake with inlet nozzle or suction elbow, pull-out design available, discharge nozzle arranged above- or underfloor, flanges to DIN or ANSI standards available.

Modular self-cooling frequency inverter that enables continuously variable speed control of asynchronous and synchronous reluctance motors by means of analog standard signals, a field bus or the control panel. As PumpDrive is self-cooling, it can be mounted on a motor, on the wall or in a control cabinet. Up to six pumps can be controlled without needing an additional controller.

Modular self-cooling frequency inverter that enables continuously variable speed control of asynchronous and synchronous reluctance motors by means of analog standard signals, a field bus or the control panel. As PumpDrive R is self-cooling, it can be mounted on the wall or in a control cabinet. Up to six pumps can be controlled without needing an additional controller. PumpDrive R extends the power range of PumpDrive 2 up to a rated power of 250 kW (standard) / 1400 kW (on request).

Device for monitoring the operation of one pump. It is an intelligent pressure transmitter for pumps, with on-site display of measured values and operating data. It records the load profile of the pump in order to indicate any potential for optimising energy efficiency and availability. The device comprises two pressure sensors and a display unit. PumpMeter is supplied completely assembled and parameterised for the pump it is used with. It is ready for operation as soon as the M12 plug connector is plugged in.

Single-stage axially split volute casing pump for horizontal or vertical installation, with double-entry radial impeller, mating flanges to DIN, EN or ASME.

Axially split volute casing pump for horizontal installation, with one, two or three stages and double-entry radial impeller, mating flanges to DIN, ISO or ANSI.

Vertical single-stage reactor coolant pump with forged circular casing plated on the inside, with diffuser, either with integrated pump thrust bearing or shaft supported by motor bearing.

Vertical single-stage centrifugal pump with discharge to the top and parallel with the pump shaft, pump base designed to act as suction strainer. Pump and motor are rigidly connected by a support column. Supplied ready to be plugged in, with 1.5-metre power cable and level switch.

Horizontal radially split volute casing pump in back pull-out design, to API 610, ISO 13709 (heavy duty), type OH2, single-stage, with single-suction radial impeller and centreline pump feet; with inducer if required. ATEX-compliant version available.

Horizontal single-entry single-stage radially split overhung centreline-mounted process pump with circular casing to API 610 (ISO 13709), type OH2. Special design for low flow rates. ATEX-compliant version available.

Vertical single-stage sump pump to API 610 and ISO 13709 (heavy duty), type VS4, with integral thrust bearing assembly and separate discharge line. ATEX-compliant version available.

Heavy-duty horizontal radially split between-bearings volute casing pump to API 610, ISO 13709 (heavy duty), type BB2, with radial impellers, single- or double-entry, single- or two-stage design with centreline pump feet. ATEX-compliant version available.

Vertical single-stage reactor coolant pump. Seal-less design with integrated wet rotor motor and integrated flywheel. Product-lubricated bearings, no oil supply systems required.

Close-coupled volute casing pump for horizontal or vertical installation, with various next-generation impeller types, discharge flange to DIN and ANSI standards. Explosion-proof version available.

Volute casing pump for horizontal or vertical installation, with various next-generation impeller types, discharge flange to DIN and ANSI standards. Explosion-proof version available.

Vertical tubular casing pump with open mixed flow impeller, pump intake with inlet nozzle or suction elbow, pull-out design available, discharge nozzle arranged above- or underfloor, flanges to DIN or ANSI standards available.

Vertical tubular casing pump with mixed flow impeller, single-stage, with maintenance-free Residur bearings, discharge nozzle arranged above- or underfloor.

Package pump station with tank made of glass fibre reinforced polyester, equipped with two dry-installed Sewabloc pumps with a rating of 2.2 to 30 kW, integrated valves and a control unit with frequency inverters. Pump operation is adjusted in line with flow rate demand, thus minimising energy costs. This maintenance-friendly pump station prevents intermediate storage of waste water and the related odour nuisance.

Fully automatic package pressure booster system with either two or three vertical high-pressure pumps. Continuously variable speed adjustment of all pumps for fully electronic control of the required supply pressure at the consumer installations. Design and function to DIN EN 806-2 and DIN 1988. Automated with BoosterControl.

Horizontal high-pressure end-suction centrifugal pump offering maximum resistance to wear and ease of maintenance. The conventional single-wall design transfers stress loads from the wear parts to the casing covers in high-pressure applications. Pump components made of highly wear-resistant white cast iron.

Single-stage or multistage single-entry centrifugal pump in ring-section design for vertical or horizontal installation. Optionally available with lift check valve or connection branch. For well diameters of 8 inches and above.

Single-stage or multistage single-entry centrifugal pump in ring-section design for vertical or horizontal installation. Mixed flow hydraulic systems with impellers that can be turned down. Optionally available with lift check valve or connection branch. For well diameters of 10 inches and above.

Single-stage or multistage single-entry centrifugal pump in ring-section design for vertical or horizontal installation. Mixed flow hydraulic systems with trimmable impellers. Optionally available with lift check valve or connection branch. For well diameters of 12 inches and above.

Single-stage or multistage single-entry centrifugal pump in ring-section design for vertical or horizontal installation. Mixed flow hydraulic systems with impellers that can be turned down. Optionally available with lift check valve or connection branch. For well diameters of 14 inches and above.

Multistage centrifugal pump in ring-section design made of stainless steel for well diameters of 100 mm (4 inches) and above, available with single-phase AC motor or three-phase motor with motor lead.

All-stainless steel single-stage or multistage centrifugal pump in ring-section design, suitable for vertical or horizontal installation, for well diameters of 150 mm (6 inches) and above.

The KSB switchgear is suitable for level control and protection of submersible borehole pumps, submersible motor pumps and dry-installed pumps with single-phase AC motors 1~ 230 V or three-phase motors 3~ 230 / 400 V / 50 Hz. The motor is started DOL. Enclosure: IP56, dimensions: 205 × 255 × 170 mm (H × W × D).

Service-friendly volute casing pump with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system. All wetted components are made of 1.4404/1.4409 (AISI 316L/CF3M) stainless steel. Designed with very little dead volume; open impeller, electropolished surface, excellent efficiency. Hygienic design for the highest requirements on cleanability (CIP/SIP-compatible), certified by the TNO Nutrition and Food Research Institute to EHEDG standards. All materials comply with FDA standards and EN 1935/2004. ATEX-compliant version available.

Service-friendly volute casing pump with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system. All wetted components are made of 1.4404/1.4409 (AISI 316L/CF3M) stainless steel. Designed with very little dead volume; open impeller, electropolished surface, excellent efficiency. Hygienic design for the highest requirements on cleanability (CIP/SIP-compatible), certified by the TNO Nutrition and Food Research Institute to EHEDG standards. All materials comply with FDA standards and EN 1935/2004. Trolley available among other accessories. ATEX-compliant version available.

Service-friendly non-self-priming single-stage hygienic close-coupled pump in back pull-out design with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system. The pump features a semi-open impeller and electropolished surfaces. It is very easy to clean by CIP/SIP thanks to its almost complete lack of dead volume and narrow clearances. Its wetted components are made of 1.4404/1.4409 (AISI 316L/CF3M) stainless steel. Vitachrom is EHEDG-certified. All materials comply with FDA standards and EN 1935/2004. ATEX-compliant version available.

Sturdy rotary lobe pump in hygienic design, bi-directional operation possible, horizontal or vertical orientation of connections. Hygienic design, excellent CIP/SIP compatibility due to its almost complete lack of dead volume or narrow clearances. All wetted components made of 1.4404/1.4409 (AISI 316L/CF3M) stainless steel; various rotor types, shaft seals and process connections available. Installed as a pump set with gear unit and standardised motor. Vitalobe is EHEDG-certified. The pump elastomers comply with the FDA standards and EN 1935/2004. Accessories include a trolley, a heatable casing or casing cover and a pressure relief arrangement. ATEX-compliant version available.

Service-friendly close-coupled side-channel pump (self-priming) with magnetless KSB SuPremE motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 and PumpDrive variable speed system. All wetted components are made of 1.4404/1.4409 (AISI 316L/CF3M) stainless steel. Hygienic design for the highest cleanability requirements (CIP/SIP-compatible). All materials comply with FDA standards and EN 1935/2004. Trolley available among other accessories. ATEX-compliant version available.

Multistage centrifugal pump in close-coupled design for vertical or horizontal installation. All wetted components are made of 1.4401/1.4408 (AISI 316/CF8M) stainless steel. Versatile, robust and especially energy-efficient. CIP/SIP-compatible. All materials comply with FDA standards and EN 1935/2004. Trolley also available among other accessories.

Patented design with state-of-the-art hydraulic system and highly wear-resistant materials for high-pressure applications. The pump casing is designed to withstand maximum stresses, e.g. during pressure surges.

Vertically suspended, single-casing, lineshaft, diffuser-type pump with integral thrust bearings and discharge through column pipe in accordance with API 610 / ISO 13709 (VS1). Available in single-stage and multistage configurations and with either single or double suction first-stage impeller.

Multistage horizontal high-pressure centrifugal pumps in ring-section design with radially split suction, discharge and stage casings. The individual casing parts are sealed by O-rings and clamped together by external tie bolts. The pump feet are cast integrally with the suction and discharge casings, and are arranged beneath the pump.

Vertical, multistage, barrel pull-out ring-section pump for underground installation on a base frame in the pump sump, radial impellers, single-entry suction impellers, flanges to DIN or ANSI.

Vertical can-type ring-section pump on base frame, multistage, first-stage impeller designed as a double-entry suction impeller, radial impellers. Flanges to DIN or ANSI.

Vertically suspended, double-casing, lineshaft, diffuser-type pump with integral thrust bearings and discharge through column pipe in accordance with API 610 / ISO 13709 (VS6). Available in single-stage or multistage configurations and with single suction first-stage impeller.

Multistage horizontal high-pressure centrifugal pumps in ring-section design with radially split suction, discharge and stage casings. The individual casing parts are sealed by O-rings and clamped together by external tie bolts. The pump feet are cast integrally with the suction and discharge casings, and are arranged beneath the pump.

Whether as a modern employer, a key driver of the transition to green energies or a home for innovation: Read how KSB and its diverse, international team of more than 15,000 employees are tackling today’s major challenges and social megatrends – in a diverse, innovative and efficient environment. Have a look!

Submersible pumps can be used for a variety of fluids. Depending on their design, submersible motor pumps can be used for clear water and much more. Grey water pumps, for example, are able to pump sludge and grey water containing solids with a particle size of up to 35 millimetres.

In combination with explosion-proof motors and wear- and corrosion-resistant materials they are employed in municipal and industrial waste water disposal. The motors all meet the requirements of enclosure IP68. The compact design prevents major wear, keeps maintenance to a minimum and saves you cash, whether it is a submersible pump for a buried rainwater storage tank or for an industrial application.

Submersible pump in multi-stage construction with radial or mixed flow impellers coupled with oil or water filled, single/three phase submersible motors. Pumps with SS jacket are also available up to 100 mm diameter. Suitable for horticulture, irrigation, housing, building services and farm houses, ornamental fountains etc.

KSBsol - A complete Stainless Steel Solar pump series viz. CORAChrom in 100 mm (4”) & 150 mm (6”) is built in India with German technology. KSBsol offers a range of borewell submersible pump and AC motor sets are specially designed and matched to your requirements of solar pumping application. KSBsol CORAChrom 100mm (4”), 150mm (6”) series are compliant to MNRE (Ministry of New & Renewable Energy) specifications.

Single Stage, monobloc, 3 phase openwell Submersible pumps. Suitable for agriculture, drinking water supply, fountains, buildings, farm houses etc. Available in both Aluminium and Copper rotor.

Single Stage, monobloc, 3 phase openwell Submersible pumps. Suitable for agriculture, drinking water supply, fountains, buildings, farm houses etc. Available in both Aluminium and Copper rotor.

Single stage, monobloc, open-well submersible pumps with C.I. motor body, high grade Stainless Steel shaft. Suitable for agriculture, drinking water supply, fountains, buildings, farm houses etc. Available in three phase models.

Multistage monobloc openwell submersible pumpset. 1Ø in S.S. construction & 3Ø in C.I. construction. Suitable for agriculture, farm houses, drinking water supply etc.

Horizontal self priming volute casing pumps, single stage with semi open impeller, in back pull out design. Long coupled on baseplate, suction lift up to 7 metres. Suitable pump for pumping muddy water, sewage, polluted liquids including solids etc. and applications where priming & foot valve is to be avoided.

Horizontal self priming volute casing pumps, single stage with semi open impeller, in back pull out design. Monobloc, mono shaft design, hydraulics are assembled on extended motor shaft, suction lift up to 7 metres.

Mini monobloc pumpsets in compact design. Available in 8 models - PERIBLOC I & II, Delite I & Delite II, Deluxe I & Deluxe II, PERIBLOC GX I & GX II are available in CI version. Suitable for pumping of water to overhead tanks, in bungalows, fountains, car washing etc.

Self priming mini monobloc pump fitted with SKF bearings in compact design. Can withstand wide voltage range. Suction lift up to 8m is possible. Suitable for pumping of water to overhead tanks, in bungalows, fountains, farmhouses etc.

Centrifugal pumps in monobloc construction. Self priming up to 6 m. Robust and sturdy design. Capacitor start and run type design eliminates centrifugal switch. Suitable for pumping of water to overhead tanks, in bungalows, fountains, car washing, lawn sprinklers etc.

Single stage, monobloc pumps in compact and light weight design. These pumps are available in single phase power supply. Dynamically balanced rotating parts ensures minimal vibrations. Suitable for agriculture, industries, gardens, fountains etc.

Centrifugal pumps in monobloc construction. Self priming up to 8 m. Capacitor start and run induction run single phase motor for high torque. Suitable for car washing, booster application, water circulation in solar heating systems etc.

Self priming centrifugal pumps designed for application in open and shallow wells, sumps. These pumps find wide applications in residential bunglows, hotels, small farms, lawns etc.

Centrifugal pumps in monobloc construction. Self priming up to 8 m. Robust and sturdy design. Capacitor start and run type design eliminates centrifugal switch. Pressure die cast rotor with TEFC enclosure for motors. Suitable for pumping of water to overhead tanks, in bungalows, fountains, car washing, lawn sprinklers etc.

Single stage monobloc pumps in compact design. Stainless Steel casing with Brass impellers and Stainless Steel shaft, Aluminium die cast motor body. Pumps can be used for booster applications, residential flats, water circulation in solar systems etc.

Open-well submersible pumpsets in monobloc construction Wide voltage range. SS jacketed motor with NORYL impellers. Suitable for pumping of water to overhead tanks, flood irrigation, de-watering of storm water etc.

Horizontal, centrifugal, radially split, multistage pumps fitted with pressure tank, pressure sensor and gauge. Suitable for water pressure boosting applications in bungalows, flats, bathrooms etc.

Single stage, submersible, centrifugal pumps of closed coupled (monobloc) construction. Amarex IN pumps are suitable for handling waste water transport, storm water transport, waste water treatment etc.

Vertical, monobloc pumpset, free flow impeller of two sizes, 1Ø and 3Ø motors with IP 68 protection, 1Ø motor with built-in thermal overload protection and float switch, bi-directional mechanical seal. Suitable for pumping surface water, rain water, waste water containing solids, drainage of sumps liable to flood, agricultural pits and canals.

Single stage, submersible centrifugal pumps of closed coupled (monobloc) construction. De-watering pumps for storm water and rain water pumping applications.

Single stage, monobloc, open-well submersible pumps. Suitable for agriculture, drinking water supply, fountains, buildings, farm houses etc. Available in single phase models.

Horizontal self priming volute casing pumps, single stage with semi open impeller, in back pull out design. Long coupled on baseplate, suction lift up to 7 metres. Suitable pump for pumping muddy water, sewage, polluted liquids including solids etc. and applications where priming & foot valve is to be avoided.

Horizontal self priming volute casing pumps, single stage with semi open impeller, in back pull out design. Monobloc, mono shaft design, hydraulics are assembled on extended motor shaft, suction lift up to 7 metres.

KSB, a leading manufacturer of Pumps, Valves and Systemsoffers it’s clients the latest pumping technology through avariety of pumpsets designed for the future.KSB open well monobloc pumpsets “MONOSUB R can beinstalled in the open wells and sumps. Theseread more... Brochure

ProductsPumps, valves and related services for industrial applications, building services, water and waste water management as well as energy and mining processes

KSB SE & Co. KGaA is a German multinational manufacturer of pumps, valves with headquarters in Frankenthal (Pfalz), Germany. The KSB Group has manufacturing plants, sales and marketing organizations, and service operations on every continent.

KSB’s first subsidiary outside Germany was founded in Great Britain in 1896, managed by Jacob Klein, the younger brother of Johannes Klein. Between 1924 and 1934 KSB acquired further plants in Germany and set up European subsidiaries. KSB Compañía Sudamericana de Bombas in Argentina was KSB"s first subsidiary in the Americas and commenced operations in 1941.

The company"s first Asian-Pacific subsidiary was set up in Pakistan in 1953. The companies of Pumpen AG (Homburg), Kleinschanzlin-Bestenbostel (Bremen) and AMAG-Hilpert-Pegnitzhütte AG (Nuremberg/Pegnitz) were amalgamated into Klein, Schanzlin & Becker AG.

In 1960 the KSB-Stiftung (KSB Foundation) was set up with stated aims of encouraging research in the natural sciences and supporting education in technology, natural science and economics. Otto Klein-Kühborth transferred a qualified majority holding of the company"s share capital to the KSB-Stiftung (KSB Foundation) in 1964.

KSB took over French pump manufacturer, Paris-based Pompes Guinard S.A., in 1986 and acquired the world’s second-largest butterfly valve manufacturer, Paris-based Amri S.A., Paris, in 1989. In 1988 KSB entered the slurry pumps market with the acquisition of GIW Industries, Inc., Grovetown, USA. In 1990 KSB consolidated the eastern German Hallesche Pumpenwerke GmbH as part of the overall AG. The joint venture KSB Shanghai Pumps Co. Ltd. was founded in 1994. MIL Controls Ltd., Mala (Kerala), India, producer of ANSI valves and control valves, was acquired years later.

In 2003 KSB took over Dutch pump supplier DP industries B.V., producer of pumps made of deep-drawn stainless sheet steel for building services and industrial applications. In the same year, KSB acquired a majority interest in Bombas ITUR, S.A. of Zarautz, Spain, with sales in industry, building services and marine applications . KSB establishes Dalian KSB AMRI Valves Co. Ltd. in the Chinese foreign trade zone in 2004, specialising in the manufacture and assembly of butterfly valves for industrial and building services applications. One year later, KSB acquired the valve business of IVC S/A Indústria de Válvulas e Controles, a Brazilian company whose products are primarily employed in the oil and gas industry, in power stations, paper mills and other industrial applications.

In 2006 KSB received an order for valves to the value of roughly €17 million, its largest valves contract. In December 2006, the 60,000th Eta pump leaves the factory.

In 2007 the Supervisory Board approves a large investment to construct of new halls and modern production and test facilities at the Frankenthal and Halle sites. KSB’s Microchem is the first centrifugal pump for handling the very small quantities in micro-process engineering applications.

In 2008 KSB establishes joint ventures with two Asian companies. The German-Japanese cooperation Nikkiso-KSB GmbH develops and sells canned motor pumps for the European and Middle Eastern markets. The German-Chinese joint venture company Shanghai Electric-KSB Nuclear Pumps and Valves Co. manufactures safety-relevant pumps and valves for the Chinese nuclear power station market.

The German-Chinese joint venture SEC-KSB Nuclear Pumps and Valves Co. Ltd. starts constructing a factory construction in Lingang, near Shanghai, in 2009. 125 employees produce pumps, and later valves, for Chinese nuclear power stations.

In 2010 KSB acquired an 80 percent interest in ITACO s.r.l., an Italian drive specialist, producer of a new kind of energy-efficient motor. The South Korean company Seil Seres Co. Ltd. makes valves for marine applications.

In 2016 KSB AMRI, Inc. was acquired by Bray International, Inc. The acquisition included AMRI"s production site and employees as well as the ACRIS and AMRESIST brands.

Within the KSB Group, centrifugal pumps account for around two thirds of sales revenue. These pumps, as well as valves, are sold to engineering contractors, OEMs and end users or, in some cases, distributed via dealers. The same applies to control and monitoring systems, and to package units with pumps and valves.

The best developed sales market for these products is Europe, where KSB operates its main manufacturing facilities in Germany and France. KSB AG’s main plant in Frankenthal is its largest in Europe, ahead of the production sites in Pegnitz (Bavaria) and Halle (Saxony-Anhalt) in Germany, and La Roche-Chalais in France.

The second-largest market for KSB products is the Region Asia, followed by the Region Americas/Oceania and the Region Middle East/Africa. Outside Europe, KSB’s biggest manufacturing plants are in Brazil, China, India and the USA.

KSB manufactures products and components in a total of 16 countries; they are sold through the Group’s own companies or agencies in more than 100 countries. With their products, the Group companies serve customers in industry including the chemical and petrochemical industries, customers in the energy and construction/building services sectors, transport equipment manufacturers and operators (e.g. ships, rail vehicles), water and waste water utilities, and mining companies. Once again in 2015, the top-selling markets for their products were the industrial and energy supply sectors.

KSB Amarex N submersible cutter pumps are designed for transferring all types of wastewater, especially untreated sewage containing long fibres and solid substances, drainage systems, and sludge disposal. The beauty of these submersible sewage pumps is that they are also suitable for pumping fluids containing gas or air, raw, activated or digested sludge, industrial flood drainage and more. Able to pump wastewater over a long distance or high heads, these electric submersible pumps by KSB can be used in both temporary and permanent pumping installations.

Manufactured from tough cast-iron, stainless-steel shaft and supplied with double mechanical seals to ensure long life and reliability, Amarex N submersible sewage pumps are reliable and robust pumping solutions. These single stage submersible pumps also benefit from a cutter impeller which helps effectively break down solids and bearings sealed on both sides, lubricated for life, to minimise pump maintenance. To further enhance the pump design, the Amarex N submersible sewage cutter pumps have a completely watertight design and require zero maintenance which makes them ideal for continuous duty applications.

KSB Amarex N submersible sewage pump ranges are highly resistant to wear or damage and are carefully designed to provide the highest pump quality and efficiency. This, combined with their lightweight design, makes them a preferable pumping solution for many domestic, industrial and agricultural applications.

As a longstanding KSB Pumps supplier, Whisper Pumps are highly experienced in all models. If you are unsure on the submersible wastewater pump model you require, please contact our technical sales team today on 01777 871100 for free, expert advice.

KSB was founded in Frankenthal, Germany back in 1871. As technology and engineering concepts have evolved, so has this leading manufacturer of pumps, valves and related systems. Their equipment is used in a wide spectrum of applications, from water treatment and transportation to power plants, building infrastructure, and industry.

With 170 service centers and more than 3,000 employees worldwide, KSB sets the standard for providing its customers with comprehensive inspection and maintenance services. All the while, KSB continues to innovate and evolve thanks to its industry-leading research and development work. KSB is always pushing the envelope and is committed to driving the pump industry forward.

KSB’s core philosophy is about creating “Growth that’s Sustainable.” As an independent company, KSB prides itself on a corporate culture built on these core values:

The KSB team is committed to building a reputation among customers as the best in the industry. This means taking a leading position in key markets and sustaining growth without compromising the company’s principles.

When it comes to manufacturing and service, KSB believes nothing is more important than quality. This can be seen in everything KSB does, whether it’s designing innovative and long-lasting products or providing expert customer consultation and maintenance support.

KSB develops quality pumps, valves, automation systems, and water circulators to help your operation run efficiently. Their equipment is designed specifically to handle different applications and each product is rated to meet current standards in applications including

Each piece of high-grade KSB equipment is rated based on which fluids and process materials it can handle. Depending on your application, there is a KSP pump, custom components and system configuration that’s ideal for your operation. They also offer installation, maintenance and repair services to ensure that you get the most out of your system for a long time to come.

In addition to the pumps described above, KSB is a leading manufacturer of valves, automated systems and other exceptional industrial products including:

To learn more about KSB and their product offerings, and for help in selecting and configuring the right KSB equipment for your specific operation and applications, contact DXP Cortech today. We are a proud supplier of KSB pumps and components and we will be happy to answer any questions you have.

The Amarex N is a proven performer, used since 2003 in global markets. With more than 180,000 units sold to date worldwide, KSB is able to offer the reliable, easy-to-maintain Amarex N to U.S. municipalities and industries at a competitive price level.

Grinder pumps with 2 inch discharge and featuring KSB’s S-type impeller macerate and grind solids that come into contact with the pump, easily carrying them through the pump for discharge.

Vortex pumps employ KSB’s F-type impeller with discharge sizes ranging from 2-inch to 4-inch. The 3-inch and 4-inch discharge sizes prevent clogging and are particularly suited to municipal applications. The smaller models are an excellent fit for residential applications.

KSB creates pumps with easy maintenance in mind. Bearings are lubricated for life and the motor casing and discharge volute are cast as a single piece, which means fewer parts requiring routine maintenance.

The Amarex N features an air-filled motor and double mechanical seals in an environmentally friendly oil chamber. All Amarex N models come with KSB’s stainless steel Type 420 shaft for long service life and to easily handle fluids with abrasive or corrosive characteristics. All pumps are fitted with motor winding temperature protection and moisture sensor to enhance motor service life. KSB can also customize pumps for more extreme conditions by enhancing features such as cable quality, coatings and mechanical seals.

Featuring the best hydraulic efficiencies in the market for submersible pumps under 5HP, the Amarex N line is the best response for a reliable operation with long service life for most of wastewater applications.

KSB’s Sewatec pump brings many industry leading advantages to wastewater plants.The most unique feature of this wastewater pump is its sealing technology. The pump is designed to operate in a dry environment – no need for a source of clean water to lubricate the pump seals.With a variety of impeller options and mounting methods, the Sewatec wastewater pump is perfect for moving raw wastewater as well as thicker mediums (i.e. bio-solids/sludge).

Waste water pumps from KSB feature efficient drives, non-clogging impellers and wear-resistant materials. The materials developed in KSB’s materials laboratory are capable of withstanding corrosive and abrasive waste water with a high solids content. Durable components capable of providing decades of reliable service under the harshest conditions are essential for keeping costs down for waste water transport in the long term.

With a wide range of different waste water pump designs, KSB is capable of supplying the right product for every system requirement. The Amarex KRT submersible pump and the Sewatec dry-installed waste water pump, for instance, are designed with non-clogging impellers and large free passages to ensure that even highly solids-laden waste water is handled efficiently. The

8613371530291

8613371530291