mud pump fluid ends manufacturer

At Kerr Pumps, we know that the fluid end is the heart of pumping performance. We take great pride in our proven designs and manufacture the highest quality fluid ends. The tolerances achieved by our CNC machines are equal to or better than anyone in the industry. To achieve the smoothest flow, each forging is precision machined with our proprietary tooling that mills a precise combination of taper, radius, and polish enabling a Kerr fluid end to outperform and last longer than the competition.

Premium Oilfield Technologies takes the responsibility of listening to our clients’ concerns very seriously. Acting on those needs enables Premium to offer robust solutions to customer issues at the rig. The Caliber® DS-7500 Fluid Ends bring together our years of field experience and unmatched client interface to represent the NEW standard for your Gardner Denver pumps.

A new innovation either refurbishing existing fluid ends (subject to initial condition), or as a new fluid end with a significantly reduced manufacturing cost !. The revised fluid end is fitted with single unit cartridge style check valves, which are easily accessed, allowing simpler maintenance and improving operational efficiency.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

Fluid end modules are workhorses of mud pump systems, but extreme working environments make them especially vulnerable to stress, wear and damage. In choosing durable fluid end parts that resist cracking and corrosion, you’re making a wise long-term investment for your operations.

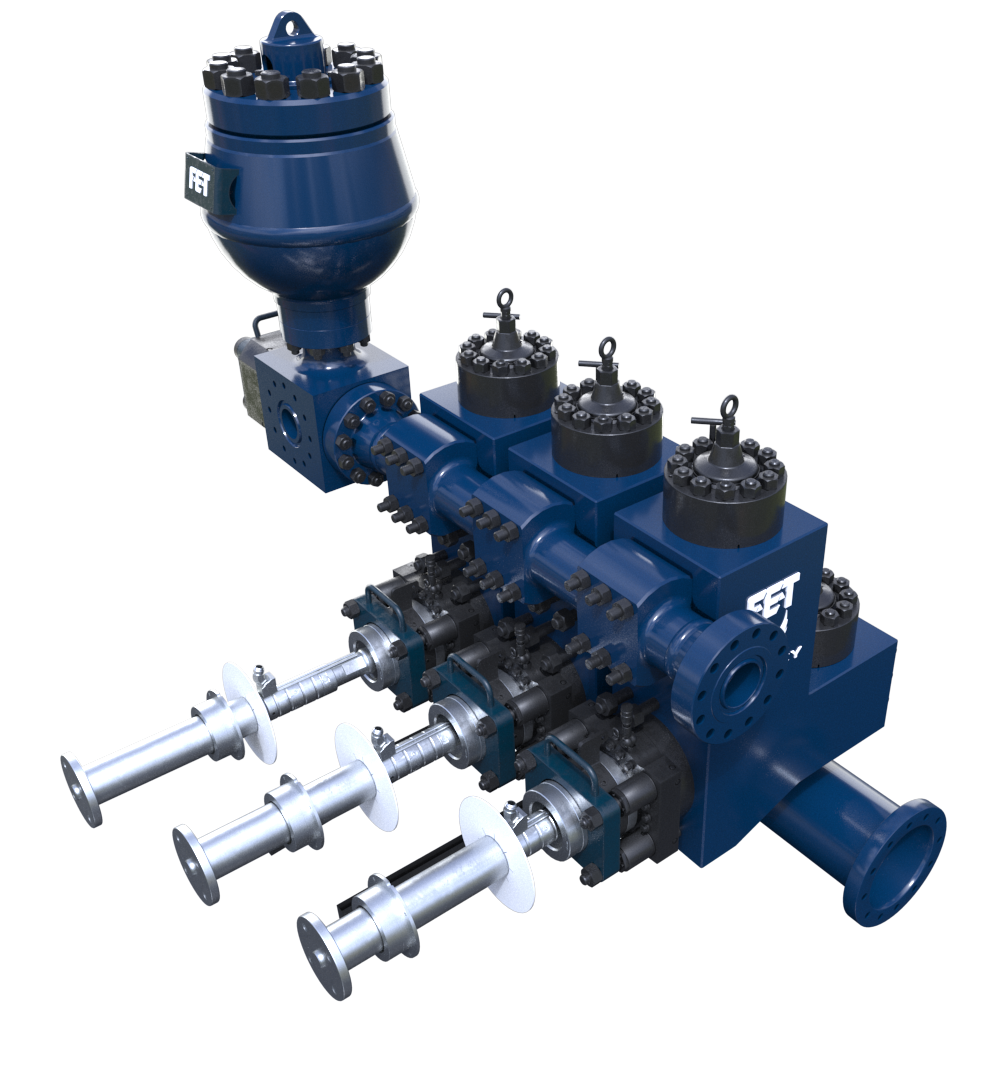

Forum offers a full line of high-quality fluid end modules that are entirely manufactured in the United States. Designed for the challenges of higher-pressure drilling, they are crafted with industry-leading materials and technologies to resist cracking and reduce stress concentrations for significantly longer life. Complementary features include our industry-leading P-Quip® liner retention and rod systems. Additional benefits and features include:

For over 60 years, Southwest Oilfield Products has been providing the industry with high-quality mud pump parts and we are excited to expand our product offering to include well service pump fluid ends and consumable parts. With over 15 domestic store locations, we are certain to have a convenient location that is ready to serve you.

Packing: Our well-service pump packing options are all-inclusive from moderate to severe service sealing designs. We offer both replacement and complete packing sets.

GPM International is a supplier of durable oilfield replacement parts for a wide variety of drilling mud pumps. Inventory products including mud pump fluid end parts, handling tool, etc. All of our products are fully exchangeable with O.E.M. standards.

We also served as the acting shop and field repair representative for the Western Gear Company and as a manufacturing facility for Wilson Manufacturing Company based in Wichita Falls, Texas. Wilson was a manufacturer of well service rigs and mud pumps. SMC Inc. has served and currently serves as a manufacturing and repair center for Oil Well Supply, Cabot-Franks, National, Halliburton, The Western Company, B.J. Hughes, Gardner Denver and many others. We manufacture a triplex pump of 165 H.P. with parts interchangeable to the Gardner Denver model TEE and are currently developing a 500 H.P. pump with parts interchangeable to Oilwell"s SA-644-5 pump. SMC has a large warehouse full of quality replacement parts for various types of equipment such as Triplex Plunger Pumps, Mud Pumps, Swivels, Drawworks and Rotaries.

We manufacture positive displacement pumps and replacement parts vital to the oil industry worldwide. We have customers that include both domestic and foreign oil companies. We also manufacture and repair a variety of products used in routine maintenance by customers with rock crushers, aggregate and commercial cement manufacturing plants.

ALICE, TX (July 24, 2018) - VP Sales & Manufacturing, a leading manufacturer and seller of high-quality frac fluid ends and replacement parts, launches Hercules2 (H2), a new fluid end design with proprietary technology.

The H2 is engineered to decrease overall cost of ownership and cost per pumping hour by eliminating stuck nuts, D-ring washouts, and increasing packing life. With a more reliable compression seal than the standard radial seal (d-ring), this fluid end is designed to be disassembled within minutes in the field, allowing for maintenance between fracking stages and increased reliability between maintenance intervals.

“This is a completely new approach to solving an industry wide epidemic of fluid end failures in modern frac conditions. We wanted to give our clients a better solution for more fluid end hours, less washouts, less failures, and a simplified maintenance routine,” said Erik Perez, Vice President of VP Sales & Manufacturing.

The Hercules2 provides the end user a quick and easy access for maintenance, while eliminating problematic seal areas. No special tools are needed for this new frac fluid end, all that is required for disassembly is a 6# hammer.

“We want the industry to know that this is not just another fluid end, and we believe that this revolutionary design changes the frac fluid end industry,” said Perez.

The Hercules2 (H2) has an increased lifespan of more than 50% in some cases by eliminating common failure areas found on competitors fluid ends. The design is also very user-friendly and allows for quick disassembly in the field.

ABOUT VP SALES & MANUFACTURING:VP Sales & Manufacturing is a leading manufacturer and provider of frac fluid ends, expendables, replacement parts, and centrifugal pumps. Headquartered in Alice, Texas, VP has continued to provide the highest quality oilfield products, oilfield product repairs and world-class service to ensure that our customers’ expectations are constantly exceeded. Our expertises range from mud pumps to workover rigs, hydraulic fracturing equipment and more. With more than 25 years in business, VP Sales & Manufacturing can assist you today by analyzing and providing experience and solutions to meet all our customers’ fracking needs. For more information, please visit our website. www.vpsalesmfg.com

Premium Rig Parts is a leading manufacturer and supplier of mud pump parts, drilling rig expendables to the oil drilling industry. Our specialties include, but are not limited to, expendables for mud pump systems including Emsco, Brewster, National ... ... Read More

TSC"s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel and heat treated for long working life. These modules are machined to perfection and packaged for delivery.

8613371530291

8613371530291