mud pump cap wrench manufacturer

Designed for easier removal of mud pump caps with less damage than the most traditional methods. These wrenches feature heavy handle design for greater strength and a fitted safety lock pin to help prevent injuries.

At Mud King Products we don’t believe in selling you on flashy Mission statements or Guarantees, we let our Product do the talking and word of mouth do the selling. With our headquarters centrally located in Houston, TX we are here to serve you, because ultimately that is what is most important.

Each and every one of these components can be as important as the next. Our objective at Mud King is to exceed your expectations in every way possible. Our team is committed to this, our company lives by this.

Informed the customer"s mud company about water amounts and got confirmed that this was no problem. We have double barriers on the water supply. In addition to that, we have procedures to disconnect the supply line when not in use to avoid water unintentionally leaking into the well. We communicated with Rigtools to make sure that they understood what kind of beating it had to be able to take without parting. They ensured us that it had been thought of. As the tool arrived it was easy to understand that it"s a robust construction. It"s also important to be aware of how much clearance you get from the rotary table to the BHA wash tool, and check this against how deep any type of spiders or other equipment might stick.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

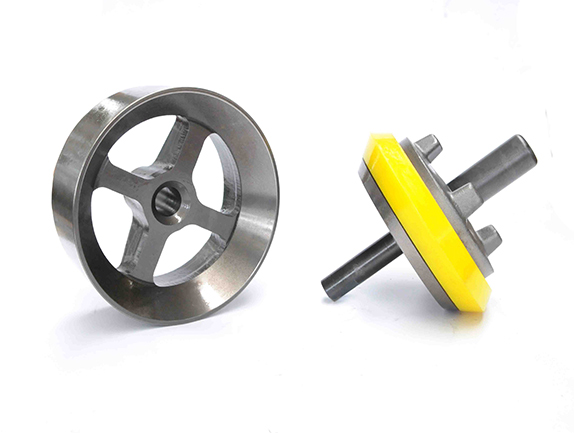

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

SafeLock is offered as an optional upgrade on new GD Energy Products drilling pumps and modules, and can also be used for retrofit on GD Energy Products HD, F and Y series drilling pump modules with bore seal technology.

Simple Operation -No tools, no problems. SafeLock’s quarter-turn design eliminates the need for hydraulic pumps, torque wrenches, drills, or impact guns for installation and removal. To install or remove SafeLock, simply grab the handles and turn 25 degrees, it’s that easy!

GPM International is a supplier of durable oilfield replacement parts for a wide variety of drilling mud pumps. Inventory products including mud pump fluid end parts, handling tool, etc. All of our products are fully exchangeable with O.E.M. standards.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

8613371530291

8613371530291