ksb mud pump made in china

The KSB Group is one of the leading suppliers of quality pumps and valves and related services with an annual sales revenue of almost 2400 million euros, the company has a presence on all continents with its own sales and marketing organisations, manufacturing facilities and service operations. KSB employs more than 15,000 people.

The success of the company is founded on innovative technology that is the fruit of its own global research and development activities. As well as customers and employees, KSB also serves society at large. Examples of our CSR activities include environmental and educational projects. We are committed to the United Nations’ Global Compact. Its principles reinforce social, environmental and economic fairness worldwide.

The KSB Shanghai Pump Co., Ltd is a joint venture between KSB and Shanghai Electric (Group) Corporation. The Total Registered Capital is 27 million US Dollar, and the Total Investment 29.8 million US Dollar.

KSB Shanghai manufactures and sells reliable and efficient pumps and valves for water, waste water, industry, building, energy and mining applications.

KSB offers innovative service solutions on site and in the workshop, such as installations commissioning, maintenance and repair, maintenance inspection management, Total Pump Management, System Efficiency Service, Technical consultancy, Retrofit.

100% fully interchangeable with KSB omega type pump full line. Split casing pump. We have very competitive price in China suppliers. The quality is good and the price is good.

We are Ningguo Sarl Imp.&Exp. Company of China(3 hours to Shanghai). We are manufacturing various types of centrifugal pumps (DIN24255, ANSI, ISO) as per our customer"s requirements and also reverse engineering various types of centrifugal pumps from much known pump companies.

The importance of pump manufacturers is rising across the globe. The pump manufacturing industry is one of the largest and fastest-growing industries globally. JEE Pumps was established in 1993. It has a tremendous demand for pumps of all kinds, including centrifugal pumps, reciprocating pumps, rotary vane pumps, screw pumps, magnetic drive pumps, and many others. In addition, manufacturing energy-efficient pumps tailored to engineering requirements are becoming the industry norm.

Several factors have contributed to this rapid growth in the industry. One of these is the increasing global population and its rising living standards. As people’s living standards improve, they tend to consume more resources like water or energy. This has led to a significant increase in demand for the products manufactured by companies in the pump manufacturing industry.

Another important factor driving this growth is rapid technological advancements and innovations that have made various types of pumps much more efficient and cost-effective. Overall, the pump manufacturing industry is expected to continue thriving in the years as some of the best pump manufacturers in the world compete making the market highly lucrative.

Grundfos, a European firm, is one of the largest pump manufacturers with a global reach spanning more than 130 countries. The company offers a wide range of pump solutions for water and wastewater applications and industrial, agricultural, and building services. Grundfos is headquartered in Denmark and has more than 50,000 employees across more than 100 countries. Grundfos has a strong commitment to sustainable development and provides energy-efficient solutions that reduce water consumption and greenhouse gas emissions.

Xylem is another leading player in the global pump market, operating in more than 150 countries. Xylem’s product portfolio includes pumps for water and wastewater applications and HVAC, industrial, and other commercial uses. In addition, the company has built a strong reputation for working on providing return water to major industrial complexes, residential buildings, and commercial estates. With over 16,500 employees serving customers and based out of New York, Xylem does business in three key segments: Water Infrastructure, Environment & Industrial, and Semiconductor.

KSB is a German pump manufacturer with a solid global presence. The company operates in more than 100 countries. It offers a wide range of pumps for water and wastewater applications and oil & gas, power generation, and other industries. KSB has been manufacturing pumps since 1898. Today, KSB Group comprises over 15 000 employees worldwide working to develop innovative solutions for its customers. KSB has a long history of innovation and is constantly developing new products and services to meet the needs of its customers.

JEE Pumps, an India-based company is one of the best pump manufacturers in the world. It manufactures and exports a wide range of pumps in agriculture, domestic, and industrial applications and caters to over 25 countries. Through its state-of-the-art manufacturing units, JEE Pumps manufactures a wide range of pumps such as submersible pumps, centrifugal pumps, jet pumps, etc. The company also offers customized solutions to meet the specific requirements of its clients. JEE Pumps has a team of experienced engineers who design the products as per the latest technology trends. The products offered by JEE Pumps are known for their high efficiency, low noise operation, and long service life.

Flowserve is one of the world’s largest suppliers of pumps and related flow control products and services. The company operates in more than 50 countries. It offers a comprehensive range of pumps for water and wastewater applications and the oil & gas, chemical, and other industries. Apart from pumps, it is also one of the world’s largest suppliers of valves, seals, automation, and services to power, oil, gas, chemical, and other industries.

Weir Group is a UK-based engineering company with a solid global presence. The company’s product portfolio includes a wide range of pumps for water and wastewater applications and mining, oil & gas, and other industries. The company operates in over 70 countries employing approximately 14,000 people focused on mining, oil and gas, and power markets.

Ebara Corporation is a Japanese company that manufactures and markets pumps, compressors, water treatment equipment, and other fluid handling products. The company is headquartered in Tokyo, Japan, and has manufacturing facilities in Japan, China, Italy, Brazil, and the United States. The company was founded in 1912 as Ebara Shokai by Saburosuke Ebara, and its first product was a hand-operated diaphragm pump. Over the years, it has captured a good market share in Southeast Asia with its innovative and reliable products.

Pedrollo SpA is an Italian-based company that manufactures pumps and other water-related products. The company was founded in the early 1900s, and it has since grown to become one of the leading pump manufacturers in the world. Pedrollo produces a wide range of pumps for various applications, including domestic, industrial, agricultural, and municipal. Some of the most popular Pedrollo pumps include submersible pumps, jet pumps, centrifugal pumps, and diaphragm pumps.

ITT Goulds Pumps is one of the oldest and most experienced pump manufacturers globally. The company started in Seneca Falls, New York, in 1848 and today has over 3,000 employees worldwide. Goulds Pumps offers a wide range of pumps for various applications, including industrial, municipal, residential, and agricultural. The company’s products are used in many industries, including mining, oil and gas, power generation, water and wastewater treatment, food and beverage processing, and more.

All the best pump manufacturers in the world rely heavily on providing quality and energy-efficient pump solutions. When choosing the pump manufacturer, you need to consider the location. Importing heavy-duty pumps can attract a lot of logistics costs that you can avoid by choosing a regional pump provider. Cost is another factor you need to consider. US and European suppliers charge a premium amount for products that you can get at a discounted rate from India or other Asian nations. Choosing the proper pump manufacturer can ensure your system’s reliable and cost-effective operations.

Single stage, submersible centrifugal pumps of closed coupled(monobloc) construction.For pumping all types of sewage, and effluent in water treatmentand industry, especially untreated sewage, with long fibers andsolid substances, liquids containing air and gas as well as raw,activated and digested sludge.

Responding to customer demand for larger slurry pumps, KSB is designing and manufacturing pumps that are bigger and more energy-efficient — all in the name of sustainability.

We’ve served the mining industry in South Africa for more than 120 years, and KSB Pumps (SA) has served customer needs for local sales, operations, and service in sub-Saharan Africa for more than six decades.

With operations in more than 100 countries, KSB Mining’s global network encompasses sales and service centres for pump packages and technical support for hard rock and industrial mineral applications. We’ve served the mining industry in Australia for over 80 years. Meet our team at KSB Down Under.

Pumps experience a wide variety of pressures and loads during operation, and it is important for operators to know how and when they occur. "Vane pass" is no exception. This term refers to the pressure pulsations generated within the pump as the impeller vanes pass the cutwater.

Frequent shutdowns due to underperforming pumps are frustrating and costly, yet many operators in the Oil Sands struggle with such downtime on a regular basis.

With so much moisture present during operation, slurry pumps become notably vulnerable to damage in cold weather. Frozen water in your pump system can lead to crippling issues ranging from improper functioning and premature parts failure all the way to more costly damage caused by freeze-and-thaw issues or thermal shock.

An optimized pump and slurry system can make or break a business in the Canadian Oil Sands. Costing up to $100,000 per hour due to lost production, it’s no secret that sites plagued by frequent shutdowns, pump malfunctions, or constant parts replacements struggle to control costs.

GIW has a long and rich history in the world of dredge pumps. Although GIW"s pump quality and engineering capabilities are globally renowned, European customers mostly relied on GIW for our ultra-reliable parts and small to medium-sized pumps. However, two massive projects have shifted this vision, propelling GIW from a parts provider to a complete dredge pump supplier in the European and global dredge market.

GIW Industries, the leader in the design, manufacture, and application of heavy-duty centrifugal slurry pumps, recently named Jonathan Samuel as sales and marketing vice-president. With more than 22 years of hands-on expertise in the pumping industry, he brings a wealth of experience and knowledge to the position.

New updates to the GIW® Minerals" High-Volume Froth (HVF) Pump have been announced that make this innovative pump even more beneficial to mining, wastewater, paper recycling, oil sands, and other markets.

GIW Industries, leader in the design, manufacture, and application of heavy-duty, centrifugal slurry pumps, is proud to announce its 125th year in operation.

GIW Industries, a leader in the design, manufacture, and application of heavy-duty, centrifugal slurry pumps, is proud to announce its foundry grand opening.

GIW Industries, a leading company in the design, manufacture, and application of heavy-duty, centrifugal slurry pumps, is proud to announce success at a South American copper mine.

GIW Industries Inc, the leader in the design, manufacture and application of heavy-duty centrifugal slurry pumps, has announced the successful design and installation of a unique underwater pump system for a major Chinese dredging contractor.

GIW Industries Inc, the leader in the design, manufacture and application of heavy-duty, centrifugal slurry pumps, is honoured to be named the 2014 Company of the Year in Manufacturing by the Development Authority of Columbia County, Georgia.

GIW Industries is the leader in the design and manufacture of heavy-duty centrifugal slurry equipment, pumps and parts. The company is expanding its REGEN Service Centre in Fort McMurray, Alberta, Canada, to meet the growing needs of the nearby oil sands industry.

GIW Industries, a leader in slurry, froth and process pumps for the mining industry, has released specifications for the Hydroclone APEX Replacement Kits.

GIW, the leader in the design and manufacture of heavy duty centrifugal slurry pumps, is proud to announce that long-time GIW mechanical engineer and industry expert, Reab Berry, was awarded the 2013 SME Hero of the Industry award at the 28th Annual Phosphate Conference.

GIW Industries, the leader in the design, manufacture and application of heavy duty, centrifugal slurry pumps, announced the application of its hard-wearing double-wall pumps in Lianyungang, China.

GIW Industries, the leader in the design, manufacture, and application of heavy duty, centrifugal slurry pumps, is excited to announce a new record in employment longevity: as of January, Reab Berry, Mechanical Engineer and renowned slurry pump expert, has been with GIW for 50 years.

GIW Industries, the leader in the design, manufacture, and application of heavy-duty, centrifugal slurry pumps, announced two major contracts with Mexico"s Industrias Peñoles.

GIW Industries, the leader in the design, manufacture and application of heavy duty, centrifugal slurry pumps, announced that global talc producer Mondo Minerals has installed GIWs high volume froth (HVF) pump at its talc processing plant in Outokumpu, Finland

DUBAI, UAE / ACCESSWIRE / September 15, 2020 / According to a new market study by Future Market Insights (FMI), the global dewatering pumps market is projected to behold remarkable growth in terms of value between 2018 and 2028.

The growth of the market is majorly attributed to persistent demand in commercial and industrial applications coupled with an increasing number of construction and mining activities. Furthermore, rapid urbanization and industrialization in emerging economies have created a significant demand for construction, which in turn, is expected to burgeon the demand for dewatering pumps.

Furthermore, a rising emphasis on improving drinking water facilities in developing economies such as Asia Pacific and MEA will continue to drive the sales of dewatering pumps in these regions. Along similar lines, exploration of new water sources and the growing number of desalination projects are creating demand for pumps with enhanced capacity and efficiency.

Dewatering Pumps Market - Key TakeawaysThe global dewatering pumps market is forecasted to expand at a healthy CAGR of 5.2% through 2028 and will surpass a valuation of US$ 9.5 Bn.

An increase in water supply in rural regions and the introduction of government-backed sanitation projects in Asia Pacific is expected to transmute into the sales of centrifugal pumps, especially in domestic and agricultural applications.

Dewatering Pumps Market - Key TrendsThe proliferating production volume of oil and gas, especially in the US, is offering lucrative revenue opportunities to the market players.

High demand for automated, energy-efficient, and environmental-friendly pumps in the energy & power sector has emerged as a lucrative trend driving the growth of the market.

Dewatering Pumps Market - Regional AnalysisAsia Pacific, led by China and India, is forecasted to metamorphose into the largest regional market owing to the presence of major manufacturers and increased spending on energy and water infrastructure development.

Key players operating in the dewatering pumps market include Sulzer, Grundfos, The Weir Group, Xylem, Ebara, KSB, Tsurumi Pump, Wacker Neuson, Honda Power Equipment, Zoeller Pumps, Nanfang Pump Industry, Mersino Dewatering, Veer Pump, and Zhejiang EO Pump, among others. Market players are focusing on expanding their geographical footprint and product portfolio to gain a competitive edge. Moreover, players are seeking contracts and long-term tie-ups with Engineering Procurement and Construction (EPC) companies to secure long-term growth prospects.

Future Market Insights, in its new offering, provides an unbiased analysis of the global dewatering pumps market, presenting historical demand data and forecast statistics for the period from 2018-2028. The study divulges compelling insights on the dewatering pumps market, allowing readers to glean qualitative and quantitative information which will enable them to make informed market decisions in the upcoming forecast period.

Mud Pumps Market The mud pumps market is anticipated to surpass an impressive revenue threshold by the end of the forecast period ranging from 2020 to 2030, concludes FMI"s recently published research report on the market.

Chopper Pumps Market: FMI"s compelling study on the chopper pumps market sheds light on the prominent dynamics influencing the growth trajectory for the upcoming forecast period 2020-2030 through detailed segmental and regional analyses.

Submersible Pump Market: The submersible pump market report offers a 360-degree analysis, bringing to the fore insights that can help stakeholders identify key challenges and opportunities across the upcoming decade"s growth trajectory.

As one of the world"s leading pump manufacturers, Sulzer provides a wide range of products for engineered, configured, and standard pumping solutions as well as essential auxiliary equipment. We are renowned for our state-of-the-art products, performance reliability and efficient solutions.

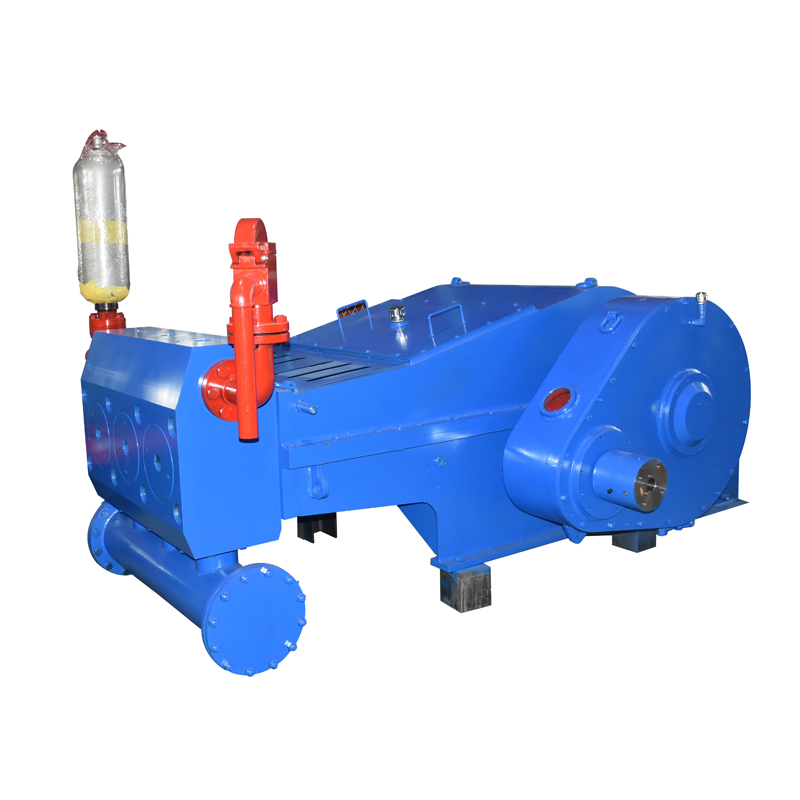

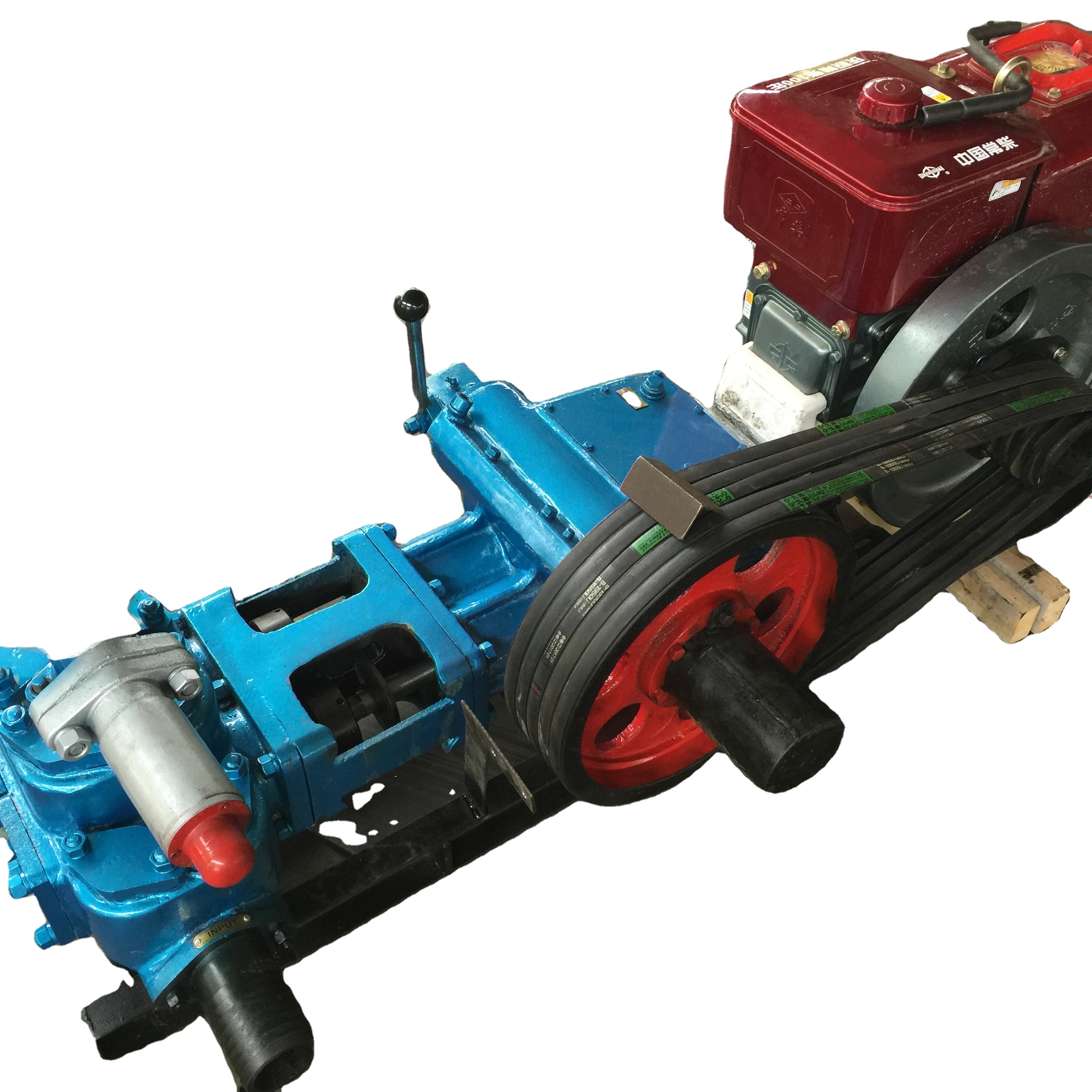

The mud pumps market size is expected to grow at a significant rate during the forecast period. A mud pump is a large, high-pressure (up to 7500 psi), single-acting triplex reciprocating pump used to circulate mud in a well at a specific flow rate (between 100 and 1300 gallons per minute). Instead of a triplex reciprocating pump, a double-acting two-cylinder reciprocating pump is occasionally utilized as a mud pump. Typically, a rig operator keeps two or three mud pumps on hand, one of which is active and the others on standby in case of an emergency. Mud is gathered up with the use of mud pumps, which use suction to circulate the mud from the wellbore to the surface during the drilling process.

Increased demand for directional and horizontal drilling, higher pressure handling capabilities, and some new oil discoveries are the main drivers of this market"s growth. Mud pumps are specialized pumps that are used to transport and circulate drilling fluids and other related fluids in a variety of industries, including mining and onshore and offshore oil and gas. The global energy demand is boosting the market for mud pumps. However, high drilling costs, environmental concerns, and shifting government energy and power laws may stymie industry growth.

Innovation in technology is the key for further growth for example, MTeq uses Energy Recovery’s Pressure exchanger technology in the drilling industry, as the ultimate engineered solution to increase productivity and reduce operating costs in pumping process by rerouting rough fluids away from high-pressure pumps, which helps reduce the cost of maintenance for operators.

The major key player in global mud pumps market are Flowserve (U.S.), Grundfos (Denmark), Halliburton (U.S.), Sulzer (Switzerland), KSB Group (Germany), Ebara Corporation (Japan), Weir Group (U.K), and SRS Crisafulli, Inc (U.S.). Tsurumi Pump (Japan), Shijiazhuang Industrial Pump Factory Co. Ltd (China), Excellence Pump Industry Co.Ltd (China), Kirloskar Ebara Pumps Limited (India), Xylem Inc (U.S.), and Goulds Pumps (U.S.) are among others.

In the drilling business, MTeq uses Energy Recovery"s Pressure exchanger technology as the ultimate engineering solution to boost productivity and lower operating costs in the pumping process by rerouting abrasive fluids away from high-pressure pumps, which helps operators save money on maintenance. The latest trend reveals that regulatory agencies are persuading manufacturers and consumers to choose electric mud pumps over fuel engine mud pumps to reduce the environmental impact of fuel engine mud pumps.

The global mud pumps market is segmented on the basis of type (duplex pump, triplex pump, and others), component (fluid end and power end), application (oil & gas industry and building industry), and Region (North America, Europe, Asia Pacific, and Rest of the World).

Based on type, mud pumps can be segmented as duplex and triplex pumps. Triplex pumps are expected to progress because of the ~30.0% lesser weight than duplex pumps offering similar efficiency. The pump transfers the fluids with the help of mechanical movements.

Based on application, mud pumps market can be segmented as oil & gas industry and building industry. As oil and gas fields going mature, operators must drill wells with large offset, high laterals, widening their applicability by using mud motors, and high-pressure pumps. To fulfill the demand drilling companies increase their mud pumping installation capacity, with higher flexibility. For instance, LEWCO has developed W-3000 mud pump model for oil drilling, which can handle power up to 3000 HP.

Based on region, North America is predominant because of tight oil and shale gas sources, followed by Asia-Pacific due to the increased number of wells in the regions, especially in countries such as China and India due to the rapid urbanization and industrialization. Authorities in countries such as India, China are working on enhancing their production capacities for reducing the import bills, which ultimately help in the growth of mud pumps market.

This market is broadly driven by oil and gas industry as mud pumps are used to move massive amount of sludge and mud at the time of drilling. Countries such as China, Russia, Saudi Arabia, and the U.S. have the largest number of oil wells. The demand for mud pumps will increase with the number of oil wells, across the globe.

8613371530291

8613371530291