mud pump concrete slab quotation

Mudjacking costs $3 to $6 per square foot, and foam jacking is $5 to $25 per square foot. The average cost of slabjacking to raise a concrete slab is between $511 and $1,790, with most spending $830. Concrete leveling prices depend on the size and condition of the slab and soil conditions.

Concrete settling or sagging is normal, especially when it"s old. Some foundation issues can be serious and lead to additional damage if not fixed right away. Concrete slab leveling is an inexpensive and quick way to fix uneven concrete and add structural support to a foundation.

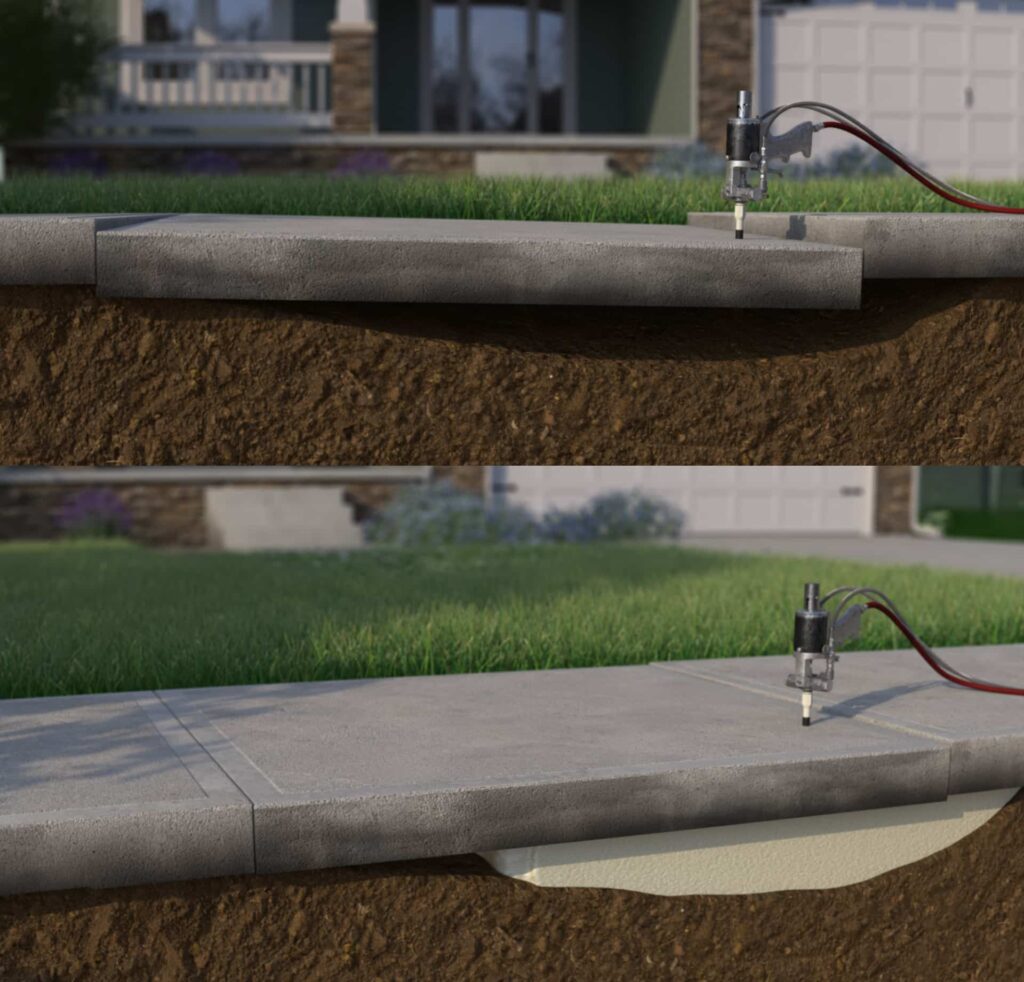

The two main options to raise concrete are mudjacking and foam leveling. Each has considerable differences and is better suited for specific areas. Mudjacking requires larger holes drilled and costs $3 to $6 per square foot, while the stronger polyurethane foam runs $5 to $25 per square foot.

Mudjacking is a method of lifting a sunken concrete slab by pumping a mud-like mixture under the concrete to make it level again. Mudjacking, also known as "slab jacking" or "concrete leveling," is a quick and cost-effective way to level sinking concrete foundations, sidewalks, patios, and driveways.

The mudjacking process starts by strategically drilling holes 1” to 2” wide and injecting material to fill any voids under the slab, raising the sagging concrete within minutes. Mudjacking is eco-friendly, cures in 24 to 48-hours, and typically costs 25% to 50% less than concrete replacement.

Foam jacking, also known as "polyfoam" or "polyjacking," is a modern version of mudjacking that levels concrete slabs in a less invasive way. High-density polyurethane foam is injected into ⅝” holes that expand to lift and level the sunken concrete. Polyfoam is stronger and longer-lasting than traditional mudjacking.

Concrete leveling foam cures in 30 minutes, is mold and water-resistant, is not subject to erosion, and provides 6,000 to 14,000 lbs. per square foot of support. However, it"s more expensive than mudjacking.

Mudjacking costs $3 to $6 per square foot, while polyurethane foam jacking or PolyLevel runs $5 to $25 per square foot on average. Larger, thicker structures such as porches are more costly per square foot than simple slabs like sidewalks.

The warning signs to level your concrete are not always apparent. Cracked, sinking concrete is the main sign of a poorly compacted subsoil, erosion from water leaks, animals tunneling underground, or other structural issues that require leveling.

Mudjacking works for most situations, although the thick mud may not get into every crack, and the subsoil could sink again over time. One solution is to drill more holes, which increases the invasiveness and limits the effectiveness.

Mudjacking may not be the best option for load-bearing parts of the foundation or if your concrete is severely cracked. Consider using stronger polyfoam or an alternative repair option if:

Concrete leveling typically costs $500 to $1,800, with most homeowners spending $800 on average. The cost to level a concrete floor is 25% to 50% less than concrete slab replacement. Prices depend on the size of the slab, the amount of concrete damage, and underlying soil conditions.

Repairing a foundation with foam jacking costs $10,000 to $25,000 and up or from $5 and $25 per square foot, depending on the foam type and amount used. Leveling an uneven slab foundation with mudjacking costs $4,500 to $9,000, although mud pumping is weaker and less stable than foam.

Estimates to level a concrete slab foundation vary drastically depending on subsoil conditions, excavation costs, and because it’s difficult to determine the volume of gaps below the surface until after the work begins.

Mudjacking a small section of a driveway costs $600 to $1,200 on average. The average cost to level an entire driveway is $1,400 to $2,700 for mudjacking, and between $3,000 and $7,000 for lifting with high-density polyurethane foam.

Driveways typically sink when downspouts pour water next to the slab, or if rebar was not used to reinforce the concrete. Also, concrete settles when builders use inadequately filled and uncompacted soil, or if rotting roots were left underground that decompose to make gaps.

The average cost of mudjacking 2 to 4 sections of a garage floor is $300 to $900. Raising an entire 2-car garage floor costs $1,100 to $2,200 for mudjacking or between $2,500 and $5,400 for foam injection. Mudjacking a garage floor is cheaper than repouring new concrete or using a self-leveling compound.

Identifying the root cause that made the garage floor sink is vital. If you have a steep slope against the side of the garage where the subsoil has eroded, then you may need steel-jacking or structural foundation repairs with piers instead of mudjacking.

The average cost to level an 800-square-foot basement floor is $2,400 to $4,800 with mudjacking, or between $5,000 and $12,000 with foam jacking. Mudjacking a basement floor is advised for gaps of a few inches between the bottom of the walls and floor—where nails and insulation are visible.

In these cases, the concrete raising is performed from inside the basement. Leveling a basement floor or crawl space is not recommended if the walls are showing further structural damage.

The average cost to mudjack a concrete patio is $450 to $900, or from $3 to $6 per square foot depending on the extent of the damage. Raising a concrete patio slab costs about half as much a pouring a new concrete slab and only takes a few hours.

The average cost of mudjacking a 30" long sidewalk is $300 to $800, or about $50 per section. Sidewalk leveling next to trees, bushes, driveways, or patios costs more and takes extra time due to limited access. Empty voids under the walkway more than a couple of inches deep cost extra.

As long as contractors fix the underlying structural problems that caused the slab to sink, mudjacked sidewalks can last for 20 years. Mudjacking is advised against old walkways due to a higher risk of damage.

Mudjacking concrete steps costs $200 to $400 or about $300 to $800 for foam jacking a 20 to 40 square foot stoop. Mudjacking is typically half the price of completely replacing the steps.

Leveling concrete steps may require drilling through the surrounding slab and sidewalk areas. Otherwise, hydraulic levers raise the steps from the sides, and the slurry or foam is pumped in directly underneath.

Mudjacking a 400-square-foot pool deck costs $1,200 to $2,400 on average or between $2,800 to $6,000 when using concrete leveling foam. Poly foam is excellent for pool decks since it’s the best erosion and water-resistant material. Contractors should know that excessive fill materials in the wrong places could damage underground piping systems leading to the pool.

Slab jacking costs depend on the size of the concrete slab, the method of slabjacking, excavation requirements, soil conditions, the extent of concrete damage, and the quality and amount of fill materials needed.

Any water drainage issues, lack of gutters, large trees, or plumbing leaks that caused the concrete to sink must be mitigated before mudjacking to ensure long term results.

Using per-square-foot estimates of a concrete surface area doesn’t factor in the material depth. If burrowing animals dug tunnels under the concrete, there could be an extra 30 feet of holes in the ground which require filling.

Reputable mudjacking companies use an electronic elevation survey, or a Ground Penetrating Radar Scanning (GPR) system to inspect the subsoil and measure the cavity size before estimating and drilling. GPR provides a more accurate estimate and helps professionals avoid in-floor obstacles such as plumbing and wiring.

Mudjacking fill can contain cement, limestone, clay, or sand-based grout. The materials used dictate the weight-bearing capacity and longevity. Low-quality slurry that’s mostly mud and sand doesn"t last as long. Ask your contractor for a high-quality fill that maintains the concrete elevation longer.

Concrete lifting foam comes in various types, each with different prices and weight-bearing capacities. Contractors use a high-density polyurethane foam that’s much stronger than the spray foam used for insulating homes.

Mudjacking fill contains water, which can cause the concrete slab to shift while curing. Once the mudjacking fill is fully dry, it contracts slightly, making it less stable than polyurethane lifting foam.

Heavy mudjacking fill material adds a burden to a poorly compacted subgrade, which can cause the slab to sink again. However, polyjacked slabs rarely sink again.

Significant foundation repairs cost between $2,300 and $6,750, depending on the extent of the damage and type of fix. Not every concrete repair requires leveling. Here are additional methods to consider.

Pouring a new concrete slab costs between $7 and $16 per square foot, which includes old slab demolition, and is recommended for major issues where damage is beyond repair.

After any method of repair, ask contractors to apply a weatherproof concrete sealant to prevent further sinking and cracking as the slab goes through freezing and thawing cycles.

Sand pumping costs $3 to $7 per square foot or between $550 to $1,000 to level a 12" x 12" concrete driveway slab. Sandjacking costs about 50% less than installing a new slab. Sandjacking is a variation of mudjacking that uses dry limestone sand to lift concrete slabs.

Sandjacking is typically noninvasive and doesn"t require drilling holes through the slab if the fill can be pumped in from under the sides. Sandjacking is recommended in areas where the soil is often wet. The fill compacts more and allows for better drainage. Sandjacking has no curing time and is ready to use right away.

PolyLevel costs about $15 per square foot or around 30% to 40% more than standard mudjacking. PolyLevel is a patented, high-density polyurethane foam used for heavy-duty concrete stabilization projects like home foundation and driveway work. This polyfoam cures in as few as 30 minutes.

Building permit requirements depend on local homeowner laws and the size of your project. Most concrete installation projects at or above grade level do not need permits. In some places, only licensed contractors may do any residential concrete work that costs more than $200.

Mudjacking lasts 5 to 10 years on average, depending on the subsoil base below. PolyLevel foam doesn’t break down like mud fill and lasts much longer. Still, both mudjacking and polyjacking can sink without a stabilized subsoil. Contractors should work to prevent future subsoil erosion to increase longevity.

Mudjacking can lift between 6,000 and 14,000 pounds per square foot, depending on the type of foam used. These polyurethane foams are stronger than bedrock and provide more than enough support for most homes and slabs.

Mudjacking is used successfully to level foundations with a relatively noninvasive procedure. Mudjacking only requires several 1” to 2” holes to be drilled into the foundation without damaging the surrounding landscape. This technique costs half as much as removing and replacing your existing foundation.

The average concrete leveling project is completed in one day or less. Mudjacking a small concrete pad takes around 5 hours, and leveling a sunken basement takes about 30 hours. Mudjacking takes anywhere from a few hours to a few days to cure, depending on the project"s size.

Most insurance policies exclude coverage for mudjacking, foundation cracking, or a house sinking. Homeowner’s insurance typically covers foundation damage due to natural disasters or other issues such as plumbing. For new homes under warranty, the builder may be responsible for mudjacking expenses.

DIY concrete leveling projects are possible for concrete slabs 4 square feet or less. Anything larger requires an experienced contractor with mudjacking equipment. Concrete slabs of all sizes are extremely heavy. Without adequate weight-bearing equipment and careful preparation, you risk breaking the slab.

Concrete leveling foam kits cost $50 to $700 and are suitable for small concrete crack-filling repairs. This method is only a cosmetic solution and doesn’t raise or level the concrete. Foam kits are epoxy or polyurethane mixes that are applied with a caulking gun to hide the appearance of cracks.

Some DIY enthusiasts try to level concrete with spray polyurethane foam insulation kits; however, polyfoam insulation doesn"t have the strength to bear the weight of concrete, people, or cars.

Self-leveling concrete costs $1 to $5 per square foot if you install it yourself, which is about half the price of mudjacking. Only pour self-leveling cement on slabs that have sunken an inch or less, and avoid using it on basement floors.

Using a self-leveling compound requires experience since it’s challenging to repair if the installation goes wrong. Be sure to fix the erosion or foundation problems that initially caused your concrete to sink before installing.

For small concrete slabs of 4 square feet or less that aren’t cracked, minor raising and leveling is possible using a system of fulcrum blocks. You can hoist the slab up with industrial sized clamps attached to a 4x4 beam while supporting the concrete with two car jacks underneath it.

After propping up the concrete, fill the ground underneath with 1 to 2-inch size gravel or Foamular 250 insulation sheathing, a high-density foam board designed to bear the weight of smaller residential slabs.

When using gravel, fill the hole at least one inch above ground level since the weight of the slab will likely compact it. Spraying water into the gravel makes it settle down farther if the slab is too high. Use fill dirt, pea gravel, or sod to seal the edges around the slab.

Most areas don"t have mudjacking pump rentals available for the general public because local laws require a contractor’s license. New foam and mudjacking equipment costs $4,000 to $10,000. The mud slurry fill, power drills, and extension hoses are sold separately.

Polyjacking equipment generally has an extra heating component to warm the fill up to 90°F before sending it through the high-pressure pump that combines the poly-spray with a special hardening agent right inside the nozzle.

Mudjacking is an equipment-intensive project that requires a specialized professional. Be sure your contractor has up to date licensing, insurance, and bonding before signing a contract. Insurance is necessary to protect you accidental property damage or injuries that may occur.

Check their online reviews and experience. The best mudjacking companies have at least 5 years of experience with great reviews on HomeGuide and Google.

Don"t let contractors overcharge by purposely overestimating the amount of fill. They may not refund the balance if they use less filler. Polyurethane pumps have a gauge that tracks the amount of foam pumped. Check the gauge before they start and after they finish, and compare with the pricing in the contract.

The greatest advantage to raising and leveling concrete with polyurethane foam compared to replacement is cost. While the price for each job varies, a good rule of thumb is that raising and leveling concrete is usually around 50%-80% less than cost of replacement! So in example a typical $4,000 concrete driveway replacement may cost around $800 – $2,000 to raise and level. Keep reading to get a better idea of what your concrete project may cost.

To give you a more realistic understanding of the average price for raising concrete here are some typical projects and average costs for each. Understand that these are just to give you a ballpark range to get a general idea. Most concrete lifting companies have minimum starting prices that can be anywhere from $400 – $1,500 depending on the area, time of year and how busy the company is.

Also, concrete that can be a challenge to lift such as slabs that require saw cutting or the use of jacks or concrete with lots of cracks can be tricky to lift and the price may reflect that extra time required.

A common issue we see are patios sinking along the foundation causing water to drain towards the home – not good. Raising three 8’ x 8’ sections of patio along the home up 2” would cost around $850- $1,200. Along with concrete raising, there are other improvements you can do to fix-up your patio. Here is a good example of a complete patio make-over on this St Charles raising and repair project. Here is another patio raised and repaired in Naperville.

The size of the slab and the amount needed to be lifted are the main factors that determine price. Since there are fixed costs to each job no matter how big it is, such as travel and set-up, larger projects will cost less per square foot than smaller ones. A single section of sidewalk may cost $250-$450 to raise. Whereas that same section may only cost $60 if it’s completed with 10 other sections. Also, the location of the raising project can affect what you pay. You may pay less if you are closer to the contractors shop or other jobs they have. Finally, the difficulty of the job will impact the price. Slabs that are hard to reach or have many cracks will take longer and cost more.

Lastly, most reputable concrete raising companies have job minimum requirements to cover travel time, set-up and clean-up. We have seen most minimums around $450 -$950. So if you have a small job such as a singe walkway section to raise it will typically cost you what the minimum is, unless you can bundle your job with a neighbor.

Be skeptical of contractors who don’t specify the type of material they will be injecting below the concrete or are very vague about it. Materials such as sand, cement, and limestone will reduce the cost of the job but the repair may not last long. Ensure that only geotechnical polyurethane specifically engineered for raising concrete is being used. Anyone who tries to sell anything else and claims it’s the best is either misinformed or being dishonest. Read more about why polyurethane is the best here: polyurethane vs mudjacking

Some concrete leveling companies will charge additional fees if the project requires more polyurethane than what was estimated. There is nothing wrong with this practice assuming the company was realistic with the original estimate and the additional fees are fair. Unfortunately that’s not always the case and some companies attract customers with low estimates and later charge excessive amounts based on “extra material” that was needed. A $600 patio leveling project can turn into a $900 project to complete.

Its can be tempting to save a few bucks and go with the lowest quote on a concrete leveling project. However, if the company doing the work only offers a 1-2 year warranty or no warranty at all, those saving will be short lived if the work will need to be redone a few years later. Make sure to read and understand the terms and conditions of the warranty to ensure your investment will last.

To prevent your concrete from settling again, the cracks and gaps around the raised sections need to be sealed with a high quality sealant. Crack and Joint repair is typically not included as part of the standard raising process. Never assume its part of the job. If its not listed, its most likely not included. Learn more about crack and joint repair.

If you are still reading then you can see that giving a standard price for concrete lifting services can be difficult and the only true way to know is to have a professional concrete raising contractor visit your home to inspect the concrete in person to determine the price. We at Concrete Hero typically wont give a price over the phone for this reason.

In all of these cases, the concrete is in good shape and not crumbling or cracked all over the place. The surfaces have just sunken, tilted, or sloped the wrong way slowly over time. These scenarios are all fixable ones that could be corrected with some type of concrete repair service.

Two common methods of concrete repair that would fix these problems are mud jacking and polyjacking. At Anchor Foundation Repair, we have been repairing concrete driveways, sidewalks, patios, parking lots, and more for decades in the Bryan/College Station Area.

We’ve done some polyjacking in the past, but are currently only offering mud jacking for concrete repair services. We recognize that there is value in both choices at different times. This article will compare mud jacking and polyjacking by reviewing their basic materials, installation processes, and features, as well as the cost of each repair type.

Part of our mission is to impartially educate and inform Brazos Valley homeowners about the available foundation and concrete repair services and choices in the community. We share this info in a fair and equal manner so that you can decide which one might be right for you.

Sure, you could just break up and remove the whole piece of problem concrete and replace it with newly poured concrete. But that would be the most expensive, time-consuming, and intrusive thing to do. Full replacement of concrete might not even be necessary with this duo of less costly choices on the market. *Enter mud jacking and polyjacking to the rescue*

The first thing that is the same about both of these repair types is that they are better than pouring brand new concrete for a few reasons. Both are less costly, faster, and less of a production than a full replacement.Okay, I guess that’s three things . . .

A related similarity between the two is that they are both less wasteful and more eco-conscious than a full replacement. Each method aims to preserve the concrete rather than “throwing it away” and starting over, creating the need for new materials. Getting rid of a big chunk of concrete will take up space in a landfill somewhere too if they don’t recycle it.

Another similarity between these two methods is in the name, but really it’s in the concept of how this repair works. Notice the word “jacking” appears in both concrete repair types? *Not a coincidence*

They both use the idea of lifting or moving as if with a jack i.e. to jack up a car to change a flat tire. In both cases, the “jack” is not a metal tool that comes in the trunk of your car, but a material that is pumped underneath the concrete slab that lifts the surface back into position.

So, mud jacking and polyjacking use the same basic principle of lifting from underneath to complete the repair, but this is where the similarities end.

Here are some basics about what material is used in mud jacking, the installation process, key features of the method, and estimated costs so that we can begin to make comparisons.

The “mud” in mud jacking is actually not mud but something else, sort of like mud but not so sticky. In the construction industry, the liquid-like substance is called slurry. *Terminology alert* Slurry is not a sweet and frosty treat in a cup, like the kind you get at Sonic® or Dairy Queen®. I know . . . bummer.

The slurry is a flowing mix ofPortland Cement, topsoil, and water that is combined to form a fluid that can be pumped through a hose. Not only does slurry lift the concrete surface from underneath, but this substance also fills in all the voids and pockets of space in the ground under the surface, and then hardens when dry for solid support.

A contractor will drill 2-inch holes in strategic locations into the sunken concrete surface and a nozzle is then inserted into the holes. The liquid-like slurry is pumped into the holes through to the ground under the concrete and slowly lifts the surface from underneath. The crew will continually check for the proper elevation of the slab and then patch the hole with concrete when done.

Mud jacking fills open spaces and voids under the concrete surfaces thoroughly by its very nature. Filling the voids completely is what ultimately lifts the section of concrete and creates strength in the cured slurry. The mud jacking material is heavy and strong on its horizontal surface, so it can withstand heavy objects moving across it like cars and trucks.

Mud jacking material is permeable to water and can be subject to erosion BUT due to its weight, compression, and ability to fill voids, it prevents water from getting under the repair surface with these qualities.

Mud jacking is better for larger repair jobs than smaller ones as there is more mobilization work to get the project started. It might take a little longer and a bit more work to get started, but most typical jobs are done in one half to one full day.

Another reason that mud jacking is better for larger repair jobs than smaller ones is because of material costs. Since slurry is made with cement mix, topsoil, and water, it’s not very expensive stuff. Larger jobs will require lots of material for the “jacking” process so it makes sense that lower supply costs would be beneficial.

You probably really want something more “concrete” as far as pricingis concerned. We are here to help with well-placed puns and also the information in this chart outlining approximate costs for basic, average, and extensive mud jacking repair work.

In a nutshell, a basic mud jacking project with one or two concrete panels needing repair would cost around $1,600. An average-sized mud jacking repair falls in the $2,700 range, and an extensive repair that includes the entire driveway could be up to $7,000 or more.

Polyjacking is different from mud jacking in the materials used, the installation process, key features of the method, and of course the cost. This section outlines the basics of polyjacking.

Just a note on the word “polyjacking”– it’s not an official dictionary word but more of an industry inducted term that has many variations that all mean the same thing. Whether it’s called polyjacking, poly jacking, poly-jacking, polyfoam injection, poly leveling, or polyurethane concrete raising: it’s all the same thing.

Like mud jacking material, it can also be “cut” with a sharp shovel concentrated at one point, and can also withstand heavy loads moving across it and won’t crumble under weight-distributed vertical compression. Polyjacking is frequently used in highway and major roadway repair because of its sustained strength and quick application.

A contractor will drill⅝” holes in strategic locations into the sunken concrete surface and a nozzle is then inserted and clamped in place into the holes. The polyfoam is injected into the holes through to the ground under the concrete and slowly lifts the surface up from underneath. The crew will continually check for the proper elevation of the slab and then patch the hole with concrete when done.

While it is impermeable to water and will last forever because of that, it does not fill up every tiny crevice under a concrete slab so there can still be erosional effects on the soil from any water moving underneath this repair. The foam won’t erode, but the dirt still can.

Polyjacking is very strong and installs and cures quickly. It is great for fine applications where much control is needed to lift a section of concrete with precision, think of the small hole that lets basic school glue out of the bottle vs. a tube of toothpaste.

This method is great for smaller projects because it has super-fast prep time and the work can be handled by just a couple of guys. They can be in and out in a few hours with little mess or cleanup. Another big plus for homeowners is that the size of the holes needed for this process is much smaller than they are for mud jacking.

Because it is a proprietary chemical mix of ingredients, the cost is higher than the basic concrete/soil mix of mud jacking. When projects get very large, the costs can exceed comparable mud jacking jobs because of the big difference in materials cost. Polyjacking might save money in labor costs but adds to the expense in materials.

So far, we know that concrete repair costs can vary depending on the method chosen. Mud jacking and polyjacking are the most popular techniques used in raising concrete flat-work surfaces around your home back to their original position.

The charts in this article show that mud jacking costs range from $1,600 to $7,000 depending on the extent of repairs needed. Polyjacking costs start at around $900 for a basic job up to $7,500 for extensive needs. We mentioned that both of these repair types are more cost-effective than a full replacement of concrete surfaces.

You can see that the pricing for full replacements is significantly higher than either of the repair methods we are talking about here, with a base cost of $4,500, average-sized project cost of $7,500, and full driveway replacement cost of $18,000. The cost of full replacement can be around three times as much as mud jacking.

Mud jacking and polyjacking each use different materials, installation processes, and have key qualities that make them viable choices. Both are good options if you would like to repair and reuse your concrete surfaces rather than ripping everything out and starting over. Either way, you will save money over a full replacement.

We understand and see the merits of both choices in concrete repair and there are no bad service decisions to be made here but here’s a few guidelines.

For smaller jobs or instances where you are very concerned about the size of the installation holes, polyjacking is the way to go. For more extensive work like whole driveways, or parking lots, mud jacking would be a better option. For medium sized projects, you can’t go wrong with either method, so go with whichever is cheaper or the contractor you like better.“Both methods are amazing services and fantastic tools to easily, inexpensively, and efficiently restore the evenness and functionality of all your concrete flat-work surfaces. It’s hard to pick sometimes even for me.” Craig Tripp – Anchor Foundation Repair Owner, President, CEO, and Foundation Repair Extraordinaire

We did ultimately pick a side though. We see value in polyjacking, and have tried it out in the past and may try it out again in the future. But for now, the concrete repair method we provide to the community is mud jacking.

Not once have we had to go back out and redo our mud jacking work due to further erosion under the slab. So, we feel confident about what this method can do to prolong the good life of your concrete surfaces and stand by mud jacking’s fine qualities.

Rather than just relying on the estimates presented in this article, would you like to get a formal and firm bid on repairing your driveway or other concrete flat-work surfaces around your home? Please reach out to us using our Contact Form and ask for Mud Jacking services from Anchor Foundation Repair.

Concrete isn’t a single material; it’s a mixture of cement, water, and an aggregate material such as sand or gravel. The strength of concrete, also called its grade, depends on the ratio of these ingredients and is measured with numbers ranging from M5 to M70. Concrete mix with a grade of M10 to M25 is typically strong enough for residential use and less expensive than higher grades. (Higher numbers are used in large-scale commercial projects).

The word “grade” can also refer to concrete poured over an incline, like for a driveway that goes up a hill. A concrete contractor may charge more if the incline is steep since working with heavy machinery on a slope can be difficult. Your cost will also be higher if the ground grade needs to be increased or lowered before pouring the concrete.

Concrete is quite versatile. It can be stained, stamped, or sealed to create a variety of appearances, though this will cost more than pouring basic concrete. Stain or dye to change the concrete’s color costs an additional $3.50–$7.50 per square foot. Stamping a design such as tiles or cobblestones into the wet concrete costs $10–$14 per square foot, though more elaborate designs and engraving can cost $18–$20 per square foot. A smooth epoxy finish or a weather-resistant concrete sealer will each add about $4.50 per square foot.

The $4–$8 per square foot average usually includes professional labor at about $50 per hour. However, some projects require extra labor. For example, if you’re replacing an old concrete pad, it will need to be demolished and removed before the new concrete is poured. This can cost anywhere from $500–$1,800. You may also need to hire a pump truck for about $900 if the concrete needs to be poured in an area that’s difficult to access.

Depending on how much your new concrete slab will change your yard’s layout, you may need to hire a landscaping service to move or replace trees, shrubs, or turf. Many landscapers can also change the incline of the subgrade soil surface if necessary. These services can cost up to $200 per hour for design and implementation.

Additional materials are usually needed for slabs that hold a great deal of weight, particularly concrete foundations. Wire mesh ($0.35 per square foot) and steel rebar ($2–$3 per square foot) both add strength, particularly when the ground underneath the concrete is poor. Additionally, some home improvement projects require reinforced concrete slabs with thicker edges that can hold more weight. These edges add $1–$2 per square foot. Chemical additives also increase the strength of the concrete mixture itself.

Finally, house foundation costs are higher than other concrete slab projects because most require a 2-inch styrofoam under-slab insulation layer at the cost of $0.50– $2 per square foot. Adding a vapor barrier to keep moisture out is also a good idea, which adds about $0.50 per square foot.

Concrete is a highly durable material that can expand and contract with changing temperatures, but excessive weight, shifting soil, and obstacles such as tree roots can create cracks over time. It may be possible to repair an existing concrete slab in some cases. For example, a driveway or walkway with cracks or chips in only the top layer can sometimes beresurfacedrather than entirely replaced. Cracks may cost between $500 and $2,500 to repair, and driveway resurfacing can cost anywhere from $1–$10 per square foot.

Looking to spruce up your backyard with a nice patio? Want a sturdy foundation for your next tool shed? Consider having a concrete slab as your base. Concrete slabs are inexpensive, long-lasting and easy to install—as well as multi-purpose.

Note: For the sake of this cost estimate, exact dimensions (in feet) have been given to reflect the different price points. Costs may be lower or higher depending on the size of the slab. All costs have been calculated at a rate of $6 per square foot.

A concrete slab is composed of wet cement mixed with additional materials (usually gravel). This mix is poured onto a gravel bed bordered by a wooden frame, the latter typically made from standard lumber like 2x4s or 2x6s. Once the concrete has cured, this frame—also known as the formwork—is removed, leaving behind a fully shaped piece of concrete—the slab.

Concrete slabs are known for being extremely durable. If properly installed and maintained, they can easily last 100 years or more. Though the name “slab” brings to mind an uninteresting flat gray surface, in truth, concrete slabs offer a lot of design flexibility—from the shape of the formwork to any texturizing or colorizing done after the concrete has been poured.

As a reminder, cement and concrete refer to two different types of material despite often being used interchangeably. Concrete is a composite substance that includes cement and is more durable.

Concrete is fairly inexpensive when compared with other materials like stone or brick. Expect to pay a base cost of around $6 per square foot for the material itself, or within a range of $4 to $8 per square foot depending on factors like labor and concrete thickness.

A standard concrete slab will typically be four or six inches thick, but this can be adjusted depending on the needs of your project. Thickness is key in determining the final cost of the project: the thicker the slab, the more expensive it will be. A four-inch slab, for example, can cost anything from $0.50 to $1 less than a six-inch slab.

It may be necessary to make the edge of your concrete slab thicker, depending on the end design and function of the slab itself. The weight of the concrete is also a factor here, since you do not want the frame buckling under the pour. Expect to pay an additional $1 to $2 per square foot.

If you aren’t fond of the classic concrete slab look, there are a variety of texturizing and colorizing options that you can use to finish your slab. Adding any kind of finish and design—whether it be stenciling, staining or engraving—can bump up your final cost from $8 to $18 per square foot. If you desire a fully bespoke or advanced design, you may pay even more.

For the most part, the typical price range of $4 to $8 per square foot includes labor. However, if your project requires the use of specialized equipment—such as any machines needed for grading—the cost can skyrocket. For example, a single pump truck (used to pour concrete if your build location is too difficult for a standard concrete truck to access) can tack on around $900. Keep this in mind especially if you are doing a DIY install, since you will need to rent or buy any equipment you do not have.

Depending on your specifications or contractor recommendations, your project may require the use of additional materials. Things like a vapor barrier, a Styrofoam layer or using wire mesh will add between $0.30 to $2 per square foot. When mixing concrete, you may also be charged extra if you require more cement than normal.

Dirt work and grading refers to any preparation of the substrate that needs to occur before laying the formwork and pouring the concrete. This can be as simple as leveling the surface, or as complicated as consulting with a structural engineer on how to build the slab on a slope. Some contractors will include grading in their services at no additional cost, but this is highly dependent on the complexity of the site and its requirements.

With careful planning and preparation, it is entirely possible to install a simple concrete slab by yourself. The process is time and labor intensive, so set aside at least a week to complete it—which should cover everything from preparing the form to allowing the concrete to set and cure. Keep in mind that while the installation itself is relatively straightforward, there are lots of little factors and steps that may make the process more hassle than it’s worth.

Details like permit requirements, leveling and grading the sub-surface, properly staking and bracing the frame and smoothing the concrete after it has been poured can all affect the final build of your slab. Any finishing you want to do should also be thoroughly researched so that you do not apply a finish too early or late in the curing process.

Wet concrete is also considered toxic and can cause chemical burns, so take the appropriate safety precautions to make sure that you are not exposing your skin and eyes.

More contractors are turning to foam slab jacking instead of mud jacking to lift driveways, side walks, garage floors, and even airport runways. Powerful Graco foam slab jacking pumps easily fill all underfloor cavities with expanding polyurethane foam, whereas concrete slurry often fails to fill the voids. Resettling could, therefore, happen again. But when you inject foam under pressure, all air cavities are filled permanently.

We then clean the surface and place foam plugs in the holes as needed. The holes are then patched with a special concrete mix, and your concrete is ready to use.

Scritchlow Concrete Lifting and Slab Jacking specializes in raising your concrete. It"s what we do. Concrete settling and sinking is quite common. It occurs when the soil, at the time of installation, was not compacted properly, or when water runoff is not channeled properly. While this can be prevented up front, not all contractors follow proper compaction steps. Scritchlow Concrete Raising and Slab Jacking was started to help

Sunken, settled, and uneven concrete slabs are not uncommon in Ohio.Mudjackingandpolyjacking are two common concrete leveling solutions for property owners looking for an alternative to costly replacement. Is one concrete leveling method better than the other? Let’s compare mudjacking vs. polyjacking.

Mudjacking is a concrete leveling method that pumps mud under a building, driveway or other sunken concrete to lift it. A specialized hydraulic pump pushes the mud mix into holes drilled in the slabs.

Mr. Level considers mudjacking the “Flintstones” approach to concrete leveling. With mudjacking, your sunken concrete is drilled with dime-size holes, pumped with mud and then the mud hardens up. To support the lifted concrete, mudjacking relies on underlying soils, which are impacted by the same elements that lead to cracking and sinking, so contractors are not able to guarantee the work.

Recently, we were hired to come in and correct a mudjacking job. In this video, you can see the product they used to pump the uneven patio hardened up, and the slab ended up back in its old sunken state. The mudjacking product distorted the property and rendered the patio unusable.

An alternative concrete leveling option, polyjacking uses polyurethane foam in place of mud. We call this the “Jetsons” approach. The foam expands after filling the holes drilled in the concrete slab. As the polyurethane expands, the concrete is lifted.

Mr. Level uses polyurethane foam to raise concrete, fill voids and stabilize soil. By drilling a 5/8” hole (about the size of a thumbnail) into the concrete slab, we’re able to install a tapered delivery port into the same hole. The injection gun is connected to the port, delivering the polyurethane through the port and slab. Within seconds, the polyurethane expands, compressing loose soils and raising concrete. Polyurethane causes a chemical reaction with underlying soils that stabilizes the soil and concrete, so it doesn’t fracture or fail. This method proves longer lasting, which is why Mr. Level is able to offer a lifetime guarantee on our services.

The job (pictured above) would have cost $4,500 to replace it. For a fraction of the cost, Mr. Level was able to repair it using polyurethane concrete leveling.

Ready to put these two concrete leveling methods to the test? See how mudjacking andpolyjackingcompare in terms of appearance, longevity, environmental friendliness, and price.

With polyurethane, fewer and smaller holes (an inch smaller, to be exact) are drilled into the concrete slabs. Compare that to the much larger and more numerous holes required for mudjacking. Ultimately, polyjacking results in a cleaner, more polished final product. Additionally, fewer resources and heavy equipment are required, so the job site is neater, the surrounding landscape isn’t damaged, and the disruption

Polyurethane is fast compared to mudjacking. Polyurethane foam cures in minutes, so it’s ready to be walked and driven on right away. Mudjacking, on the other hand, can take 24 to 72 hours to cure and allow for foot traffic on the lifted concrete. This is not only inconvenient but can cause hurt commercial owners who rely on their parking lots for business.

Mudjacking relies on underlying soils to support the lifted concrete. Heaving from a dramatic freeze and thaw cycle or settling from decaying tree roots or water damage can cause the underlying soils to shift and crack your concrete. There’s no guarantee your concrete will remain smooth and level with mudjacking.

With polyurethane, however, the chemical reaction with the soil causes the foam to harden, so it doesn’t fail. This stabilizes the soil and concrete, so your concrete should last a lifetime.

Polyjacking is hydrophobic, meaning that the polyurethane can be used underwater or in wet conditions. The foam-like material creates a moisture barrier that is resistant to water penetration. This can not only keep your concrete level but can also help prevent water from leaking into your home or building. Mudjacking, which as previously discussed can shift, doesn’t offer any water resistance to protect your concrete or structure.

Settled concrete is often the result of poor soil conditions under the slab. You’ll want a lightweight material, so you don’t further burden the already weak soil. Mudjacking typically weighs 100 lbs. per cubic foot, whereas polyurethane is far more lightweight, weighing only 2 to 4 lbs. per cubic foot.

The cost of mudjacking runs cheap compared to polyurethane. However, because there is no warranty or guarantee your concrete will remain leveled, you’ll likely need to pay to repeat the process.

Uneven concrete is not only unattractive but can also be harmful to pedestrians and your vehicles. Not to mention, neglected, uneven concrete will only worsen over time, meaning more money to repair and more structural and safety issues to address.

Raise your concrete the right way the first time around. Contact Mr. Level today for more information on our polyurethane concrete leveling services or to get a free quote.

Mudjacking is the process of raising and leveling sunken or settled concrete as near to its original position as possible. Sidewalks, driveways and garage floors can become cracked and unleveled due to factors such as soil erosion, freezing and thawing beneath the slabs, shifts in tectonic plates and other various conditions that cause the ground beneath concrete to settle, sink or otherwise deteriorate. To raise the existing concrete, our team drills a series of 1 inch holes around the fissures and then pumps a slurry material beneath the cracked concrete slab. This process allows us to position the raised concrete correctly and add patching material via the drilled holes between the sunken ground and the existing concrete. Once the patch has hardened, the leveled and realigned concrete will be as stable as the other surrounding slabs.

Our services will save you time as well. Mudjacking projects are usually completed within a single day as opposed to the lengthy process of replacing damaged concrete. It involves considerably less mess and will not disturb your landscaping.

We offer a two year limited warranty on all concrete raising and leveling services along with crack sealing services to ensure the longevity of your mudjacking project.

Whether you have damaged driveways, sidewalks, pool decks, basement or garage floors, concrete stairways or foundations, one phone call to M&S Mudjacking will provide you with a quick, affordable and effective fix to any concrete problem. Schedule your consultation today! 309-281-7267

Mudjacking, also referred to as slabjacking or muckjacking, is the process of raising concrete slabs by hydraulically pumping a grout mixture, usually sand-based material infused with cement, under the slab of concrete. This is the more classic way of repairing a sinking concrete slab, but recently the process of polyjacking is gaining popularity in the industry. The mudjacking process has been perfected over many years of use and we can use it to effectively level you sinking, sloping, or settling concrete slabs. Whether it is a sidewalk, your driveway, a patio, or even a garage slab, mudjacking can restore the slabs to their original position.

Mudjacking is a very straightforward process and our team can quickly begin working on your sinking slabs to get them back to a safe height and position. Our mudjacking process is below.

Conventional concrete lifting uses a fairly simple process that is similar whether you are using foam or mud: drill, pump, patch. See the table below for a comparison between the two processes.

2. PumpInsert ports and inject a two-part foam in a liquid state which subsequently creates a foam pillow to lift the concrete.Insert hose and use pressure from the mud pump to create lift directly beneath and adjacent to the drilled port.

Aesthetically, the hole size for poly foam lifting is much smaller than that of mudjacking. In stamped concrete or tile floor applications, a 3/8” port can be used and is drilled in the grout lines to better hide the patches.

Unsurprisingly, poly foam is much lighter than mud used in the mudjacking process. In situations where the soil bearing capacity is already marginal, poly foam minimizes additional weight and can also be used to perform deep foamjection to increase soil bearing capacity using the same holes.

As you can see, mud fills the void in a conical shape and doesn’t spread as far (depending on the consistency of the slurry mixture mixed by the operator). Because the foam travels in its liquid form and then makes foam, a much more complete lift and support matrix is created.

Poly foam’s biggest enemy is the sun. It does not do well against UV light. However, there is a severe absence of sun beneath your concrete, making it an extremely reliable solution for lifting concrete! It does very well in the presence of all environmental conditions beneath a slab, including water, which erodes mud! Now consider the presence of water and how it erodes dirt. The lack of resistance to water is one of the downfalls of mudjacking. Not only will the adjacent soils erode, but the mud itself will also erode in the presence of water.

Remember that no soils stand the test of time in the presence of water. Water puts soil particles in suspension and carries them away ever so slowly. For this reason, proper maintenance of your concrete is very important. Keep all open cracks/joints properly sealed, and keep all slabs properly backfilled. Anytime you can see the bottom of a slab, future problems are inevitable.

Poly foam is widely understood to be more expensive than mud-jacking. As discussed in this article, there are technical tradeoffs that influence someone to use one process over the other.

This company was recommended by a friend. I had him do two projects for me, my personal patio and my Mom"s slab floor in her family room. My patio came out as promised and was very satisified. The true test for this company was with my Mom"s family room slab, the settlement of the concrete pad also did extensive damage to her fireplace. The company representative came out multiple times to ensure the job could be completed as promised. I asked for his insurance documents, his agent had them emailed to me before the end of the same business day. The job came out phenominal, above and beyond our expectations (wish I could show before and after photo"s). I am very confident in recommending this company to anyone needing this type of work.

Will I save money by mudjacking instead of replacing the concrete?Absolutely! Most mudjacking services cost half, if not a third, as much as replacing concrete.

Why has my concrete sunken / no longer level?Mother nature can do a number on the soil and ground beneath your concrete. Over time, soil settles, erosion happens, and nature takes its toll, causing your once level concrete to shift and settle. It’s a totally natural occurrence, and it’s most prevalent in areas of the country where there is an annual freeze-thaw cycle, like St. Louis. Through this shifting of earth, your concrete may sink, raise, and even crack. The good news is that mudjacking can help level your concrete once again.

There is a “void” in my concrete. What does that mean?A void is an empty space under the concrete caused by water eroding the soil. This can lead to buckling, cracking, or settling of the concrete above.

Are rodents a reason why my concrete cracks and buckles?They certainly could be. Some rodents, like groundhogs, dig tunnels that can cause the concrete above to buckle, crack or settle.

Should I just replace my concrete instead of mudjacking it?Tearing out and replacing concrete slabs/patios/floors can be very expensive – usually far more than the cost of mudjacking. Mudjacking also takes a much shorter amount of time to complete. Once we’re done mudjacking, you’ll be able to walk on the area also immediately – no waiting for concrete to dry. And it’s a much less messy process than new concrete work.

How long does mudjacking take?Depending on the mudjacking service, you can expect mudjacking to take anywhere from 1 hour to most of the day. However, once finished, you can immediately walk on the concrete that has been fixed.

Do I have to be home while you mudjack?If the slabs you need mudjacked are on the exterior of your home, then, no, you don’t need to be home. We can fix sidewalks, patios, etc, while you’re away. However, if you need a slab in your garage or other interior area mudjacked, then we’ll need you there.

What exactly is the mudjacking process?If you are wondering how we fix uneven concrete, check out our What is Mudjacking page to see a video of how it works.

Why should I do choose concrete leveling instead of just replacing my concrete?If your concrete is not heavily cracked, concrete leveling will be about 1/2 to 1/3 less expensive than replacing the concrete. You will also save time and hassle by choosing concrete leveling. The process usually takes a couple of hours instead of several days, and you can drive or walk on the surface within hours rather than waiting a day or two for concrete to dry.

Will there be a lot of noise? What about dust and debris?Mudjacking pumps make about as much noise as a lawnmower. In terms of dust and debris, part of the process involves drilling small holes, which may make some dust. Occasionally, concrete needs to be sawed, which can make a lot of dust. If you’d like to manage the amount of dust, water can be used during this process.

Will mudjacking cause damage to my yard or sprinklers?In most situations, you will not see any damage from the mudjacking process. However, if your yard is wet and soft or sprinklers are running, there may be small ruts created by the pump.

Could my concrete crack during the mudjacking process?It is possible that your concrete will crack when being moved into place during the mudjacking process. Some concrete, when sunken, gets small cracks on the bottom that are not necessarily visible. When moved, this crack could become larger. However, these cracks are not caused by mudjacking. If you useexperienced, professional mudjackerswho use the correct process, cracking is highly unlikely.

Will any patched holes match the current concrete?Probably not, unless your concrete is new. Newer concrete is lighter, meaning the patched holes will probably match it better. Older concrete will be darker than the new patching, but that will darken to match over time.

What problems might I experience if I decide to mudjack?If you hire a mudjacking company that does not use the correct methods, your concrete may crack. That’s whySt Louis Mudjackingis a great choice!

Mudjacking is an alternative to replacing concrete. We drill holes in the existing concrete slab and use a sand slurry mixture to raise the existing slab back to its original elevation. It normally costs significantly less that concrete replacement and can fix a host of problems, including drainage issues, trip hazards, steps that are too big and many other liabilities.

Our slurry is a specially prepared blend of several types of earth that is the densest fill material we can get our hands on. It is denser than the existing ground on which your concrete sits and is ideal for the mudjacking application.

When mudjacking first started, it was thought that adding concrete improved the quality of the job. This has actually been proven false as the industry has developed over the years. The single most important part of mudjacking is to completely fill the voids under a slab in order to stabilize it. Adding concrete to the slurry mix actually increases the drag as the slurry travels under the concrete. This in turn means the slurry doesn’t flow as well and, as a result, doesn’t fill the voids as well. A straight sand, slurry mix with no concrete added actually flows much better under the slab resulting in a complete fill of voids under the slab which insure a better job that will last longer.

While it varies based on the size of the job, virtually all residential jobs can be complete in a day or less. Mudjacking is a relatively quick process and the area is ready for immediate use again. The only exception being areas on which cars park (garage floors and driveways). We ask the customers keep their cars off of these areas until the next morning. Having said this, you will not hurt the work if you MUST drive your car on it immediately afterwards – we simply tell customers the day as an added precaution.

We start by drilling a series of holes in the concrete with a rock drill. After mixing up our mud slurry (the consistency of it is determined by the requirements of each individual job), we load it into our pump and then use large mud hose and something called “the wand” to pump the mud into the holes we have drilled and underneath the slab. As the slurry is pumped in, the slab slowly begins to rise. We continue this until the slab is at its proper elevation. After the slab has been raised, we wash everything down and then plug the holes we cement.

The most important step in raising concrete is not the actually raising of the slab. Instead, the critical component is making sure all the voids under the concrete are filled after it has been raised. This includes the voids that were present before the slab was raised, as well as, any voids created during the raising process. Too many contractors doing our work will raise the slab on pillars or columns of material (whether a traditional slurry or the newer poly foam products) and leave voids in between these columns. Imagine holes that are 5 feet apart with 18” diameter pillars underneath them, for example. There will be a large void, or cavity, between these pillars that is not filled in. A job that is done like this (i.e. raised but not stabilized) will fail. To insure a job that lasts, a contractor must not only raise the slab but also fill the voids created during the raising process.

We drive a full size semi-truck with a big box on the back that carries 10 yards of material. We also have a 30 foot equipment trail hooked up behind. The full rig is almost 60 feet long and carries twice as much material as anyone else doing this work. All that material insure that we always have enough material to not only raise your concrete but make sure that all the voids are filled, the single most critical step to a complete, lasting mudjacking job.

Yes, we do! If your concrete has a void, cavity or empty space under it, but has not yet sunk, one of the best things you can do is get that void filled. This way you will get a solid support underneath it to insure that it does not sink in the future.

As patios, walkways, driveways, and concrete steps sink, they can crack and create uneven surfaces. Sinking concrete is unsightly, and it can create a tripping hazard.

Mud jacking involves pumping a mortar-based mixture of "mud" or "slurry" underneath a settling slab. This injected material is a mixture of water, soil, sand, and Portland cement that cures to become a solid, stable fill.

As the mixture is pumped underneath the concrete slab, it fills all empty spaces and creates pressure on the slab that lifts the surface upwards. Once injected, the slurry will then harden into a solid fill that"s more stable than the soil, yet lighter than concrete.

Ayers Basement Systems offers a fast, effective, and less invasive approach to concrete leveling with PolyLevel®. The PolyLevel® system involves injecting an expanding polymer foam under the concrete for a durable, long-lasting solution. If you"re interested in learning about what PolyLevel® can do for you, call us for a free estimate in Lansing, Grand Rapids, Kalamazoo, and nearby.

Mud jacking is effective for heavier concrete structures when used in conjunction with slab piers. It should not be considered as a standalone solution to lifting a footing or floor slab that has settled in your home.

In most cases, mud jacking alone will not be able to lift both a slab and the heavy partition walls that sit on top of it. In cases where mud jacking isn"t effective, we often recommend installing slab piers instead.

More importantly, this kind of solution is temporary. Even with the voids filled, the soil below is likely to continue settling over time. Ultimately, you"d have to call your contractor to your home over and over again to repeat the mud jacking process -- or call someone who can use a different solution that can fix it once and for all!

Mud jacking is also not appropriate as a "do-it-yourself" repair. Mud jacking requires special equipment and professional experience. All work should be done through a trained, professional mud jacking contractor who has excellent knowledge of local soil conditions.

Ayers Basement Systems is Michigan"s trusted concrete leveling contractor. Schedu

8613371530291

8613371530291