mission magnum mud pump price

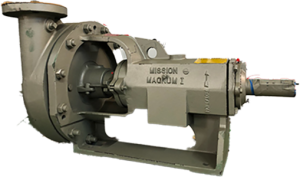

Tobee"s Mission Magnum I Pump 8x6x14 and wet parts are made from Hard Iron or High Chrome alloy materials that they are 100% interchangeable with original Nov Mission Magnum 8x6x14 Pumps and Parts.

The revolutionary design of the MAGNUM I provides supreme-duty performance in all types of fluid pumping operations. Although it offers greater capacity and higher heads, the MAGNUM I remains the competitive pump of choice for aggressive applications.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

According to the different working conditions, Mission centrifugal pumps can be used as Frac discharge pump, Frac suction pump, Oil drilling centrifugal pump, electric centrifugal transfer pump, Skid mounted mixing pump, Transfer pump, Trash pump, Grinding pump, Circulating mud pump, Centrifugal sludge pump, Drilling fluid centrifugal pump, Horizontal directional drilling pump, Denver pump, Filling pump, Feeding pump, etc

Mission Magnum XP Blender Pump and MCM XL Pump are ideally suited for pumping high volumes of heavy slurries that are abrasive, corrosive, and difficult to pump. The compact overall dimensions make it an excellent choice for high volume mobile and stationary applications where a small footprint is critical. High chrome alloy or hard iron material options for different applications

A wide variety of mission mud pump options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mission mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether mission mud pump is 1.5 years, 6 months, or unavailable.

Our company is Direct factory of slurry pump, gravel sand pump , dredging pump and Spare parts,which are widely used in mine, metallurgy, coal, electric power ,dredge and other sectors of the national economy.

Our pumps are exported to more than 20 countries and regions,such as South America, Africa, Southeast Asia, Russia and so on.Our products have won unanimous favorable comments from the market.

Naipu Pump also Accept OEM (Original Equipment Manufacture)Order,such as the shafts,shaft sleeves,bearing housing,etc. We also can design and produce the complete pumps for your special need.

Naipu oil pumps is designed for pumping drilling fluid or industrial suspension (slurry), the use of advanced design theory can be pumping abrasive, liquid viscosity (resistance) and corrosion. Compared with an ordinary pump, excellent flow, high temperature, long life, easy maintenance, high reliability, significant energy saving effect and so on, now widely used around the world on land and offshore drilling. We will provide users with the best products to meet the needs of the different working conditions.

The SXP type frac pump is single-stage, single suction centrifugal slurry sand pump, which is used on frac truck mostly. The Mission Magnum XP centrifugal pump is good at handling big capacity of high abrasive, corrosive and plain tough slurries. The Mud pump wet parts are made of high chrome alloy, hardness HRC58-62. The impeller is open type and back vane design decrease the slurry pressure to stnffing box maximally, increasing the pump life. the small footprint design is specially for compact overall dimensions of the S XP minging pump make it an excellent choice for high volume mobile and stationary applications. We have two pump models 14×12×22 and 12×10×23, caacity 3000-75000 gpm (681-1703m3/h), head 75-410 feet (23-125m). Sunbo frac pump can meet the frac track whole equipment system 100%, welcome to contact us.

Magnum XP series mud centrifugal pumps are mainly design for solids control circulating system of oilfield drill rig. It can be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer, to assure these equipments work efficiently.

Tobee® Mission Magnum I Pumps are proven as reliable, heavy-duty, low-cost slurry pumps. The 3×2×13 through 8×6×14 pumps all feature the same power end, which ensures production and reduced spare-part inventory requirements. The Mission MAGNUM I has been engineered for the toughest jobs in drilling, production, well-servicing, and industrial applications. The MAGNUM I is more powerful, more durable, and easier to maintain than any conventional pump in use today.

v We have a wide range of centrifugal pumps for oil & gas industries. These pumps are designed for a wide range of flow rates from few gallons to hundred of gallon per minute. Our centrifugal pumps are used in various industrial applications.

v Our energy series pumps are designed for drilling, production, well servicing and industrial application. These pumps are designed for all types of fluid pumping application.

ü Casing of Energy 250 pumps are made up of WCB which makes casing stronger and thicker. (it can perform better with corrosion & wear)pumps are designed of concentric casing so it can reduce abrasive wear and improve life of pump.

ü Our spare parts of pumps are interchangeable with most of the international brand including MCM, NOV, MISSION, MALTCO, HARRISBURG which helps customer to source spare parts easily.

An easily removable stuffing box allows these pumps to be customized to meet customer needs. The different options available are stuffing boxes to accommodate:

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

8613371530291

8613371530291