mud pump concrete slab factory

More contractors are turning to foam slab jacking instead of mud jacking to lift driveways, side walks, garage floors, and even airport runways. Powerful Graco foam slab jacking pumps easily fill all underfloor cavities with expanding polyurethane foam, whereas concrete slurry often fails to fill the voids. Resettling could, therefore, happen again. But when you inject foam under pressure, all air cavities are filled permanently.

Whether you need an entirely new mudjacking system, or just new components, HMI mudjacking system components are the right choice for you. At HMI, we make it easy to build out your very own slabjacking system—fully tested by industry-leading concrete raising companies and built to last, our mudjacking components outperform the rest—this makes you more confident in your work, and more profitable as a business.

There are five main components to a mudjacking system that are needed for a complete mudjacking business: a hydraulic pump, material mixer, power drill, transportation for materials, and a concrete cutting saw.

A material mixer is absolutely essential to your mudjacking business. HMI includes mixers with the Quik Mix Pro Hopper Truck, Mini Mudjacking Trailer, and customized carrying rack.

Tip: If building your own mudjacking system, the mixer should be located where raw materials can be easily loaded in to the mixer and the contents can be dumped out of the mixer into a mudjacking pump.

Concrete cutting saws are extremely important if you need to cut sections free to allow a free floating slab to be raised. Saws can be purchased from your local dealer or home improvement store.

We’ve all noticed uneven sidewalks or cracks on a concrete driveway. Maybe you’ve even seen them on your patio or garage floor. These cracks are due to settling concrete; concrete settles naturally over time, often thanks to weak soil that expands and contracts to depend on its water level. But uneven concrete can be a dangerous trip hazard for you and your family. Even worse, replacing it can be an expensive headache.

In many cases, breaking and replacing the entire concrete slab isn’t necessary. Helitech has established a special leveling process that effectively raises sinking concrete at a third the cost of replacement.

In these cases, we use a hydraulic pressure system to insert a grout combination below the surface. Helitech offers traditional mudjacking and polyurethane concrete leveling for your concrete slab.

Mudjacking is a cost-effective concrete leveling solution that raises a concrete slab to make it level. In the mudjacking process, we pump a mixture of cement, aggregate, and water under the surface of your sunken concrete slab, which raises the concrete surface to its original level, making it look as good as new.

Mudjacking is a long-lasting and less invasive form of concrete repair than entirely replacing your concrete. This concrete lifting process won’t impact your landscaping or home.

Polyurethane concrete leveling is an even more advanced process for concrete raising and leveling. If you have concrete floors that don’t need to look flawless, mudjacking will likely work for you—think basement floors and industrial applications. But for a good-as-new look, Helitech recommends our PolyLock™ polyurethane leveling services.

Helitech’s PolyLock™ Polyurethane leveling requires fewer holes in the existing concrete and those holes are also smaller. Once these holes are placed, we use a lightweight polyurethane foam injection to raise and level concrete. The holes are then filled with cement and repaired, leaving you with a slab that looks like brand new concrete—without any of the tripping hazards.

Traditional concrete leveling services often remove and replace concrete slabs in order to perform sidewalk leveling and driveway repair work. This is a highly invasive and expensive concrete leveling process that can take a long time. That’s why Helitech recommends traditional mudjacking or polyurethane leveling. Not only are they less invasive and longer-lasting, but they’re more cost-effective too!

Now that you understand the differences between each of our concrete leveling services, it’s important to know how to spot problems with your concrete slabs so you can quickly take action.

When the concrete street outside your home or your driveway expands during hot months, it puts excess pressure on your driveway, sidewalks, and ultimately, your foundation. This is called street creep and it can cause a lot of damage, often requiring foundation repair if left unchecked for too long. Look out for these warning signs that indicate your home and the surrounding concrete is experiencing street creep:

Cracks where your driveway meets the street usually means the street is expanding up against your driveway. This expansion can push each of your driveway slabs until it reaches your house.

When cracks appear in the middle of your patio, weeds can start poking through, making your backyard look more messy than marvelous. If you’re noticing cracks in your patio, that’s the biggest sign that you could benefit from concrete leveling services—likely removing and replacing the concrete slab.

You won’t always need to entirely replace your concrete patio; if you’re experiencing soil erosion underneath the slab, we can often solve this through polyurethane leveling.

A swimming pool apron is the concrete pool deck that goes around the perimeter of an in-ground pool and it needs to be kept smooth and crack-free to protect bare feet! When you have cracks in your pool deck, water can seep in and put pressure on the walls of your pool, threatening the stability of everyone’s favorite backyard feature.

Using polyurethane leveling your sinking porch is one way to make a seriously impactful curb appeal upgrade. Keeping your porch level is crucial for safety and can keep any concrete stairs from tilting as well.

Nobody wants unsightly concrete around their home. Call us today for a free, no-obligation consultation on how Helitech’s Poly Jacking System can help heal your home.

Poor or improper compaction of the base: Failure to properly compact base materials before pouring can lead to hastened settling. The weight of the slab will further compact the base after curing and settlement can happen quickly.

Climate: The freeze and thaw cycle experienced in many regions causes the ground underneath the slab to expand when frost is present. This in turn will cause slabs to heave or raise. When the frost melts the slabs will settle and most often not to their original elevation. Slabs may become uneven resulting in trip spots. Drought often causes soil such as expansive clays to shrink causing settling issues for concrete slabs. When expansive clay soils encounter wet conditions they may swell leading to shifting concrete that needs leveling.

Erosion: Many different factors can lead to eroded base materials under concrete. Damaged water lines or sewer lines can lead to washout of base materials causing slabs to settle. Improperly placed downspouts can cause pooling of water which can lead to erosion.

Machine/Traffic Vibrations: Concrete slabs may move or settle in industrial/highway settings where movement and heavy loads are present. The vibrations from the machinery and passing traffic can lead to the base compacting and the slabs settling or slab movement.

Slab Curl/Rocking Slabs: Slab curl occurs when a relatively large section of concrete is poured. During the curing process, the top of the slab may cure slightly faster. This leads to slabs that curl and may rock and be unstable. Vibration may also causes slabs to eventually settle.

Nothing: Settled concrete is an issue that needs to be addressed, not only from an aesthetic standpoint, but most importantly from a liability standpoint. The Americans with Disabilities Act (ADA) of 1990 defines a ‘trip hazard’ as any vertical change of over 1/4 inch or more at any joint or crack. Since the ADA demands strict compliance, trip hazards represent a legal liability to clients. Cities, school districts, hospitals, private communities, shopping malls, universities, apartment complexes, and other property owners are all extremely concerned with this liability.

Grinding:This is an inexpensive option that is unattractive. Grinding exposes aggregate in the concrete which makes this unappealing. The integrity and strength of the slab is also compromised when using this method. Slabs that continue to settle after grinding cannot be raise back to original levels.

Replacement: This option is the most expensive option. It is also very time consuming. This method may lead to downtime for businesses, losses of productivity, and lost revenues. The colors will not match existing adjacent concrete.

Raising & Stabilizing: May be done with traditional mudjacking or cementitous grouting. This process utilizes a hydraulically powered pump to install a slurry mix under the slab with enough pressure to compact weak soil underneath and raise the slab. Water, fly ash, top soil, sand, clay, agricultural lime, and cement are materials used to create these slurries. This method, when used on subgrade that has already settled, adds excessive weight and may lead to resettling.

Roth Concrete Lifting Process: With polyurethane, the method for concrete raising utilizes the slab itself as a means of delivering raising, void filling, and stabilizing foam. A 5/8” hole is drilled through the slab into the subgrade. A tapered delivery port is then installed in the 5/8”hole. The injection gun, which delivers the dual component polyurethane material, is then connected to the port. Material is then injected through the port and slab. Expansion of the material occurs within seconds, compressing loose soils and raising concrete.

Raising concrete with polyurethane foam is done with incremental injections. Lifting foam will fully expand within 10-15 seconds. This allows the applicator to monitor the raise and prevents over raising the slab.

Void Filling: Concrete settling is not the only issue that foam can solve. Voids under slabs are often present in areas where wash out or excessive settling can occur.

Joint/Slab Stabilization: Slab stabilization is often required when slabs lack support, but may or may not be settled. Slabs can crack when loads exceeding its capacity are applied. Slab/joint stabilization applications require the voids to be filled to eliminate movement and offer support.

Foam specifically designed for joint/slab stabilization has a very long reaction time and minimal expansion strength. It will take longer to expand allowing for better coverage under the slab or down a joint.

Roth Concrete Lifting’sprocess and material will provide long lasting repair to sunken or moving concrete slabs in need of lifting and/or stabilization. The repair method has proven to be more cost effective for the customer and save them time in completing their repairs. Time is of the essence when considering commercial projects where productivity could be lost when replacing slabs as opposed to the process of raising them with polyurethane foam.

Roth Concrete Lifting encompasses residential, commercial, industrial, and government projects involving small walk way slabs, factory floors, airport runways and highways.

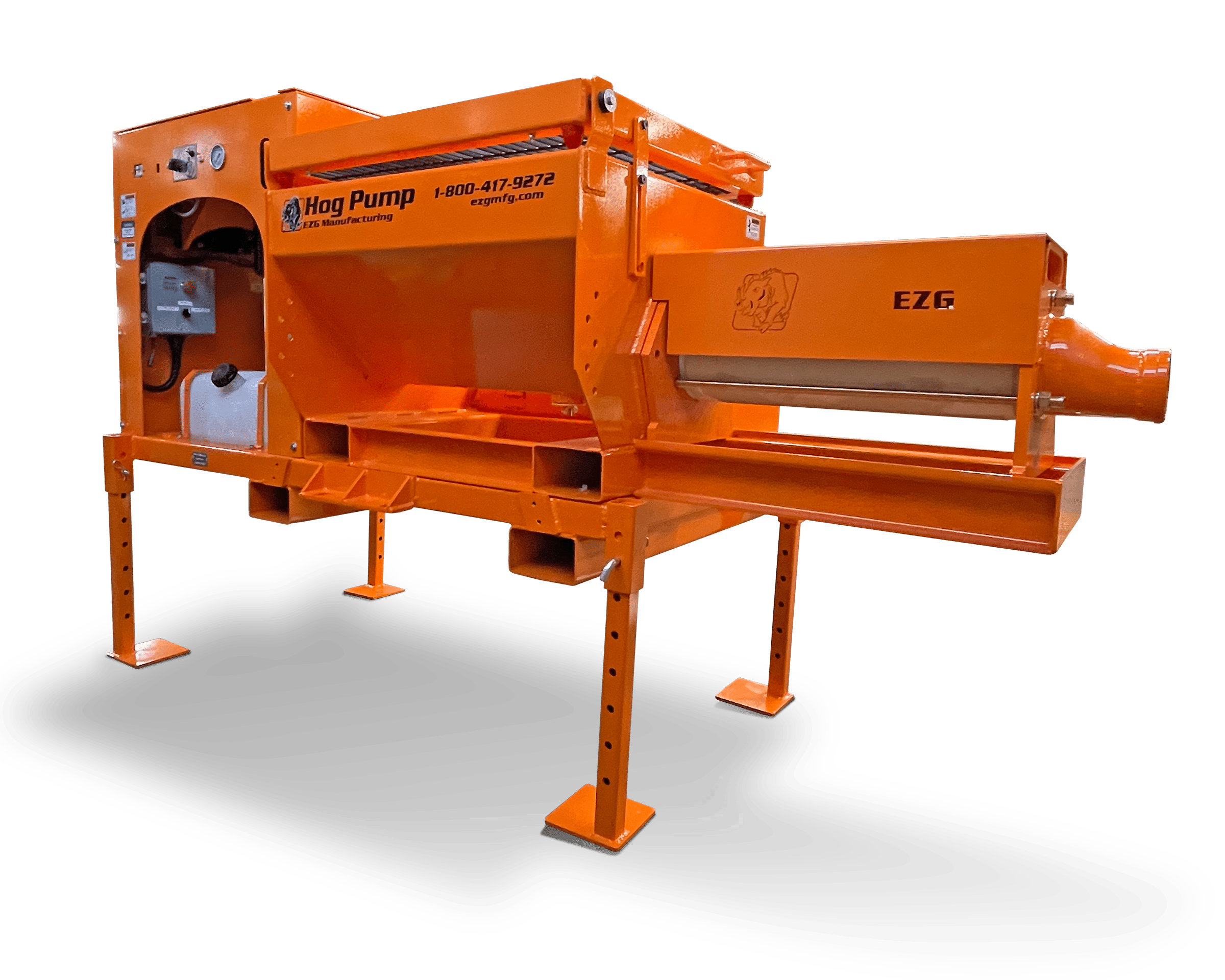

Manufacturer of concrete raising equipment & mud jacking & polyurethane accessories. Distributor of used equipment. Various products include pumps, trailers, hopper trucks, gun clamps & tips, insertion guns, breakers, hammers, drills, remote controls, bins, bits, compressors, extension cords, foam, generators, grease, hose, mixers, kits, O-rings, ports, hydraulic power-packs, ramps, reactors, rigs, electric saws, material screens, switches, tires, transmitters & workbenches. Made in USA.

HMI is proud of all its innovations and products, but perhaps the greatest innovation is the Quik Mix Pro automated volumetric hopper/mixer unit. The first fully automated unit rolled off the production line in March of 2003. This slabjacking unit, when mounted on a truck body, can carry a slab raising pump, dry material, cement, and water. Along with its unique twin shafted mixer, it can automatically mix and place material into the hopper of a pump. No shoveling is required!

Expanding beyond just the slabjacking industry, in 2008 HMI developed a revolutionary new Hydraulic Power Pack 10. With a new 2 in 1 design it offers 10,000 psi at 1 ½ gallons per minute, or 3,000 psi at 9 gallons per minute. Not only is the unit great as a seperate hydraulic power pack for running hydraulic tools (mixers and mudpumps), piering contractors can use it to install helical and resistance piers.

Hydraulic Mudpumps, Inc. is committed to future refinements and development to its product line. Our future will be determined by requests from you, our customer, and the upcoming industry demands.

Our company started with other brands of pumps and decided in the early 2000"s we needed an upgrade to a more reliable concrete pump. After shopping with different manufacturing companies, comparing prices and viewing customer comments, we were convinced that Reinert was the path we needed to follow. We now own 5 Reinert concrete pumps. We are very pleased with the quality and the service that Reinert provides.

MANITOWOC, WI – August 27, 2014 – I never would have imagined that forty years ago when I was working to pay off interest on a loan to my father-in-law for my first house by working weekends raising concrete for him, that I would soon become the owner of a world leading manufacturer of concrete raising equipment and material.

That fortuitous weekend of labor was the start of it all. The growth and innovations have followed, whether it was the invention of the first hydraulic mud pump or the introduction of polyurethane systems at the entrepreneur level.

RaiseRite Concrete Lifting, Inc. began in 1974, by myself and two others, with no money to buy our equipment so we rented it from my father-in-law. Our first truck was a 1951 Chevy flatbed, we affectionately named "Bullwinkle". By September, RaiseRite needed to add another crew to cover Green Bay.

In 1978, I knew there had to be a more efficient and less strenuous way to raise concrete, so I developed the first hydraulic mudpump. The next year, sales were well on their way as was HMI as we began manufacturing the "new" hydraulic mudjacking pumps. Today, HMI continues to manufacture mudjacking pumps and systems, polyurethane foam lifting systems, and polyurethane foam.

Monthly, HMI hosts Discovery and Training Seminars either at our Manitowoc training facility or various metropolitan areas throughout the United States. These seminars offer individuals looking to add to their existing business or start-up a business, the opportunity to experience "hands-on" how to raise concrete. As a supplier and trainer, HMI has helped put over 1200 families into business and have contributed to the employment of over 10,000 people.

I am still retaining the position of CEO, but I work side by side with my two sons: Jeff-President HMI and Brian-President of RaiseRite. Over the past 40 years, we have lifted and leveled 14,000,000 sq. ft. of concrete participating in over 70,000 projects. HMI"s equipment has lifted and leveled 240,000,000 sq. ft. of concrete on every continent, but Antarctica. I look at this anniversary not being about us at HMI/RaiseRite. It is all about you-our customers-Thank you again!

About HMI/Raise Rite: HMI/Raise Rite has two Manitowoc locations: 4803 Leonard Lane and 1025 E. Albert Dr. employing approximately 30 individuals. In addition to concrete raising, RaiseRite has a foundation piering and waterproofing division. For more information, please use the contact information and links provided below.

Slabjacking is an alternative to replacing sunken or uneven concrete, restoring sunken concrete slabs to their original grade. The name, slabjacking, (also referred to as mudjacking or pressure grouting) is the process of jacking or raising up a slab of cement and restoring it to its original level. This process can involve lifting one solid piece such as cement steps, or readjusting several pads. Slabjacking or mudjacking has been in common use for about 50 years.

Selecting the proper pump and proportioning grout are critical to success, a lesson learned in the 50-year history of slabjacking. We have a wide variety of equipment available to our customers to better solve their concrete lifting problems.

Why do slabs fail? The primary culprit is water, usually not enough, or an unequal distribution. The most common reason concrete settles is due to water causing the soil underneath to compact under the weight of the concrete and its many uses. Concentrated loads, such as buildings or slabs can literally squeeze air and water from soils. Sinking foundations, slab cracks, and foundation failures are very common.

Slab Jacking is a great alternative to removing and replacing concrete that has become a hazard, holding water or causing water to drain back toward buildings. A cracked and damaged slab can be quickly repaired. Since slabs are not being removed, there is little mess, no inconvenience or color change. The area can be used immediately after the slabs are raised (please allow 24 hours in the case of parking pads or garage floors).

Slabjacking is a cost-effective alternative to removing and replacing problem concrete. The alternative requires demolition of the existing slab, pouring new concrete and curing time. Our method allows you to walk on the surface almost immediately after work is completed. With those kinds of benefits, it’s easy to see why slabjacking has become the concrete repair method of choice when it comes to raising concrete that has settled and sunk into the ground.

In slabjacking, your contractor will pump a cement grout underneath the failing concrete slab or foundation in order to raise it up to its original level and provide it with a better sub-surface to set on. The grout is typically comprised of water, Portland cement, or lime and sand. Additives may be used to prevent shrinkage in some rare cases. The “slurry” displaces air pockets, water and water saturated materials, raises the slab and leaves a firm, permanent sub grade. This completely fills any voids, and usually allows raising the concrete to its original height. After the lifting is complete, we clean the area of excess drill tailings and grout, patch the holes with our custom color matching system.

Marco Concrete Lifting technicians have extensive experience with the slab jacking process and monitor the work carefully while in progress. More than contractors, our experts are service professionals who specialize in the field of concrete lifting (slab jacking) and foundation repair. We will be happy to schedule a free inspection and estimate. We have an excellent reputation and stand behind our work.

The Pumpmaster MJ-17 is a self-propelled grout pump designed for mudjacking/slabjacking, void fill and general pressure grouting applications. The MJ-17 features a hard-chrome long-life material cylinder, Subaru key start gasoline engine, 6 cu ft. material hopper, open throat manifold system and plunger-type piston, pivoting front axle, construction grade remote, joystick operated self-propulsion and the Airplaco exclusive hydraulic flow control valve.

Built from over 60 years of manufacturing experience and on-the-job mudjacking experience, the Airplaco PumpMaster MJ-17 is one of the most durable pumps available in the industry and is backed by superior customer service. Airplaco offers the PumpMaster MJ-17 slabjack / mudjack pump as part of an all-in-one trailer–for details call 630-766-3498

In the time it takes you to read this sentence, the global building industry will have poured more than 19,000 bathtubs of concrete. By the time you are halfway through this article, the volume would fill the Albert Hall and spill out into Hyde Park. In a day it would be almost the size of China’s Three Gorges Dam. In a single year, there is enough to patio over every hill, dale, nook and cranny in England.

After water, concrete is the most widely used substance on Earth. If the cement industry were a country, it would be the third largest carbon dioxide emitter in the world with up to 2.8bn tonnes, surpassed only by China and the US.

Concrete is how we try to tame nature. Our slabs protect us from the elements. They keep the rain from our heads, the cold from our bones and the mud from our feet. But they also entomb vast tracts of fertile soil, constipate rivers, choke habitats and – acting as a rock-hard second skin – desensitise us from what is happening outside our urban fortresses.

Our blue and green world is becoming greyer by the second. By one calculation, we may have already passed the point where concrete outweighs the combined carbon mass of every tree, bush and shrub on the planet. Our built environment is, in these terms, outgrowing the natural one. Unlike the natural world, however, it does not actually grow. Instead, its chief quality is to harden and then degrade, extremely slowly.Q&A

Our species is addicted to concrete. We use more of it than anything else except water. Like that other manmade wonder material, plastic, concrete transformed construction and advanced human health. But, as with plastic, we are only now waking up to its dangers.

Concrete causes up to 8% of global CO2 emissions; if it were a country it would be the world"s worst culprit after the US and China. It fills our rubbish dumps, overheats our cities, causes floods that kills thousands of people – and fundamentally changes our relationship to the planet.

Can we kick our addiction, when it"s so hard to imagine modern life without it? In this series of articles, Concrete Week will explore the impact of the material on our environment and us, and look at alternative options for the future.

All the plastic produced over the past 60 years amounts to 8bn tonnes. The cement industry pumps out more than that every two years. But though the problem is bigger than plastic, it is generally seen as less severe. Concrete is not derived from fossil fuels. It is not being found in the stomachs of whales and seagulls. Doctors aren’t discovering traces of it in our blood. Nor do we see it tangled in oak trees or contributing to subterranean fatbergs. We know where we are with concrete. Or to be more precise, we know where it is going: nowhere. Which is exactly why we have come to rely on it.

This solidity, of course, is what humankind yearns for. Concrete is beloved for its weight and endurance. That is why it serves as the foundation of modern life, holding time, nature, the elements and entropy at bay. When combined with steel, it is the material that ensures our dams don’t burst, our tower blocks don’t fall, our roads don’t buckle and our electricity grid remains connected.

It also magnifies the extreme weather it shelters us from. Taking in all stages of production, concrete is said to be responsible for 4-8% of the world’s CO2. Among materials, only coal, oil and gas are a greater source of greenhouse gases. Half of concrete’s CO2 emissions are created during the manufacture of clinker, the most-energy intensive part of the cement-making process.

But other environmental impacts are far less well understood. Concrete is a thirsty behemoth, sucking up almost a 10th of the world’s industrial water use. This often strains supplies for drinking and irrigation, because 75% of this consumption is in drought and water-stressed regions. In cities, concrete also adds to the heat-island effect by absorbing the warmth of the sun and trapping gases from car exhausts and air-conditioner units – though it is, at least, better than darker asphalt.

This touches on the most severe, but least understood, impact of concrete, which is that it destroys natural infrastructure without replacing the ecological functions that humanity depends on for fertilisation, pollination, flood control, oxygen production and water purification.

Concrete can take our civilisation upwards, up to 163 storeys high in the case of the Burj Khalifa skyscraper in Dubai, creating living space out of the air. But it also pushes the human footprint outwards, sprawling across fertile topsoil and choking habitats. The biodiversity crisis – which many scientists believe to be as much of a threat as climate chaos – is driven primarily by the conversion of wilderness to agriculture, industrial estates and residential blocks.

For hundreds of years, humanity has been willing to accept this environmental downside in return for the undoubted benefits of concrete. But the balance may now be tilting in the other direction.

The Pantheon and Colosseum in Rome are testament to the durability of concrete, which is a composite of sand, aggregate (usually gravel or stones) and water mixed with a lime-based, kiln-baked binder. The modern industrialised form of the binder – Portland cement – was patented as a form of “artificial stone” in 1824 by Joseph Aspdin in Leeds. This was later combined with steel rods or mesh to create reinforced concrete, the basis for art deco skyscrapers such as the Empire State Building.

Rivers of it were poured after the second world war, when concrete offered an inexpensive and simple way to rebuild cities devastated by bombing. This was the period of brutalist architects such as Le Corbusier, followed by the futuristic, free-flowing curves of Oscar Niemeyer and the elegant lines of Tadao Ando – not to mention an ever-growing legion of dams, bridges, ports, city halls, university campuses, shopping centres and uniformly grim car parks. In 1950, cement production was equal to that of steel; in the years since, it has increased 25-fold, more than three times as fast as its metallic construction partner.

Debate about the aesthetics has tended to polarise between traditionalists like Prince Charles, who condemned Owen Luder’s brutalist Tricorn Centre as a “mildewed lump of elephant droppings”, and modernists who saw concrete as a means of making style, size and strength affordable for the masses.

The politics of concrete are less divisive, but more corrosive. The main problem here is inertia. Once this material binds politicians, bureaucrats and construction companies, the resulting nexus is almost impossible to budge. Party leaders need the donations and kickbacks from building firms to get elected, state planners need more projects to maintain economic growth, and construction bosses need more contracts to keep money rolling in, staff employed and political influence high. Hence the self-perpetuating political enthusiasm for environmentally and socially dubious infrastructure projects and cement-fests like the Olympics, the World Cup and international exhibitions.

But there is only so much concrete you can usefully lay without ruining the environment. The ever-diminishing returns were made apparent in the 1990s, when even the most creative politicians struggled to justify the government’s stimulus spending packages. This was a period of extraordinarily expensive bridges to sparsely inhabited regions, multi-lane roads between tiny rural communities, cementing over the few remaining natural riverbanks, and pouring ever greater volumes of concrete into the sea walls that were supposed to protect 40% of the Japanese coastline.

In his book Dogs and Demons, the author and longtime Japanese resident Alex Kerr laments the cementing over of riverbanks and hillsides in the name of flood and mudslide prevention. Runaway government-subsidised construction projects, he told an interviewer, “have wreaked untold damage on mountains, rivers, streams, lakes, wetlands, everywhere — and it goes on at a heightened pace. That is the reality of modern Japan, and the numbers are staggering.”

He said the amount of concrete laid per square metre in Japan is 30 times the amount in America, and that the volume is almost exactly the same. “So we’re talking about a country the size of California laying the same amount of concrete [as the entire US]. Multiply America’s strip malls and urban sprawl by 30 to get a sense of what’s going on in Japan.”

Construction firms were once again ordered to hold back the sea, this time with even taller, thicker barriers. Their value is contested. Engineers claim these 12-metre-high walls of concrete will stop or at least slow future tsunamis, but locals have heard such promises before. The area these defences protect is also of lower human worth now the land has been largely depopulated and filled with paddy fields and fish farms. Environmentalists say mangrove forests could provide a far cheaper buffer. Tellingly, even many tsunami-scarred locals hate the concrete between them and the ocean.

There was an inevitability about this. Across the world, concrete has become synonymous with development. In theory, the laudable goal of human progress is measured by a series of economic and social indicators, such as life-expectancy, infant mortality and education levels. But to political leaders, by far the most important metric is gross domestic product, a measure of economic activity that, more often than not, is treated as a calculation of economic size. GDP is how governments assess their weight in the world. And nothing bulks up a country like concrete.

That is true of all countries at some stage. During their early stages of development, heavyweight construction projects are beneficial like a boxer putting on muscle. But for already mature economies, it is harmful like an aged athlete pumping ever stronger steroids to ever less effect. During the 1997-98 Asian financial crisis, Keynesian economic advisers told the Japanese government the best way to stimulate GDP growth was to dig a hole in the ground and fill it. Preferably with cement. The bigger the hole, the better. This meant profits and jobs. Of course, it is much easier to mobilise a nation to do something that improves people’s lives, but either way concrete is likely to be part of the arrangement. This was the thinking behind Roosevelt’s New Deal in the 1930s, which is celebrated in the US as a recession-busting national project but might also be described as the biggest ever concrete-pouring exercise up until that point. The Hoover Dam alone required 3.3m cubic metres, then a world record. Construction firms claimed it would outlast human civilisation.

But that was lightweight compared to what is now happening in China, the concrete superpower of the 21st century and the greatest illustration of how the material transforms a culture (a civilisation intertwined with nature) into an economy (a production unit obsessed by GDP statistics). Beijing’s extraordinarily rapid rise from developing nation to superpower-in-waiting has required mountains of cement, beaches of sand and lakes of water. The speed at which these materials are being mixed is perhaps the most astonishing statistic of the modern age: since 2003, China has poured more cement every three years than the US managed in the entire 20th century.

Today, China uses almost half the world’s concrete. The property sector – roads, bridges, railways, urban development and other cement-and-steel projects – accounted for a third of its economy’s expansion in 2017. Every major city has a floor-sized scale model of urban development plans that has to be constantly updated as small white plastic models are turned into mega-malls, housing complexes and concrete towers.

Yu has led the charge against concrete, ripping it up whenever possible to restore riverbanks and natural vegetation. In his influential book The Art of Survival, he warns that China has moved dangerously far from Taoist ideals of harmony with nature. “The urbanisation process we follow today is a path to death,” he has said.

Yu has been consulted by government officials, who are increasingly aware of the brittleness of the current Chinese model of growth. But their scope for movement is limited. The initial momentum of a concrete economy is always followed by inertia in concrete politics. The president has promised a shift of economic focus away from belching heavy industries and towards high-tech production in order to create a “beautiful country” and an “ecological civilisation”, and the government is now trying to wind down from the biggest construction boom in human history, but Xi cannot let the construction sector simply fade away, because it employs more than 55 million workers – almost the entire population of the UK. Instead, China is doing what countless other nations have done, exporting its environmental stress and excess capacity overseas.

This will almost certainly mean more criminal activity. As well as being the primary vehicle for super-charged national building, the construction industry is also the widest channel for bribes. In many countries, the correlation is so strong, people see it as an index: the more concrete, the more corruption.

This was followed by a new highway through the Amazon rainforest – the TransAmazonia – and then from 1970, South America’s biggest hydroelectric power plant, the Itaipu on the Paraná river border with Paraguay, which is almost four times bulkier than the Hoover Dam. The Brazilian operators boast the 12.3m cubic metres of concrete would be enough to fill 210 Maracanã stadiums. This was a world record until China’s Three Gorges Dam choked the Yangtze with 27.2m cubic metres.

Such corruption is not just a theft of tax revenue, it is a motivation for environmental crime: billions of tonnes of CO2 pumped into the atmosphere for projects of dubious social value and often pushed through – as in the case of Belo Monte – against the opposition of affected local residents and with deep concerns among environmental licensing authorities.

Although the dangers are increasingly apparent, this pattern continues to repeat itself. India and Indonesia are just entering their high-concrete phase of development. Over the next 40 years, the newly built floor area in the world is expected to double. Some of that will bring health benefits. The environmental scientist Vaclav Smil estimates the replacement of mud floors with concrete in the world’s poorest homes could cut parasitic diseases by nearly 80%. But each wheelbarrow of concrete also tips the world closer to ecological collapse.

Architects believe the answer is to make buildings leaner and, when possible, to use other materials, such as cross-laminated timber. It is time to move out of the “concrete age” and stop thinking primarily about how a building looks, said Anthony Thistleton.

“Concrete is beautiful and versatile but, unfortunately, it ticks all the boxes in terms of environmental degradation,” he told the Architects Journal. “We have a responsibility to think about all the materials we are using and their wider impact.”

But many engineers argue that there is no viable alternative. Steel, asphalt and plasterboard are more energy intensive than concrete. The world’s forests are already being depleted at an alarming rate even without a surge in extra demand for timber.

Instead, he calls for existing structures to be better maintained and conserved, and, when that is not possible, to enhance recycling. Currently most concrete goes to landfill sites or is crushed and reused as aggregate. This could be done more efficiently, Purnell said, if slabs were embedded with identification tags that would allow the material to be matched with demand. His colleagues at Leeds University are also exploring alternatives to Portland cement. Different mixes can reduce the carbon footprint of a binder by up to two-thirds, they say.

Arguably more important still is a change of mindset away from a developmental model that replaces living landscapes with built environments and nature-based cultures with data-driven economies. That requires tackling power structures that have been built on concrete, and recognising that fertility is a more reliable base for growth than solidity.

Guardian Concrete Week investigates the shocking impact of concrete on the modern world. Follow Guardian Cities on Twitter, Facebook and Instagram and use the hashtag #GuardianConcreteWeek to join the discussion or sign up for our weekly newsletter

When a homeowner begins to look into the problem of foundation damage, several questions usually arise. At some point, the term “Mud Pumping” is likely to come up. But what is it, and is it necessary?

Getting the facts is vital to making wise decisions for your home. Foundation damage largely results from changes in soil moisture that causes soil movement under your home’s foundation. When this shrinking and swelling of clay soil occurs repeatedly over time, the strain placed on the concrete slab leads to damage to both the foundation and the home. When the foundation is damaged, gaps and voids can be created under your home, and mud pumping is a part of the repair process.

Repairing the concrete slab foundation involves supporting and leveling the slab. Most of the focus, rightly so, is on the foundation. When portions of that slab have cracked and collapsed (settlement) they must be raised and supported, and often a substantial void is created between the bottom of the foundation and the soil. This is now an open air pocket under the foundation and nothing is supporting the majority of the foundation above. If repair efforts are stopped with the slab only, the repaired and leveled foundation will have to “bridge” these voids with no support. A residential concrete slab foundation was never designed to function as a bridge. Foundations are engineered to rest on level soil. Mud pumping fills these voids by pumping a mixture of soil and cement – “mud” – under the newly leveled foundation. Both the foundation support system and the voids must be addressed to ensure that your home is secure and stabilized.

Most foundation repair companies will NOT complete the job with mud pumping, and it’s important to insist on this step for your home. Mud pumping is expensive for the repair company, as the machinery involved is more expensive than any other equipment in the repair process. There are additional elements of time needed to perform the mud pumping, too. And, the homeowner may be asked to take certain protective steps like turning on flowing water, running washing machines, etc. to avoid clogging in the pipes. However, mud pumping will avoid additional repair needs at a later time, and it is well worth the extra time and investment. Many companies will try to suggest that this is an optional service, but that would be a mistake. It may be a bit more time consuming to complete the job, but an incomplete foundation repair makes little sense when so much is at stake in your home.

8613371530291

8613371530291