mission mud pump pistons factory

Acumen International has been aligned with NOV Mission Fluid King in excess of 25 years. We have the ability to offer the complete NOV Mission line including Centrifugal pumps and parts, Retsco, T3, Mud pump expendables, etc.

We offer not only time-tested, high-pressure mud-pumping systems, but we are also on the forefront of innovation and cutting-edge design of mud pumps with constant improvements and new ideas to fit your needs.

All the National Oilwell Varco mud-pumping technologies, including the top of the line mud pump control systems, are equipped to expertly handle any operation.

This pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications, and are designed for a wide range of flow rates.

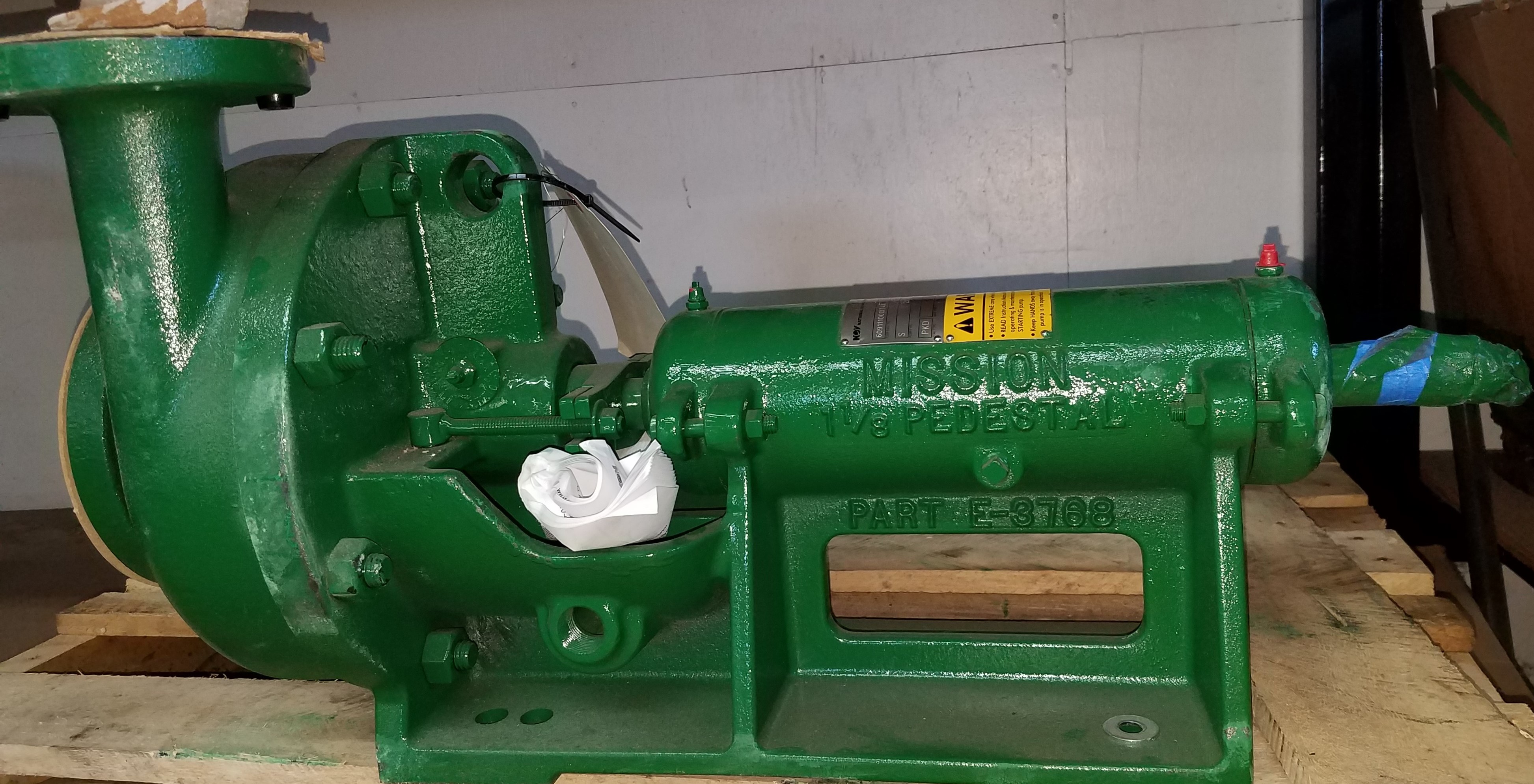

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

Tobee® Mission Magnum I Pumps are proven as reliable, heavy-duty, low-cost slurry pumps. The 3×2×13 through 8×6×14 pumps all feature the same power end, which ensures production and reduced spare-part inventory requirements. The Mission MAGNUM I has been engineered for the toughest jobs in drilling, production, well-servicing, and industrial applications. The MAGNUM I is more powerful, more durable, and easier to maintain than any conventional pump in use today.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

A wide variety of mission mud pump options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mission mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether mission mud pump is 1.5 years, 6 months, or unavailable.

During the 1950’s the Mission” 1780 type “W” pumps were introduced to replace duplex pumps while creating the first low pressure mud system. The use of a high quality concentric type centrifugal pump allowed abrasive fluids to be mixed and transferred while reducing initial and maintenance costs for the drilling industry. The low-pressure mud system with Mission 1 780 Type “W” centrifugal pumps became the industry standard.

As well depths increased so did the need for heavier mud weights. When the mud weight began exceeding 14 ppg the need for a pump that could withstand greater horsepower loads arose. During the 1970’s Mission organized a design team that engineered the Mission Magnum. The Magnum was designed to have the same footprint, flange locations, and drive shaft diameter as the 1780 “W”. This allowed a 1780 to be replaced by a Magnum without any skid modifications. The Magnums were originally engineered with a 2-1/2″ shaft (3″ between the bearings), double row bearings with an engineered life of over 2 years at 200 HP, larger impellers and heavier frames. The Magnum allowed drilling contractors to upgrade their centrifugal pumps and mix heavier fluids.

The National Oilwell Varco” Mission centrifugal pump line has proven to be the best centrifugal design for handling abrasive mud. This pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications. These pumps are designed for a wide range of flow rates, from a few gallons per minute to thousands of gallons per minute.

Each pump contains the finest materials, engineering and craftsmanship available in the industry. Described are like features of these pump lines and unique features are described on the following pages.

National Oilwell Varco utilizes unique design features developed for slurries. Three major differences from most pump designs include the concentric casing, wider impellers and increased re-circulation areas. Each feature contributes to reducing wear when handling abrasive fluids.

All of the pumps feature a concentric casing. This casing averages 37% thicker than conventional pump casings, and up to 50% thicker for the larger, mud pumping models. They are pressure rated at 1 .5 times the flange rating and are designed with a 1 /8″ erosion allowance. The concentric style casing has proven to offer the greatest pump life and reduced downtime. The walls of a concentric style casing are an equal distance from the impeller throughout the impeller circumference, which results in a smooth flow pattern. A volute style casing has a cutwater point that disturbs the fluid flow pattern creating an eddy. The concentric casing eliminates vibration, turbulence and aeration that is caused by the cutwater point in conventional volute pumps. It also reduces the high bearing loads and shaft deflection even at near shutoff flows.

The shaft is much larger in diameter than conventional pump shafts for heavy-duty performance, minimum deflection and increased operating life of the seal or packing. With a 2-1/2″ diameter at the seal area and 3″ diameter between the bearings these pumps can be direct connected or belt driven.

Rig Parts Oilfield Supply Co., Ltd ( RPS ) is committed to providing the world with the best drilling equipments and services at the best prices, especially mud pump and parts, plunger pump parts, handling tools and solid control equipments.

Since 2010, Best-all Petroleum Machinery Co., Ltd. has been supplying high quality products to the oil well drilling industry. Our core focus is to provide performance enhancing mud pump parts and solutions that meet the oil well drilling standards. We have developed, tested and enhanced mud pump components that decrease downtime, improve safety and perform in the toughest drilling environments.

We are committed to developing and manufacturing the best mud pump parts of all for drilling contractors worldwide, continuously meeting and exceeding the customers" expectations, and creating positive impacts on our customers" projects.

Today"s economy requires that greater attention be given to improve performance of drilling equipment. Understanding the operation of the piston (slush) pump and the associated mud system is vital to improving operations. Improved operation of the piston pump is achieved by providing a mud supply which insures proper filling of the piston pump on each stroke. Testing in a high pressure mud pump research laboratory provided the substantiation of the analytical design approach presented in this paper.Noisy or Normal Pump Operation

Unusual noise or knocks resulting from various problems. Some are mechanical; parts are loose or broken and must be repaired. One unusual knock is called valve hammer1; which is usually a result of valve and spring design and pump speed. This can also be the result of wear or broken springs. A common noise is hydraulic knock; this is a result of inadequate suction pressure at the operating speed. It results in separation of fluid and piston; this results in water hammer.2 Air intrusion may also cause sound effects where large amounts sometimes cause knocking and small amounts produce a quietening effect. Leaks causing air intrusion should be sealed throughout the piping system and air traps avoided. Air entering through pump packing or pistons on triplex pumps 3 can be eliminated by using new parts or by keeping the cylinder pressure above atmospheric pressure at all times throughout the stroke.Required Suction Pressure Fundamentals

A specific amount of pressure is necessary to force the mud from the tank through the suction piping system into the pump through the valves and against the piston in order to keep the line full of mud. If the line is not full at every point, a void will occur. These voids begin to occur at a particular pump speed. The piston speed varies throughout the stroke. If a void has developed, filling occurs in the last portion of the stroke. When the fluid catches the piston, a collision and knock occur.

The pressure needed to prevent a void is greatest at the start of the stroke. This happens because the piston velocity and the mud in the line to a cylinder is standing still; inertia is high and the mud is difficult to move or accelerate. A large amount of pressure is required to start motion at the rate at which the power end is moving the piston. Pressure is needed to overcome the piping friction and to overcome the inertia of the mud.

We also served as the acting shop and field repair representative for the Western Gear Company and as a manufacturing facility for Wilson Manufacturing Company based in Wichita Falls, Texas. Wilson was a manufacturer of well service rigs and mud pumps. SMC Inc. has served and currently serves as a manufacturing and repair center for Oil Well Supply, Cabot-Franks, National, Halliburton, The Western Company, B.J. Hughes, Gardner Denver and many others. We manufacture a triplex pump of 165 H.P. with parts interchangeable to the Gardner Denver model TEE and are currently developing a 500 H.P. pump with parts interchangeable to Oilwell"s SA-644-5 pump. SMC has a large warehouse full of quality replacement parts for various types of equipment such as Triplex Plunger Pumps, Mud Pumps, Swivels, Drawworks and Rotaries.

We manufacture positive displacement pumps and replacement parts vital to the oil industry worldwide. We have customers that include both domestic and foreign oil companies. We also manufacture and repair a variety of products used in routine maintenance by customers with rock crushers, aggregate and commercial cement manufacturing plants.

Sales7@tobeepump.com Web: www.tobeepump.com | www.slurrypumpsupply.com | www.tobee.store | www.tobee.cc | www.hydroman.cn Mission Sandmaster Centrifugal Pump Designs: • Compact heavy-duty frame design for small space; • Multiple application in the oil and gas industrial; • Full open impeller reduces shaft loading; • Available in hard ductile iron, high chrome alloy fluid ends(casing, impeller, wear pad, stuffing box), customized fluid ends in stainless steel or aluminum bronze acceptable;

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

Tired of changing mud pump pistons? We have your solution. The TD will work in all types of drilling mud including oil based, synthetic and water based. It was specifically designed to work in applications where water based mud is used or in situations where WBM is used on the top side & OBM is used on the bottom end. This eliminates the need for changing the piston midway through the drilling program. The “TD” or “Total Depth” name reflects our commitment to make a single piston that will last from “spud” to “TD”. This piston has been engineered with a unique friction reducing material bonded into the urethane of the sealing lip. Because the TD is built to withstand friction in the liner, wear on your parts is minimized and savings is maximized. The Patriot™ TD is also designed to meet pressures of 7500 psi as well as temperatures up to 220 degrees.

8613371530291

8613371530291