lubi self priming mud pump in stock

Commenced in the year 2011, we, Moto Drives,are a Sole Proprietorship Firm engaged in manufacturing, supplying, trading, wholesaling and distributing an extensive and quality tested range ofElectric Pump, Electric Motor, Worm Gear Box, Slurry Pump, Submersible Dewatering Pump, Energy Efficient Induction Motor, Helical Gear Box, VFD Drive, Open Well Submersible Pump, Multistage Pump and many more. These products are produced using finest quality inputs, which are sourced from the genuine and industry leading. Our range of products finds its application in varied industries. The range offered by us to our customers is created to excellence by our technological experts and is well known globally for its diverse features like sturdy built, dimensional correctness and longer service existence.

The pump shall have back pull out design so as to enable the rotating parts to be removed and serviced without dismantling the suction and discharge pipe work.

Leading Wholesale Distributor of kirloskar dewatering mud pump, kirloskar self priming mud pump - bare pump, lubi dewatering mud pump and crompton dewatering mud pump from Mumbai.

Industrial pumps are an integral part of many applications taking place in various industries. As a trustworthy industrial pump provider in Gujarat, we provide heavy duty industrial pumps specifically designed and manufactured for demanding industrial processes. Industrial pumps are available in different shapes and sizes and they are used to move a huge variety of products or elements including oil, water, chemicals, food, slurry, wastewater and sludge to name a few. Whether you are looking for centrifugal or positive displacement pumps, Every Spare Parts (ESP) has you covered. We are known for offering world-class range of industrial pumps manufactured by the best of manufacturers in India.

If you have been looking for Lubi SMSJ Self Priming Pump 1HP 2900 RPM 0.75kW 2 Pole suppliers, your search ends here as you can get the best Lubi SMSJ Self Priming Pump 1HP 2900 RPM 0.75kW 2 Pole suppliers in top cities such as Delhi NCR, Mumbai, Chennai, Bengaluru, Kolkata, Pune, Jaipur, Udaipur, Hyderabad, Surat, Vadodara and Ahmedabad.

You can purchase Lubi SMSJ Self Priming Pump 1HP 2900 RPM 0.75kW 2 Pole of the finest quality and rest assured to get the best in terms of both durability and performance. If you are bothered about the Lubi SMSJ Self Priming Pump 1HP 2900 RPM 0.75kW 2 Pole prices, you can be totally sure to get the best rates as Every Spare Part (ESP) brings you genuine Lubi SMSJ Self Priming Pump 1HP 2900 RPM 0.75kW 2 Pole rates and quality assured products only from the best of brands with exclusive brand discounts you won?t find anywhere else.

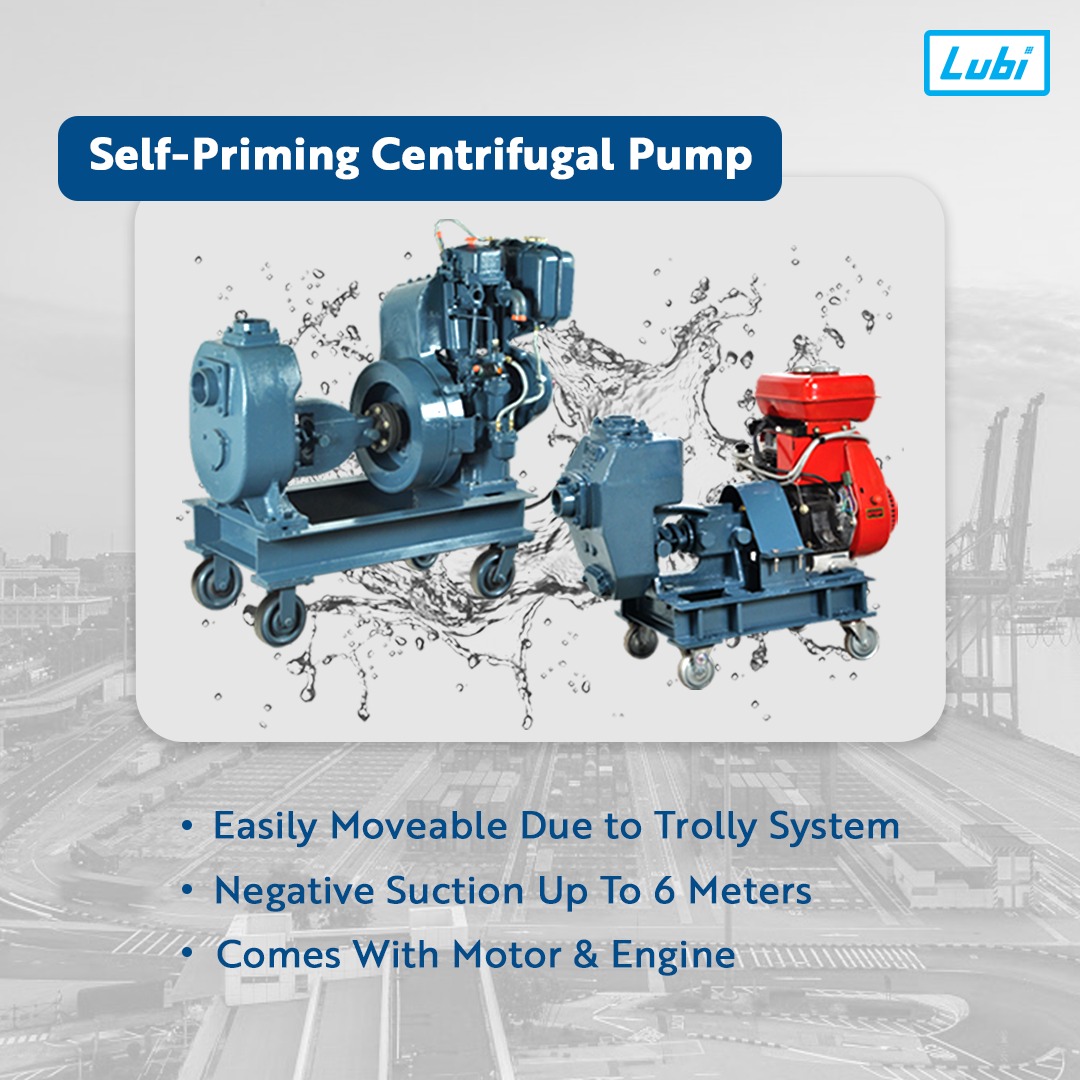

Our clients can avail from us Self Priming Mud Pump that comes with self priming action, which ensures easy maintenance. These are durable, cost effective and also provided with non-clogging impeller to handle suspended solids. Designed using latest technology, these pump optimum performance and are used in steel & thermal plants.

self-priming centrifugal pump has two phases of operation: priming mode andpumping mode. ... The rotating impeller generates a vacuum at the impeller"s "eye" which draws air into the pump from the suction line. At the same time, it also creates a cylindrical ring of liquid on the inside of the pump casing.

Heavy Duty Sewage Pumps (2.0 HP to 60.0 HP) Performance Range Flow rate up to 24,000 l/min. (1440 m3/hr) ^ Drainage of waste water from the liberation tank, purifying tank and sewage tank in water treatment plant. Drainage of waste water containing fibrous additives from leather factory, dyeing factory and food processing factory. Sewage management, accumulated water, septic tank, stock farm. Pumping sewage from single and multi family dwellings. Pumping sewage from hotels, restaurants, schools International standard design : VCT cable, thermal overload protector, silicon carbide mechanical seal, high grade cast iron, good P / E Multiple impeller designs to handle solids laden sewage and/or fibrous substance. For Extra protection, an oil seal ring has been installed under the oil chamber. This lip seal helps prevent the ingress of silt and sand into the lower seal chamber. outlet pipe Superior abrasion resistant mechanical seal manufactured with silicon carbide to ensure the best seal effect. Full range offering low to high head and flow capabilities, with compact and easy installation. Also available with Guide Rail System, which allows automatic remote connection and disconnection without entering the pit. Oil lip seal mounted outside of seal chamber stops solids gathering around seal faces. Thermal overload protector «t Equipped with Automatic reset motor protector, prevents motor from burning due to high temperature/phase failure/voltage drop and lock impeller. Casing cover Cable base Epoxy resin seal cable base to prevent water intrusion into motor through prevent clogging. ^ Single channel non-clog impeller, allows large solids passage preventing clogging and allowing higher head applications with solids laden media. ^ Vortex impellers create a hydraulic passage, allowing long fibrous materials to pass through without any contact with the impeller. Pump of U type impeller (3 Phase) operating in a higher current when L reverse, please adjust into fit directions Special Features on request

Leading Wholesale Distributor of kirloskar dewatering mud pump, kirloskar self priming mud pump - bare pump, lubi dewatering mud pump and crompton dewatering mud pump from Mumbai.

Self-priming pumps are a specific type of liquid pump designed to have the required liquid inside the cavity or pump body necessary to start the pumping process.This offers the potential for increased operating efficiencies in process plants where pumps are used for a variety of repeated yet intermittent operations.

Some pumps are designed to always have the requisite start-up liquid in the pump’s chamber or body. These are called “self-priming” pumps. Other pumps require the start-up liquid be added to the pump before initiating operation. No one type of pump is intrinsically superior to another: it simply depends on what the pump is used for and how often.

Some types of pumps are engineered to be automatically self-priming.Pumps of this nature feature close tolerance working parts that trap fluids in the pump’s body, preventing them from returning from the discharge side of the pump to the suction side when the pump is not in operation.

In these types of pumps, the constant presence of fluid in the pump’s body allows the pump to better handle what are called “air pockets”. Air pockets are an accumulation of air bubbles in the pump’s working mechanism, which can impair proper pump operation.

For these types of low viscosity fluids, a V-type centrifugal pump design is often preferred, featuring a vacuum pump and positive seal that is located close to the discharge port. This allows a V-type centrifugal pump to readily pull a vacuum until it is full of fluid.

However, standard centrifugal pumps are not designed to be self-priming.Unlike the pump types already described, standard centrifugal pumps do not trap liquids when not in use — although engineered modifications to the pump’s housing may allow some of these types of pumps to be self-priming.

With centrifugal pumps, the pumping action occurs when an impeller is rotated in a liquid within a cavity or chamber of the pump, displacing the liquid and forcing it to flow into the discharge port of the pump via centrifugal force.

Fluids typically enter the pump at the center of the impeller and are discharged via a port on the outer perimeter of the pump’s body. The impeller is often directly coupled to the pump’s motor, in what is called a monoblock design.

Air is the primary enemy of this type of pump. When a standard centrifugal pump encounters air pockets, it can become “air bound”, and refuse to operate. Air intrusion into standard centrifugal pumps is typical, as these types of pumps don’t feature tightly coupled pumping mechanisms such as gears or screws and have no seals between the suction and discharge sides of the pump.

Self-priming centrifugal pumps overcome air binding by initially mixing any residual air in the pump’s working mechanism with fluid during the priming process.

This blending allows the resulting mix to move readily through the pump’s body on initial start-up, removing the air and aiding product flow on the suction side of the pump. The process liquids and any entrained air move toward the impeller, and normal pump operations commence.

In comparison to a standard centrifugal pump, what’s notable in the design of a self-priming centrifugal pump is that it features a liquid reservoir built into the body of the pump, typically either above or in front of the impeller.

This reservoir allows the pump to rid the pump’s body and suction line of air during the priming cycle, replacing it with liquid from the reservoir that is blended into the residual air. The “self-priming” capability of this type of centrifugal pump comes from the ability of the reservoir to retain liquid after its very first prime.

When compared to submersible-type pumps, self-priming centrifugal pumps will continue to pump liquids even after the pump is no longer submerged in a liquid tank or vessel

Due to the need for a liquid reservoir, this type of centrifugal pump can be larger than a standard model, which may cause issues in applications where space is limited

The LKH Prime pump from Alfa Laval is a centrifugal-type self-priming pump that is ideal forCIP operations. The LKH Prime also easily pumps products with entrained air. Once the liquid no longer contains entrained air, you are left with a highly efficient and quiet LKH Pump, one of the most capable centrifugal pumps produced.

For product applications, this pump features an air screw coupled with a highly efficient centrifugal impeller to effectively handle a variety of process media.

The SP Series is a liquid ring pump from Ampco that uses compression chambers to pump, and only uses centrifugal force to seal the chambers with a liquid. It is excellent for CIP return operations and pumping products with entrained air.

The SP Series pump is efficient at emptying tanks and drums, and can handle shear-sensitive products due to its tight manufacturing tolerances and unique impeller shape.

Bornemann’s SLH Twin Screw Pump is a self-priming positive displacement pump best for aseptic processes and applications involving high viscosities, high pressures, or sensitive materials. The variable speed feature of this pump is suited for varying operating conditions.

The C-Series is an eccentric disc pump featuring Mouvex technology. This positive displacement pump uses its strong suction power and ability to run dry to gently and effectively move both liquid and dry products.

The C-Series is available in stainless steel models that carry 3-A approval and are designed to meet EHEDG specifications. This pump can be flushed and cleaned using CIP methodswithout disassembly and can pump both high and low viscosity products with outputs not affected by variations in liquid viscosity.

This guide is intended for engineers, production managers, or anyone concerned with proper pump selection for pharmaceutical, biotechnology, and other ultra-clean applications.

For hygienic processing applications that require the frequent yet intermittent use of liquid pumps, choosing a self-priming pump may be the best solution for ensuring efficient pump operations.We"re here to help!

CSI offers a number of self-priming pumps based on centrifugal, twin screw, and eccentric disc technologies. Contact CSI at (417) 831-1411 to discuss your requirements.

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.

We are providing our customers with a very high quality Crompton Greaves Selfpriming Dewatering Mud Pumps. They are manufactured using very high quality raw material procured from the reliable vendors of the industry. It is a cost effective product and is easily available to our clients. The product is manufactured under the surveillance of our expert professionals keeping in mind the latest market trends.

The pump volute shall be of cast Iron as per grade FG 260 of IS 210/ISO 186 with vertical discharge port. The pumps shall have non clog semi open impeller with material of construction of Cast Iron (standard supply), CF8 and CF8M, suitable for pumping liquids up to 50 deg. C.

The Pump shaft sealing shall be accomplished with double mechanical shaft seal of material Carbon /Ceramic/NBR/AISI 304 Up to 1 Hp and above 1 Hp the mechanical shaft seal material shall be Sic/Sic /Viton /AISI 316 on the pump side.

The pump shall be close coupled with a dry submersible motor, having class F insulation, IP 68 protection, 2900 rpm, epoxy sealed cable entry, with S1 duty for fully submerged and S3 duty for partially submerged application.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Self-priming centrifugal pumps are unique. As the name suggests, they have the ability to prime themselves under suction lift conditions. They draw fluid up from tanks or pits below, making them easier and safer to work on than those that work below ground. Under the right conditions, they’ll free themselves of entrained gas and function normally on their own, but sometimes, they can’t.

A BRIEF NOTE OF CAUTION:Just because self-priming pumps able to pull fluid into them, doesn’t mean that they should start up dry. Self-priming, centrifugal pumps need fluid in the casing to get started. Running dry, even for a short while, will cause damage to the mechanical seal, and pump failure.

Once the pump is turned on, the impeller begins to turn in a counter clockwise rotation. The fluid inside, or the “initial prime”, flows through the volute into the discharge cavity. Here, the air and fluid separate, the air evacuates through an open ended line, or air release line, while the fluid returns to the impeller through a recirculation port.

As fluid moves up the suction line, the air ahead of the fluid is pushed into the casing and handled as the initial prime was handled through the recirculation process. Once the fluid arrives in the pump, it operates as normal.

As fluid recirculates in the pump and forces air out of the discharge chamber, it’s trying to create an area of low pressure. However, if there’s a leak in the suction line, air continues to be drawn into the pump, never allowing it to release enough to create that area of low pressure.

If a valve on the air release line is closed, and the valve on the discharge line is closed, again, it"s giving no place for the air to go and get out of the pump.

If there is excessive clearance between the impeller and the wear plate, the pump has a difficult time creating a low-pressure area. This is typically caused by wear, but could also be due to improper reassembly.

During the priming process, as discussed above, fluid is recirculated through the volute casing. If the recirculation port becomes plugged, the eye of the impeller is unable to create an area of low pressure in which to pull liquid up the suction line.

If you’ve undersized the pump for the suction line, it will not be able to create the low-pressure area it needs to prime. It’s important to understand the suction lift requirements before selecting a pump for the application. Use Gorman-Rupp’s Pump Selection Guide for the calculations you’ll need.

The ability for self-priming pumps to prime hinges on all the right conditions. The pump must be able to evacuate air from inside the pump, create a low-pressure area at the eye of the impeller, and also be properly sized for the right NPSHconditions.

Engineers and experts rely on Crane Engineering for insight and help with centrifugal pumps and positive displacement pumps. Our in-house team of engineers can answer questions related to not only pumps but valves and skid systems. We provide a complete service and repair team who will fix pumps back to OEM standards. We are ready to assist you, contact us, today!

We are a leading Wholesale Supplier of crompton submersible pumps, lubi non clog self priming mud monoblock pump, cri mini submersible pump: self priming, non self priming, mono blocks pump, kirloskar air - cooled pumpset and crompton ow- water filled motor from Coimbatore, India.

Our pumps are specially design for muddy water, sewage, polluted liquids including solids and other waste handling requirements which are mostly useful in ceramic industries. We also manufacturer self priming pumps with semi open type impeller as per the requirement of the clients.

8613371530291

8613371530291