mud pump brands quotation

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

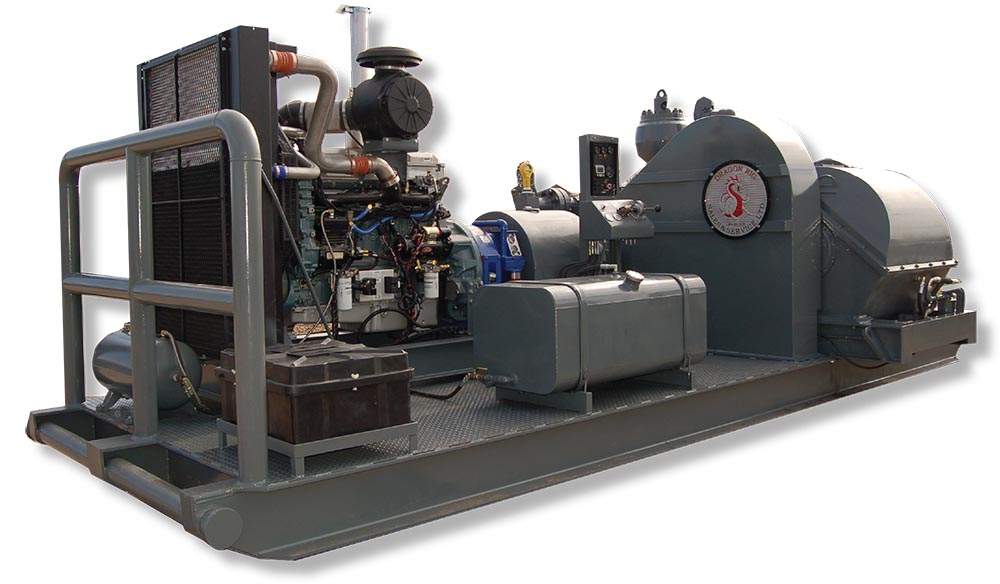

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

*Pump companies, pump models and seal models are listed for reference only. SAF Seals and SAF Precision Manufacturing Ltd. are NOT affiliated with any pump manufacturers.

Before you directly go to the topic of Drilling Mud Pump Companies in Houston, it is important for us to know about this specific pump. So what exactly is this pump and its role? Well, a mud pump is the one which is basically a reciprocating piston pump that is specially designed for circulating fluid and that too under the high level of pressure through the drill string and then again back till the annulus. It mostly contains clay like bentonite in order to provide sufficient viscosity for carrying cutting chips up to the surface besides minerals like barite in order to enhance the weight of the pump column for stabilizing the borehole. It is one of the critical equipment available on the rig which needs expertise for making proper use.

If we wish to make an investment in high-quality Drilling Mud Pump for our industrial needs, then it is advisable for us to do some research on the companies which are into manufacturing of such types of equipment. When we made such investments, we gave importance to below-mentioned points.

For experience, we also took into consideration the reputation the company is having in the industry and the nature of feedback it received from the customers who invested in the Drilling Mud Pump manufactured by them. If the number of positive feedbacks is more compared to average or negative feedbacks, then that again signals we can go for their manufactured products.

Performance and durability of the pump are also one of the most important points as that will decide the price of the pump and help us in planning the budget for the same.

Shale Pumps is one of the leading and reputed manufacturers of this particular pump besides various other types of equipment which are needed by different industries. For more information about the pumps and its features, the professionals of this company are ready to assist the clients.

Our Non-Clog Self Priming Mud Pump Is Prime Quality Of Industrial Pump Used To Circulate The Mud. It Is A Non-clog Gland Packing Type Pump Also Known As SSPP Series Of SUJAL ENGINEERING. Basically MUD PUMP Is Mainly Applicable For To Circulate Drilling Mud On A Drilling Rig At High Pressure.APPLICATIONS:ETP, STPWater From MarineCeramic IndustriesPumping Of Domestic Sewage PlantsSwimming PoolsMERITS:Low MaintenanceQuick Priming Of Dirty WaterAutomatic Air Release Du Continue

8613371530291

8613371530291