mud pump frame cover brands

At GD Energy Products, the safety of our customers is our top priority. That’s why we developed SafeLock, our innovative hammerless valve cover lock. SafeLock utilizes GD Energy Products’ bore seal valve cover design which requires no preload to create an effective and reliable seal during pressurized operation. Along with easing equipment maintenance, SafeLock’s simplistic design results in a robust and durable product in even the most extreme drilling environments.

SafeLock is offered as an optional upgrade on new GD Energy Products drilling pumps and modules, and can also be used for retrofit on GD Energy Products HD, F and Y series drilling pump modules with bore seal technology.

Simple Operation -No tools, no problems. SafeLock’s quarter-turn design eliminates the need for hydraulic pumps, torque wrenches, drills, or impact guns for installation and removal. To install or remove SafeLock, simply grab the handles and turn 25 degrees, it’s that easy!

Safety & Efficiency Built-in -SafeLock eliminates the need for the dangerous and time-consuming practice of hammering 65+ pound valve covers. The innovative mechanical lock simply drops in and engages with a quarter turn allowing the valve cover lock to be safely installed within 10 seconds.

The Hammerless Frac Suction Cover Retainer allows for the installation and loading of joints without the use of sledge hammers, reducing the risk of injury to onsite personnel. It improves safety on the jobsite by holding a pump’s valve cover in place during pumping operations, and prolongs fluid end life by eliminating valve cover seal issues, fluid end thread failures and stuck retainer nuts.

The products shown below are direct replacements to the drain cover shown above.They are designed to fit in/over the existing mud frame. Please ensure that the replacement drain cover has an adequate volumetric flow rating to meet the application"s highest flow potential and that the application meets the replacement drain cover"s sump depth requirements. For more information about this, please

Drain covers must be sized to handle the highest possible flow rate for the specific pump and system - not the flow rate the pump is expected to operate at most of the time. A pump’s highest potential flow rate is found at the end of the model’s specific performance curve, it’s important to select a cover with a higher flow rating.

NOTICE:Pump flow potential is best determined by measuring flow or measuring the TDH of the system during high-speed, clean-filter operation and then looking up the actual flow using the manufacturer’s published pump curve. To avoid oversizing drain covers and suction piping, the use of a flow meter or the TDH measurement method is suggested for pumps larger than 3 HP.

Sump depth is the distance between the underside of a drain cover or grate and the suction pipe opening. If you find that a drain is installed with an incorrect sump depth, replacing it with a sumpless cover is a great solution.

Solution:Check the sump prior to selecting a cover. If insufficient, increase the sump depth to match the cover’s requirement or choose a cover rated for zero sump depth installations.

IT"S THE LAW.The VGB law that went into effect in 2008 requires that all public pools and spas have drain covers that comply with the ASME/ ANSI Al 12.19.8 performance standard, or any successor standard, currently ANSI/ APSP 16- 2011. This standard requires that manufacturers determine a life expectancy and place a permanent mark with “Life: X Years”; on each cover to indicate service life lifespan. At AquaStar, based on UV, structural and fastener testing, we’ve determined that our drain covers should be replaced every five years or ten years from the date of installation, as stated in our instructions. We have partnered with you to make sure your customers are in compliance with following the law and our customer service department is here to help in any way we can.

REDUCE LIABILITY.The law requires that compliant drain covers be installed in all public pools and spas, in accordance with manufacturer instructions. Failure to comply can result in pool closings and stiff civil penalties, as well as resulting liability in the event of a tragedy.

IT"S SIMPLE.Public pools are required to install compliant covers in accordance with manufacturer instructions. You want your residential customers to have the same level of protection. To ensure structural integrity and avoid accidents with broken covers, the drain covers that public pools and spas installed five years ago need to be replaced. Our drain cover solutions give you the selection you need to meet any requirements. See our replacement Cross-Reference Chart (page 17), Visual VGB Suction Outlet Replacement Guide (page 18-23), or our mobile phone friendly Drain Cover Replacement Guide on www.aquastarpoolproducts.com to view our wide array of available replacement options. If you don’t currently have an AquaStar drain cover, we also have many retro-fit choices that will adapt to other manufacturers frames and sumps. Keep in mind that you must also assess the integrity of the existing frame or sump to ensure that it is structurally sound and able to get three threads of engagement with the new screws provided with each cover. Remember, at AquaStar, every product is held to the highest standard of quality, resulting in superior, dependable products that last.

IT"S SMART BUSINESS.When you remind your customers about their upcoming drain cover expirations, you are more than just a pool supply vendor for them. You"re a trusted resource and partner helping them stay compliant with the law and keeping consumers safe. And that"s good for business.

DON"T WAIT UNTIL IT"S TOO LATE.While replacing drain covers is the legal thing to do, it"s also the safe thing to do. Help your customers make the right decision - at the right time.

Yes. The VGB law that went into effect in 2008 requires that all public pools and spas have drain covers that comply with the ASME/ANSI A112.19.8 performance standard, or any successor standard, currently ANSI/APSP 16-2011.

This standard requires that manufacturers determine a life expectancy and place a permanent mark with “Life: X Years” on each cover to indicate lifespan. At AquaStar, based on UV, structural and fastener testing, we’ve determined that our drain covers should be replaced every five years from the date of installation, as stated in our instructions.

Our Certificate of Compliance provides space to keep track of drain cover expiration. Please fill out and safely store this document, it may be requested during inspection processes.

The manufacture date is molded on to each drain cover, it is represented by a small dial that has the year in the center and an arrow pointing to the month.

Be sure to record the manufacture date on the Certificate of Compliance supplied by our website for the drain cover you are replacing BEFORE installation.

The P series mud pumps are featured by its compact structure, small weight, and land use and high efficiency and can be equipped with drilling rigs according to the requirements and site conditions.

The P series mud pumps are durable and compact and can ensure stable operation. During shallow and middle to deep drilling, the P series mud pumps can meet the special requirements of users.

The durable fluid end of P series mud pumps significantly increases the performance of three-cylinder mud pumps. In addition, the independent structure is easy to inspect and maintain.

The base of the machine frame adopts one-piece welded structure and the seats of the main bearing and transmission bearing are made of one-piece cast steel. The whole pump has good stiffness and strength.

The extension rods are connected to the crossheads by pinholes, so as to ensure the concentricity of the pump. The packing adopts quad-layer sealing structure, which realizes good seal performance.

The fast rotary valve cover is easy to remove and install. The cone bolts have a self-locking mechanism that helps to reduce vibration at the valve cover and to ensure the fastening and stability.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

Includes shaft, sleeve (if required), coupling key, retaining ring, bearings, bearing lock nut, lock washer, bearing housing O-ring, bearing housing, labyrinth oil seals, bearing frame, and viewpoint.

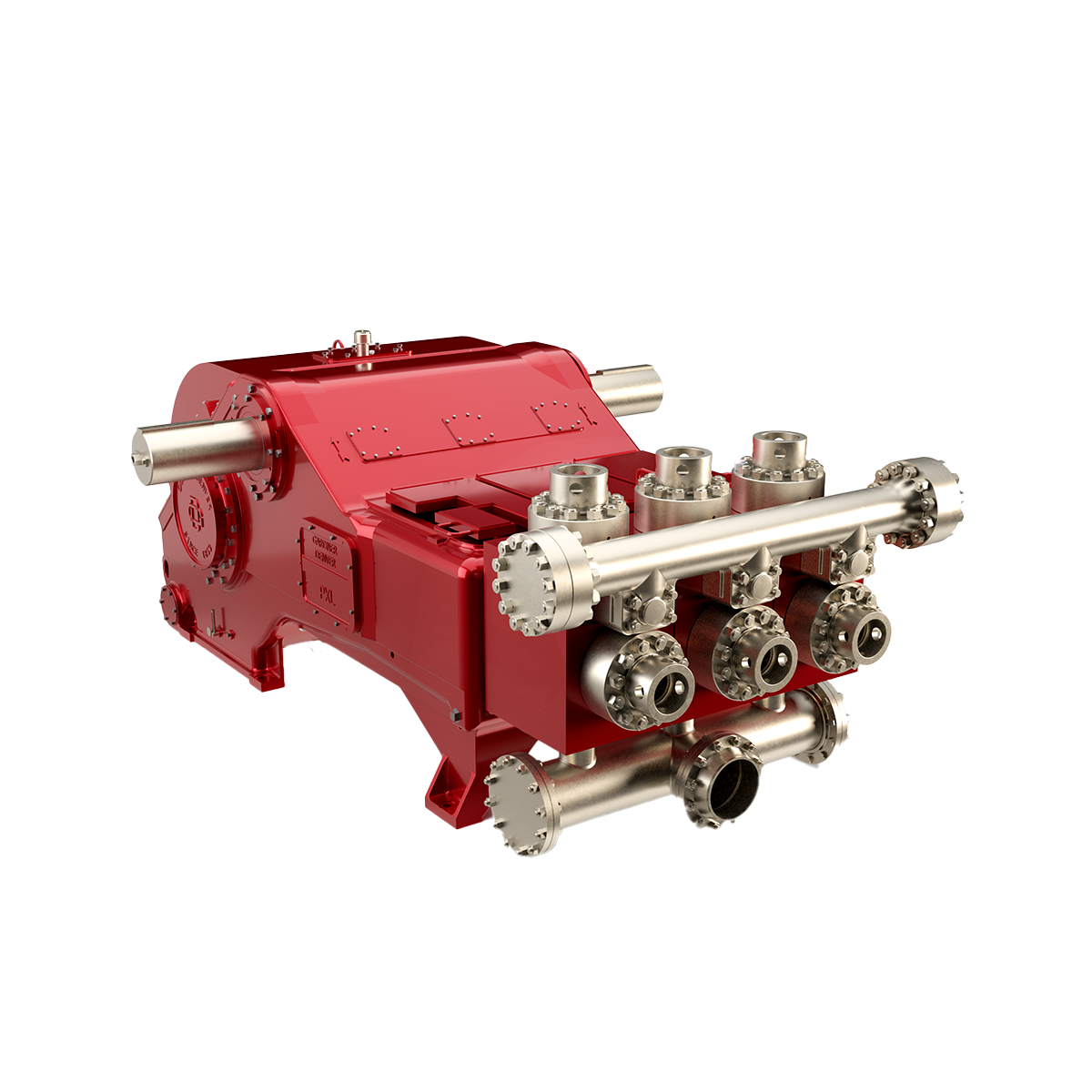

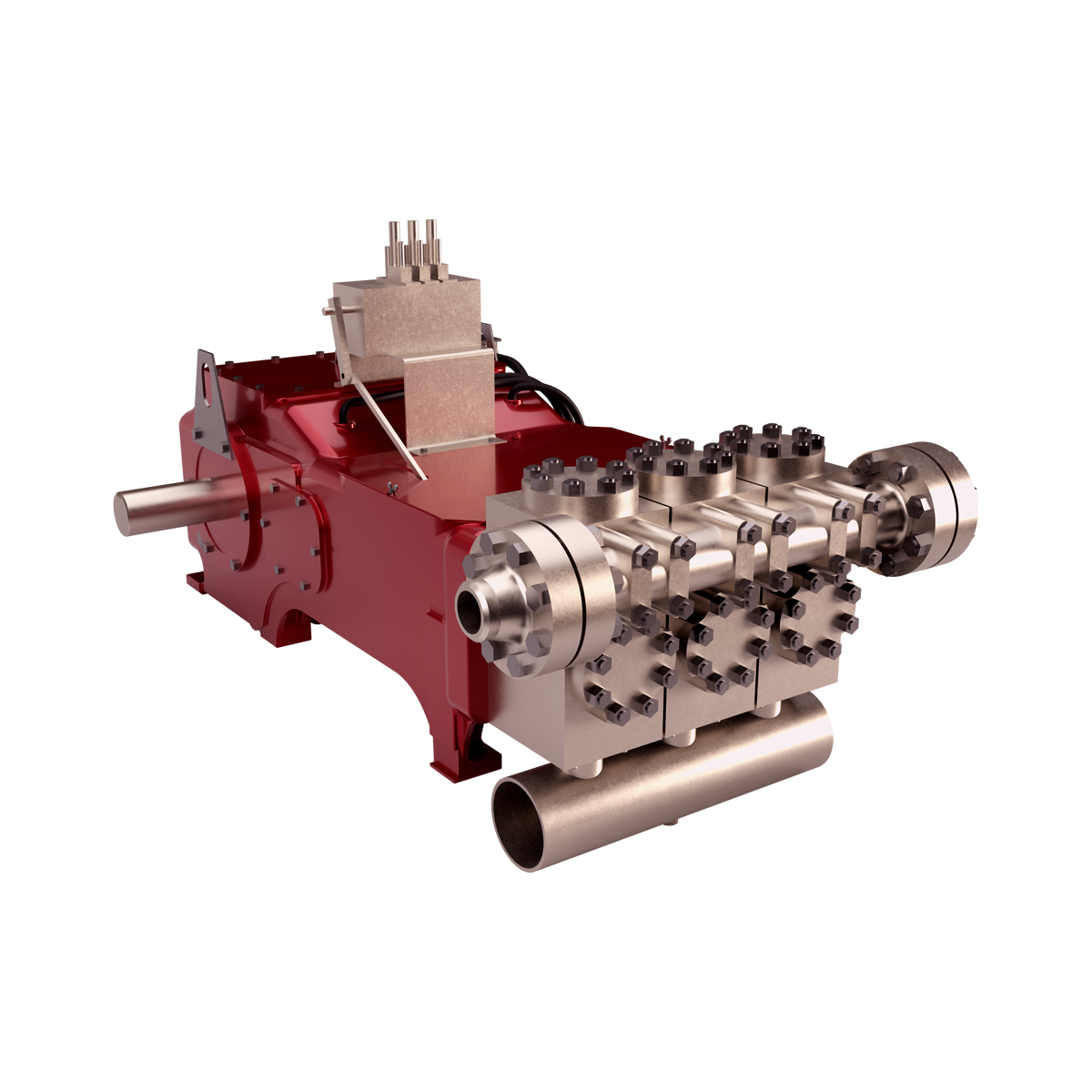

Since the NOV A1700-PT Triplex Mud Pump was built approximately 60 years ago, the industry has widely accepted the three cylinder or triplex style pump. Triplex mud pumps are manufactured worldwide, and many companies have emulated the original design and developed an improved form of the triplex pump in the past decade.

NOV A1700-PT Triplex Mud Pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;They cost less to operate

One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

NOV A1700-PT Triplex Mud Pump is gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. NOV A1700-PT Triplex Mud Pump has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

The products shown below are direct replacements to the drain cover shown above.They are designed to fit in/over the existing mud frame. Please ensure that the replacement drain cover has an adequate volumetric flow rating to meet the application"s highest flow potential and that the application meets the replacement drain cover"s sump depth requirements. For more information about this, please

Drain covers must be sized to handle the highest possible flow rate for the specific pump and system - not the flow rate the pump is expected to operate at most of the time. A pump’s highest potential flow rate is found at the end of the model’s specific performance curve, it’s important to select a cover with a higher flow rating.

NOTICE:Pump flow potential is best determined by measuring flow or measuring the TDH of the system during high-speed, clean-filter operation and then looking up the actual flow using the manufacturer’s published pump curve. To avoid oversizing drain covers and suction piping, the use of a flow meter or the TDH measurement method is suggested for pumps larger than 3 HP.

Sump depth is the distance between the underside of a drain cover or grate and the suction pipe opening. If you find that a drain is installed with an incorrect sump depth, replacing it with a sumpless cover is a great solution.

Solution:Check the sump prior to selecting a cover. If insufficient, increase the sump depth to match the cover’s requirement or choose a cover rated for zero sump depth installations.

IT"S THE LAW.The VGB law that went into effect in 2008 requires that all public pools and spas have drain covers that comply with the ASME/ ANSI Al 12.19.8 performance standard, or any successor standard, currently ANSI/ APSP 16- 2011. This standard requires that manufacturers determine a life expectancy and place a permanent mark with “Life: X Years”; on each cover to indicate service life lifespan. At AquaStar, based on UV, structural and fastener testing, we’ve determined that our drain covers should be replaced every five years or ten years from the date of installation, as stated in our instructions. We have partnered with you to make sure your customers are in compliance with following the law and our customer service department is here to help in any way we can.

REDUCE LIABILITY.The law requires that compliant drain covers be installed in all public pools and spas, in accordance with manufacturer instructions. Failure to comply can result in pool closings and stiff civil penalties, as well as resulting liability in the event of a tragedy.

IT"S SIMPLE.Public pools are required to install compliant covers in accordance with manufacturer instructions. You want your residential customers to have the same level of protection. To ensure structural integrity and avoid accidents with broken covers, the drain covers that public pools and spas installed five years ago need to be replaced. Our drain cover solutions give you the selection you need to meet any requirements. See our replacement Cross-Reference Chart (page 17), Visual VGB Suction Outlet Replacement Guide (page 18-23), or our mobile phone friendly Drain Cover Replacement Guide on www.aquastarpoolproducts.com to view our wide array of available replacement options. If you don’t currently have an AquaStar drain cover, we also have many retro-fit choices that will adapt to other manufacturers frames and sumps. Keep in mind that you must also assess the integrity of the existing frame or sump to ensure that it is structurally sound and able to get three threads of engagement with the new screws provided with each cover. Remember, at AquaStar, every product is held to the highest standard of quality, resulting in superior, dependable products that last.

IT"S SMART BUSINESS.When you remind your customers about their upcoming drain cover expirations, you are more than just a pool supply vendor for them. You"re a trusted resource and partner helping them stay compliant with the law and keeping consumers safe. And that"s good for business.

DON"T WAIT UNTIL IT"S TOO LATE.While replacing drain covers is the legal thing to do, it"s also the safe thing to do. Help your customers make the right decision - at the right time.

Yes. The VGB law that went into effect in 2008 requires that all public pools and spas have drain covers that comply with the ASME/ANSI A112.19.8 performance standard, or any successor standard, currently ANSI/APSP 16-2011.

This standard requires that manufacturers determine a life expectancy and place a permanent mark with “Life: X Years” on each cover to indicate lifespan. At AquaStar, based on UV, structural and fastener testing, we’ve determined that our drain covers should be replaced every five years from the date of installation, as stated in our instructions.

Our Certificate of Compliance provides space to keep track of drain cover expiration. Please fill out and safely store this document, it may be requested during inspection processes.

The manufacture date is molded on to each drain cover, it is represented by a small dial that has the year in the center and an arrow pointing to the month.

Be sure to record the manufacture date on the Certificate of Compliance supplied by our website for the drain cover you are replacing BEFORE installation.

Bruce Suggs, vice president of marketing and sales for White Star, speaks with DC editorial coordinator Katherine Scott about White Star’s quadraplex mud pump at its headquarters in Waller, Texas, on 17 February.

Drilling Contractor visited the manufacturing facility of White Star Pump Company in Waller, Texas, on 17 February to view a demonstration of the company’s quadraplex mud pump, which was designed to address the challenges of the conventional triplex pump.

“After working on all the different brands of (triplex) pumps, it became evident that they all had the same common issues,” said Bruce Suggs, vice president of marketing and sales for White Star. “(We) tried to build a triplex and ended up with the Quatro.”

Instead of taking an existing triplex pump and trying to make it better, White Star approached the project with a clean-sheet design. The Quatro pump features a width of only 82 in. and easily fits on a standard-width trailer, a potential advantage in areas with limited space, such as on offshore rigs and in shale plays like the Marcellus. With the fluid modules sitting inside the frame, change-out time can be reduced to 23 minutes versus up to 10 hours for conventional triplex pumps. The quadraplex pump also uses a fully assembled crankshaft that requires no castings or welding. Using a crankshaft that is fully assembled and supported by modern bearing placement dramatically reduces crankshaft bending and cracking.

Additionally, the Quatro is equipped with two pulsation dampeners, one for each pair of pistons, unlike the triplex, which carries only one. This allows mud to be dampened before it gets to the strain across, creating a quieter, smoother fluid flow and reducing vibrations.

The Liberty Process LL6 Progressive Cavity Pump is ideal for abrasive applications such as use in hydraulic fracking fluids and drilling mud pumping applications. The LL6 is one of the most popular *L-Frame designs in use today in many different applications due to its robust construction.

Liberty Progressive Cavity pumps and parts are direct aftermarket replacements for the *Moyno® L6 frame, *Tarby® TL6 frame and *Continental CL6 Series frame of progressive cavity pumps. Fracking and drilling mud pumps work under high-pressures with solids laden content, the LL6 can achieve flow rates from 5-47 GPM (5.20 Gallons per 100 revolutions) up to a top pressure of 225 psi.

The LL6"s modularity with simple hardened pinned joint drive assembly is a proven design that can handle the most difficult fluid pumping applications. The LL6 PC Rotors are typically tool steel or 316 stainless steel with a hard chrome plating for added durability and resistance to fracking fluids and the grit from mud pumping. All other wetted parts are either carbon steel or 316 stainless steel.

If you currently have a *Moyno®, *Continental®, or *Tarby® brand pump frame, Liberty aftermarket pumps and parts will work with your current unit saving you thousands of dollars, and come with a full warranty and money-back guarantee.

The LL6 is one of the most popular sizes for the L-Frame PC Pump by all pump manufacturers. It has a proven track record of excellence in pumping fluids and as a mud pump for platform installations.

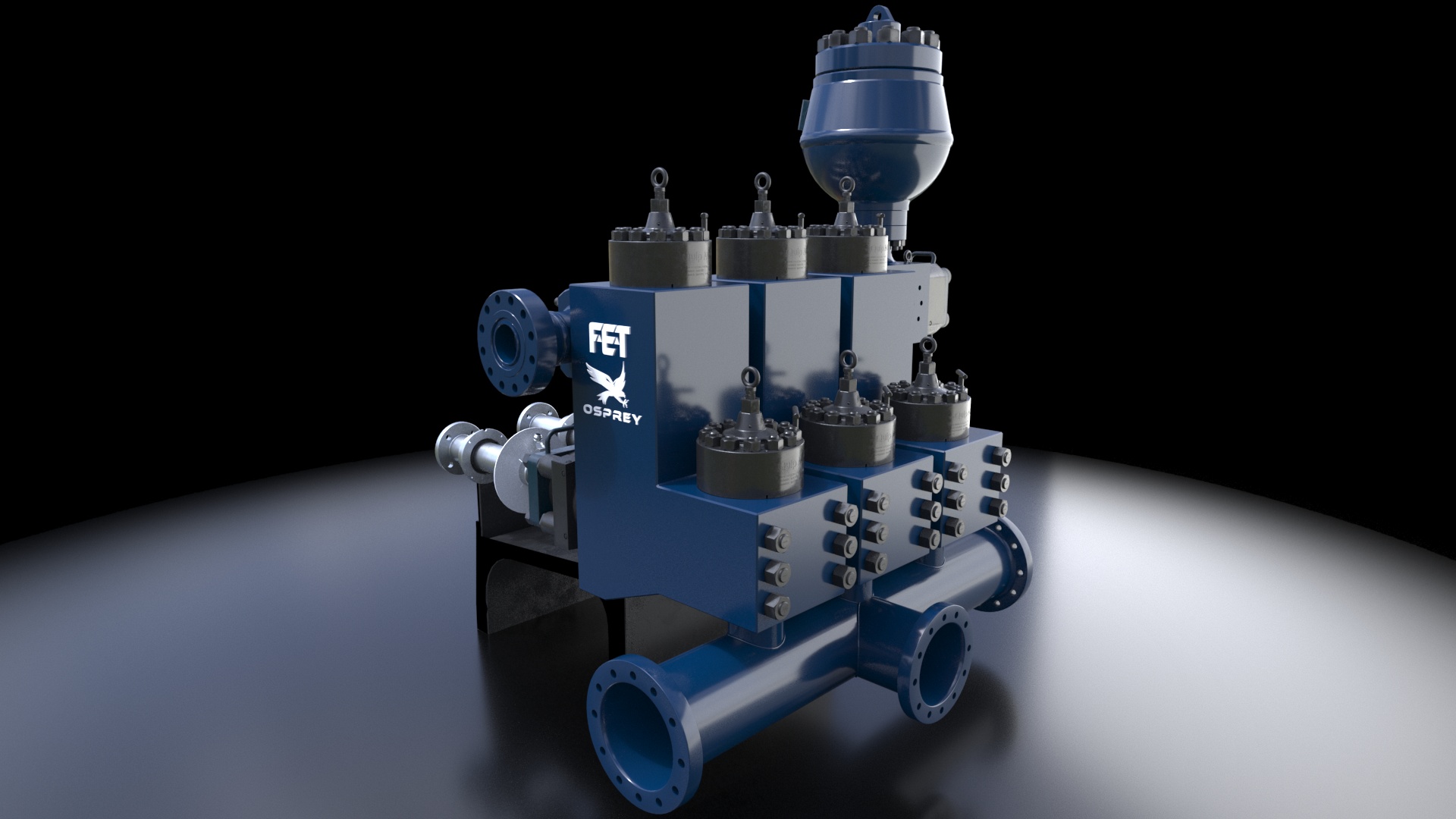

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

Jan112016SPARES FOR GD-TEE AND GD-PAH MUD PUMP (PO NO-4050010004) - GASKET MAINFOLD TO CYLINDER (PART NO - 25BD3)United StatesNhava Sheva SeaNOS1832,2541,792

Jan112016SPARES FOR GD-TEE AND GD-PAH MUD PUMP (PO NO-4050010004) - GASKET SUCTION MANIFOLD TO CYL (PART NO - 25AL62)United StatesNhava Sheva SeaNOS1822,6751,260

Jan112016SPARES FOR GD-TEE AND GD-PAH MUD PUMP (PO NO-4050010004) - VALVE COVER GASKET (PART NO - 301PJH715)United StatesNhava Sheva SeaNOS3691,5152,542

Dec092015SPARES FOR GARDNER DENVER MAKE PZ-9 MUD PUMPS (PO NO -4050009999) - GASKET, INSPECTION PLATE (PART NO - 25C1818)United StatesBombay SeaNOS1370370

Dec092015SPARES FOR GARDNER DENVER MAKE PZ-9 MUD PUMPS (PO NO -4050009999) - GASKET VALVE COVER (PART NO - 300PZJ715)United StatesBombay SeaNOS3098,1443,271

Dec092015SPARES FOR GARDNER DENVER MAKE PZ-9 MUD PUMPS (PO NO -4050009999) - VALVE COVER GASKET (PART NO - 25AL35)United StatesBombay SeaNOS159,010601

Dec092015SPARES FOR GARDNER DENVER MAKE PZ-9 MUD PUMPS (PO NO -4050009999) - GASKET OIL STOP HEAD (PART NO - 25C2693)United StatesBombay SeaNOS51,368274

Dec092015SPARES FOR GARDNER DENVER MAKE PZ-9 MUD PUMPS (PO NO -4050009999) - GASKET, INSPECTION PLATE (PART NO - 25C1788)United StatesBombay SeaNOS103,425342

Dec092015SPARES FOR GARDNER DENVER MAKE PZ-9 MUD PUMPS (PO NO -4050009999) - GASKET BEARING HOUSING (PART NO - 25C2377)United StatesBombay SeaNOS108,401840

Dec092015SPARES FOR GARDNER DENVER MAKE PZ-9 MUD PUMPS (PO NO -4050009999) - GASKET RETAINER PLATE TO (PART NO - 25C2692)United StatesBombay SeaNOS1023,5552,355

8613371530291

8613371530291