mud pump drilling pdf supplier

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

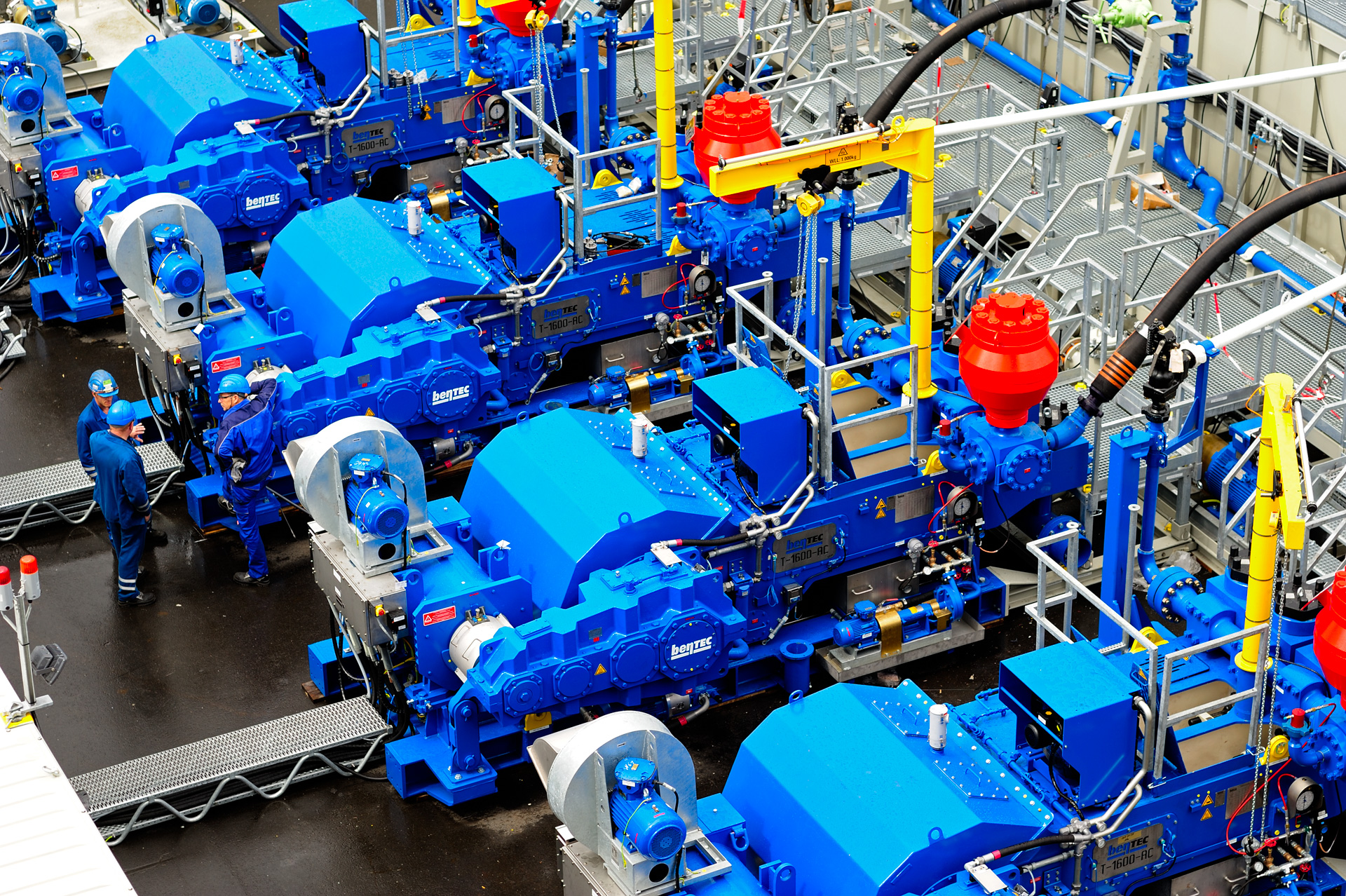

The complexity of today’s drilling projects, especially the need for sufficient pressure and flow rate for wellbore cleaning, challenge mud pumps manufacturers. Their efforts focus on the improvement of pump running time and efficient maintenance management to reduce or eliminate nonproductive time and HSE risks. Drilling rigs rely on mud pumps to efficiently circulate the mud, and synchronized pumps are employed to minimize mud pulsation effects. The mud circulation system is of major interest…Expand

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

Mud pump liner selection in today"s drilling operations seldom (at best) considers electrical implications. Perhaps, with more available useful information about the relationships between mud pump liner size and operational effects on the electrical system, certain potential problems can be avoided. The intent of this paper is to develop those relationships and show how they affect an electrical system on example SCR rigs.Introduction

There, seems to be little consideration for the relationships between liner size and demand on a rig"s engine/generator set(s). Yet, consideration for this relationship can prove to be very helpful to drillers and operators in efficiency of a rig"s electrical system. In order to develop the relationships and help drillers and operators understand the importance of each, relationships between liner size, pump speed, pump pressure, and electrical power will be developed. Only basic physical laws will be used to develop the relationships; and, once developed, the relationships are readily applied to realistic examples utilizing a mud pump manufacturer"s pump data. Finally, conclusions will be drawn from the examples.DEVELOPMENT OF RELATIONSHIPS BASIC RELATIONSHIPS

where HHP= Hydraulic horsepower, GPM = Mud pump volumetric flow rate in gallons per minute, and PST Mud pump output pressure in pounds peer square inch.

Hydraulic horsepower is reflected to the mud pump motor via a multiplier for mechanical efficiency. it follows that motor horsepower is then represented by

When you"re seeking the field flexibility to complete your drilling faster, easier and safer, count on Geoprobe® drill rigs engineered for versatility and manufactured for reliability. Industry leaders depend on our ongoing commitment to innovation and industry-leading customer support to advance their business ahead of the competition. Digital readouts providing instant feedback, enhanced safety features, easy operation, and availability of training options mean veteran drillers find their jobs simplified while new drillers build confidence, making them productive as they"re quickly coming up the learning curve.

Increase depth advancement and recovery speeds while minimizing waste with the 8150LS sonic drilling rig engineered for driller safety, sampling speed, and operation efficiency.

From crowded street corners to far removed places, tackle various environmental, geotechnical and exploration applications with a single machine combining rotary drilling and direct push, saving time and money required to mobilize multiple drill rigs.

Efficiently complete geotech investigations sliding between drilling functions all without the need for a class A/B CDL, safely bringing new drillers up the learning curve on the drilling truck.

Maximize the value of your investment by choosing a CPT drilling platform best suited to your specific business model. Whether you’re seeking a dedicated CPT drilling rig or a versatile drilling rig to run a variety of applications, you’ll find the combination of features to push your business ahead.

Generating a name for itself and redefining the way sites are investigated in the environmental industry, Geoprobe® continues to advance direct push drilling through continued innovation of its line of high-quality, hydraulically-powered direct push drilling rigs

With the necessary tophead rotation speed, head feed speed, and plenty of mud pump options to get the job done, complete your water well drilling, geothermal drilling, and cathodic protection drilling jobs with a single, compact water well drill.

Tophead offering both torque and speed to the impressive power to weight ratio make the DM450 well suited for water well, geothermal, and/or cathodic protection drilling while minimizing maintenance.

Outfit as down the hole drill or mud drill with the power of 28.5-foot stroke, 40,000 lb pullback, and 8,000 ft-lb torque to handle deeper wells along with weight of steel casing.

8613371530291

8613371530291