mud pump fluid end assemblies manufacturer

Fluid end modules are workhorses of mud pump systems, but extreme working environments make them especially vulnerable to stress, wear and damage. In choosing durable fluid end parts that resist cracking and corrosion, you’re making a wise long-term investment for your operations.

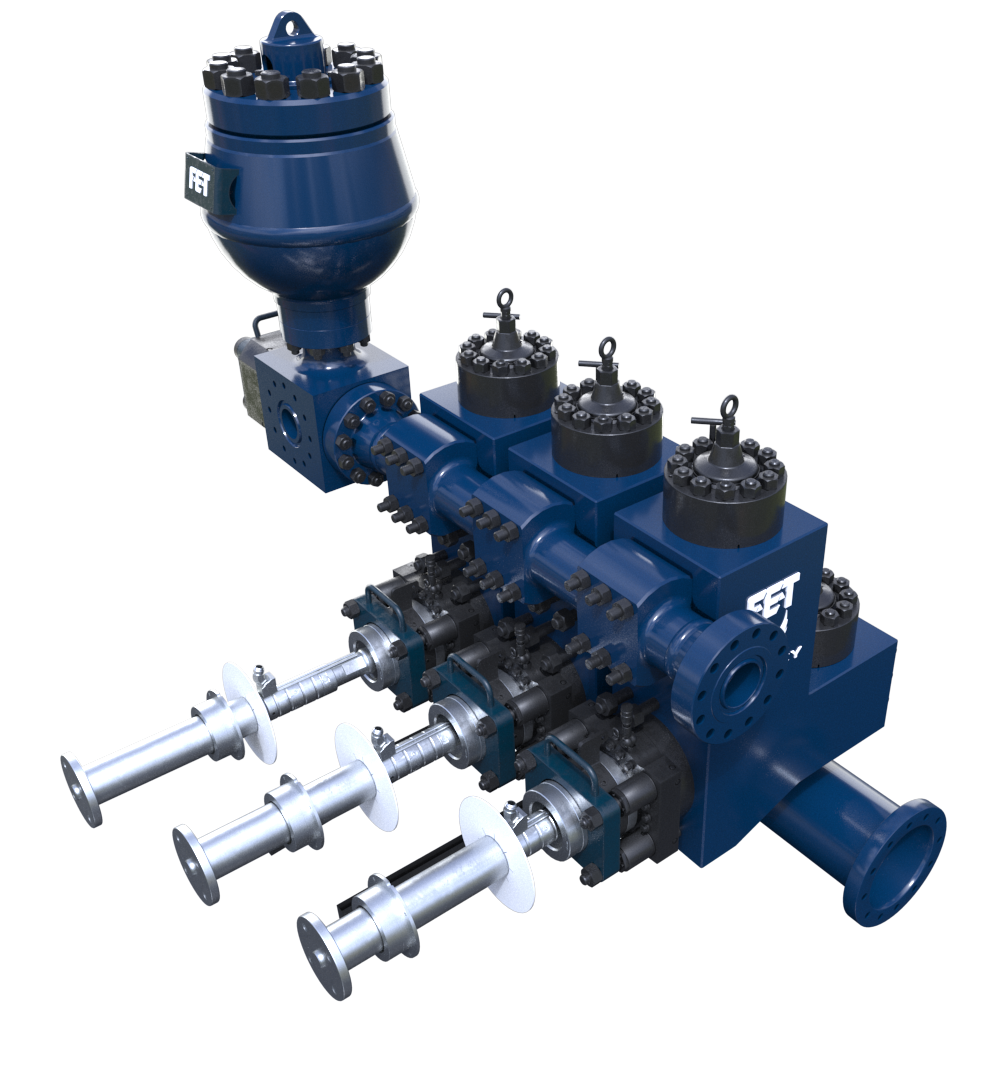

Forum offers a full line of high-quality fluid end modules that are entirely manufactured in the United States. Designed for the challenges of higher-pressure drilling, they are crafted with industry-leading materials and technologies to resist cracking and reduce stress concentrations for significantly longer life. Complementary features include our industry-leading P-Quip® liner retention and rod systems. Additional benefits and features include:

BOPM manufactures frac pump fluid end assembly for various OEMs, all of our fluid ends are interchangeable with OEMs, including SPM, GD, JAMC, Serva, Etc.

Throughout the whole process of procurement, production, heat treatment and inspection, BOPM"s quality control system is playing its critical role to ensure the excellent integrity and performance of each fluid end assembly, and all manufacturing practice is in accordance to ISO 9001 and API quality management system.

Kerr Pumps manufacturers a wide variety of high quality valves and seats. We offer plenty of configurations and materials to choose from such as our more popular salt bath nitrided 17-4 stainless steel. We also keep in stock a full line of Well Service inserted valves and o-ringed seats.

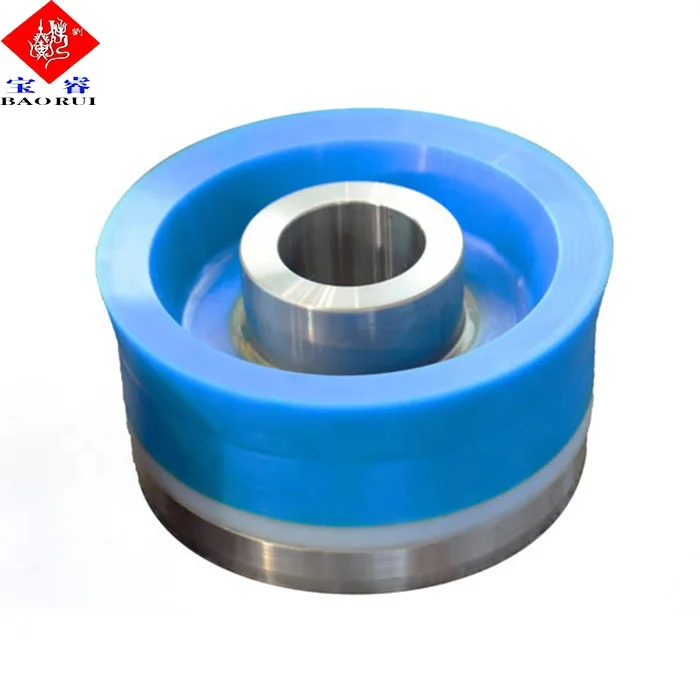

Our engineers have developed piston assemblies with precision molded replaceable piston cups, molded in fabric reinforced nitrile rubber. Coupled with a 300 series stainless steel piston body, this assembly ensures optimum corrosion and abrasion resistance, regardless of liner material.

All of our pony rod glands are machined in-house on one of our many CNC lathes. The level of precision and finish in each gland gives an incredible repeatability from part to part. This consistency extends the life of each seal and pony rod which keeps you pumping longer in the field.And Many More!

We believe that making incredible pumps is just part of the game. Our main focus is taking care of our customers. That is why we stock a full line of pump replacement parts. We do our absolute best in meeting customer demands and continue to strive to be the most responsive pump company.

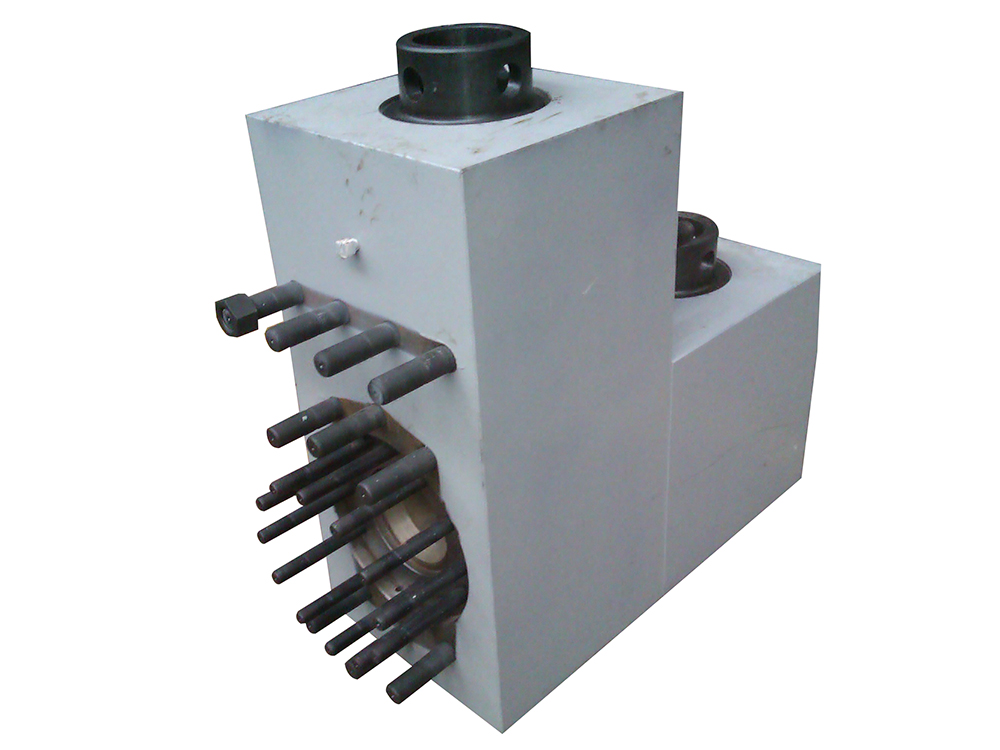

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

All sealing parts are tightened, featuring good sealing performance. Vertical fluid end features good suction performance. Our mud pump fluid end parts are interchangeable with other abroad brands. Call us if you have such requirements on mud pump parts.

A new concept in Check Valves. Fitting these style of Check Valves does require a revised fluid end (see L Shaped Fluid Ends), but these can either be modified from exisitng or more cost-effective new units produced. Read More

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

RPS’s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel, heat-treated for a long working life, machined to perfection, and packaged for delivery with anti-corrosion protection. The precision-made jewelry, like the exterior finish, reflects the superior quality inside.

RPS offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such asNational, Emsco, Gardner Denver, Bomco, Ideco, Weatherford, Drillmec, Eweco, Baker, Texma, Mud King, Honghua, RG, RS, GPM, LS-NOW, Wirth, and Oilwell. We offer both standard OEM style replacement parts and Two-piece “L” Shaped fluid ends. Manufactured to the highest quality, our products offer the best performance and durability. 5000psi & 7500psi available.

ALL COUNTRIESAfghanistanAlbaniaAlgeriaArgentinaArmeniaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBelarusBelgiumBermudaBoliviaBrazilBrunei DarussalamBulgariaCameroonCanadaAlbertaBritish ColumbiaManitobaNew BrunswickNewfoundlandNorthwest TerritoriesNova ScotiaOntarioPrince Edward IslandQuebecSaskatchewanYukonChileChinaColombiaCongoCroatia (Local Name: Hrvatska)CyprusCzech RepublicDenmarkEcuadorEgyptEl SalvadorEquatorial GuineaEstoniaFinlandFranceGambiaGeorgiaGermanyGhanaGibraltarGreeceGuatemalaGuineaHaitiHong KongHungaryIcelandIndiaAndaman & NicobarAndhra PradeshArunachal PradeshAssamBiharChandigarhChattisgarhDadra & Nagar HaveliDaman & DiuDelhiGoaGujaratHaryanaHimachal PradeshJammu & KashmirJharkhandKarnatakaKeralaLakshadweepMadhya PradeshMaharashtraManipurMeghalayaMizoramNagalandOrissaPondicherryPunjabRajasthanSikkimTamil NaduTelanganaTripuraUttar PradeshUttarakhandWest BengalIndonesiaIran (Islamic Republic Of)IraqIrelandIsraelItalyJamaicaJapanJordanKazakhstanKenyaKorea, Republic OfKuwaitLatviaLebanonLiberiaLibyan Arab JamahiriyaLithuaniaLuxembourgMacedonia, The Former Yugoslav Republic OfMalaysiaMaltaMauritaniaMauritiusMexicoMonacoMoroccoNepalNetherlandsNew ZealandNigeriaNorwayOmanPakistanPanamaPeruPhilippinesPolandPortugalPuerto RicoQatarRomaniaRussian FederationSao Tome And PrincipeSaudi ArabiaScotlandSerbia and MontenegroSingaporeSlovakia (Slovak Republic)SloveniaSouth AfricaSpainSri LankaSwedenSwitzerlandSyrian Arab RepublicTaiwanThailandTrinidad And TobagoTunisiaTurkeyUkraineUnited Arab EmiratesUnited KingdomUnited StatesAlabama (AL)Alaska (AK)Arizona (AZ)Arkansas (AR)California (CA)Colorado (CO)Connecticut (CT)Delaware (DE)District of Columbia (DC)Florida (FL)Georgia (GA)Hawaii (HI)Idaho (ID)Illinois (IL)Indiana (IN)Iowa (IA)Kansas (KS)Kentucky (KY)Louisiana (LA)Maine (ME)Maryland (MD)Massachusetts (MA)Michigan (MI)Minnesota (MN)Mississippi (MS)Missouri (MO)Montana (MT)Nebraska (NE)Nevada (NV)New Hampshire (NH)New Jersey (NJ)New Mexico (NM)New York (NY)North Carolina (NC)North Dakota (ND)Ohio (OH)Oklahoma (OK)Oregon (OR)Pennsylvania (PA)Rhode Island (RI)South Carolina (SC)South Dakota (SD)Tennessee (TN)Texas (TX)Utah (UT)Vermont (VT)Virginia (VA)Washington (WA)West Virginia (WV)Wisconsin (WI)Wyoming (WY)UruguayVenezuelaViet NamYemenYugoslaviaZimbabwe

Mud pumps offer advantages that make mud pumps for drilling rigs the most suitable. The pumps are free of pulsations or suspension mixing due to the low speeds achieved in the flow of liquid in combination with the high levels of pressure that are produced. On a weight to suction capability ration, the mud pumps score high, with the capability for high suction power despite the lesser weight. This makes the mud pumps suitable for operations at remote locations. At Shalepumps we have always developed products that offered value to oil and gas exploration. We take you through the finer details of the role of mud pump fluid end modules in mud pumps.

Circulating drilling fluid – Tasked with circulating the drilling fluid downhole under high pressure, the fluid end modules are vital assemblies in mud pumps for drilling rigs. Our experiences in fluid end mechanics design concepts have helped us at Shalepumps to manufacture the most efficient components and equipment. The fluid end of the mud pump comprises pistons which intake or discharge fluid. Fluid is actually a term for the mud in drilling operations. The pistons alternatively suck in mud through the suction valves and force the mud out through the discharge valves.

Double acting pumps help to move more mud on a single stroke – Unlike a single stroke pump, double acting pumps offer greater mud moving capability on every stroke. The action of sucking in and forcing mud out alternately on a single stroke have actually lent the name double acting pumps. The pumps are generally powered by motors that drive the operations of the pump. The older versions relied on chain drives to drive the pump, while other models used belts or power bands to convert movement.

Mud pump fluid end modules work in absolute unison with the power end to create the reciprocating effect for movement of the drilling fluid as per needs. The size of the borehole and the depth are variables that determine the adjustments in the power end which need to function in seamless efficiency for better output.

Woodhouse International remains one of the region’s leading fluid end parts suppliers. A position we have held since the mideighties. Many brand names have been lost through acquisition & mergers over the years; Harrisburg, Wooley, Halco, Baker to name but a few.

Woodhouse International introduced to the Middle East the South West style high pressure quick change valve cover & HP fluid end assembly. We equally introduced the bonded piston & the Roughneck style full open valve & seat.

Woodhouse now offers its own in House Liner. The company in question, has been engaged in the R&D, and manufacture of mud pump liners since 1987. Strict quality control ensures ISO9001 certification, and the right to use API Spec 7K monogram in their manufacturing process. The same company supplies most major ”OEM’s” & thus we have total confidence in promoting these liners which we now hold in our facility at Jebel Ali.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

8613371530291

8613371530291