mud pump cavitation free sample

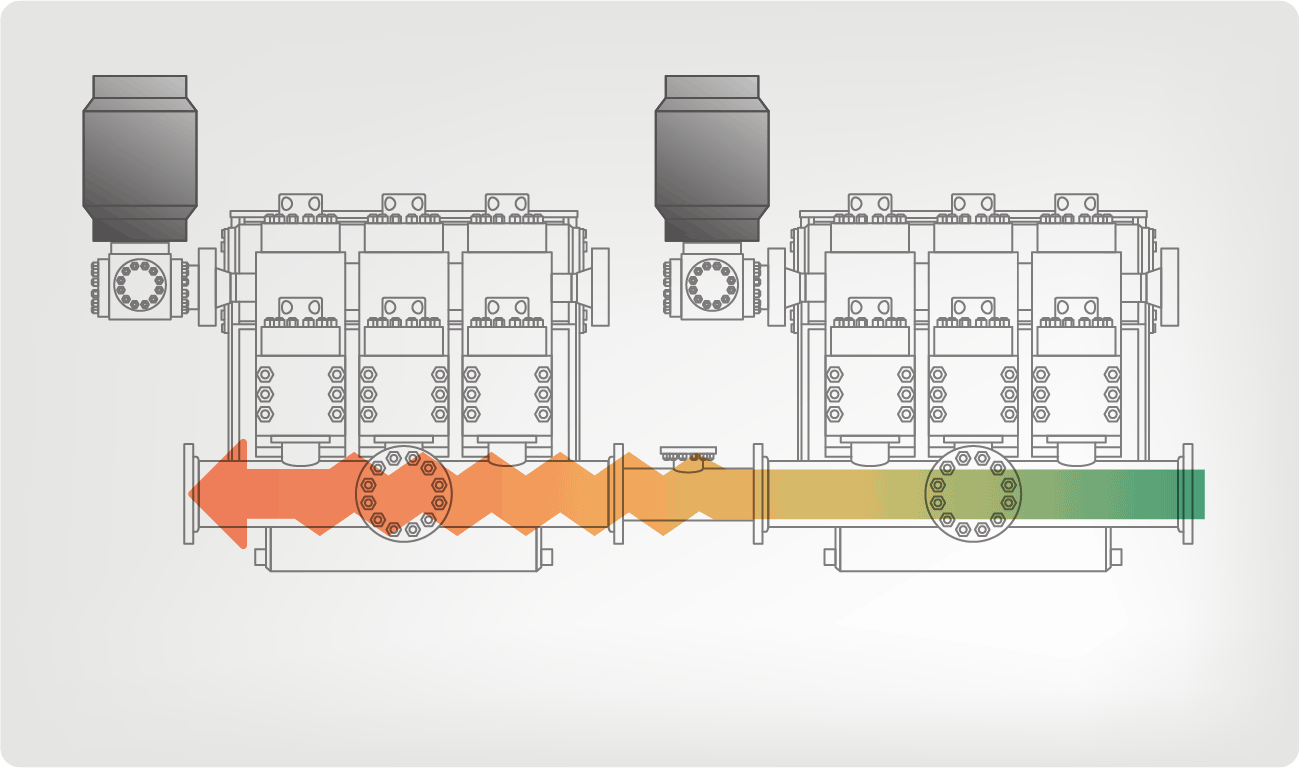

Cavitation is an undesirable condition that reduces pump efficiency and leads to excessive wear and damage to pump components. Factors that can contribute to cavitation, such as fluid velocity and pressure, can sometimes be attributed to an inadequate mud system design and/or the diminishing performance of the mud pump’s feed system.

Although cavitation is avoidable, without proper inspection of the feed system, it can accelerate the wear of fluid end parts. Over time, cavitation can also lead to expensive maintenance issues and a potentially catastrophic failure.

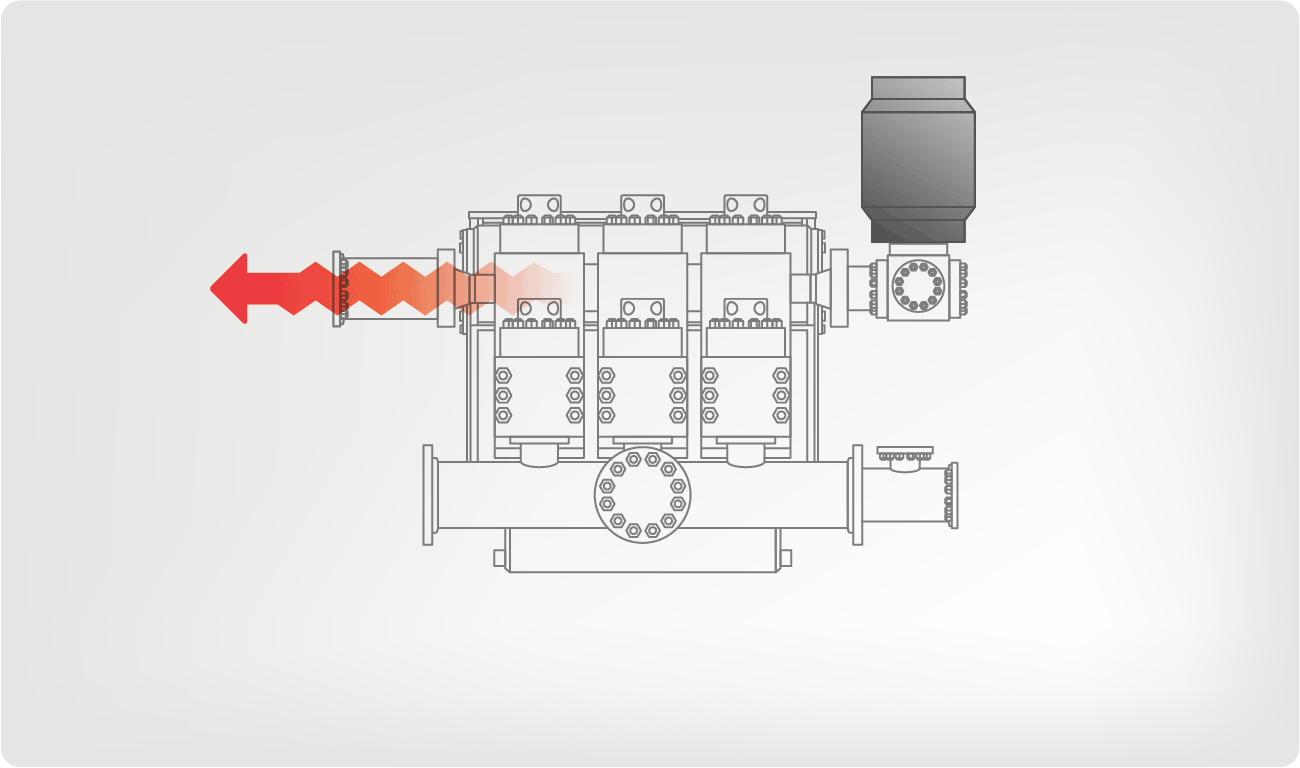

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump “knocking,” which typically sounds like marbles and stones being thrown around inside the equipment. However, the process of cavitation starts long before audible signs reveal themselves – hence the name “the silent killer.”

Mild cavitation begins to occur when the mud pump is starved for fluid. While the pump itself may not be making noise, damage is still being done to the internal components of the fluid end. In the early stages, cavitation can damage a pump’s module, piston and valve assembly.

The imperceptible but intense shock waves generated by cavitation travel directly from the fluid end to the pump’s power end, causing premature vibrational damage to the crosshead slides. The vibrations are then passed onto the shaft, bull gear and into the main bearings.

If not corrected, the vibrations caused by cavitation will work their way directly to critical power end components, which will result in the premature failure of the mud pump. A busted mud pump means expensive downtime and repair costs.

As illustrated in Figures 1 and 2, cavitation causes numerous pits to form on the module’s internal surface. Typically, cavitation pits create a stress concentration, which can reduce the module’s fatigue life.

To stop cavitation before it starts, install and tune high-speed pressure sensors on the mud suction line set to sound an alarm if the pressure falls below 30 psi.

Accelerometers can also be used to detect slight changes in module performance and can be an effective early warning system for cavitation prevention.

Although the pump may not be knocking loudly when cavitation first presents, regular inspections by a properly trained field technician may be able to detect moderate vibrations and slight knocking sounds.

Gardner Denver offers Pump University, a mobile classroom that travels to facilities and/or drilling rigs and trains rig crews on best practices for pumping equipment maintenance.

Severe cavitation will drastically decrease module life and will eventually lead to catastrophic pump failure. Along with downtime and repair costs, the failure of the drilling pump can also cause damage to the suction and discharge piping.

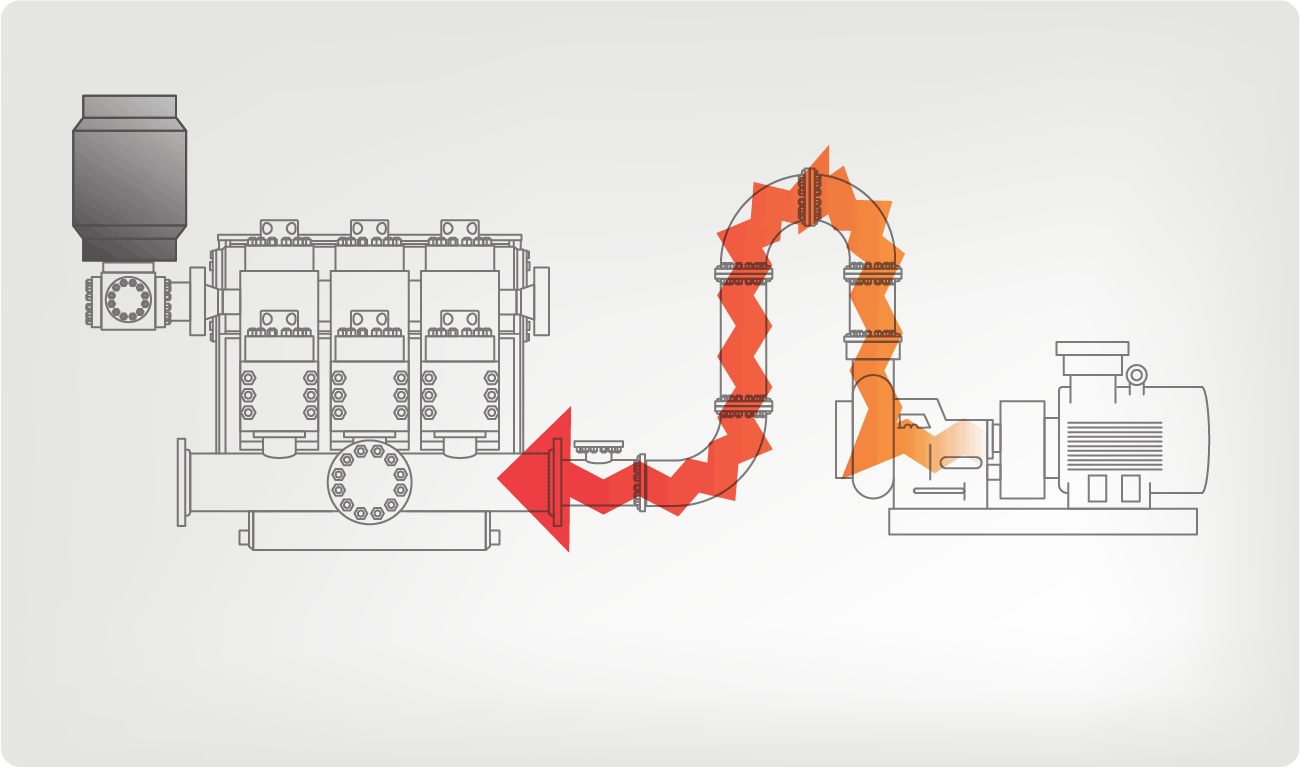

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump ‘knocking’… However, the process of cavitation starts long before audible signs reveal themselves – hence the name ‘the silent killer.’In 2017, a leading North American drilling contractor was encountering chronic mud system issues on multiple rigs. The contractor engaged in more than 25 premature module washes in one year and suffered a major power-end failure.

Gardner Denver’s engineering team spent time on the contractor’s rigs, observing the pumps during operation and surveying the mud system’s design and configuration.

The engineering team discovered that the suction systems were undersized, feed lines were too small and there was no dampening on the suction side of the pump.

Following the implementation of these recommendations, the contractor saw significant performance improvements from the drilling pumps. Consumables life was extended significantly, and module washes were reduced by nearly 85%.

Although pump age does not affect its susceptibility to cavitation, the age of the rig can. An older rig’s mud systems may not be equipped for the way pumps are run today – at maximum horsepower.

I’ve run into several instances of insufficient suction stabilization on rigs where a “standpipe” is installed off the suction manifold. The thought behind this design was to create a gas-over-fluid column for the reciprocating pump and eliminate cavitation.

When the standpipe is installed on the suction manifold’s deadhead side, there’s little opportunity to get fluid into all the cylinders to prevent cavitation. Also, the reciprocating pump and charge pump are not isolated.

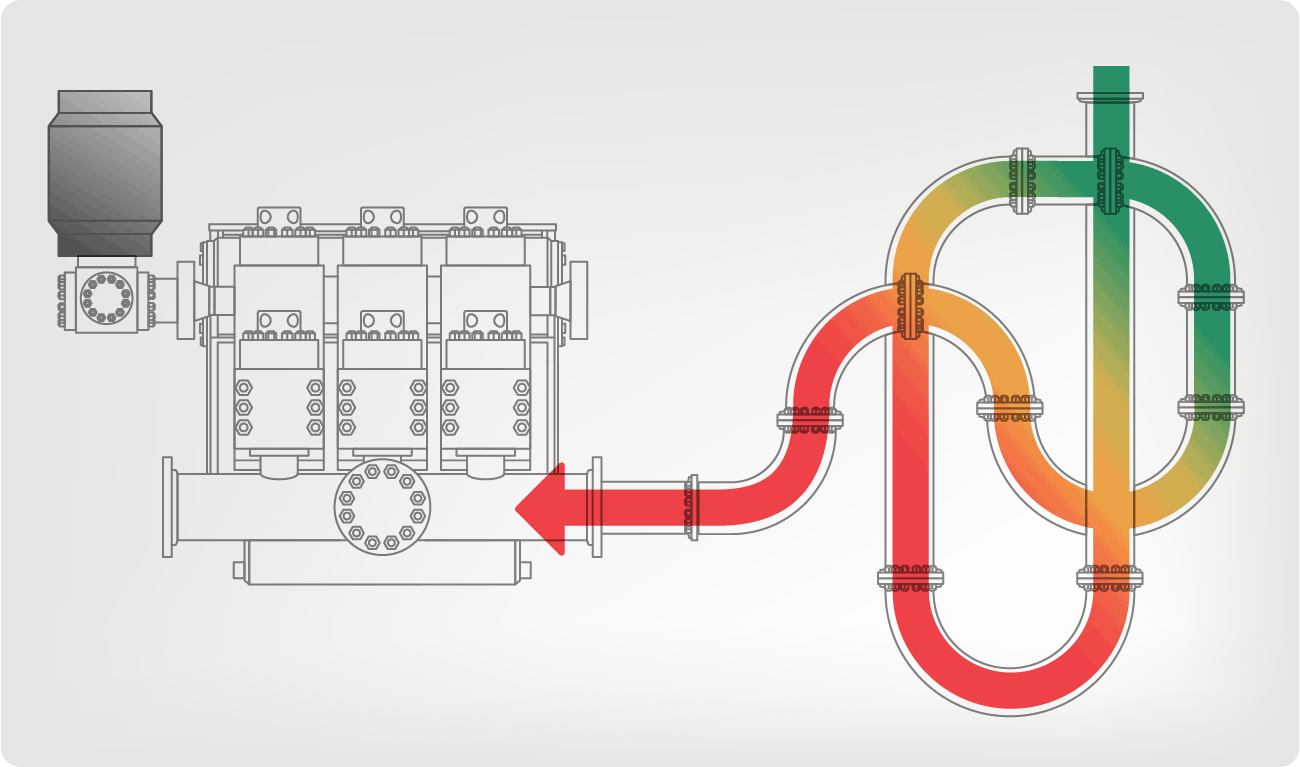

Installing a suction stabilizer from the suction manifold port supports the manifold’s capacity to pull adequate fluid and eliminates the chance of manifold fluid deficiency, which ultimately prevents cavitation.

The suction stabilizer’s compressible feature is designed to absorb the negative energies and promote smooth fluid flow. As a result, pump isolation is achieved between the charge pump and the reciprocating pump.

The isolation eliminates pump chatter, and because the reciprocating pump’s negative energies never reach the charge pump, the pump’s expendable life is extended.

Investing in suction stabilizers will ensure your pumps operate consistently and efficiently. They can also prevent most challenges related to pressure surges or pulsations in the most difficult piping environments.

Mud pump cavitation: Routineinspections, maintenance canprevent ‘silent killer’ from reducingrig efficiency, equipment reliabilityWith pumps being run at max horsepower at today’s well sites, best practicescan help contractors to avoid premature damage, extend consumables life

CAVITATION IS AN UNDESIR ABLE will see the equipment shaking and hear the a sealing surface. These unexpected failurescondition that causes a reduction in pump pump “knocking,” which typically sounds are expensive and lead to a minimum ofefficiency and excessive wear/damage to like marbles and stones being thrown around eight hours of rig downtime for modulepump components. Factors that can contrib- inside the equipment. However, the process replacement.ute to cavitation, such as fluid velocity and of cavitation starts long before audible signspressure, can sometimes be attributed to an reveal themselves – hence the name, “the PREVENTING CAVITATIONinadequate mud system design and/or the silent killer.” Stopping cavitation before it starts is adiminishing performance of the mud pump’s Mild cavitation begins to occur when matter of routine inspection and mainte-feed system. the mud pump is “starved” for fluid. While nance. For starters, install and tune high- Other factors contributing to cavitation the pump itself may not be making noise, speed pressure sensors on the mud suctioninclude: damage is still being done to the internal line to alarm if the pressure falls below • Improper sizing of charge pump; components of the fluid end. Mild cavita- 30 psi. Accelerometers can also be used to • Improper maintenance of charge pump tion damages the module, piston and valve detect slight changes in module performanceimpellers – worn impellers cause a reduction assembly. These hidden and intense shock and can be a good early warning systemof fluid pressure; waves generated by cavitation travel directly for cavitation prevention. Routinely conduct • Dirty or clogged charge pump feed and from the fluid end to the pump’s power end, visual inspections on the pump. While thedischarge lines; causing premature damage (vibration) to knocking may not be loud, if inspections are • Improper size of plumbing from charge the crosshead slides, thus passing onto the conducted on a regular basis, a field techni-pump to mud pump; shaft, bull gear and into the main bearings. cian will be able to detect moderate vibra- • Elevation changes and excessive elbows If not corrected, the vibrations caused by tions or knocking sounds. Finally, maintainin plumbing from mud tank to mud pump; cavitation will work their way directly to the gear end of the pump and check oil on aand these critical power end components, caus- regular basis. • Lack of/or inadequate suction and dis- ing premature failure, expensive downtime Gardner Denver offers Pump Universitycharge dampening. and repair costs. (PumpU), a mobile classroom that travels to Cavitation is an avoidable issue, but with- As referenced in Figures 1 and 2, the customers’ facilities and/or drilling rigs andout proper inspection of the feed system it process of cavitation causes numerous pits trains rig crews on how to properly maintaincan accelerate the wear of fluid end parts. Tis to form on the module’s internal surface. pumping equipment. Participants in thecan lead to expensive maintenance issues and Typically, cavitation pits result in a stress program have found that their improveda potentially catastrophic failure. concentration that results in a reduced maintenance skills have extended the life fatigue life of the module. Washouts are one of fluid end expendables on their sites, inMILD VS SEVERE CAVITATION of the leading causes of module failure and addition to lowering repair costs, decreasing When a mud pump has entered full cavita- take place when the high-pressure fluid cuts production costs and reducing workplacetion, rig crews and field service technicians through the module’s surface and damages hazards.

FIGURES 1 (LEFT) AND 2: Long-term, severe cavitation can cause surface pitting on a module crossbore and reduce the module’s fatigue life. Overtime, cavitation can lead to expensive maintenance issues and a potentially catastrophic failure.

RESULTS OF CAVITATION formance. Consumables life has been extend- The best way to prevent pump cavitation At the onset of cavitation, there will be ed significantly, and module washes have is to check the system’s feed lines and equip-reduced life in expendables and gradual wear been reduced by nearly 85%. This improved ment daily for any signs of abnormal noise oron the modules and power end. Severe cavi- performance has drastically reduced rig vibrations. Although it’s impractical to flushtation will drastically decrease module life downtime and has increased the operational system piping during drilling operations,and will eventually lead to catastrophic pump efficiency and customer satisfaction for the strainer screens should be checked daily tofailure, causing unwanted and costly down- drilling contractor. remove any debris or other flow restrictions.time. In addition, failure of the drilling pump Additionally pre-charge (centrifugal) pumpscan also cause damage to the suction and THE IMPACT OF TODAY’S DRILLING should be inspected regularly to ensure out-discharge piping. RIGS put flow and pressure is adequate. Following While pump age does not affect its sus- these simple steps will allow you to achieveCAVITATION IN THE FIELD ceptibility to cavitation, the rig’s age can. maximum performance from your pumping A leading North American drilling con- Oftentimes, a rig’s mud systems aren’t equipment and reduce unplanned equipmenttractor encountered chronic mud system equipped for the way pumps are run today – outages. DCissues on multiple rigs. The company expe- at maximum horsepower.rienced more than 25 premature modulewashes in one year and a major power-endfailure. Gardner Denver’s engineering teamwas called and spent time on the contractor’s When a mud pump has entered fullrigs observing the pumps during operation

technicians will see the equipment shakingtems were undersized, feed lines were toosmall and there was no dampening on thesuction side of the pump. There were also

and hear the pump ‘knocking’... However,issues with the feed line maintenance – linesweren’t cleaned out on a regular basis andsolids from the fluid had formed a thick cake

the process of cavitation starts long beforeon the bottom of the pipe, further reducingits diameter. The engineering team recom-mended increasing the diameter of the feed

audible signs reveal themselves – hence thelines and routine cleanings to improve flowand reduce the risk of cavitation. Following the implementation of these

Knowing how your pump sounds when it"s running healthy can save you a lot of money in the future. Every pump will make a “healthy” free flowing sound as a medium is passed through it unimpeded. A rhythmic vibration should be produced by the motor. By familiarising yourself with these sounds, you can quickly identify when something is wrong, a change of sound is a a great indicator that there is a problem somewhere. This will allow you to take the correct course of action, and could save you a fortune in future maintenance or replacement costs. Let"s take a look at the kind of sounds you might encounter, and talk about the most common culprit – cavitation.

Cavitation is a problem which results in damage to equipment. It occurs during low pressure and can also be found in pump systems with high vacuum conditions. This happens when there is reduced or impeded flow, which is usually a symptom that a pump isn’t working properly or is not suitable for transporting a specific fluid. These changes in pressure result in tiny bubbles within a moving liquid which are small enough to be transported to the discharge side of a pump. There, the pressure increases drastically which causes any bubbles present in the liquid to implode. These implosions produce energy which releases outward shock waves and can cause damage to surrounding surfaces.

The wear and tear caused by cavitation impedes pump performance and will eventually degrade materials so much that components will have to be replaced. This most commonly affects the impeller and there are some great explanations of the physics of cavitation and why this is so common.

Cavitation can create a number of sounds. Rather than an occasional rattle, which might be caused by mineral deposits or eroded material from inside a pump system, cavitation sounds like popping bubbles or even rocks passing through the system. This can also be accompanied with a cracking noise and perhaps even a continual rumble. Depending on the type of of pump and its application, your pump should hum, it won"t be silent, but if it"s doing its job efficiently then it should produce a consistent sound.

If you are having any issues with your pump not performing correctly, please contact the team at Global Pumps who will be able to analyse your system.

Anyone on a location when it is happening knows for certain what is happening when a positive displacement or triplex pump starts to cavitate. The characteristic knocking starts up, sometimes barely noticeable and sometimes rising to a deafening hammering sound. On some occasions it will sound like a thump like a badly balanced washing machine, and on others it will sound like someone inside the pump banging on it randomly with a sledgehammer. But what is going on INSIDE the pump when you hear this outside the pump? (note – if you aren’t familiar with the operation of triplex pumps and other positive displacement pumps you can go here for a great basic tutorial: http://www.drillingformulas.com/basic-understanding-about-positive-displacement-in-drilling-industry/ or here for just a video:

The short answer to what’s going on is that somewhere there is air inside the pump. Let’s take the example of a triplex pump circulating at 3,000 psi (207 bars)Lets suppose that some air gets in from outside the pump at the inlet conditions of the pump – usually somewhere around 50 psi (3 bars).

When the cylinder starts to push forward on the power/discharge part of the cycle, the discharge valve opens, and it is exposed to the 3,000 psi (207 bars) in the outflow side of the pump system. This is 70 times higher than our inlet pressure was. Suddenly the air in the pump has been compressed a size about 70 times smaller than it was before the piston began the discharge part of the cycle. The air bubbles collapse and the work that was being done in the pump to push the otherwise relatively uncompressible liquid out of the pump by the drive rod on the piston suddenly drops nearly to zero for as long as it takes for the piston to ‘catch up’ and compress the air to the new equilibrium volume.

In a triplex pump, only one cylinder is in the compression/discharge stage at any given time, so when there is no constant discharge of fluid taking place while the air is getting compressed, suddenly the load on the driveshaft, engine and power end of the pump is close to zero briefly then shoots back up to normal as the air is compressed to 3,000 psi (207 bars) This causes the knocking and banging sounds as the different parts of the engine and power end rapidly change speeds, move from tension to compression, hit bearings, etc. So how did the air get in the system?

The simplest answer is that it was already there. A positive displacement pump will not draw or pull fluid into it. There must be some other type of pump or pressure or gravity forcing fluid into the pump for it to operate. If that process, called priming was not done correctly it may have left some air in the piping that is in between the source of the fluid and the pump. It only takes a small amount of air trapped somewhere in the intake system to create knocking and cavitation. If this is the source of the problem, it will tend to go away after a short period of use. If the fluid source is changed, the lines and piping for the inlet system altered or the pump is started or stopped briefly it can come back again. This is especially the case if the properties of the fluids being pumped change – for example switching from a low viscosity fluid to cement is notorious for causing issues in systems where the intake system is not properly purged and prepared. Sometimes these issues are so bad that it becomes difficult to conduct a good cement job because the volume of fluids being pumped cannot be rapidly and accurately measured with common equipment.

It can be the case that the intake lines instead of leaking fluid out (which might be obvious) there is a place where air is leaking IN. this is almost always between the fluid source and the centrifugal charge pump for the triplex. Between the charge pump and the positive displacement pump, the fluid usually has enough pressure that it leaks out, but sometimes between these two points the pressure is low enough for air to leak in. If general checking for tight connections and good seals does not solve the problem these problems can be hard to track down. In some cases it may be necessary to stop pumping and turn the centrifugal pump off in order to be able to look for the source of the pumping fluid which can now leak outwards under gravity from the fluid source without the suction from the centrifugal charge pump on the system. This is obviously a sort of problem you want to discover and resolve before getting into a critical situation. These problems tend to occur in temporary lines, in systems which have been used to pump solvents or acids which destroy seals in the suction system, in systems which are used to pump cement or other abrasives which damage the lines, and in systems which are permanent but which have not been maintained and checked on a regular basis. One final area which is often overlooked is to watch for leakage on/in the seals of the central shaft of the centrifugal pump itself.

So your system is properly primed up, and you checked your suction system for leaks but the pump is STILL having issues. No idea where the air is getting in. In fact, there might not be any leaks or residual air in the system. This leads to one final potential problem and that is low charge pressure. Typical inlet pressure for a positive displacement pump is somewhere around 50 psi (3 bars) but this number is usually measured at the charge pump itself. Between the charge pump and the positive displacement pump there is inevitably some piping, and of course there are the valves on the triplex pump itself which are usually spring loaded to ensure they close properly and must be pushed open by the charge pressure for the pump. If the pressure and associated feed rate of the system gets too low by the time it reaches the positive displacement pump, then some odd non-intuitive things occur.

At one atmosphere/1 bar water boils at 100 degrees Celsius (212 F) but what if the inlet pressure to the pump is lower than this? When the piston on the pump begins to pull back something must come in through the inlet valve and fill the space being made in there. If fluid is not coming in fast enough to fill up the space with liquid, then some of the liquid will begin to boil off at room temperature to make up the difference. At ~ 0.15 bars (2 psi) water boils at room temperature. The resulting steam (steam at room temperature!) then fills the space in the piston. Now that it is a gas, it acts exactly like our air did when we looked at what causes cavitation in the first place. When the piston starts the discharge stroke it compresses, and in addition unlike air it recondenses into liquid and in both cases causing all that knocking and equipment damage.

How do we diagnose and resolve this? Usually if the problem is a lack of charge pressure it will not be present at low discharge rates (because the charge system can keep up) but it will begin and worsen as discharge rates increase. It will also get worse with thick viscous fluids like cement or heavy pills because they have more friction in the piping between the charge pump and the positive displacement pump, making it harder for the charge rate to keep up. This can occur suddenly and unexpectedly when switching from a relatively low viscosity working fluid to a higher viscosity one. It will also get worse if materials with a low vapor pressure like xylene, toluene or other flammable and combustible solvents. This is because they already boil at a low temperature and have a high vapor pressure – it does not take a lot of loss of inlet pressure before a lot of vapor is developed by these fluids. The solutions are in two parts: increasing the charge pressure and decreasing the losses between the charge point and the positive displacement pump. Sometimes this means using a ‘boost’ charging pump closer to the positive displacement pump than the normal one – other times it means bypassing the normal charging pump in favor of a larger temporary one. Decreasing pressure losses between the charging point and the pump can be done if piping and lines can be shortened, straightened made larger diameter or if excessive valves and junctions can be avoided. Another way to reduce pressure losses in some cases is by selecting valves and seats on the pump which have a larger inlet area and/or a weaker return spring.

Cavitation and pump knocking are often created by complicated problems, but usually have simple solutions. In situations where there are consistently issues, a careful consideration of the causes and ways to prevent them will usually resolve the issues. For any given type of pump system and installation experienced crews and operators will learn to recognize the limitations of the systems and how to resolve them. It is good practice to write these things down and ensure they do not get ‘lost’ because the wrong person is on vacation or retires! Having a quick reference of best practices and issues for the systems and fluids commonly used can avoid major difficulties with ‘known problems’ and can also predict the sorts of problems and solutions for fluid systems and combinations which aren’t as well understood through experience.

Cavitation occurs when the absolute pressure at the eye of the impeller falls below the vapor pressure of the liquid being pumped. When this occurs, vapor bubbles or “cavities” form in the liquid. As the bubbles move from the low-pressure area near the impeller toward the high-pressure area near the pump discharge, they implode violently back to their liquid state.

These little implosions of collapsing bubbles sometimes cause loud popping noises which can be heard externally when the pumps are operating. Internally, this ongoing process of implosion creates shockwaves that can result in considerable physical damage. Over time, cavitation can destroy impellers and pump housings, cause seal and bearing failure, impact flow and pressure, and consume significantly more power.

As long as NPSHA > NPSHR, cavitation will not happen. NPSHR is a characteristic of the pump and is readily available from its manufacturer for a given duty condition. NPSHA is a function of the entire “system” feeding the pump, which will include:

Hps = The absolute pressure on the surface of the liquid in the tank supplying the pump. In an open-top tank, this is simply atmospheric pressure. But in an enclosed (closed top) tank this could be either higher or lower (vacuum) than atmospheric pressure. (Remember that atmospheric pressure by definition is zero-gauge pressure but always a positive number in absolute terms.) NPSHA is always calculated using absolute terms. It also must be given in terms of head of the liquid being pumped. This will require conversion from units of pressure to units of head.

Hss = The static suction head either above or below the pump centerline. This number is usually positive but is negative in cases where the pump is above the liquid level in the supply tank (e.g., a suction lift condition).

Hf = The piping entrance and friction losses from the supply tank to the pump’s suction flange. Hf is a positive number that is always subtracted from Hps when evaluating NPSHA.

Hvp = The vapor pressure, in absolute units, of the liquid at the temperature it is being pumped. This term is subtracted in the equation because cavitation will happen if the absolute pressure inside the impeller eye or suction piping drops below the liquid vapor pressure. To account for that situation, we simply subtract the vapor pressure of the liquid being pumped. As with Hps, this will require conversion from units of pressure to units of head.

Having defined terms, let’s apply it to a specific instance. Consider a pump mounted some distance away from an open-top tank. The liquid level inside the tank is 6ft (1.8m) above the centerline of the pump, which is at 4000ft (1219m) ASL. The liquid being pumped is water at a temperature of 120F (49C). Assume the total friction losses from the tank to the pump at the desired flow rate are 8ft (2.4m). The pump requires 17ft (5.2m) of NPSHR at the desired flow rate. Will it cavitate?

Notice that NPSH is just an energy calculation, (e.g., Bernoulli’s equation). Since a centrifugal pump can’t add energy to a liquid until that liquid is inside the impeller, NPSHA represents all the energy available to feed the pump. NPSHR is essentially a measure of energy loss — measured as pressure drop — as the liquid enters the pump on its way to the impeller, where the pump can begin to add energy — in the form of pressure — back into the liquid. As long as NPSHA > NPSHR, cavitation will not pay an unwelcome visit to your pump installation.

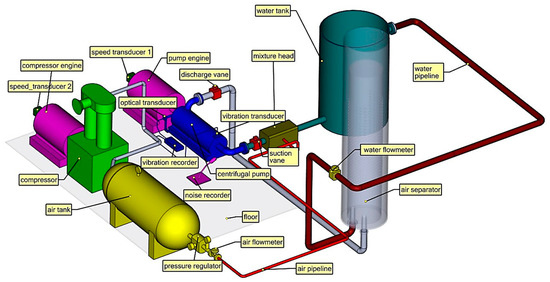

Generally, the measured values are on very low level from 1 to 2.5 m. The suction number reaches about (), which is significantly higher than the standard centrifugal pumps and demonstrates normally a

Across any pumping system there is a complex pressure profile. This arises from many properties of the system: the throughput rate, head pressure, friction losses both inside the pump and across the system as a whole. In a centrifugal pump, for example, there is a large drop in pressure at the impeller and an increase again within its vanes (see diagram). In a positive displacement pump, the fluid’s pressure drops when it is drawn, essentially from rest, into the cylinder. The fluid’s pressure increases again when it is expelled.

If the pressure of the fluid at any point in the pump is lower than its vapour pressure, it will literally boil, forming vapour bubbles within the pump. The formation of bubbles leads to a loss in throughput and increased vibration and noise but the big danger is when the bubbles pass on into a section of the pump at higher pressure. The vapour condenses and the bubbles implode, releasing, locally, huge amounts of energy. This can be very damaging, causing severe erosion of the pump’s components.

To avoid cavitation, you need to match your pump to the fluid, system and application. This is a complex area and you are advised to discuss your application with the pump supplier.

To avoid cavitation, the pressure of the fluid must be maintained above its vapour pressure at all points as it passes through the pump. Manufacturers specify a property referred to as the Net Positive Suction Head Required or NPSH-R – this is their minimum recommended fluid inlet pressure, expressed in metres. The documentation supplied with your pump may contain charts showing how NPSH-R varies with flow.

In fact, NPSH-R is defined as the suction-side pressure at which cavitation reduces the discharge pressure by 3%. So, in designing the suction-side pipework for your system, you must ensure that it exceeds the manufacturer’s NPSH-R rating for the operating conditions. Your calculated value is termed the NPSH-Available (NPSH-A).

Remember, a manufacturer’s NPSH-R rating is the minimum recommended inlet head pressure: a pump is already experiencing cavitation at this pressure. Consequently, it is important to build in a safety margin of 0.5 to 1m to take account of this and other factors such as:

Pumps, and especially centrifugal pumps, work most efficiently when the fluid is delivered in a surge-free, smooth, laminar flow. Any form of turbulence reduces efficiency and increases wear and tear on the pump’s bearings, seals and other components.

There should be at least 5 pipe diameters’ worth of straight piping connecting to the pump. Never connect an elbow, reducer, valve, or strainer within this final run of pipework. If you connect an elbow directly to the pump flange, the fluid is effectively centrifuged towards the outer curve of the elbow and not directed into the centre (the eye) of the impeller. This creates stress on the pump’s bearings and seals which often leads to wear and premature failure.

Sometimes, it’s just not possible to make provision for a sufficient settling distance in the pipework before the pump. In these cases, use an inline flow conditioner or straightener.

It’s standard practice to employ suction-side piping one or two sizes bigger than the pump inlet - you should certainly never use any piping that is smaller than the pump’s inlet nozzle.

Small pipes result in larger friction losses, which means it costs more to run your pumping system. On the other hand, larger diameter pipes are more expensive – so you need to weigh up the increased cost with the likely energy saving resulting from reduced friction losses.

Larger pipework means that you’ll need a reducer before the pump inlet. A reducer is a constriction and requires careful design to avoid both turbulence and the creation of pockets where air or vapour might collect. The best solution is to use an eccentric reducer orientated to eliminate the possibility of air pockets.

It’s best to keep air or vapour out of the pipework. Entrained gases cause a loss in pump performance, increase noise, vibration and component wear and tear. It’s therefore important to position the feed pipe correctly in the tank or vessel. It should be fully submerged. If it’s too close to the surface of the fluid, the suction creates a vortex, drawing air (or other vapours) into the liquid and through the pumping system. The feed pipe should also be clear of any other pipes, agitators or stirrer-paddles – anything that might drive air into the fluid. In shallow tanks or ponds, it may be advisable to use a baffle arrangement to protect the feed pipe from air entrainment.

Some displacement pumps can cope with a mixed phase supply without any damage or major loss in performance. Centrifugal pumps are not so robust and must be protected from solids. In this situation you’ll need to install a filter or strainer. Filters can create a large pressure drop and be responsible for cavitation and friction-loss. The filter screen should have at least three times the free area of the pipe cross-section. Use a differential pressure gauge across the screen to look out for any increased pressure drop before clogging problems arise. This will also help in the accurate assessment of NPSH-A.

Obviously, pumps should be securely located - but so should the pipework. Don’t use one to support the other. All other components must be just as securely located and create no stresses or strains on any other parts of the system. Ensure that the pipe connecting to the pump’s inlet flange is aligned precisely with it. If you need to install non-return valves or flow control valves fit them on the discharge side of the pump, and never in suction-side pipework.

Ensure that conditions do not favour cavitation, particularly if you are using a centrifugal pump. This requires careful selection of the pump, its positioning and the head pressure.

Centrifugal pumps basically consist of a stationary pump casing and an impeller mounted on a rotating shaft. The pump casing provides a pressure boundary for the pump and contains channels to properly direct the suction and discharge flow. The pump casing has suction and discharge penetrations for the main flow path of the pump and normally has small drain and vent fittings to remove gases trapped in the pump casing or to drain the pump casing for maintenance.

Some centrifugal pumps contain diffusers. A diffuser is a set of stationary vanes that surround the impeller. The purpose of the diffuser is to increase the efficiency of the centrifugal pump by allowing a more gradual expansion and less turbulent area for the liquid to reduce in velocity. The diffuser vanes are designed in a manner that the liquid exiting the impeller will encounter an everincreasing flow area as it passes through the diffuser. This increase in flow area causes a reduction in flow velocity, converting kinetic energy into flow pressure.

Impellers of pumps are classified based on the number of points that the liquid can enter the impeller and also on the amount of webbing between the impeller blades.

Centrifugal pumps can be classified based on the manner in which fluid flows through the pump. The manner in which fluid flows through the pump is determined by the design of the pump casing and the impeller. The three types of flow through a centrifugal pump are radial flow, axial flow, and mixed flow.

A centrifugal pump with a single impeller that can develop a differential pressure of more than 150 psid between the suction and the discharge is difficult and costly to design and construct. A more economical approach to developing high pressures with a single centrifugal pump is to include multiple impellers on a common shaft within the same pump casing. Internal channels in the pump casing route the discharge of one impeller to the suction of another impeller. Figure 9 shows a diagram of the arrangement of the impellers of a four-stage pump. The water enters the pump from the top left and passes through each of the four impellers in series, going from left to right. The water goes from the volute surrounding the discharge of one impeller to the suction of the next impeller.

Centrifugal pumps vary in design and construction from simple pumps with relatively few parts to extremely complicated pumps with hundreds of individual parts. Some of the most common components found in centrifugal pumps are wearing rings, stuffing boxes, packing, and lantern rings. These components are shown in Figure 10 and described on the following pages.

Some wear or erosion will occur at the point where the impeller and the pump casing nearly come into contact. This wear is due to the erosion caused by liquid leaking through this tight clearance and other causes. As wear occurs, the clearances become larger and the rate of leakage increases. Eventually, the leakage could become unacceptably large and maintenance would be required on the pump.

To minimize the cost of pump maintenance, many centrifugal pumps are designed with wearing rings. Wearing rings are replaceable rings that are attached to the impeller and/or the pump casing to allow a small running clearance between the impeller and the pump casing without causing wear of the actual impeller or pump casing material. These wearing rings are designed to be replaced periodically during the life of a pump and prevent the more costly replacement of the impeller or the casing.

In almost all centrifugal pumps, the rotating shaft that drives the impeller penetrates the pressure boundary of the pump casing. It is important that the pump is designed properly to control the amount of liquid that leaks along the shaft at the point that the shaft penetrates the pump casing. There are many different methods of sealing the shaft penetration of the pump casing. Factors considered when choosing a method include the pressure and temperature of the fluid being pumped, the size of the pump, and the chemical and physical characteristics of the fluid being pumped.

One of the simplest types of shaft seal is the stuffing box. The stuffing box is a cylindrical space in the pump casing surrounding the shaft. Rings of packing material are placed in this space. Packing is material in the form of rings or strands that is placed in the stuffing box to form a seal to control the rate of leakage along the shaft. The packing rings are held in place by a gland. The gland is, in turn, held in place by studs with adjusting nuts. As the adjusting nuts are tightened, they move the gland in and compress the packing. This axial compression causes the packing to expand radially, forming a tight seal between the rotating shaft and the inside wall of the stuffing box.

The high speed rotation of the shaft generates a significant amount of heat as it rubs against the packing rings. If no lubrication and cooling are provided to the packing, the temperature of the packing increases to the point where damage occurs to the packing, the pump shaft, and possibly nearby pump bearings. Stuffing boxes are normally designed to allow a small amount of controlled leakage along the shaft to provide lubrication and cooling to the packing. The leakage rate can be adjusted by tightening and loosening the packing gland.

It is not always possible to use a standard stuffing box to seal the shaft of a centrifugal pump. The pump suction may be under a vacuum so that outward leakage is impossible or the fluid may be too hot to provide adequate cooling of the packing. These conditions require a modification to the standard stuffing box.

One method of adequately cooling the packing under these conditions is to include a lantern ring. A lantern ring is a perforated hollow ring located near the center of the packing box that receives relatively cool, clean liquid from either the discharge of the pump or from an external source and distributes the liquid uniformly around the shaft to provide lubrication and cooling. The fluid entering the lantern ring can cool the shaft and packing, lubricate the packing, or seal the joint between the shaft and packing against leakage of air into the pump in the event the pump suction pressure is less than that of the atmosphere.

In some situations, packing material is not adequate for sealing the shaft. One common alternative method for sealing the shaft is with mechanical seals. Mechanical seals consist of two basic parts, a rotating element attached to the pump shaft and a stationary element attached to the pump casing. Each of these elements has a highly polished sealing surface. The polished faces of the rotating and stationary elements come into contact with each other to form a seal that prevents leakage along the shaft.

A diffuser increases the efficiency of a centrifugal pump by allowing a more gradual expansion and less turbulent area for the liquid to slow as the flow area expands.

Wearing rings are replaceable rings that are attached to the impeller and/or the pump casing to allow a small running clearance between the impeller and pump casing without causing wear of the actual impeller or pump casing material.

Many centrifugal pumps are designed in a manner that allows the pump to operate continuously for months or even years. These centrifugal pumps often rely on the liquid that they are pumping to provide cooling and lubrication to the pump bearings and other internal components of the pump. If flow through the pump is stopped while the pump is still operating, the pump will no longer be adequately cooled and the pump can quickly become damaged. Pump damage can also result from pumping a liquid whose temperature is close to saturated conditions.

The flow area at the eye of the pump impeller is usually smaller than either the flow area of the pump suction piping or the flow area through the impeller vanes. When the liquid being pumped enters the eye of a centrifugal pump, the decrease in flow area results in an increase in flow velocity accompanied by a decrease in pressure. The greater the pump flow rate, the greater the pressure drop between the pump suction and the eye of the impeller. If the pressure drop is large enough, or if the temperature is high enough, the pressure drop may be sufficient to cause the liquid to flash to vapor when the local pressure falls below the saturation pressure for the fluid being pumped. Any vapor bubbles formed by the pressure drop at the eye of the impeller are swept along the impeller vanes by the flow of the fluid. When the bubbles enter a region where local pressure is greater than saturation pressure farther out the impeller vane, the vapor bubbles abruptly collapse. This process of the formation and subsequent collapse of vapor bubbles in a pump is called cavitation.

Cavitation in a centrifugal pump has a significant effect on pump performance. Cavitation degrades the performance of a pump, resulting in a fluctuating flow rate and discharge pressure. Cavitation can also be destructive to pumps internal components. When a pump cavitates, vapor bubbles form in the low pressure region directly behind the rotating impeller vanes. These vapor bubbles then move toward the oncoming impeller vane, where they collapse and cause a physical shock to the leading edge of the impeller vane. This physical shock creates small pits on the leading edge of the impeller vane. Each individual pit is microscopic in size, but the cumulative effect of millions of these pits formed over a period of hours or days can literally destroy a pump impeller. Cavitation can also cause excessive pump vibration, which could damage pump bearings, wearing rings, and seals.

A small number of centrifugal pumps are designed to operate under conditions where cavitation is unavoidable. These pumps must be specially designed and maintained to withstand the small amount of cavitation that occurs during their operation. Most centrifugal pumps are not designed to withstand sustained cavitation.

Noise is one of the indications that a centrifugal pump is cavitating. A cavitating pump can sound like a can of marbles being shaken. Other indications that can be observed from a remote operating station are fluctuating discharge pressure, flow rate, and pump motor current. Methods to stop or prevent cavitation are presented in the following paragraphs.

To avoid cavitation in centrifugal pumps, the pressure of the fluid at all points within the pump must remain above saturation pressure. The quantity used to determine if the pressure of the liquid being pumped is adequate to avoid cavitation is the net positive suction head (NPSH). The net positive suction head available (NPSHA) is the difference between the pressure at the suction of the pump and the saturation pressure for the liquid being pumped. The net positive suction head required (NPSHR) is the minimum net positive suction head necessary to avoid cavitation.

The condition that must exist to avoid cavitation is that the net positive suction head available must be greater than or equal to the net positive suction head required. This requirement can be stated mathematically as shown below.

When a centrifugal pump is taking suction from a tank or other reservoir, the pressure at the suction of the pump is the sum of the absolute pressure at the surface of the liquid in the tank plus the pressure due to the elevation difference between the surface of liquid in the tank and the pump suction less the head losses due to friction in the suction line from the tank to the pump.

If a centrifugal pump is cavitating, several changes in the system design or operation may be necessary to increase the NPSHA above the NPSHR and stop the cavitation. One method for increasing the NPSHA is to increase the pressure at the suction of the pump. For example, if a pump is taking suction from an enclosed tank, either raising the level of the liquid in the tank or increasing the pressure in the space above the liquid increases suction pressure.

It is also possible to increase the NPSHA by decreasing the temperature of the liquid being pumped. Decreasing the temperature of the liquid decreases the saturation pressure, causing NPSHA to increase. Recall from the previous module on heat exchangers that large steam condensers usually subcool the condensate to less than the saturation temperature, called condensate depression, to prevent cavitation in the condensate pumps.

If the head losses in the pump suction piping can be reduced, the NPSHA will be increased. Various methods for reducing head losses include increasing the pipe diameter, reducing the number of elbows, valves, and fittings in the pipe, and decreasing the length of the pipe.

It may also be possible to stop cavitation by reducing the NPSHR for the pump. The NPSHR is not a constant for a given pump under all conditions, but depends on certain factors. Typically, the NPSHR of a pump increases significantly as flow rate through the pump increases. Therefore, reducing the flow rate through a pump by throttling a discharge valve decreases NPSHR. NPSHR is also dependent upon pump speed. The faster the impeller of a pump rotates, the greater the NPSHR. Therefore, if the speed of a variable speed centrifugal pump is reduced, the NPSHR of the pump decreases. However, since a pump’s flow rate is most often dictated by the needs of the system on which it is connected, only limited adjustments can be made without starting additional parallel pumps, if available.

The net positive suction head required to prevent cavitation is determined through testing by the pump manufacturer and depends upon factors including type of impeller inlet, impeller design, pump flow rate, impeller rotational speed, and the type of liquid being pumped. The manufacturer typically supplies curves of NPSHR as a function of pump flow rate for a particular liquid (usually water) in the vendor manual for the pump.

For a given centrifugal pump operating at a constant speed, the flow rate through the pump is Figure 11 Centrifugal Pump Characteristic Curve dependent upon the differential pressure or head developed by the pump. The lower the pump head, the higher the flow rate. A vendor manual for a specific pump usually contains a curve of pump flow rate versus pump head called a pump characteristic curve. After a pump is installed in a system, it is usually tested to ensure that the flow rate and head of the pump are within the required specifications. A typical centrifugal pump characteristic curve is shown in Figure 11.

A centrifugal pump is dead-headed when it is operated with no flow through it, for example, with a closed discharge valve or against a seated check valve. If the discharge valve is closed and there is no other flow path available to the pump, the impeller will churn the same volume of water as it rotates in the pump casing. This will increase the temperature of the liquid (due to friction) in the pump casing to the point that it will flash to vapor. The vapor can interrupt the cooling flow to the pump’s packing and bearings, causing excessive wear and heat. If the pump is run in this condition for a significant amount of time, it will become damaged.

When a centrifugal pump is installed in a system such that it may be subjected to periodic shutoff head conditions, it is necessary to provide some means of pump protection. One method for protecting the pump from running dead-headed is to provide a recirculation line from the pump discharge line upstream of the discharge valve, back to the pump’s supply source. The recirculation line should be sized to allow enough flow through the pump to prevent overheating and damage to the pump. Protection may also be accomplished by use of an automatic flow control device.

Centrifugal pumps must also be protected from runout. Runout can lead to cavitation and can also cause overheating of the pump’s motor due to excessive currents. One method for ensuring that there is always adequate flow resistance at the pump discharge to prevent excessive flow through the pump is to place an orifice or a throttle valve immediately downstream of the pump discharge. Properly designed piping systems are very important to protect from runout.

Gas binding of a centrifugal pump is a condition where the pump casing is filled with gases or vapors to the point where the impeller is no longer able to contact enough fluid to function correctly. The impeller spins in the gas bubble, but is unable to force liquid through the pump. This can lead to cooling problems for the pump’s packing and bearings.

Centrifugal pumps are designed so that their pump casings are completely filled with liquid during pump operation. Most centrifugal pumps can still operate when a small amount of gas accumulates in the pump casing, but pumps in systems containing dissolved gases that are not designed to be self-venting should be periodically vented manually to ensure that gases do not build up in the pump casing.

Most centrifugal pumps are not self-priming. In other words, the pump casing must be filled with liquid before the pump is started, or the pump will not be able to function. If the pump casing becomes filled with vapors or gases, the pump impeller becomes gas-bound and incapable of pumping. To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. The same effect can be gained by supplying liquid to the pump suction under pressure supplied by another pump placed in the suction line.

Damage to pump impeller, bearings, wearing rings, and sealsTo avoid pump cavitation, the net positive suction head available must be greater than the net positive suction head required.

Gas binding of a centrifugal pump is a condition where the pump casing is filled with gases or vapors to the point where the impeller is no longer able to contact enough fluid to function correctly.

Centrifugal pumps are protected from runout by placing an orifice or throttle valve immediately downstream of the pump discharge and through proper piping system design.

A positive displacement pump is one in which a definite volume of liquid is delivered for each cycle of pump operation. This volume is constant regardless of the resistance to flow offered by the system the pump is in, provided the capacity of the power unit driving the pump or pump component strength limits are not exceeded. The positive displacement pump delivers liquid in separate volumes with no delivery in between, although a pump having several chambers may have an overlapping delivery among individual chambers, which minimizes this effect. The positive displacement pump differs from centrifugal pumps, which deliver a continuous flow for any given pump speed and discharge resistance.

Positive displacement pumps can be grouped into three basic categories based on their design and operation. The three groups are reciprocating pumps, rotary pumps, and diaphragm pumps.

During the suction stroke, the piston moves to the left, causing the check valve in the suction Figure 12 Reciprocating Positive Displacement Pump Operation line between the reservoir and the pump cylinder to open and admit water from the reservoir. During the discharge stroke, the piston moves to the right, seating the check valve in the suction line and opening the check valve in the discharge line. The volume of liquid moved by the pump in one cycle (one suction stroke and one discharge stroke) is equal to the change in the liquid volume of the cylinder as the piston moves from its farthest left position to its farthest right position.

Reciprocating positive displacement pumps are generally categorized in four ways: direct-acting or indirect-acting; simplex or duplex; single-acting or double-acting; and power pumps.

Some reciprocating pumps are powered by prime movers that also have reciprocating motion, such as a reciprocating pump powered by a reciprocating steam piston. The piston rod of the steam piston may be directly connected to the liquid piston of the pump or it may be indirectly connected with a beam or linkage. Direct-acting pumps have a plunger on the liquid (pump) end that is directly driven by the pump rod (also the piston rod or extension thereof) and carries the piston of the power end. Indirect-acting pumps are driven by means of a beam or linkage connected to and actuated by the power piston rod of a separate reciprocating engine.

A simplex pump, sometimes referred to as a single pump, is a pump having a single liquid (pump) cylinder. A duplex pump is the equivalent of two simplex pumps placed side by side on the same foundation.

The driving of the pistons of a duplex pump is arranged in such a manner that when one piston is on its upstroke the other piston is on its downstroke, and vice versa. This arrangement doubles the capacity of the duplex pump compared to a simplex pump of comparable design.

A single-acting pump is one that takes a suction, filling the pump cylinder on the stroke in only one direction, called the suction stroke, and then forces the liquid out of the cylinder on the return stroke, called the discharge stroke. A double-acting pump is one that, as it fills one end of the liquid cylinder, is discharging liquid from the other end of the cylinder. On the return stroke, the end of the cylinder just emptied is filled, and the end just filled is emptied. One possible arrangement for single-acting and double-acting pumps is shown in Figure 13.

Power pumps typically have high efficiency and are capable of developing very high pressures. Figure 13 Single-Acting and Double-Acting Pumps They can be driven by either electric motors or turbines. They are relatively expensive pumps and can rarely be justified on the basis of efficiency over centrifugal pumps. However, they are frequently justified over steam reciprocating pumps where continuous duty service is needed due to the high steam requirements of direct-acting steam pumps.

In general, the effective flow rate of reciprocating pumps decreases as the viscosity of the fluid being pumped increases because the speed of the pump must be reduced. In contrast to centrifugal pumps, the differential pressure generated by reciprocating pumps is independent of fluid density. It is dependent entirely on the amount of force exerted on the piston. For more information on viscosity, density, and positive displacement pump theory, refer to the handbook on Thermodynamics, Heat Transfer, and Fluid Flow.

Rotary pumps operate on the principle that a rotating vane, screw, or gear traps the liquid in the suction side of the pump casing and forces it to the discharge side of the casing. These pumps are essentially self-priming due to their capability of removing air from suction lines and producing a high suction lift. In pumps designed for systems requiring high suction lift and selfpriming features, it is essential that all clearances between rotating parts, and between rotating and stationary parts, be kept to a minimum in order to reduce slippage. Slippage is leakage of fluid from the discharge of the pump back to its suction.

Due to the close clearances in rotary pumps, it is necessary to operate these pumps at relatively low speed in order to secure reliable operation and maintain pump capacity over an extended period of time. Otherwise, the erosive action due to the high velocities of the liquid passing through the narrow clearance spaces would soon cause excessive wear and increased clearances, resulting in slippage.

There are many types of positive displacement rotary pumps, and they are normally grouped into three basic categories that include gear pumps, screw pumps, and moving vane pumps.

There are several variations of gear pumps. The simple gear pump shown in Figure 14 consists of two spur gears meshing together and revolving in opposite directions within a casing. Only a few thousandths of an inch clearance exists between the case and the gear faces and teeth extremities. Any liquid that fills the space bounded by two successive gear teeth and the case must follow along with the teeth as they revolve. When the gear teeth mesh with the teeth of the other gear, the space between the teeth is reduced, and the entrapped liquid is forced out the pump discharge pipe. As the gears revolve and the teeth disengage, the space again opens on the suction side of the pump, trapping new quantities of liquid and carrying it around the pump case to the discharge. As liquid is carried away from the suction side, a lower pressure is created, which draws liquid in through the suction line.

With the large number of teeth usually employed on the gears, the discharge is relatively smooth and continuous, with small quantities of liquid being delivered to the discharge line in rapid succession. If designed with fewer teeth, the space between the teeth is greater and the capacity increases for a given speed; however, the tendency toward a pulsating discharge increases. In all simple gear pumps, power is applied to the shaft of one of the gears, which transmits power to the driven gear through their meshing teeth.

There are no valves in the gear pump to cause friction losses as in the reciprocating pump. The high impeller velocities, with resultant friction losses, are not required as in the centrifugal pump. Therefore, the gear pump is well suited for handling viscous fluids such as fuel and lubricating oils.

There are two types of gears used in gear pumps in addition to the simple spur gear. One type is the helical gear. A helix is the curve produced when a straight line moves up or down the surface of a cylinder. The other type is the herringbone gear. A herringbone gear is composed of two helixes spiraling in different directions from the center of the gear. Spur, helical, and herringbone gears are shown in Figure 15.

The helical gear pump has advantages over the simple spur gear. In a spur gear, the entire length of the gear tooth engages at the same time. In a helical gear, the point of engagement moves along the length of the gear tooth as the gear rotates. This makes the helical gear operate with a steadier discharge pressure and fewer pulsations than a spur gear pump.

The herringbone gear pump is also a modification of the simple gear pump. Its principal difference in operation from the simple spur gear pump is that the pointed center section of the space between two teeth begins discharging before the divergent outer ends of the preceding space complete discharging. This overlapping tends to provide a steadier discharge pressure. The power transmission from the driving to the driven gear is also smoother and quieter.

The lobe type pump shown in Figure 16 is another variation of the simple gear pump. It is considered as a simple gear pump having only two or three teeth per rotor; otherwise, its operation or the explanation of the function of its parts is no different. Some designs of lobe pumps are fitted with replaceable gibs, that is, thin plates carried in grooves at the extremity of each lobe where they make contact with the casing. The gib promotes tightness and absorbs radial wear.

There are many variations in the design of the screw type positive displacement, rotary pump. The primary differences consist of the number of intermeshing screws involved, the pitch of the screws, and the general direction of fluid flow. Two common designs are the two-screw, low-pitch, double-flow pump and the three-screw, high-pitch, double-flow pump.

The complete assembly and the usual flow Figure 18 Three-Screw, High-Pitch, Screw Pump path are shown in Figure 17. Liquid is trapped at the outer end of each pair of screws. As the first space between the screw threads rotates away from the opposite screw, a one-turn, spiral-shaped quantity of liquid is enclosed when the end of the screw again meshes with the opposite screw. As the screw continues to rotate, the entrapped spiral turns of liquid slide along the cylinder toward the center discharge space while the next slug is being entrapped. Each screw functions similarly, and each pair of screws discharges an equa

8613371530291

8613371530291