mud pump displacement formula pricelist

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Pump body thick. The pump body is made of high quality pig iron, durable and equipped with a thickened base. Thickened impeller, wear-resistant and dry rotating.

(Place the vertical mud pump upright or tilted in the liquid. Make sure the pump case is completely submerged in water. In addition, the motor part can not be immersed in water.)

Sewage pump is mainly used for industrial sewage, sewage treatment, in environmental protection has played a great role. The sewage pump is also a sewage pump with a cutting wheel, so the sewage pump can cut up the dirt, and then the sewage is extracted clean. Mud pump without cutting impeller, mostly used for pumping mud. The two main performance parameters of mud pump are displacement and pressure, displacement to discharge a number of liters per minute calculation, and drilling diameter and the required flushing fluid from the bottom of the hole back speed, that is, the larger the aperture, the larger the required displacement. The upward return velocity of the flushing fluid is required to flush cuttings and rock powders removed from the bottom of the hole in time and carry them reliably to the surface. By drilling and pumping, the mud under the ground can be obtained.

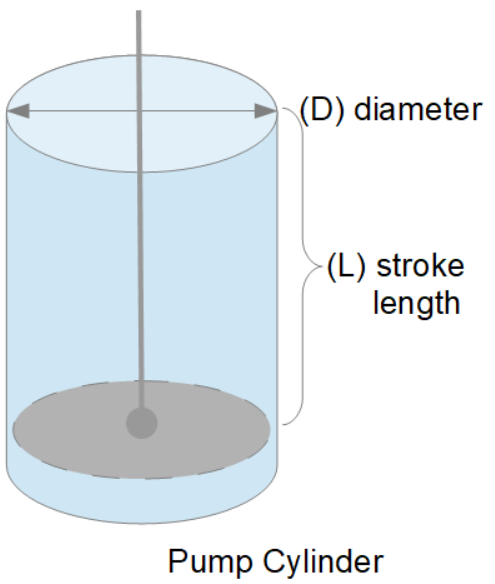

Oil and Gas drilling process - Pupm output for Triplex and Duplex pumpsTriplex Pump Formula 1 PO, bbl/stk = 0.000243 x ( in) E.xample: Determine the pump output, bbl/stk, at 100% efficiency for a 7" by 12". triplex pump: PO @ 100%,= 0.000243 x 7 x12 PO @ 100% = 0.142884bbl/stk Adjust the pump output for 95% efficiency: Decimal equivalent = 95 + 100 = 0.95 PO @ 95% = 0.142884bbl/stk x 0.95 PO @ 95% = 0.13574bbl/stk Formula 2 PO, gpm = [3(D x 0.7854)S]0.00411 x SPM where D = liner diameter, in. S = stroke length, in. SPM = strokes per minute Determine the pump output, gpm, for a 7" by 12". triplex pump at 80 strokes per minute: PO, gpm = [3(7 x 0.7854) 1210.00411 x 80 PO, gpm = 1385.4456 x 0.00411 x 80 PO = 455.5 gpm

Example:Duplex Pump Formula 1 0.000324 x (liner diameter, in) x ( stroke lengh, in) = ________ bbl/stk -0.000162 x (rod diameter, in) x ( stroke lengh, in) = ________ bbl/stk Pump out put @ 100% eff = ________bbl/stk Example: Determine the output, bbl/stk, of a 5 1/2" by 14" duplex pump at 100% efficiency. Rod diameter = 2.0": 0.000324 x 5.5 x 14 = 0.137214bbl/stk -0.000162 x 2.0 x 14 = 0.009072bbl/stk Pump output @ 100% eff. = 0.128142bbl/stk Adjust pump output for 85% efficiency: Decimal equivalent = 85 100 = 0.85 PO@85%)= 0.128142bbl/stk x 0.85 PO@ 85% = 0.10892bbl/stk Formula 2

PO. bbl/stk = 0.000162 x S[2(D) - d] where S = stroke length, in. D = liner diameter, in. d = rod diameter, in. Example: Determine the output, bbl/stk, of a 5 1/2". by 14". duplex pump @ 100% efficiency. Rod diameter = 2.0in.: PO@100%=0.000162 x 14 x [ 2 (5.5) - 2 ] PO @ 100%)= 0.000162 x 14 x 56.5 PO@ 100%)= 0.128142bbl/stk Adjust pump output for 85% efficiency: PO@85%,= 0.128142bb/stkx 0.85 PO@8.5%= 0.10892bbl/stk Metric calculation Pump output, liter/min = pump output. liter/stk x pump speed, spm. S.I. units calculation Pump output, m/min = pump output, liter/stk x pump speed, spm. Mud Pumps Mud pumps drive the mud around the drilling system. Depending on liner size availability they can be set up to provide high pressure and low flow rate, or low pressure and high flow rate. Analysis of the application and running the Drill Bits hydraulics program will indicate which liners to recommend. Finding the specification of the mud pumps allows flow rate to be calculated from pump stroke rate, SPM. Information requiredo Pump manufacturer o Number of pumps o Liner size and gallons per revolution Weight As a drill bit cutting structure wears more weight will be required to achieve the same RoP in a homogenous formation. PDC wear flats, worn inserts and worn milled tooth teeth will make the bit drill less efficiently. Increase weight in increments of 2,000lbs approx. In general, weight should be applied before excessive rotary speed so that the cutting structure maintains a significant depth of cut to stabilise the bit and prevent whirl. If downhole weight measurements are available they can be used in combination with surface measurements to gain a more accurate representation of what is happening in the well bore.

The water-based mud in the wellbore from the previous hole section is displaced and replaced with POBM drilling fluid. The first step is to lower the viscosity and gel strength of the water-based mud. The suggested method is to dilute the fluid with water to obtain a low rheology (Patel [3]). The optimal thinning of the water-based mud will dictate how easy the mud will be displaced out of the hole. The spacer is pumped first, followed by the POBM mud at maximum pump rate to get the mud in the annulus moving (Table 8).

After drilling and prior to running completion hardware, the fluid in the borehole is often displaced to a water-based completion fluid, usually a solution of various salts. During this displacement, chemical washes and viscous spacers are placed in the solution to make surfaces water- wet, while helping to remove oil mud and residual oil-wet material from the borehole (Ali et al. [4]).

The viscosity and gel strengths of the POBM are low prior to displacement. The suggested method was to dilute the fluid with premix, base fluid or a thinner to obtain the low rheology if this is necessary. The optimal thinning of the POBM fluid will dictate how easy the mud will be displaced out of the hole.

Each pump is passing a full load factory acceptance test to verify its mechanical and hydraulic performance. WARMAN* Centrifugal Slurry Pumps GEHO* PD Slurry Pumps LINATEX* Rubber Products VULCO* Wear Resistant Linings CAVEX* Hydrocyclones FLOWAY* PUMPS Vertical Turbine Pumps ISOGATE* Slurry Valves MULTIFLO* Mine Dewatering Solutions HAZLETON* Specialty Slurry Pumps LEWIS PUMPS™ Vertical Chemical Pumps WEIR MINERALS SERVICES Weir Minerals Netherlands b.v. designs, manufactures and markets piston, piston diaphragm and hose pumps under the brand name GEHO®. Since 1957 our company has...

Consultancy You are welcome to let our experts review your slurry pumping needs (application). Customers in the global mining, mineral processing and power industries usually call on GEHO® pumps for advice in the development of a slurry processing system and in studying the technical and economic feasibility of a project. We have considerable knowledge and experience in all aspects of slurry, ranging from sample testing, slurry characterisation, flow behaviour, pressure loss calculation and flow sheet optimisation to the selection and bidding of the appropriate pump. This consultancy work...

Product innovation The piston pump, model ZPR, was developed in the 1960"s in conjunction with municipalities to meet an emerging demand for the transport of sewage sludge. A large number of these early pumps are still in operation in Europe and elsewhere and transfer screened raw sludge, feed filter presses or pump drilling mud. Even today, municipal customers often prefer this double-acting crankshaft driven piston pump to ram pumps and hose-type piston diaphragm pumps. We have supplied more than 10,000 wellpoint dewatering pumps over 50 years. These two-cylinder vacuum piston pumps lower...

TZP – Triplex single-acting crankshaft driven piston pump The TZP is a three-cylinder single-acting crankshaft driven piston pump. The principal difference to a ZPR is the single-acting piston. The TZP does not use a stuffing box. It reduces the number of wear parts and makes this design attractive to the handling of more abrasive slurry and higher pressure. The capital expenditure of this piston pump is substantially lower than that of an equivalent size diaphragm pump and offsets the piston and liner (wear) parts usage when pumping mildly abrasive slurry and/or moderate pressure. The...

ZPM and TZPM – Duplex and triplex crankshaft driven piston diaphragm pump Model TZPM The principal difference between a piston and a piston diaphragm pump is the genuine diaphragm that protects the piston and liner from the sliding contact with the abrasive slurry. The diaphragm is a pre-moulded design that eliminates elongation of the elastomer. Its long fatigue life allows for routine annual maintenance to be carried out. The diaphragm position is controlled in either direction of the stroke by adding or removing propelling fluid that fills the cavity between the piston and diaphragm. A...

DHC and DHT – Hydraulic driven piston pump DHC - Piston pump with actuator assisted valves The model DHC piston pump is fitted with large diameter, high lift, actuator assisted suction and discharge valves and handles rather viscous pastes and particles typically not larger than 15 mm. It uses the valve design from the diaphragm pump, except that the valve cone bolts directly onto the actuator rod. The actuator load and activation sequence is arranged such that a valve will not open against the pump discharge pressure. As a result the system is inherently protected against backflow, even if...

DHT – Piston pump with transfer tube The model DHT’s pump water end comprises a hopper with transfer tube. This S-form pipe pivots on the discharge side whilst the inlet is intermediate between the opening of the paired cylinders. At the end of a suction stroke it covers the cylinder opening and isolates the filled cylinder from the suction hopper. During the subsequent discharge stroke, the piston forces the product through the tube into the discharge pipe. During switch over the tube partly overlaps and short-circuits the cylinders for a fraction of a second. When pumping a paste...

Pump Systems Surface disposal of tailings, as a thickened paste, as opposed to conventional slurry deposition in a pond, offers considerable advantages and reduces the environmental impact. GEHO® has played an active role in the development, promotion and global acceptance of the high concentration tailings disposal system. The pioneering red mud (alumina tailings) Thickened Tailings Disposal (TTD) systems were the result of alumina producers and key equipment suppliers working in close partnership. They combined efforts in the development of the concept, laboratory testing, process design,...

Aftermarket support By aligning our own objectives with those of our enduser customers, we are forming long-term mutually beneficial partnerships. We provide comprehensive support under flexible agreements tailored to customer needs. The unique design and technology of a GEHO® pump warrants that we supervise its installation and start-up. We also provide on-site technical product training to enhance personnel performance in maintenance and operations. Participants review and exercise proper start-up, shutdown, maintenance and troubleshooting procedures and are taught about the function and...

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis.

When a pump contains two or more pump mechanisms with fluid being directed to flow through them in series, it is called a multi-stage pump. Terms such as two-stage or double-stage may be used to specifically describe the number of stages. A pump that does not fit this description is simply a single-stage pump in contrast.

In biology, many different types of chemical and biomechanical pumps have evolved; biomimicry is sometimes used in developing new types of mechanical pumps.

Pumps can be classified by their method of displacement into positive-displacement pumps, impulse pumps, velocity pumps, gravity pumps, steam pumps and valveless pumps. There are three basic types of pumps: positive-displacement, centrifugal and axial-flow pumps. In centrifugal pumps the direction of flow of the fluid changes by ninety degrees as it flows over an impeller, while in axial flow pumps the direction of flow is unchanged.

Some positive-displacement pumps use an expanding cavity on the suction side and a decreasing cavity on the discharge side. Liquid flows into the pump as the cavity on the suction side expands and the liquid flows out of the discharge as the cavity collapses. The volume is constant through each cycle of operation.

Positive-displacement pumps, unlike centrifugal, can theoretically produce the same flow at a given speed (rpm) no matter what the discharge pressure. Thus, positive-displacement pumps are constant flow machines. However, a slight increase in internal leakage as the pressure increases prevents a truly constant flow rate.

A positive-displacement pump must not operate against a closed valve on the discharge side of the pump, because it has no shutoff head like centrifugal pumps. A positive-displacement pump operating against a closed discharge valve continues to produce flow and the pressure in the discharge line increases until the line bursts, the pump is severely damaged, or both.

A relief or safety valve on the discharge side of the positive-displacement pump is therefore necessary. The relief valve can be internal or external. The pump manufacturer normally has the option to supply internal relief or safety valves. The internal valve is usually used only as a safety precaution. An external relief valve in the discharge line, with a return line back to the suction line or supply tank provides increased safety.

Rotary-type positive displacement: internal or external gear pump, screw pump, lobe pump, shuttle block, flexible vane or sliding vane, circumferential piston, flexible impeller, helical twisted roots (e.g. the Wendelkolben pump) or liquid-ring pumps

Drawbacks: The nature of the pump requires very close clearances between the rotating pump and the outer edge, making it rotate at a slow, steady speed. If rotary pumps are operated at high speeds, the fluids cause erosion, which eventually causes enlarged clearances that liquid can pass through, which reduces efficiency.

Hollow disk pumps (also known as eccentric disc pumps or Hollow rotary disc pumps), similar to scroll compressors, these have a cylindrical rotor encased in a circular housing. As the rotor orbits and rotates to some degree, it traps fluid between the rotor and the casing, drawing the fluid through the pump. It is used for highly viscous fluids like petroleum-derived products, and it can also support high pressures of up to 290 psi.

Vibratory pumps or vibration pumps are similar to linear compressors, having the same operating principle. They work by using a spring-loaded piston with an electromagnet connected to AC current through a diode. The spring-loaded piston is the only moving part, and it is placed in the center of the electromagnet. During the positive cycle of the AC current, the diode allows energy to pass through the electromagnet, generating a magnetic field that moves the piston backwards, compressing the spring, and generating suction. During the negative cycle of the AC current, the diode blocks current flow to the electromagnet, letting the spring uncompress, moving the piston forward, and pumping the fluid and generating pressure, like a reciprocating pump. Due to its low cost, it is widely used in inexpensive espresso machines. However, vibratory pumps cannot be operated for more than one minute, as they generate large amounts of heat. Linear compressors do not have this problem, as they can be cooled by the working fluid (which is often a refrigerant).

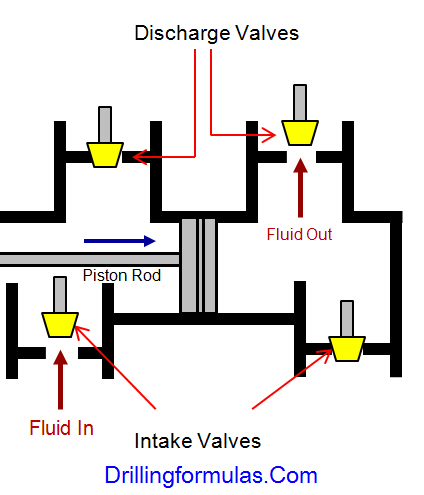

Reciprocating pumps move the fluid using one or more oscillating pistons, plungers, or membranes (diaphragms), while valves restrict fluid motion to the desired direction. In order for suction to take place, the pump must first pull the plunger in an outward motion to decrease pressure in the chamber. Once the plunger pushes back, it will increase the chamber pressure and the inward pressure of the plunger will then open the discharge valve and release the fluid into the delivery pipe at constant flow rate and increased pressure.

Pumps in this category range from simplex, with one cylinder, to in some cases quad (four) cylinders, or more. Many reciprocating-type pumps are duplex (two) or triplex (three) cylinder. They can be either single-acting with suction during one direction of piston motion and discharge on the other, or double-acting with suction and discharge in both directions. The pumps can be powered manually, by air or steam, or by a belt driven by an engine. This type of pump was used extensively in the 19th century—in the early days of steam propulsion—as boiler feed water pumps. Now reciprocating pumps typically pump highly viscous fluids like concrete and heavy oils, and serve in special applications that demand low flow rates against high resistance. Reciprocating hand pumps were widely used to pump water from wells. Common bicycle pumps and foot pumps for inflation use reciprocating action.

These positive-displacement pumps have an expanding cavity on the suction side and a decreasing cavity on the discharge side. Liquid flows into the pumps as the cavity on the suction side expands and the liquid flows out of the discharge as the cavity collapses. The volume is constant given each cycle of operation and the pump"s volumetric efficiency can be achieved through routine maintenance and inspection of its valves.

This is the simplest form of rotary positive-displacement pumps. It consists of two meshed gears that rotate in a closely fitted casing. The tooth spaces trap fluid and force it around the outer periphery. The fluid does not travel back on the meshed part, because the teeth mesh closely in the center. Gear pumps see wide use in car engine oil pumps and in various hydraulic power packs.

A screw pump is a more complicated type of rotary pump that uses two or three screws with opposing thread — e.g., one screw turns clockwise and the other counterclockwise. The screws are mounted on parallel shafts that have gears that mesh so the shafts turn together and everything stays in place. The screws turn on the shafts and drive fluid through the pump. As with other forms of rotary pumps, the clearance between moving parts and the pump"s casing is minimal.

Widely used for pumping difficult materials, such as sewage sludge contaminated with large particles, a progressing cavity pump consists of a helical rotor, about ten times as long as its width. This can be visualized as a central core of diameter x with, typically, a curved spiral wound around of thickness half x, though in reality it is manufactured in a single casting. This shaft fits inside a heavy-duty rubber sleeve, of wall thickness also typically x. As the shaft rotates, the rotor gradually forces fluid up the rubber sleeve. Such pumps can develop very high pressure at low volumes.

Named after the Roots brothers who invented it, this lobe pump displaces the fluid trapped between two long helical rotors, each fitted into the other when perpendicular at 90°, rotating inside a triangular shaped sealing line configuration, both at the point of suction and at the point of discharge. This design produces a continuous flow with equal volume and no vortex. It can work at low pulsation rates, and offers gentle performance that some applications require.

A peristaltic pump is a type of positive-displacement pump. It contains fluid within a flexible tube fitted inside a circular pump casing (though linear peristaltic pumps have been made). A number of rollers, shoes, or wipers attached to a rotor compresses the flexible tube. As the rotor turns, the part of the tube under compression closes (or occludes), forcing the fluid through the tube. Additionally, when the tube opens to its natural state after the passing of the cam it draws (restitution) fluid into the pump. This process is called peristalsis and is used in many biological systems such as the gastrointestinal tract.

Efficiency and common problems: With only one cylinder in plunger pumps, the fluid flow varies between maximum flow when the plunger moves through the middle positions, and zero flow when the plunger is at the end positions. A lot of energy is wasted when the fluid is accelerated in the piping system. Vibration and

Triplex plunger pumps use three plungers, which reduces the pulsation of single reciprocating plunger pumps. Adding a pulsation dampener on the pump outlet can further smooth the pump ripple, or ripple graph of a pump transducer. The dynamic relationship of the high-pressure fluid and plunger generally requires high-quality plunger seals. Plunger pumps with a larger number of plungers have the benefit of increased flow, or smoother flow without a pulsation damper. The increase in moving parts and crankshaft load is one drawback.

Car washes often use these triplex-style plunger pumps (perhaps without pulsation dampers). In 1968, William Bruggeman reduced the size of the triplex pump and increased the lifespan so that car washes could use equipment with smaller footprints. Durable high-pressure seals, low-pressure seals and oil seals, hardened crankshafts, hardened connecting rods, thick ceramic plungers and heavier duty ball and roller bearings improve reliability in triplex pumps. Triplex pumps now are in a myriad of markets across the world.

Triplex pumps with shorter lifetimes are commonplace to the home user. A person who uses a home pressure washer for 10 hours a year may be satisfied with a pump that lasts 100 hours between rebuilds. Industrial-grade or continuous duty triplex pumps on the other end of the quality spectrum may run for as much as 2,080 hours a year.

The oil and gas drilling industry uses massive semi trailer-transported triplex pumps called mud pumps to pump drilling mud, which cools the drill bit and carries the cuttings back to the surface.

One modern application of positive-displacement pumps is compressed-air-powered double-diaphragm pumps. Run on compressed air, these pumps are intrinsically safe by design, although all manufacturers offer ATEX certified models to comply with industry regulation. These pumps are relatively inexpensive and can perform a wide variety of duties, from pumping water out of bunds to pumping hydrochloric acid from secure storage (dependent on how the pump is manufactured – elastomers / body construction). These double-diaphragm pumps can handle viscous fluids and abrasive materials with a gentle pumping process ideal for transporting shear-sensitive media.

Devised in China as chain pumps over 1000 years ago, these pumps can be made from very simple materials: A rope, a wheel and a pipe are sufficient to make a simple rope pump. Rope pump efficiency has been studied by grassroots organizations and the techniques for making and running them have been continuously improved.

Impulse pumps use pressure created by gas (usually air). In some impulse pumps the gas trapped in the liquid (usually water), is released and accumulated somewhere in the pump, creating a pressure that can push part of the liquid upwards.

Instead of a gas accumulation and releasing cycle, the pressure can be created by burning of hydrocarbons. Such combustion driven pumps directly transmit the impulse from a combustion event through the actuation membrane to the pump fluid. In order to allow this direct transmission, the pump needs to be almost entirely made of an elastomer (e.g. silicone rubber). Hence, the combustion causes the membrane to expand and thereby pumps the fluid out of the adjacent pumping chamber. The first combustion-driven soft pump was developed by ETH Zurich.

It takes in water at relatively low pressure and high flow-rate and outputs water at a higher hydraulic-head and lower flow-rate. The device uses the water hammer effect to develop pressure that lifts a portion of the input water that powers the pump to a point higher than where the water started.

The hydraulic ram is sometimes used in remote areas, where there is both a source of low-head hydropower, and a need for pumping water to a destination higher in elevation than the source. In this situation, the ram is often useful, since it requires no outside source of power other than the kinetic energy of flowing water.

Rotodynamic pumps (or dynamic pumps) are a type of velocity pump in which kinetic energy is added to the fluid by increasing the flow velocity. This increase in energy is converted to a gain in potential energy (pressure) when the velocity is reduced prior to or as the flow exits the pump into the discharge pipe. This conversion of kinetic energy to pressure is explained by the

A practical difference between dynamic and positive-displacement pumps is how they operate under closed valve conditions. Positive-displacement pumps physically displace fluid, so closing a valve downstream of a positive-displacement pump produces a continual pressure build up that can cause mechanical failure of pipeline or pump. Dynamic pumps differ in that they can be safely operated under closed valve conditions (for short periods of time).

Such a pump is also referred to as a centrifugal pump. The fluid enters along the axis or center, is accelerated by the impeller and exits at right angles to the shaft (radially); an example is the centrifugal fan, which is commonly used to implement a vacuum cleaner. Another type of radial-flow pump is a vortex pump. The liquid in them moves in tangential direction around the working wheel. The conversion from the mechanical energy of motor into the potential energy of flow comes by means of multiple whirls, which are excited by the impeller in the working channel of the pump. Generally, a radial-flow pump operates at higher pressures and lower flow rates than an axial- or a mixed-flow pump.

These are also referred to as All fluid pumps. The fluid is pushed outward or inward to move fluid axially. They operate at much lower pressures and higher flow rates than radial-flow (centrifugal) pumps. Axial-flow pumps cannot be run up to speed without special precaution. If at a low flow rate, the total head rise and high torque associated with this pipe would mean that the starting torque would have to become a function of acceleration for the whole mass of liquid in the pipe system. If there is a large amount of fluid in the system, accelerate the pump slowly.

Mixed-flow pumps function as a compromise between radial and axial-flow pumps. The fluid experiences both radial acceleration and lift and exits the impeller somewhere between 0 and 90 degrees from the axial direction. As a consequence mixed-flow pumps operate at higher pressures than axial-flow pumps while delivering higher discharges than radial-flow pumps. The exit angle of the flow dictates the pressure head-discharge characteristic in relation to radial and mixed-flow.

Regenerative turbine pump rotor and housing, 1⁄3 horsepower (0.25 kW). 85 millimetres (3.3 in) diameter impeller rotates counter-clockwise. Left: inlet, right: outlet. .4 millimetres (0.016 in) thick vanes on 4 millimetres (0.16 in) centers

Also known as drag, friction, peripheral, traction, turbulence, or vortex pumps, regenerative turbine pumps are class of rotodynamic pump that operates at high head pressures, typically 4–20 bars (4.1–20.4 kgf/cm2; 58–290 psi).

The pump has an impeller with a number of vanes or paddles which spins in a cavity. The suction port and pressure ports are located at the perimeter of the cavity and are isolated by a barrier called a stripper, which allows only the tip channel (fluid between the blades) to recirculate, and forces any fluid in the side channel (fluid in the cavity outside of the blades) through the pressure port. In a regenerative turbine pump, as fluid spirals repeatedly from a vane into the side channel and back to the next vane, kinetic energy is imparted to the periphery,

As regenerative turbine pumps cannot become vapor locked, they are commonly applied to volatile, hot, or cryogenic fluid transport. However, as tolerances are typically tight, they are vulnerable to solids or particles causing jamming or rapid wear. Efficiency is typically low, and pressure and power consumption typically decrease with flow. Additionally, pumping direction can be reversed by reversing direction of spin.

Steam pumps have been for a long time mainly of historical interest. They include any type of pump powered by a steam engine and also pistonless pumps such as Thomas Savery"s or the Pulsometer steam pump.

Recently there has been a resurgence of interest in low power solar steam pumps for use in smallholder irrigation in developing countries. Previously small steam engines have not been viable because of escalating inefficiencies as vapour engines decrease in size. However the use of modern engineering materials coupled with alternative engine configurations has meant that these types of system are now a cost-effective opportunity.

Valveless pumping assists in fluid transport in various biomedical and engineering systems. In a valveless pumping system, no valves (or physical occlusions) are present to regulate the flow direction. The fluid pumping efficiency of a valveless system, however, is not necessarily lower than that having valves. In fact, many fluid-dynamical systems in nature and engineering more or less rely upon valveless pumping to transport the working fluids therein. For instance, blood circulation in the cardiovascular system is maintained to some extent even when the heart"s valves fail. Meanwhile, the embryonic vertebrate heart begins pumping blood long before the development of discernible chambers and valves. Similar to blood circulation in one direction, bird respiratory systems pump air in one direction in rigid lungs, but without any physiological valve. In microfluidics, valveless impedance pumps have been fabricated, and are expected to be particularly suitable for handling sensitive biofluids. Ink jet printers operating on the piezoelectric transducer principle also use valveless pumping. The pump chamber is emptied through the printing jet due to reduced flow impedance in that direction and refilled by capillary action.

Examining pump repair records and mean time between failures (MTBF) is of great importance to responsible and conscientious pump users. In view of that fact, the preface to the 2006 Pump User"s Handbook alludes to "pump failure" statistics. For the sake of convenience, these failure statistics often are translated into MTBF (in this case, installed life before failure).

In early 2005, Gordon Buck, John Crane Inc.’s chief engineer for field operations in Baton Rouge, Louisiana, examined the repair records for a number of refinery and chemical plants to obtain meaningful reliability data for centrifugal pumps. A total of 15 operating plants having nearly 15,000 pumps were included in the survey. The smallest of these plants had about 100 pumps; several plants had over 2000. All facilities were located in the United States. In addition, considered as "new", others as "renewed" and still others as "established". Many of these plants—but not all—had an alliance arrangement with John Crane. In some cases, the alliance contract included having a John Crane Inc. technician or engineer on-site to coordinate various aspects of the program.

Not all plants are refineries, however, and different results occur elsewhere. In chemical plants, pumps have historically been "throw-away" items as chemical attack limits life. Things have improved in recent years, but the somewhat restricted space available in "old" DIN and ASME-standardized stuffing boxes places limits on the type of seal that fits. Unless the pump user upgrades the seal chamber, the pump only accommodates more compact and simple versions. Without this upgrading, lifetimes in chemical installations are generally around 50 to 60 percent of the refinery values.

Unscheduled maintenance is often one of the most significant costs of ownership, and failures of mechanical seals and bearings are among the major causes. Keep in mind the potential value of selecting pumps that cost more initially, but last much longer between repairs. The MTBF of a better pump may be one to four years longer than that of its non-upgraded counterpart. Consider that published average values of avoided pump failures range from US$2600 to US$12,000. This does not include lost opportunity costs. One pump fire occurs per 1000 failures. Having fewer pump failures means having fewer destructive pump fires.

As has been noted, a typical pump failure, based on actual year 2002 reports, costs US$5,000 on average. This includes costs for material, parts, labor and overhead. Extending a pump"s MTBF from 12 to 18 months would save US$1,667 per year — which might be greater than the cost to upgrade the centrifugal pump"s reliability.

Pumps are used throughout society for a variety of purposes. Early applications includes the use of the windmill or watermill to pump water. Today, the pump is used for irrigation, water supply, gasoline supply, air conditioning systems, refrigeration (usually called a compressor), chemical movement, sewage movement, flood control, marine services, etc.

Because of the wide variety of applications, pumps have a plethora of shapes and sizes: from very large to very small, from handling gas to handling liquid, from high pressure to low pressure, and from high volume to low volume.

Typically, a liquid pump can"t simply draw air. The feed line of the pump and the internal body surrounding the pumping mechanism must first be filled with the liquid that requires pumping: An operator must introduce liquid into the system to initiate the pumping. This is called priming the pump. Loss of prime is usually due to ingestion of air into the pump. The clearances and displacement ratios in pumps for liquids, whether thin or more viscous, usually cannot displace air due to its compressibility. This is the case with most velocity (rotodynamic) pumps — for example, centrifugal pumps. For such pumps, the position of the pump should always be lower than the suction point, if not the pump should be manually filled with liquid or a secondary pump should be used until all air is removed from the suction line and the pump casing.

Positive–displacement pumps, however, tend to have sufficiently tight sealing between the moving parts and the casing or housing of the pump that they can be described as self-priming. Such pumps can also serve as priming pumps, so-called when they are used to fulfill that need for other pumps in lieu of action taken by a human operator.

One sort of pump once common worldwide was a hand-powered water pump, or "pitcher pump". It was commonly installed over community water wells in the days before piped water supplies.

In parts of the British Isles, it was often called the parish pump. Though such community pumps are no longer common, people still used the expression parish pump to describe a place or forum where matters of local interest are discussed.

Because water from pitcher pumps is drawn directly from the soil, it is more prone to contamination. If such water is not filtered and purified, consumption of it might lead to gastrointestinal or other water-borne diseases. A notorious case is the 1854 Broad Street cholera outbreak. At the time it was not known how cholera was transmitted, but physician John Snow suspected contaminated water and had the handle of the public pump he suspected removed; the outbreak then subsided.

Modern hand-operated community pumps are considered the most sustainable low-cost option for safe water supply in resource-poor settings, often in rural areas in developing countries. A hand pump opens access to deeper groundwater that is often not polluted and also improves the safety of a well by protecting the water source from contaminated buckets. Pumps such as the Afridev pump are designed to be cheap to build and install, and easy to maintain with simple parts. However, scarcity of spare parts for these type of pumps in some regions of Africa has diminished their utility for these areas.

Multiphase pumping applications, also referred to as tri-phase, have grown due to increased oil drilling activity. In addition, the economics of multiphase production is attractive to upstream operations as it leads to simpler, smaller in-field installations, reduced equipment costs and improved production rates. In essence, the multiphase pump can accommodate all fluid stream properties with one piece of equipment, which has a smaller footprint. Often, two smaller multiphase pumps are installed in series rather than having just one massive pump.

A rotodynamic pump with one single shaft that requires two mechanical seals, this pump uses an open-type axial impeller. It is often called a Poseidon pump, and can be described as a cross between an axial compressor and a centrifugal pump.

The twin-screw pump is constructed of two inter-meshing screws that move the pumped fluid. Twin screw pumps are often used when pumping conditions contain high gas volume fractions and fluctuating inlet conditions. Four mechanical seals are required to seal the two shafts.

These pumps are basically multistage centrifugal pumps and are widely used in oil well applications as a method for artificial lift. These pumps are usually specified when the pumped fluid is mainly liquid.

A buffer tank is often installed upstream of the pump suction nozzle in case of a slug flow. The buffer tank breaks the energy of the liquid slug, smooths any fluctuations in the incoming flow and acts as a sand trap.

As the name indicates, multiphase pumps and their mechanical seals can encounter a large variation in service conditions such as changing process fluid composition, temperature variations, high and low operating pressures and exposure to abrasive/erosive media. The challenge is selecting the appropriate mechanical seal arrangement and support system to ensure maximized seal life and its overall effectiveness.

Pumps are commonly rated by horsepower, volumetric flow rate, outlet pressure in metres (or feet) of head, inlet suction in suction feet (or metres) of head.

From an initial design point of view, engineers often use a quantity termed the specific speed to identify the most suitable pump type for a particular combination of flow rate and head.

The power imparted into a fluid increases the energy of the fluid per unit volume. Thus the power relationship is between the conversion of the mechanical energy of the pump mechanism and the fluid elements within the pump. In general, this is governed by a series of simultaneous differential equations, known as the Navier–Stokes equations. However a more simple equation relating only the different energies in the fluid, known as Bernoulli"s equation can be used. Hence the power, P, required by the pump:

where Δp is the change in total pressure between the inlet and outlet (in Pa), and Q, the volume flow-rate of the fluid is given in m3/s. The total pressure may have gravitational, static pressure and kinetic energy components; i.e. energy is distributed between change in the fluid"s gravitational potential energy (going up or down hill), change in velocity, or change in static pressure. η is the pump efficiency, and may be given by the manufacturer"s information, such as in the form of a pump curve, and is typically derived from either fluid dynamics simulation (i.e. solutions to the Navier–Stokes for the particular pump geometry), or by testing. The efficiency of the pump depends upon the pump"s configuration and operating conditions (such as rotational speed, fluid density and viscosity etc.)

For a typical "pumping" configuration, the work is imparted on the fluid, and is thus positive. For the fluid imparting the work on the pump (i.e. a turbine), the work is negative. Power required to drive the pump is determined by dividing the output power by the pump efficiency. Furthermore, this definition encompasses pumps with no moving parts, such as a siphon.

Pump efficiency is defined as the ratio of the power imparted on the fluid by the pump in relation to the power supplied to drive the pump. Its value is not fixed for a given pump, efficiency is a function of the discharge and therefore also operating head. For centrifugal pumps, the efficiency tends to increase with flow rate up to a point midway through the operating range (peak efficiency or Best Efficiency Point (BEP) ) and then declines as flow rates rise further. Pump performance data such as this is usually supplied by the manufacturer before pump selection. Pump efficiencies tend to decline over time due to wear (e.g. increasing clearances as impellers reduce in size).

When a system includes a centrifugal pump, an important design issue is matching the head loss-flow characteristic with the pump so that it operates at or close to the point of its maximum efficiency.

Most large pumps have a minimum flow requirement below which the pump may be damaged by overheating, impeller wear, vibration, seal failure, drive shaft damage or poor performance.

The simplest minimum flow system is a pipe running from the pump discharge line back to the suction line. This line is fitted with an orifice plate sized to allow the pump minimum flow to pass.

A more sophisticated, but more costly, system (see diagram) comprises a flow measuring device (FE) in the pump discharge which provides a signal into a flow controller (FIC) which actuates a flow control valve (FCV) in the recycle line. If the measured flow exceeds the minimum flow then the FCV is closed. If the measured flow falls below the minimum flow the FCV opens to maintain the minimum flowrate.

As the fluids are recycled the kinetic energy of the pump increases the temperature of the fluid. For many pumps this added heat energy is dissipated through the pipework. However, for large industrial pumps, such as oil pipeline pumps, a recycle cooler is provided in the recycle line to cool the fluids to the normal suction temperature.oil refinery, oil terminal, or offshore installation.

Engineering Sciences Data Unit (2007). "Radial, mixed and axial flow pumps. Introduction" (PDF). Archived from the original (PDF) on 2014-03-08. Retrieved 2017-08-18.

Tanzania water Archived 2012-03-31 at the Wayback Machine blog – example of grassroots researcher telling about his study and work with the rope pump in Africa.

C.M. Schumacher, M. Loepfe, R. Fuhrer, R.N. Grass, and W.J. Stark, "3D printed lost-wax casted soft silicone monoblocks enable heart-inspired pumping by internal combustion," RSC Advances, Vol. 4, pp. 16039–16042, 2014.

"Radial, mixed and axial flow pumps" (PDF). Institution of Diploma Marine Engineers, Bangladesh. June 2003. Archived from the original (PDF) on 2014-03-08. Retrieved 2017-08-18.

Quail F, Scanlon T, Stickland M (2011-01-11). "Design optimisation of a regenerative pump using numerical and experimental techniques" (PDF). International Journal of Numerical Methods for Heat & Fluid Flow. 21: 95–111. doi:10.1108/09615531111095094. Retrieved 2021-07-21.

Rajmane, M. Satish; Kallurkar, S.P. (May 2015). "CFD Analysis of Domestic Centrifugal Pump for Performance Enhancement". International Research Journal of Engineering and Technology. 02 / #02. Retrieved 30 April 2021.

Wasser, Goodenberger, Jim and Bob (November 1993). "Extended Life, Zero Emissions Seal for Process Pumps". John Crane Technical Report. Routledge. TRP 28017.

Australian Pump Manufacturers" Association. Australian Pump Technical Handbook, 3rd edition. Canberra: Australian Pump Manufacturers" Association, 1987. ISBN 0-7316-7043-4.

To handle a wide range of slurries with various solid concentrations, solid particle sizes, solid particle sizes, and solution compositions, slurry pumps come in a variety of designs and constructions. Pumps for liquids are not as durable as slurry pumps. To counteract wear from friction, they incorporated sacrificial materials and replaceable wear components. Slurries can be pumped using centrifugal, positive displacement, and vortex pumps. Centrifugal slurry pumps can have split casings or casings that are bonded to bearing-supported shafts and rubber or metal. The configurations include underwater, hanging vertically, and horizontal. Slurries are often categorized based on their solids concentration. Concentration, particle size, shape, and weight are all factors that engineers use to classify slurries and evaluate the level of attrition. Slurries are separated into four classes according to the engineering of slurry pumps: Class 1, Class 2, Class 3, and Class 4. A slurry pump selection is more challenging than a water or liquid pump selection. Brake horsepower and wear are influenced by a variety of parameters and duty point adjustments. A slurry pump calculation approach is offered by the Root Dynamic Centrifugal Slurry Pump. One of the primary characteristics and subtypes of slurry pumps with peripheral motion is the impeller. In order to ensure proper service life due to the high wear of particles, the velocity should adhere to the slurry type classification. Engineers take capacity, head, and solids handling capability, efficiency and output, speed, and NPSH into account when choosing the best slurry pump. In the mining, dredging, steel, and other industries, slurry pumps are frequently employed to transfer abrasive solids. They are primarily intended for use in heavy-duty applications. Some slurries, depending on the mining process, are corrosive and difficult to work with because corrosion-resistant materials, like stainless steel, are softer than high-grade steel. High chromium is the name of the metal alloy that is most frequently used to make slurry pumps. With 25% more chromium added to make it less brittle, it is essentially white iron. In some applications with minute solid particles, rubber line casings are also employed.

A unique kind of liquid pump called a self priming slurry pump is made to start the pumping operation by retaining the necessary liquid inside a cavity or inside the pump body. This can increase the operational effectiveness of process facilities where a range of repetitive and irregular tasks are carried out using pumps. Pumps are included into production lines in the sanitary and sanitation industry to carry out a number of tasks. Pumps are employed in: Product onto the production line. Pumping CIP (clean-in-place) fluids cleans and sanitizes pipes and parts. Liquid between storage containers via transfer Empty drums and tanks Some pumps have the necessary beginning fluid permanently present in the chamber or body of the pump. This type of pump is known as "self-priming. " Other pumps need to have starting fluid added to them before they can run. There is no pump that is inherently superior to another. The use and frequency of the pump will determine this.

Some kinds of pumps have an automatic self-priming feature. Pumps of this kind contain precise working parts that, even when the pump is not running, prevent backflow from the discharge side to the suction side of the pump, keeping the fluid inside the pump body. These kinds of pumps are able to manage so-called "air pockets" better since there is always liquid inside the pump body. Air pockets are air bubbles that accumulate in the workings of the pump and may prevent the pump from functioning properly. Centrifugal pumps are the most common type of liquid pump utilized in the sanitary processing sector. What are centrifugal pumps? Simple Strong Reasonable cost Ideal for pumping water and CIP solutions, which have low viscosities, in challenging suction situations. A V-shaped centrifugal pump design is frequently preferred for these kinds of low-viscosity fluids, with a vacuum pump and positive seal placed close to the discharge port. This makes it simple to easily empty the V-shaped centrifugal pump till it is filled with liquid. Normal centrifugal pumps are not self-priming, though. Standard centrifugal pumps do not trap fluid when they are not in use, in contrast to the pump types indicated above. With a centrifugal pump, the fluid is displaced and forced through the discharge port by centrifugal force as the impeller rotates through the fluid in the chamber or cavity of the pump. Typically, liquid enters the pump through the impeller"s core and escapes through ports on the pump body"s outer perimeter. In a monobloc construction, the impeller is frequently positioned directly on the pump"s motor. Air is this type of pump"s major adversary. A typical centrifugal pump may "air bounce" and stop working when it comes into contact with an air pocket. Air ingress is frequent in conventional centrifugal pumps. This is due to the lack of a seal between the pump"s suction and discharge sides and the lack of tightly connected pumping mechanisms like gears or screws. Self-priming centrifugal pumps avoid air coupling by mixing fluid during the priming process with any remaining air in the pump"s operating mechanism.

By removing air and facilitating product flow on the suction side of the pump, the resulting mixture can move readily through the pump body when it is first started up thanks to this mixing. Normal pump action starts as the process fluid and entrained air flow in the direction of the impeller. Self-priming centrifugal pumps are distinctive from conventional centrifugal pumps in that the liquid reservoir is included within the pump body, typically above or in front of the impeller. During the priming cycle, this reservoir enables the pump to remove any air from the pump body and suction line and replace it with liquid from the reservoir mixed with any remaining air. This kind of centrifugal pump"s reservoir"s capacity to hold fluids after it has been originally primed is what gives it its "self-priming" property. Self-Priming Centrifugal Pumps" Benefits Suitable for a variety of liquids Slurries, caustic liquids, and suspended solids are all suitable In contrast to a submersible pump, a self-priming centrifugal pump keeps pumping even after it is submerged in a liquid tank or container. Ideal for frequent and irregular pump operation because pump priming at startup is not required. Self-Priming Centrifugal Pumps" Drawbacks Without initial priming fluid in the reservoir, the pump won"t operate. This type of centrifugal pump may be larger than regular models due to the necessary liquid reservoir, which can be problematic in situations with restricted space. To prevent draining the pump"s fluid reservoir while it is in operation, self-priming should be situated as close to the production line as possible.

he slurry pump must frequently be installed above the liquid level in applications where liquid pumps are used. Air entering the line as a result of this could result in issues including overheating and pump failure. Self priming pumps are used to release the air before moving the fluid to prevent these issues. For a range of applications, Gainesville Industrial Electric (GIE) provides a selection of self-priming pumps. Describe self-priming. Because air must be expelled or displaced before the pump can move liquid, pumps that are partially or entirely above the liquid level may introduce air into the suction line. Self-priming pumps enable air to be purged at startup before starting the regular pumping process. Centrifugal pumps are self-priming, right? Between the suction and discharge sides of centrifugal pumps, there is no seal. This indicates that the pump is not self-priming and cannot discharge gas and air when it is above the liquid level. A tank is built around a centrifugal pump to provide the lubrication and cooling essential to keep the pump from overheating and to maintain it submerged in the fluid at all times. This makes the pump self-priming. Self-priming pumps: how do they operate? Self-priming pumps create a partial vacuum to remove water as the air is expelled, preventing the mixing of air and water. During the priming process, air and water are combined to force the air to ascend and the water to sink and sink. Water that has no air in it is forced back into the impeller by gravity, where it mixes with the air that is still in the suction line. Repeat this procedure until the suction tube is empty of all air and a vacuum is established. As a result, water is forced through the suction line and toward the impeller by atmospheric pressure. Frequently used Self-priming pumps are employed in a vast array of commercial and industrial buildings, including steel mills, power plants, sewage treatment facilities, vineyards, and breweries. Pumping water, fuel, clean water or gray water, untreated sewage, industrial effluent, etc. are common applications. Increased water pressure, irrigation system, underground flood pump, and boat Treatment of sewage Solutions for self-priming pumps The following self-priming pump options are provided by GIE: Self-priming pump FPS. Self-priming FPS pump FPS self-priming pumps are made to handle both sediments and clear water. The pump, which can handle solids up to 3 inches in diameter or length, is designed with a self-priming mechanism to lower the possibility of air entrainment. FPS self-priming pumps are available with electric, frame mount, and gas engine drives from GIE. The gasoline engine can produce up to 27 horsepower, depending on the model. A priming pump was available from Goulds. Silver Pump Pumps for suction and self-priming with clear liquid Clean water may be handled by these self-priming pumps for a range of commercial and industrial applications. To integrate with almost any relevant system, they are offered in portable contractor pump type with mounted impellers and bronze fittings. Fluid pressures of 250 psi and 250 °F can be handled by Gould"s self-priming and suction pumps. Self-priming Marlow Series 20EVP pump. Self-priming Marlow Series Pumps Without the possibility of air entrainment, these self-priming pumps are made to be mounted anywhere between 10 and 20 feet above the liquid surface. Depending on the particular model chosen, it can handle solids of varying sizes in addition to clean water. For usage in industrial chemical and petroleum systems, Marlow specializes in vertical in-line pumps.

Viscous, abrasive, corrosive, or a combination of the three are all possible in processes. Industrial sewage slurry must be removed, transported, and handled responsibly because they can be dangerous to the environment. Pump types made to efficiently pump sludge or slurry do not survive very long, and conventional centrifugal pumps, like those used to pump water, are not ideal for heavy sludge. A mixture of pulverized solids suspended in a liquid that is denser than water is referred to as sludge. Using sludge pumps, mixing solids into sludge or slurry is an effective technique to process and move very large quantities of solids. The mining, steel processing, power generating, construction, wastewater, and fracking industries are just a few that use sludge pumps. It is crucial to have industrial heavy-duty pumps that can handle a variety of harsh and corrosive materials without experiencing maintenance issues due to the variety of sludge types. Pump operators must be knowledgeable about both the pump and the substance or sludge they are pumping. In order to maintain flow rates, extend the life of the pump, and maximize material output rates, do as such. The phrases "sludge pumps" and "slurry pumps" are interchangeable because of how similarly they operate. A sludge pump is what? To prevent the abrasive characteristics of the sludge from destroying the pump, sludge pump design is crucial. Large particles found in sludge can also cause clogs and pump failures in a variety of pump designs. The volute of the majority of centrifugal pumps" impellers has precise tolerances. This means that solids bigger than around one inch won"t get through the pump. Additionally, the slurry"s corrosive and abrasive properties shorten the volute"s lifespan and cause wear. The pump loses suction as a result of these issues, necessitating more frequent repair. When pumping sludge, this causes significant downtime that necessitates expensive repairs and spare parts. Sludge and slurry can be separated into two categories. The solids in one class, which is sludge, eventually drain, whereas the solids in the other class are suspended. Particles in permanent suspension make up sludge, which frequently behaves like water but typically contains very small, low-impact particles that can clean pumps. The particle-filled sludge that eventually separates is a more flammable slurry that doesn"t behave like a typical liquid. The flow rate and horsepower should be taken into account when choosing a sludge pump. Sludge pumps are made to be impact and abrasion resistant due to the fact that the majority of sludge or sludge applications contain coarse particles.

Each substance faces a different set of difficulties when transporting liquid slurry or slurries, and none of them are simple. This is mostly because, depending on its thickness, liquid sludge is particularly challenging to pump. They deteriorate often used mud pumps. The mud pump discharge line must flow properly and obstructions must be avoided. This increases the effectiveness of transporting particles with a mud pump. Depending on the circumstances, the most frequent difficulties for mud pumps are: Common limitations Rapid wear Failure is expected Production halts and prices rise during periods when solids are not moving. Please be aware of the following traits and difficulties: Make sure the mud pump moves the solids slowly but steadily by looking for opportunities to do so (to reduce friction and wear). Additionally, it keeps an eye on how quickly solids are moving to avoid clogs and arrange themselves. Mud pump discharge pressure should be as low as feasible to save mud pump wear and enhance fluidity. Of course, to pump in slurry pumps reliably and safely, pumping engineering principles must always be followed.

Our mission is to provide the world with free and easy-to-use calculators to solve your daily problems. Gone are the days of looking up formulas and blasting away on your physical calculator with a notepad to figure out your problem. Now, software built into websites and apps can do that for you. This can be anything from calculating your monthly payment on a mortgage or figuring out how many calories you can eat to lose weight.

8613371530291

8613371530291