mud pump crane brands

The Mount Wilson Solar Observatory was first funded by the Carnegie Institution of Washington in 1904. The site is an astronomical observatory in Los Angeles, California and contains two historically important telescopes: the 60-inch Hale telescope built in 1908 and the 100-inch Hooker telescope. The facility is used for astronomical research and offers visitors guided tours. In 1911, A Deming Triplex pump with a 15 HP motor was installed to supply the pressure for the fire hydrant system. It operated continuously for an estimated 50 years until an entire system upgrade in the 1960’s obsoleted the pump. In 2008, there was a need for a backup firefighting unit while the new system was being serviced. The 1911 Deming Triplex pump was resurrected for the application. After routine servicing the pump operated without any issues. The Deming brand was the first pump line manufactured by Crane Pumps & Systems and offers a full line of highly regarded municipal and industrial pumps today.

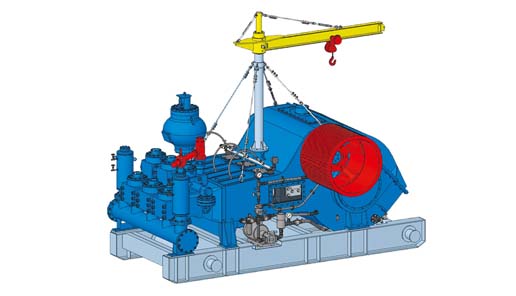

Why APPI:Drilling mud is hard on pumps as it’s both viscous and caustic. For manufacturers, this means it needs to be quick and easy to access pumps that require repair or replacement.

When Brandon Westenberg, owner of Portable Mud Systems, specified a pump for one of his mud systems he matched it with one of our HF4700 AC electric mud pump hoists with an optional strap to do the lifting.

It is mounted on a beam that goes over the pump and has epoxy based paint with stainless steel fasteners to help protect it from the elements – including the mud being slung on the jobsite.

Allied Power Products, Inc. has specialized in providing winches, hoists, capstans and cranes to meet our customers’ specific application requirements for more than 30 years.

Our First Mate, Ensign 500, and Commander 500 portable davit cranes with capacities of 500–850 lbs are recommended for lifts under 1,000 lbs. Each of these models will provide users with features such as extra hook height, streamlined set-up/disassembly, ergonomic operation, and more. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Our Ensign 1000, Commander 1000, and Commander 2000 portable davit cranes with capacities of 1,200–2,000 lbs are recommended for lifts over 1,000 lbs. Depending on the model, the cranes offer varying features such as multiple boom lengths/angles, streamlined set-up/disassembly, ergonomic operation, and more. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

For pump lifts of up to 3,000 lbs, our stationary Captain 2000, Captain 2500, and Admiral 3000 cranes are an ideal solution. Each of these models will provide users with features such as extended boom lengths, 360° rotation, a quick-disconnect anchor, and more. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Our First Mate portable davit crane is affordable, lightweight, and perfect for a wide variety of simple jobs, up to 850 lbs, where adjustable reach is not required. Other economical options to lift a lighter load include our Ensign 500 and Commander 500 portable davit cranes with capacities of 500 lbs and 650 lbs, respectively. The Ensign 500 is specially designed for clearance, lift height, and ergonomic operation, while the Commander 500 is a popular lightweight model with an adjustable boom that’s ideal for smaller loads. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Since this can be a complicated question that requires a more in-depth conversation, we encourage you to contact us directly. Depending on your situation, you may benefit from buying many bases and fewer cranes to meet your project goals and budget. Larger cranes may also be ideal based on the sizes of the pumps.

Start a conversation with us to discuss base placement and the reach required to lift each pump. We can provide product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Thern’s entire collection of portable davit cranes offer easy assembly and quick disassembly for effortless transport from base to base or storage. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Our economical Ensign 500 and Ensign 1000 portable davit cranes are specially designed for clearance, lift height, and ergonomic operation. Our Commander series also offers maximum flexibility with multiple boom lengths and angles to choose from. An optional base extension is available to provide additional hook height without affecting the rating of the crane for our First Mate and Commander Series. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

The right seal support system is critical for promoting seal reliability. John Crane customizes support systems to meet a variety of seal specifications, contributing to safe, cost-effective, reliable operation and reducing harmful environmental effects. Our support systems comply with constantly changing design codes and standards, and meet the increasingly stringent demands on end users.

Our comprehensive suite of seal face technologies are designed to overcome rigorous sealing challenges, including limited seal face lubrication and severe-service duties that adversely affect reliability, operational costs and seal life. Designed by our engineering experts, John Crane’s face treatment options help your equipment power through low-lubricity and dry-running conditions by using advanced micromachined patterns and features to improve seal face lubrication to optimize the performance of rotating equipment in all process industries

John Crane’s flexible couplings have provided a rugged and reliable service to the industry for over 50 years, helping rotating equipment operate at optimum levels and providing maximum availability.

As a result, John Crane couplings have become the first choice of many of the world’s leading companies. John Crane’s policy of constant innovation and product development ensures that we continue to satisfy the changing demands of the market while fully complying with all relevant industry standards.

John Crane offers a comprehensive range of filtration products to significantly reduce contamination, increasing the efficiency of your operation. Our products are designed to work together in complex systems to ensure optimum filter performance. Patented filtration technologies provide filter elements that are able to remove liquids in addition to solids within a single unit. Our replacement elements incorporate John Crane"s patented design features, ensuring maximum filter performance

Do you want to minimize leakage from your pumps in an effective manner? This is a challenge operators and maintenance managers face on a daily basis, which can prove costly. John Crane offers a wide selection of packing materials in compression packing, automatic packing, floating packing, and injectable packing. Learn more about our variety of packing equipped to handle the vast majority of sealing solutions and available for nearly all applications.

Crane Pumps & Systems is a world-class manufacturer of quality pumps and accessories offering a wide range of solutions and services for the municipal, residential building, commercial building, military, and industrial markets.

Its trusted brands; Barnes, Burks, Crown, Deming, Prosser and Weinman provide innovative designs and durable construction. Hudson Pump & Equipment a Division of Tencarva Machinery is proud to be the Authorized Crane Pumps & Systems distributor in Florida.

Wherever there is a need for fluid handling equipment a Crane Pumps & Systems product is hard at work – from the sump in a basement to a municipal pressure sewer system, from a split case in a commercial boiler room to a self priming pump on a marine pier or a grinder pump for a poultry process. Other applications include processing plants, power generating stations, constructions sites, utility maintenance fleets, and military.

- The pump skid weighs only 2450 kg (wet) and only covers an area of 2.4 m x 1.92 m making it very easy to move into restricted areas due to its compact abilities.

Bentec developed the idea of mud pumps completely new. The mud pumps are equipped with a direct-drive gearbox, a motor developed in-house, and stateof- the-art pump housing. There is no longer any need for an internal gear with all of its disadvantages today, and no more belt tensioning. Bentec mud pumps are reduced to the task they are made for – pump operations.

Bentec mud pumps are light-weight and have a small footprint. The 1,600 hp AC-powered motor is top-mounted. The pump is available with 5,000 or 7,500 PSI fluid ends and all of its parts subject to wear and tear meet API standards and are available worldwide. A handling crane makes it easy to handle the fluid end components.

Furthermore, Bentec uses patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec mud pump is the side-mounted gear drive.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. Especially for noisesensitive environments like offshore or densely populated locations, the Bentec mud pump is the right choice.

Along with the supply of mud pumps, Bentec acts as a system supplier. Pumps can be delivered together with a Bentec Power Control System and the Bentec Soft Pump System.

8613371530291

8613371530291