mud pump displacement calculator free sample

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

The shaft power - the power required transferred from the motor to the shaft of the pump - depends on the efficiency of the pump and can be calculated as Ps(kW) = Ph(kW)/ η (3)

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

Oil and Gas drilling process - Pupm output for Triplex and Duplex pumpsTriplex Pump Formula 1 PO, bbl/stk = 0.000243 x ( in) E.xample: Determine the pump output, bbl/stk, at 100% efficiency for a 7" by 12". triplex pump: PO @ 100%,= 0.000243 x 7 x12 PO @ 100% = 0.142884bbl/stk Adjust the pump output for 95% efficiency: Decimal equivalent = 95 + 100 = 0.95 PO @ 95% = 0.142884bbl/stk x 0.95 PO @ 95% = 0.13574bbl/stk Formula 2 PO, gpm = [3(D x 0.7854)S]0.00411 x SPM where D = liner diameter, in. S = stroke length, in. SPM = strokes per minute Determine the pump output, gpm, for a 7" by 12". triplex pump at 80 strokes per minute: PO, gpm = [3(7 x 0.7854) 1210.00411 x 80 PO, gpm = 1385.4456 x 0.00411 x 80 PO = 455.5 gpm

Example:Duplex Pump Formula 1 0.000324 x (liner diameter, in) x ( stroke lengh, in) = ________ bbl/stk -0.000162 x (rod diameter, in) x ( stroke lengh, in) = ________ bbl/stk Pump out put @ 100% eff = ________bbl/stk Example: Determine the output, bbl/stk, of a 5 1/2" by 14" duplex pump at 100% efficiency. Rod diameter = 2.0": 0.000324 x 5.5 x 14 = 0.137214bbl/stk -0.000162 x 2.0 x 14 = 0.009072bbl/stk Pump output @ 100% eff. = 0.128142bbl/stk Adjust pump output for 85% efficiency: Decimal equivalent = 85 100 = 0.85 PO@85%)= 0.128142bbl/stk x 0.85 PO@ 85% = 0.10892bbl/stk Formula 2

PO. bbl/stk = 0.000162 x S[2(D) - d] where S = stroke length, in. D = liner diameter, in. d = rod diameter, in. Example: Determine the output, bbl/stk, of a 5 1/2". by 14". duplex pump @ 100% efficiency. Rod diameter = 2.0in.: PO@100%=0.000162 x 14 x [ 2 (5.5) - 2 ] PO @ 100%)= 0.000162 x 14 x 56.5 PO@ 100%)= 0.128142bbl/stk Adjust pump output for 85% efficiency: PO@85%,= 0.128142bb/stkx 0.85 PO@8.5%= 0.10892bbl/stk Metric calculation Pump output, liter/min = pump output. liter/stk x pump speed, spm. S.I. units calculation Pump output, m/min = pump output, liter/stk x pump speed, spm. Mud Pumps Mud pumps drive the mud around the drilling system. Depending on liner size availability they can be set up to provide high pressure and low flow rate, or low pressure and high flow rate. Analysis of the application and running the Drill Bits hydraulics program will indicate which liners to recommend. Finding the specification of the mud pumps allows flow rate to be calculated from pump stroke rate, SPM. Information requiredo Pump manufacturer o Number of pumps o Liner size and gallons per revolution Weight As a drill bit cutting structure wears more weight will be required to achieve the same RoP in a homogenous formation. PDC wear flats, worn inserts and worn milled tooth teeth will make the bit drill less efficiently. Increase weight in increments of 2,000lbs approx. In general, weight should be applied before excessive rotary speed so that the cutting structure maintains a significant depth of cut to stabilise the bit and prevent whirl. If downhole weight measurements are available they can be used in combination with surface measurements to gain a more accurate representation of what is happening in the well bore.

Pumps tend to be one of the biggest energy consumers in industrial operations. Pump motors, specifically, require a lot of energy. For instance, a 2500 HP triplex pump used for frac jobs can consume almost 2000 kW of power, meaning a full day of fracking can cost several thousand dollars in energy costs alone!

So, naturally, operators should want to maximize energy efficiency to get the most for their money. Even a 1% improvement in efficiency can decrease annual pumping costs by tens of thousands of dollars. The payoff is worth the effort. And if you want to remotely control your pumps, you want to keep efficiency in mind.

In this post, we’ll point you in the right direction and discuss all things related to pump efficiency. We’ll conclude with several tips for how you can maintain pumping efficiency and keep your energy costs down as much as possible.

In simple terms, pump efficiency refers to the ratio of power out to power in. It’s the mechanical power input at the pump shaft, measured in horsepower (HP), compared to the hydraulic power of the liquid output, also measured in HP. For instance, if a pump requires 1000 HP to operate and produces 800 HP of hydraulic power, it would have an efficiency of 80%.

Remember: pumps have to be driven by something, i.e., an electric or diesel motor. True pump system efficiency needs to factor in the efficiency of both the motor AND the pump.

Consequently, we need to think about how electrical power (when using electric motors) or heat power (when using combustion engines) converts into liquid power to really understand pump efficiency.

Good pump efficiency depends, of course, on pump type and size. High-quality pumps that are well-maintained can achieve efficiencies of 90% or higher, while smaller pumps tend to be less efficient. In general, if you take good care of your pumps, you should be able to achieve 70-90% pump efficiency.

Now that we have a better understanding of the pump efficiency metric, let’s talk about how to calculate it. The mechanical power of the pump, or the input power, is a property of the pump itself and will be documented during the pump setup. The output power, or hydraulic power, is calculated as the liquid flow rate multiplied by the "total head" of the system.

IMPORTANT: to calculate true head, you also need to factor in the work the pump does to move fluid from the source. For example, if the source water is below the pump, you need to account for the extra work the pump puts in to draw source water upwards.

*Note - this calculation assumes the pump inlet is not pressurized and that friction losses are minimal. If the pump experiences a non-zero suction pressure, or if there is significant friction caused by the distance or material of the pipe, these should be factored in as well.

You"ll notice that the elevation head is minimal compared to the discharge pressure, and has minimal effect on the efficiency of the pump. As the elevation change increases or the discharge pressure decreases, however, elevation change will have a greater impact on total head.

Obviously, that’s a fair amount of math to get at the pump efficiency, considering all of the units conversions that need to be done. To avoid doing these calculations manually, feel free to use our simple pump efficiency calculator.

Our calculations use static variables (pump-rated horsepower and water source elevation) and dynamic variables (discharge flow and pressure). To determine pump efficiency, we need to measure the static variables only once, unless they change.

If you want to measure the true efficiency of your pump, taking energy consumption into account, you could add an electrical meter. Your meter should consist of a current transducer and voltage monitor (if using DC) for electrical motors or a fuel gauge for combustion. This would give you a true understanding of how pump efficiency affects energy consumption, and ultimately your bank account.

Up until this point, we’ve covered the ins and outs of how to determine pump efficiency. We’re now ready for the exciting stuff - how to improve pump efficiency!

One of the easiest ways to improve pump efficiency is to actually monitor pumps for signs of efficiency loss! If you monitor flow rate and discharge (output power) along with motor current or fuel consumption, you’ll notice efficiency losses as soon as they occur. Simply having pump efficiency information on hand empowers you to take action.

Another way to increase efficiency is to keep pumps well-maintained. Efficiency losses mostly come from mechanical defects in pumps, e.g., friction, leakages, and component failures. You can mitigate these issues through regular maintenance that keeps parts in working order and reveals impending failures. Of course, if you are continuously monitoring your pumps for efficiency drops, you’ll know exactly when maintenance is due.

You can also improve pump efficiency by keeping pumps lubricated at all times. Lubrication is the enemy of friction, which is the enemy of efficiency (“the enemy of my enemy is my friend…”).

A fourth way to enhance pump efficiency is to ensure your pumps and piping are sized properly for your infrastructure. Although we’re bringing this up last, it’s really the first step in any pumping operation. If your pumps and piping don’t match, no amount of lubricant or maintenance will help.

In this post, we’ve given you the full rundown when it comes to calculating and improving pump efficiency. You can now calculate, measure, and improve pump efficiency, potentially saving your business thousands of dollars annually on energy costs.

For those just getting started with pump optimization, we offer purpose-built, prepackaged solutions that will have you monitoring pump efficiency in minutes, even in hazardous environments.

In this article provided pump related formulas like fluid flow rate and velocity, power calculation, Specific Speed of Pump (Nq), Total Head, Pump Torque and temperature rise, Net Positive Suction Head, Affinity laws for pump, Pump Efficiency & Overall Efficiency of the Pump

Specific Speed of pump (Nq) is identifies the geometrical similarity of pumps. It is useful to comparing different pump designs irrespective of pump size

Pressure head calculated as per pumping system source tank is under some gauge pressure or vacuum open or open toatmosphericthan pressure head is calculated in metres of water column (MWC) of Feet of water column of liquid.

The amount of NPSH the pump requires to avoid cavitation is called Net Positive Suction Head Required (NPSHr). This value of the pump is determined based on actual pump test by the vendor.

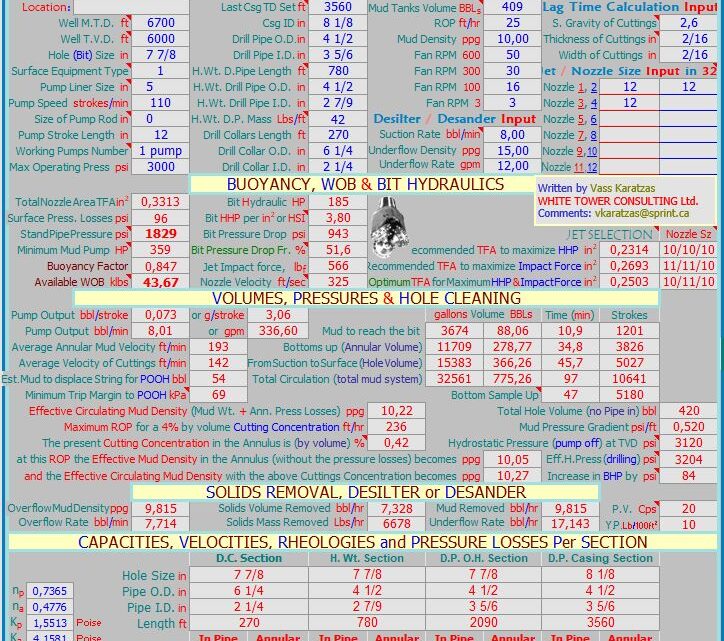

REASON: This is the mud engineers Bible on the rig. It is based on prior knowledge of all drilling parameters and gives you a step by step plan for present well being drilled. It would guide you all though the drilling process.

Study your silos, pits, mud tanks, storage tank names, its contents, volume, dead volume capacity, properties of their contents (mud: especially Mud weight).

REASON: You don’t want to be taken unawares, you need to know the type of mud you have in each pit (where your backup mud is, kill mud if any, premix, etc.), you need to be sure you have enough mud to reach TD (Total depth) most especially if the logistics of transporting mud to the rig n’est pas facile, or takes days to arrive. Finally without knowing the properties of the mud you are introducing to the active system you would not be sure if what is affecting your active mud system is coming from the formation or from the mud you are introducing to the active mud.

REASON: If there’s going to be a rig operation such as displacement, or cement job that requires you to bypass fluids to different pits or dump fluids (to avoid contamination) you need to know your lines and valves and where it leads to before such operations.

REASON: You need to be sure the shaker screens can handle the flow if the mud is cold if not temporarily screen down to a lower size mesh or ask the driller to reduce the flow rate if permissible.

REASON: Drilling fluids would normally splash the rig crew on the rig floor while pulling and racking back pipes when a stand is removed from the drill string. So a slug (same mud but with 2-2.5 ppg higher density) would be prepared in the slug tank, and pumped into the drill string. This keeps the fluids level inside the drill pipe below the surface when tripping drill pipe.

For a leak off test (LOT), the mud has to be circulated to obtain uniform weight and condition. The primary concern for the mud engineer is to ensure an equal mud weight all through the mud. Mud weight going in to the hole should be equal to mud weight coming out of the hole at the shakers.

REASON: The well needs to be properly monitored. Instead speak with the mud loggers to convert the pit you want to transfer fluid from to the active system from a Reserve pit to an Active pit on their system then you can gradually make your transfers that way all volumes would be shown as active pit volume.

REASON: It’s used to measure the relative stability of a water-in-oil emulsion. With increase of water, the E.S drops this would be a clear indication of WBM coming on surface, same the other way round, with decrease of water the E.S value climbs. But before the displacement take the initial E.S values of the concerned fluids so as to have an idea what to expect.

REASON: If the amount and average specific gravity of the solids in both fluids (i.e. the density) are different the mud weight would be a good indicator of the fluids interface during a displacement.

REASON: Calculate your hole volume, that means equal amount of mud on surface will leave you pit, so get the derrick man or personnel assisting you in the pit room to inform you when hole volume has been pumped.

REASON: Using a technique called nephelometry the turbidity can be measured. When light hits a particle the energy is scattered in all directions, it measures the level of light scattered by particles at right angles to the incident light beam. Initial NTU readings of both fluids would be the reference point for identification. After the Hi-vis passes through the driller should be told to stop pumping when the initial NTU of the filtered brine has been achieved.

For water based mud with a low alkalinity use phenolphthalein also. Add it to the mud and check for change of color to pink to know when traces of cement are on surface.

REASON: Note differences in weight between mud, spacer and cement before displacement of cement. The mud weight difference between the three fluids is a good indicator of the fluids interface on surface.

REASON: The first step is removal of cuttings from the borehole and the drilling fluid after which the mud should be condition before placing cement in the wellbore, either the density (not compromising well control) or the rheology depending on the situation. For the rheology, the yield stress, gel strength and plastic viscosity would be reduced hence reducing the driving forces necessary to displace mud with increased mud flexibility while being careful to prevent barite settling.

REASON: With no pit space to store the equivalent mud volume being replaced down hole, all pit levels should be recorded at all stages during the cement job. You would need to visit the pit room and return to the cement unit (while measuring cement density) at appropriate moments.

Measure all tank volumes before cement job i.e. when the mud has been thinned down and pump has been stopped (pit static). In case of leaks or valve mistakes all pits should be recorded.

If we get full returns during cementing it means that the cement displaced equal amount of mud and there was no loss down hole due to the cement job or due to displacement.

Prior to running casing, calculate the displacement of the casing first to know the volume it would displace, calculating from the mud line up to the casing depth.

REASON: There would be returns to the pit while running in hole casing, so set a pit ready to receive the displacement from the casing and measure its volume or measure the entire surface volume in case of any fluids transfer in your absence. Trace the losses, Get the current depth (measured Depth), and measure all the pits, when you know the subsequent increment of the pit it should tally with the displacement of the steel, i.e. if there are no losses.

REASON: From the cement program calculate the total volume of the fluids /cement that would be pumped into the hole that is not mud so as to confirm tank space to receive equal volume from the hole. If no available tank space/storage space then OBM should be back-loaded before the cement job to create space.

REASON: If it’s the pay zone, losses would require the use of acid-soluble LCM to prevent formation damage. Also considering down hole tools and motors, certain concentrations of LCM pills would not be pumped to avoid plugging/damaging the tools unless a bypass tool is part of the BHA.

Bit balling occurs in soft gumbo / swelling shales while drilling, the shale adsorbs water from the mud it then becomes plastic with a ball of compacted shale building up and covering the whole bit, stabilizers and drill collars, thus preventing further drilling progress.

To be certain it’s a bit balling issue we are dealing with the mud engineer should observe some of the following or collect the following information from the following rig personnel, with the first 3 information from the driller being very important:

To prevent bit balling from occurring it is advisable to adopt procedures that worked in your geographical area in overcoming bit balling by always reviewing previous drilling mud report (DMR).

· Use mud system that can inhibit clay swelling example: Formulating KCl mud with PHPA (to avoid using higher concentrations of KCl) in which KCl prevents clay swelling while PHPA (partially hydrolyzed polyacrylamide ) coats the shales surfaces (encapsulates) thereby inhibiting their dispersion and incorporation into the mud.7

· “When drilling gumbo, the pH should be maintained at 9.0-10.0. If bit balling occurs, increase the mud alkalinity (PM) to 5 or more with lime”.8

· “If all else fails, before you trip out of the hole, you might pump a walnut-hull sweep. It will tend to sandblast the bit and remove the ball, and won’t hurt the mud. Don’t try this if you are running small jets in the bit, as plugging can be an issue.”11

A Drilling fluids Engineer should be able to observe or carry out a test and subsequently identify the reason for a high or a low mud weight in a water-base mud or an oil-base mud system.

Before looking at the reason why the mud weight reduced or increased from the given mud program specification, it’s good to know that the major function of drilling fluids is to provide sufficient pressure to check influx of gas, oil, and water into the well bore from the drilled formation.

The hydrostatic head of the mud column must be at least equal to that of the formation pressure, and hopefully greater, but not so high as to cause loss of circulation (except where an over balanced / under balanced drilling are specifically desired).

The mud weight materials could be barite, calcium carbonate or soluble salts such as sodium chloride (NaCl), potassium chloride (KCl) and calcium chloride (CaCl2). Sometimes the desired mud weight can be achieved by combining additions of salts and barite.

a. Mud Weight (Density) Test: The mud balance may indicate that mud weight is too high or too low. b. Retort Test: The test may indicate that the percent solids by volume is high, and your solids content calculations (lb/bbl low and high gravity solids) may indicate that barite content is too high or too low. c. Rheology tests: Indicates increase or decrease in viscosity

a. Increase in pump pressure: This can indicate an increase in Mud weight. b. Change in penetration rate: Increase in penetration rate may indicate decrease in mud weight while decrease in penetration rate may indicate increase in mud weight. c. Gas bubbles: This definitely indicates decrease in mud weight.

8613371530291

8613371530291