maintenance of mud pump price

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes drilling mud pump price wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

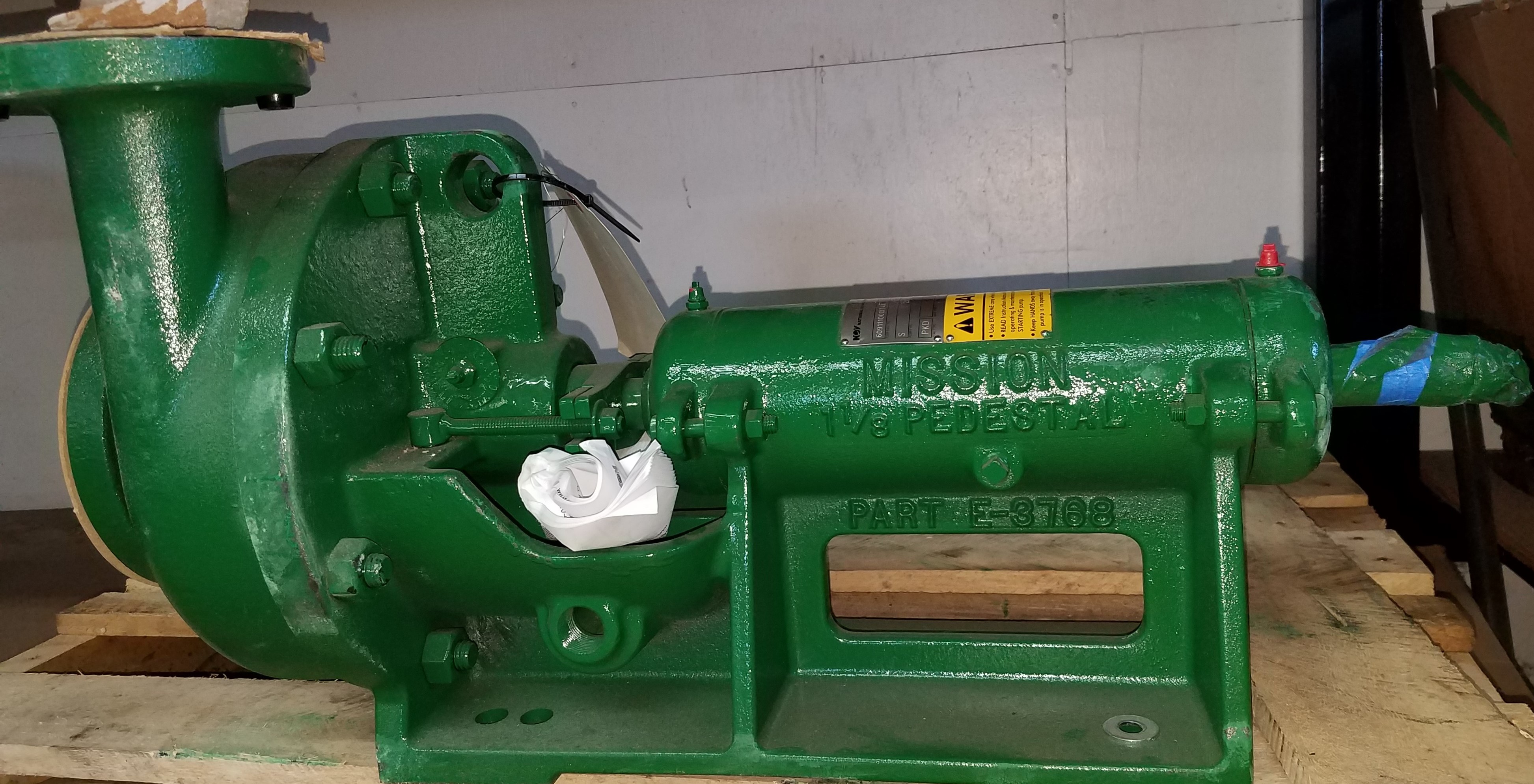

A drilling mud pump price comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the drilling mud pump price of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of drilling mud pump price for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of dr drill mud pump prices, you can find the product you want from the vast collection at Alibaba.com.ther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A comprehensive range of mud pumping, mixing, and processing equipment is designed to streamline many essential but time-consuming operational and maintenance procedures, improve operator safety and productivity, and reduce costly system downtime.

Unexpected failure of mud pumps during drilling operations can result in non-productive time (NPT) and increase well construction cost. Several prior studies and implementations of condition-based maintenance (CBM) systems for mud pumps have failed to provide a generalized solution for the variety of pump types encountered in the field, in particular by failing to detect damage early enough to mitigate NPT. Our research is aimed at improving upon this situation by developing a practical, generally-applicable CBM system for mud pumps.

In the study reported here, a laboratory test bed with a triplex mud pump was used to collect data to test a new approach to mud pump CBM. Artificial damage was introduced to the two most frequently replaced parts of the pump, i.e., the valve and piston. An accelerometer and an acoustic emission (AE) sensor were used to collect experimental data. Based on this data, an anomaly detection algorithm was constructed using a one-class support vector machine (OC-SVM) to pin-point the early onset of mud pump failure. The CBM methodology thus developed does not require prior knowledge (data) of the mud pump itself or of the failures of its components. This is key to it being more widely deployable.

The trained machine-learning algorithm in the test setup provided an accuracy greater than 90% in detecting the damaged state of the valve and piston. Only the characterization of the normal (i.e., non-damaged) state data was required to train the model. This is a very important result, because it implies that the sensors can be deployed directly onto mud pumps in the field – and additionally, that the first few hours of operation are sufficient to benchmark normal operating conditions. Also, it was observed that a multi-sensor approach improved the accuracy of detection of both the valve and piston damage. The system is able to detect early-stage damage by combining the cumulative sum control chart (CUSUM) with the damage index developed in this project.

This work is the first attempt at applying semi-supervised learning for CBM of mud pumps. The approach is applicable for field use with very little or no prior damage data, and in various working conditions. Additionally, the system can be universally deployed on any triplex pump and efficiently uses the data collected in the first few hours of operation as a baseline. Consequently, the practicality and scalability of the system are high. It is expected to enable the timely maintenance of critical rig equipment before catastrophic damage, failure and associated downtime occurs. The system has been deemed promising enough to be field-trialed, and is currently being trialed on rigs in North America.

The fluid end of a duplex or triplex pump offers hundreds of opportunities for error. The results of an error in such a high-pressure system can mean (1) expensive downtime on the pump and maybe the entire rig, (2) expensive repair-replacement, and (3) possible injury or death of a crewman or a company man. Under the laws of nature, pump pistons and liners will wear, and there will be some corrosion and metallurgical imperfections, but the majority of pump failures are manmade. Theoretically, thorough training and retraining should avoid most mud pump problems. Realistically, a critical failure analysis during repair will be necessary to determine how to correct the failure. Telltale signs of trouble are distortion of piston rods, frayed piston polymer, discoloration, odor, hard-to-remove piston, rod cracks, pitting, total fracture, valve seat wear, and unsuitable external appearance.

Essential Function Under direct supervision, performs a variety of skilled and semi-skilled tasks related to facilities maintenance, landscaping, buildings…

Able to instruct mechanics on proper maintenance techniques. If leaking pumps, pipes, flanges, etc. are observed, and assure that materials are contained and…

Housing available in Gillette, WY. Servicing and repair of rig equipment: BOP, Accumulators, Drawworks, Top Drive, Mud Pumps, Catwalk, Iron Roughneck, Traveling…

Kubota diesel engines, transfer pumps, pressure washers, mud vac, light towers, etc. The role of the mechanic is to effectively diagnose and repair oilfield…

Essential Function Under general supervision, performs mechanical equipment, facility, vehicles, tools, buildings and grounds maintenance and repair work and…

Essential Function Under direct supervision, responsible for performing a variety of skilled, semi-skilled and manual labor tasks related to the operation,…

What we do: Rain for Rent moves water every day. We are the leading provider of temporary liquid handling solutions and are known for our systems engineering…

The Roughneck maintains a clean and safe drill floor and assists with the operation and general maintenance of drill equipment. Perform all duties in…

Essential Function Under general supervision, responsible for performing engineering support work including implementation and maintenance of the Geographic…

During non-drilling operations, the rig hand"s work activities include repair and maintenance of the drilling equipment as directed by the driller, mechanic, or…

Triplex pump power end repair experience. Must be willing to be on call, work long hours, work independently, safely work alone or with others and report to…

MOTORHAND-NORTH DAKOTA - (Requisition ID: 23000025) Description Nabors is a leading provider of advanced technology for the energy industry. With operations…

Description: Summary of Responsibilities The Rig Mechanic is responsible for inspecting, troubleshooting, repairing mechanical, electrical, air systems and…

Essential Function Under general supervision, performs a variety of inspection work related to capital improvement project construction and development…

Description - External *Company Overview* Nabors is a leading provider of advanced technology for the energy industry. With operations in about 20 countries…

Manufacturer of a wide range of products which include sewage & mud pump repairing service, mud pumps services center, rental pump services sewage dewatering pumps and mud pump repairing services.

Service TypeRepair Serviceeveraging on our years of experience, we are providing best in class Sewage & Mud Pump Repairing Serviceto our reputed clients. We take in the service for boring at several regions like in farms lands, gardens, lawns and parks. This service is the sole resolution for meeting varying water supply necessities. Our offered services are precisely rendered by our adroit...

Service TypeRepair ServiceWe are ranked amongst the renowned organizations that are engaged to render the best quality Pump Repairing Service. The repairing work of pumps is executed by our highly qualified professionals using premium grade tools and the lates

BrandJay Bajarangur company is one of the most preferred service provider of the most qualitative and reliable services for Vicker Hydraulic Pump Repairing, which is rendered by technical professionals and mechanical engineers who are not only well qualified but who also have a very rich experience in the domain of Pump Repairing. Moreover, we also conduct these Repair

Manufacturer of a wide range of products which include Sewage & Mud Pump Repairing Service, Mud Pumps Services Center, Rental pump services sewage Dewatering pumps and Mud Pump Repairing Services.

everaging on our years of experience, we are providing best in class Sewage & Mud Pump Repairing Serviceto our reputed clients. We take in the service for boring at several regions like in farms lands, gardens, lawns and parks. This service is the sole resolution for meeting varying water supply necessities. Our offered services are precisely rendered by our adroit...

We are ranked amongst the renowned organizations that are engaged to render the best quality Pump Repairing Service. The repairing work of pumps is executed by our highly qualified professionals using premium grade tools and the lates

ur company is one of the most preferred service provider of the most qualitative and reliable services for Vicker Hydraulic Pump Repairing, which is rendered by technical professionals and mechanical engineers who are not only well qualified but who also have a very rich experience in the domain of Pump Repairing. Moreover, we also conduct these Repair

Prior check to the start of a mud pump for clear water inlet and outlet pipes, buttered front and rear bearings and a filled packing. The China mud pump should be equipped with a high-pressure water pump, which pumps water to the sealing fill with a pressure greater than that of the mud pump. As a protection to the fill, never turn off the water pump while the mud pump is in its working state. Otherwise, the sealing part is of immediate wear.

The service life of the mud pump depends on the clearance between the impeller and the guard plate. An unreasonable clearance is responsible for the vibration and the noise of the pump and the damage of overflowing parts. Therefore, when it comes to the impeller replacement, the clearance shall meet the requirements of the design drawing by adjusting screws on the rear bearing. Take the suction capacity of mud into account for the allowable suction range of the mud pump is determined by water transported.

The Construction Department shall have some professional person responsible for the maintenance and repair of the construction machinery. Regular check and maintenance of the mud pump and other machinery, such as the drilling mud pump parts, are useful for the early detection and a prompt solution.

Pay attention to the size of sediment particles, among which the large ones are prone to wear the vulnerable parts of the China mud pumpsuch as pump shells, bearings, impellers, and so on. Timely maintain the use and replace the damaged. Take advanced anti-wear measures to lengthen the service life of vulnerable parts, which can downturn the cost and up forward the efficiency. Meanwhile, keep backup vulnerable parts in stock in case of unexpected replacement needs.

In order to offer you Klarna’s payment methods, we might in the checkout pass your personal data in the form of contact and order details to Klarna, in order for Klarna to assess whether you qualify for their payment methods and to tailor those payment methods for you. Your personal data transferred is processed in line withKlarna’s own privacy notice

Our clients can avail from us Self Priming Mud Pump that comes with self priming action, which ensures easy maintenance. These are durable, cost effective and also provided with non-clogging impeller to handle suspended solids. Designed using latest technology, these pump optimum performance and are used in steel & thermal plants.

8613371530291

8613371530291