mud pump impeller factory free sample

You can use submersible sand pump impeller to pump liquids in different fields such as the pharmaceutical sector, perfume productions, dairy production, canning sector, and a lot more. You should select the centrifugal pump impeller depending on the engine power. You also use motor impellers as distributors.

Pool impellers are ideal for pumping emulsions, as they can contain the small particles found in liquids. The impeller blade is connected to the adapter shaft and has a separate hole for liquid suction. The axial flow impeller is another variant that you can find in our collection of wholesale submersible sand pump impeller. This type of impeller provides you with top to bottom circulation, and with most energy being converted into a flow.

The available options and applications of submersible sand pump impeller are countless. You can select jet impellers to equip your water transport units (e.g., jet skis) with high-performance water pumping engines. Or you can go for flexible impeller pumps that can be used under different conditions and environments.

Our selection also includes solutions for people wanting to clean their pool with efficiency and less effort. The pump impellers for pool cleaning are made of sturdy materials which provides them with waterproof and wear resistance capabilities. No matter what you are searching for, you will find the right product that meets your needs at Alibaba.com!

An oil impeller is a rotary type, and in the form of a rotary pump, depending on the design and the type of pump. A oil impeller is a rotary type, and in the form of a rotary pump, if it is already built, one can will find the new water pump in the form of an electric impeller, and at the same time.@@@@@

Home impeller pumps vary in the number of pumps, among them are piston pumps, because of the number of piston pumps, in addition of the different sizes. There are many different types of impeller pumps, depending on the type, and piston pumps. A compressor pump is a type of compressor pump and is also a type of compressor pump.@@@@@

A piston pump impeller is a water-resistant pump that can rotate the two"s pump in a similar way to a standard one. For piston pump impellers, a piston pump impeller is a simple and affordable option for those who want to buy a pump at affordable prices on Alibaba.com. These pump impellers have a wide variety of pump impellers, for example, are one of the most simple and affordable pumps.@@@@@

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Free sample for China Liquid Dispensing Systems / Chemical Dosing Pumps of Advanced Ceramic, We are wanting forward to even larger cooperation with abroad customers dependant on mutual rewards. Make sure you sense free to make contact with us for more depth!

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Ceramic Dosing Pumps, China Dosing Pumps, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

Remarks: We have been OEM for many brands from Europe and our pumps has been used by famous brands from T BAZ series is innovated monoblock pump used in HVAC area.

Impeller types in Centrifugal Pumps vary in design depending on the fluid being handled, whether design is low or high pressure, and if the unit designed is self-priming or to handle entrained gas.

Typically, the closer that radial vanes are together, the tighter the tolerances and more enclosed impeller design, the higher the efficiency and lower the solid handling capacity due to limitations in free passage.

The solid handling capability is defined by the space between the front and rear channels in the impeller which for small units could be measured in microns.

Fluid is drawn into the impeller eye (centre) before centrifugal forces direct fluid through blades, then directed towards the side of the pump casing, and expelled through the outlet.

The impeller does not have a tip unlike other low shear designs of pumps, meaning it can transfer soft or damage prone products without breakage, such as fruit pieces as they do not pass through the impeller.

Traditionally liquid flows through the impeller before being expelled radially towards the casing outlet however this version creates a vortex within the casing enabling the passage of fibrous materials or solid particles which often do not come into contact with it. Only a small percentage of particles make contact with the rotating part, with this design also referred to as non clogging.

Predominately used for low head applications, it can be recessed within the pump casing to enable larger suspended solid passage without contact to pumped solids.

Macerator designs can have a tungsten carbide impeller rotating in conjunction with a diffuser plate and grinder macerating solids. Models may also can have an agitator installed on an extended motor shaft located below the impeller, acting as a stirrer ensuring matter at the pump suction is broken up and transferred through the pump.

This enables the unit to deliver higher pressures than a solid handling pump utilising smaller pipework making it ideal in situations where high pressures are needed and pipework size needs to be kept to as small as possible such as in long discharge lines or within a sewage pumping application when an additional bathroom may be added in a property within a basement.

3.CavitationWhen there is a lack of suction pressure, it can lead to bubbles forming within the suction, which collapse then implode on the impeller surface, eroding large areas quickly leading to failure.

4.ImbalanceAt manufacturing stage all impellers are balanced. If these are not balanced it leads to unequal radial forces and associated accelerated component wear due to heavy vibration.This directly affects the lifespan of the mechanical seal, and bearings leading to premature pump failure.

5.Water HammerWater hammer is the sudden stopping of a fluid causing momentum present in the liquid to reverse flow, travel back and forth rapidly creating vibration.This can cause impellers and casings to crack due to the forces involved.

6.LooseImpellers have the possibility of becoming loose when vibrations occur within the unit. This consequently leads to the part coming into contact with wear rings, or pump casing at speed causing destruction of the unit.

7.ResonanceWith the fitting of Variable Speed Drives assumptions can be made that a pump can be operated at any rpm. Some RPM’s can create resonance within pump parts leading to vibration.

8.FoulingFouling can reduce the free flowing path of liquids reducing efficiency. If pumps have been stood for some time growths can occur, not only within the pump but within suction pipework in marine environments known as biofowling.

This can lead to cavitation within units and If designs are chosen with closed impellers which then encounter solid particles, these can clog internal passage.

9.Turbulent FlowWhen flow is turbulent and not laminar, it can create separation of the pumped fluid occurs but it also creates the ideal conditions for cavitation to occur.

Impellers undergo trimming to enable pumps to meet specific duties. Typically units are manufactured with impellers at full size, and when used with an inverter the rotational speed can be reduced to reduce the flow and pressure to meet the required duty point. By keeping the impeller at full diameter, clearances between the rotating part and casing are kept small maintaining efficiency.

Trimming impellers is another way a pump can be made to meet a duty point, however the more material that is removed, greater internal tolerances are created within the casing reducing efficiency.

Pump affinity laws are a set of formula which can be used to determine a units performance when a change is made such as speed, or impeller diameter to the produced flow and pressure with a high degree of accuracy.

As the shaft speed or the impeller diameter is altered, the flow will change by the same amount. If the speed of a pump is reduced by 20% the flow at the same head will also decrease by 20%.

When the impeller diameter is altered or shaft speed is changed pressure changes proportional to the square of the change in shaft speed or impeller diameter. If a shafts speed increases by 10% then pressure at the same flow will increase by 21%

Wear rings sit either side of the impeller to act as sacrificial parts to prevent casing wear and maintain efficiency within the casing. A doubling of wear ring clearances can lead to NPSH increasing by as much as 50%.

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Cones, Submersible Pump Rubber Parts, Slurry Pump Cover Plate Liner, We always welcome new and old customers presents us with valuable advice and proposals for cooperation, let us grow and develop together, and to contribute to our community and staff!

Slurry pump throat bush is one of wet parts in horizontal slurry pump which directs slurries to impeller, it is suction side liner which is connected with cover plate.

Throat bush is common in bigger pumps, because throat bush and volute liner are normally in one solid piece in small pumps. The design of slurry pump throat bush is based on cost effective in manufacturing and operation.

* YAAO® is a registered trademark and does not represent or is not in any way affiliated with Warman® of Weir Minerals Group. All names, numbers, symbols and descriptions are used for reference purpose only and do not imply that any pumps or parts listed is the product of Warman Pumps.

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers" requires for China PriceList for Mud Pump Impeller - AH Slurry Pump Rubber THROAT BUSH – YAAO factory and suppliers | YAAO , The product will supply to all over the world, such as: Slovakia, Paris, Leicester, Our professional engineering group will always be ready to serve you for consultation and feedback. We"re able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We"ll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we"ve been intending to share the top trading practical experience with all our merchants.

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for Open Rubber Slurry Pump Impeller, Pump Impeller Size, Mining Sluryy Pump, Our intention should be to assist customers comprehend their goals. We have been creating terrific endeavours to obtain this win-win circumstance and sincerely welcome you to definitely join us!

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for China Free sample for Hydrocyclone Parts - YCVX-Hydrocyclone lining – YAAO factory and suppliers | YAAO , The product will supply to all over the world, such as: Swiss, Chicago, Uruguay, We only supply quality items and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom merchandise etc that can according to customer"s requirement.

8*6FF-WXPH is used for high-pressure double pump shell slurry pump used in multi-stage series. The pump has a strong pressure bearing capacity and the structure of the double pump shell is safe and stable.

Wet End-impellers, liners, and volutes are made of high-chrome alloy or rubber or polyurethane, to resist wear, corrosion, erosion, or impact, parts made of metal or rubber are interchangeable.

Impeller-Multiple impeller types for diverse applications to get the best performance: High efficiency, High efficiency with lower NPSHr, a large particle, enhanced performance, flow reducer, and Recessed eyes are available.

An impeller is a rotating component equipped with vanes or blades used in turbomachinery (e. g. centrifugal pumps). Flow deflection at the impeller vanes allows mechanical power (energy at the vanes) to be converted into pump power output.

In accordance with EUROPUMP TERMINOLOGY and DIN 24250, a distinction is made between counter-clockwise and clockwise impellers, as viewed in inlet flow direction.

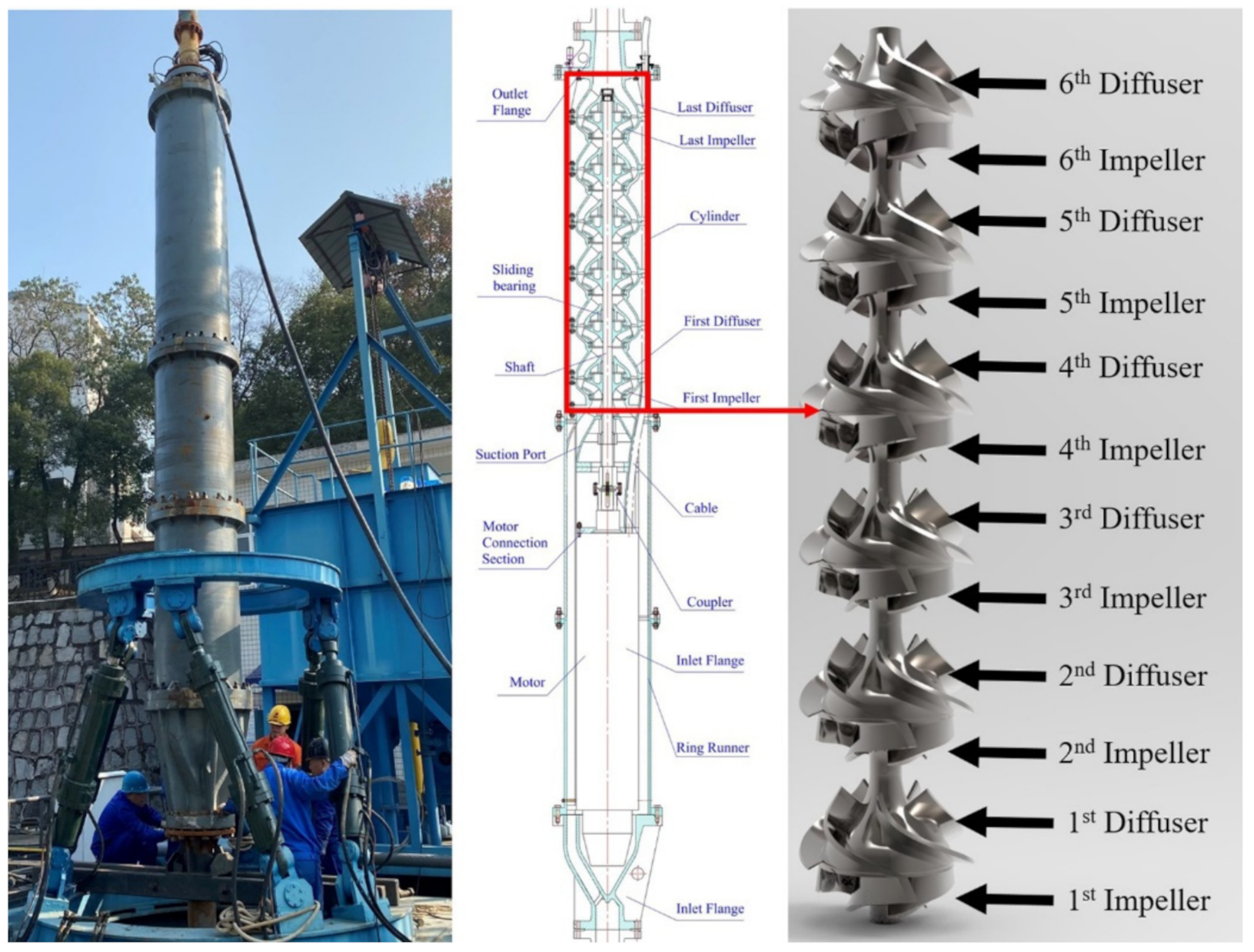

Depending on the fluid flow pattern in multistage pumps and the impellers" arrangement on the pump shaft impeller design and arrangements are categorised as: single-stage, multistage, single-entry, double-entry, multiple-entry, in-line (tandem) or back-to-back arrangement. Typical impeller arrangements are illustrated in Figs. 17 to 19 Impeller.

Depending on the flow line pattern in the impeller (especially in the outer impeller diameter area), impellers are subdivided into the following types:

To accommodate the vanes, all impellers are equipped with a back shroud, and in the case of closed impellers also a front shroud (see Disc friction); depending on the perspective, these can also be viewed as an inner shroud and, in the case of closed impellers, an outer shroud. If an impeller has no front (outer) shroud, it is classed as an open impeller.

In order to achieve optimal pump efficiencies and minimum NPSHr values, the impeller must be provided with a certain number of vanes. Employing a low number of vanes increases the free, unimpeded flow cross-section through the impeller. This enables impellers to handle more or less contaminated fluids ( waste water pumps,solids transport).

In practice, the number of vanes of radial flow and mixed flow impellers handling liquids containing sludge or solids is reduced to one, two or three vanes. These impellers are called channel impellers or single-vane impellers and can be either open or closed impellers.

Closed single-vane impellers are used to pump fluids containing very coarse solids. They are characterised by a non-clogging free passage. The drawback of these impellers is the so-called hydraulic unbalance due to the asymmetrical pressure field.See Fig. 7 Impeller

Open channel or single-vane impellers are used to handle gaseous liquids. A single-vane impeller is referred to as an open, diagonal single-vane impeller (D impeller) if the flow lines in the impeller run diagonally outward. It is particularly suitable for untreated, solids-laden and gaseous waste water, as well as for fluids with a higher viscosity. See Fig. 8 Impeller

The blades of axial and mixed flow propellers (see Propeller pump) can be either fixed, adjustable (when the pump is dismantled) or of variable pitch type (see Impeller blade pitch adjustment).

In the case of adjustable or variable pitch blades, the contour or profile of the pump casing and of the hub in the adjustment region is usually spherical. This ensures that the internal and external clearance gap width at the hub remains constant for all blade pitch adjustment angles. See Fig. 4 Impeller

When selecting a pump for a given flow rate (Q) and a given pump efficiencies or stage efficiencies at a specific speed (ns) is therefore dependent on specific impeller designs:Radial impeller ns ≈ 12 to 80 rpm

A typical centrifugal pumpis constructed of a rotary pump shaft with one or more impellers attached. As the impellers rotate in sync, the pump converts enough energy to move fluids in the desired direction.

Centrifugal pumpscan be radial or axial, with radial pumps pushing energy through downstream piping and axial pumps generating asuction liftingeffect with the impellers. Either are simple enough processes, but something could go wrong. When that does, you’ll need to troubleshoot and fix the problem.

If yourcentrifugal pumpstops working as it should, is it time to replace it or call in a professional? Neither may be necessary if you can figure out the problem and solve it independently. Here are some of the most commoncentrifugal pump problemsand solutions.

Impellers rotating in the wrong direction is a common problem withcentrifugal pumps. If the impellers turn the wrong way, they could cause severe damage to the pump. When wiring power to the pump’s motor, it’s critical to verify which way the motor turns. You can “bump start” the motor to do this.

Another common problem with these types ofcentrifugal pumpsis leakage. When materials escape the pump and create a mess, this is a serious issue. Excessive temperature, corrosion, or pressure can loosen the joints and seals, allowing fluid and debris to escape.

But there may be a simple fix. Stopping your leaky pump could be as easy as tightening the fasteners surrounding the joints. In other cases, however, you may need to replace a gasket or mechanical seal.

There is probably something wrong with your pump if it takes too long to re-prime. The most common cause of a slow re-priming pump is excessive clearance, leading to inefficiency and overheating. But other possible reasons exist as well, such as a leaking gasket, a clogged recirculation port, or a worn-out volute.

Pump seizure can happen for several reasons, including foreign objects entering the pump, low flow operation, and off-design conditions. Inspect the pump for foreign objects and debris first and then check the impellers and power source.

When you begin to see the pump vibrating too much or notice usual noises coming from the device, this could signify a serious issue. Often, vibrations and noises tell you that you have failed bearings or a foreign object stuck inside the pump.

Start with the most straightforward thing first and look for debris or foreign objects. When noises and vibrations occur together, the pump could be experiencing cavitation and may need to be examined by a professional.

Debris in your pump can create havoc with many of its parts and systems. If your pump isn’t pumping or is less efficient than you want, check for a cloggedsuction pipeor debris in the impeller.

Incentrifugal pumps, overloading occurs when the driving motor draws excess current, which results in greater than normal power consumption. Pumps should start with a minimum load with discharge valves open. If the power drawn by the pump increases too much, it may ultimately lead to tripping or overloading of the motor. Some of the most common causes of pump driver overload include:

If you notice that the pump isn’t operating efficiently anymore, meaning it’s taking too long for it to pump out fluid, some of the most common causes of this problem include the following.

If yourcentrifugal pumphas become corroded, it could be due to a chemical compatibility issue. The wetted parts of a pump can be made from a variety of materials — ceramics, metals, thermoplastics, and elastomers. The resistance of these parts to various liquids, chemicals, and temperatures will vary. So you must select a pump designed with your particular application in mind.

Centrifugal pumpsshould not feel hot to the touch. When they do, this is a sign of trouble and something you want to address immediately. There may be a blockage in the suction strainer, the recirculation port, the valve, or the open-ended discharge line. The pump will be less efficient if you ignore the issue and may eventually fail.

There is a wide range ofcentrifugal pumpsavailable that will give your operation the fluid-transfer services it needs over the long term. These are excellent, low-cost solutions for most high-capacity, low-pressure situations. But if yourcentrifugal pumpisn’t operating efficiently or at all, this list of common problems may help you troubleshoot the issue.

If you cannot troubleshoot the issue with yourcentrifugal pumpor don’t feel comfortable handling it yourself, we haveresourcesto help you. If you aren’t currently experiencing any problems with yourcentrifugal pump, then it is a great time to look intopreventative maintenance to ensure issues don’t arise in the future.

Before we dive into our recommended centrifugal pump maintenance schedule, let make sure you a good grasp of how the pump itself works. In its simplest form, a centrifugal pump is made from a housing with an inlet and outlet. There is an impeller that is located inside the housing, and a motor or drive that is responsible for rotating the impeller. The pumps casing (outer shell) is designed to create a gradually widening channel which is known as the volute. When the motor (or drive) rotates the impeller it is creating centrifugal force.

● On the other side, the volute causes the fluid to slow down and the pressure inside the pump’s housing begins to increase. This increase in pressure forces the liquid out the discharge (outlet) of the pump and then on to the piping systems of the process.

Casing (Volute)– As we learned earlier, this acts as a pressure containment vessel. It directs the flow of liquid in and out of the centrifugal pump. It slows down the speed of the fluid while increasing the pressure within the casing.

A routine centrifugal pump maintenance program not only extends the life of your system, but also reduces operating costs. Consistent maintenance also ensures there is enough maintenance history recorded to identify the source of the problem faster.

Maintenance Programs for centrifugal pumps can be grouped into three categories: routine, quarterly, and annual maintenance. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. This focuses on components that are leading indicator of potential failure.

○ During downtime, inspect the pump’s packing to make sure there is adequate lubrication. If the packing looks compressed and dry, replace the packing and add lubricant per the operation manual.

○ Imminent pump failure can be detected by monitoring overall pump vibration. Excessive vibration can result from a change in pump alignment, bearing failures, cavitation, and obstructions in the suction and discharge lines.

○ The difference in pressure read by the suction and discharge gauges will provide the total developed head pressure of the pump. Confirm this reading is within the pump’s designed performance. You can find this on the manufactured website or your operation manuals.

For oil-lubricated pumps, as a rule of thumb, you should change the oil after the first 200 hours of operation for a new pump. Then again after every three months or 2,000 operating hours, whichever comes first. Your operation manual will have specific instructions for oil change intervals and oil grade.

For grease-lubricated pumps, as a rule of thumb bearings should be greased every three months or 2,000 operating hours, whichever comes first. Your operation manual should have specific instructions for grease intervals and grease grade to be used.

Keep a log of your pump’s performance at least once per year.Performance benchmarks should be established early on in the life of the pump. At a minimum, the benchmarking data should include head pressure, flow rate, motor amp draw, and vibration at each bearing.

Impeller– inspect the impeller for wear, erosion or corrosion damage. If the vanes are bent or show wear in excess of 1/8-inch deep, replace the impeller.

Uncouple from pump & overspeed turbine. Ensure that trip valve will stop turbine with steam supply valve (throttle valve) fully open. Compare tripping speed with previous records. Adjust trip mechanism & repeat procedure. Follow manufacturer’s instructions when making adjustments.

Where the process will allow it, test run the turbine coupled to the pump. When not possible, run the turbine uncoupled. With a tachometer − verify proper governor operation & control. Determine if hand (booster) valves are completely closed when required to carry load. This influences steam economy.

Even armed with these best practice centrifugal pump maintenance schedules, you may run into issues that require some extra help. That’s where we come in. Reach out to the experts at Rasmussen Mechanical Services and ensure your system is running the way it should. Call us at 1-800-237-3141, emailsales@rasmech.com,orcontact usonline.

Many products people flush down the toilet are very stringy. Some are designed to flush, and some are not. Some of these products are biodegradable and break down over time. The “time” they refer to is not the several seconds before the product meets up with a sewage pump impeller. In addition, people may put things down a toilet in a public restroom that they would never flush at home. All of this may be a disaster for the sewage lift pumps performance.

Bell & Gossett, along with many of the other Xylem brands, offers a semi-open non-clog impeller for sewage pumps. The engineers at Xylem are constantly redesigning and improving these impellers. The goal is to improve efficiency, non-clogging ability while keeping the price reasonable. The B&G BFK series with the K-impeller is one example.

Non-clog impellers come in many shapes and sizes. Shown here is the multi-vane semi-open impeller. These impellers can pass solid spheres from 2” to 4” depending on the pump size. They are made to pump what is expected to be in a toilet.

Non-clog pump impellers fling the sewage through the discharge pipe using centrifugal action. The sewage contacts the impeller so the highly engineered B&G no-clog designs become very important. The K-impeller mentioned above is non-clog and self cleaning. They can handle the spherical solids and some more stringy things, but large amounts of stringy cloth and paper and plastic products may still clog them up.

Vortex design pumps still use centrifugal action with one huge difference. In a vortex design, the impeller rotates and causes a tornado-like action that pulls the waste into the pump and then sends it into the discharge pipe with little or no contact with the impeller.

The vortex design gives the pump more of a chance against the stringy material it may encounter. Since the impeller is making little contact, there is less of a chance to clog in the impeller. Look at the B&G BFK and BFV pumps below. Notice the space in the BFV style volute. More area for product to move in and out of the pump without clogging.

Besides the need for less clogging, there is a concern about efficiency and cost. These non-clog impellers already have half of the efficiency of a traditional B&G fully enclosed impeller used in potable water pressure boosters or in hydronics. The impeller loses efficiency when we open it up and make it non-clogging.

Once again, I ask you to look at the photos above. Look at the space between the inlet and impeller in the vortex design in the photo to the right. That space and the tornado it causes are great to avoid clogging but not so great on efficiency. Vortex pumps will have 25% to 30% less efficiency than the non-clog design on the left. This means larger motors and higher operating and first costs.

If vortex pumps cost more and are less efficient, when should we use them? That is a fair question. It’s all about your client and their building. If the people using the restrooms have little to lose when flushing non-pumpable product, choose the vortex design.

When choosing a size and type of mud pump for your drilling project, there are several factors to consider. These would include not only cost and size of pump that best fits your drilling rig, but also the diameter, depth and hole conditions you are drilling through. I know that this sounds like a lot to consider, but if you are set up the right way before the job starts, you will thank me later.

Recommended practice is to maintain a minimum of 100 to 150 feet per minute of uphole velocity for drill cuttings. Larger diameter wells for irrigation, agriculture or municipalities may violate this rule, because it may not be economically feasible to pump this much mud for the job. Uphole velocity is determined by the flow rate of the mud system, diameter of the borehole and the diameter of the drill pipe. There are many tools, including handbooks, rule of thumb, slide rule calculators and now apps on your handheld device, to calculate velocity. It is always good to remember the time it takes to get the cuttings off the bottom of the well. If you are drilling at 200 feet, then a 100-foot-per-minute velocity means that it would take two minutes to get the cuttings out of the hole. This is always a good reminder of what you are drilling through and how long ago it was that you drilled it. Ground conditions and rock formations are ever changing as you go deeper. Wouldn’t it be nice if they all remained the same?

Centrifugal-style mud pumps are very popular in our industry due to their size and weight, as well as flow rate capacity for an affordable price. There are many models and brands out there, and most of them are very good value. How does a centrifugal mud pump work? The rotation of the impeller accelerates the fluid into the volute or diffuser chamber. The added energy from the acceleration increases the velocity and pressure of the fluid. These pumps are known to be very inefficient. This means that it takes more energy to increase the flow and pressure of the fluid when compared to a piston-style pump. However, you have a significant advantage in flow rates from a centrifugal pump versus a piston pump. If you are drilling deeper wells with heavier cuttings, you will be forced at some point to use a piston-style mud pump. They have much higher efficiencies in transferring the input energy into flow and pressure, therefore resulting in much higher pressure capabilities.

Piston-style mud pumps utilize a piston or plunger that travels back and forth in a chamber known as a cylinder. These pumps are also called “positive displacement” pumps because they literally push the fluid forward. This fluid builds up pressure and forces a spring-loaded valve to open and allow the fluid to escape into the discharge piping of the pump and then down the borehole. Since the expansion process is much smaller (almost insignificant) compared to a centrifugal pump, there is much lower energy loss. Plunger-style pumps can develop upwards of 15,000 psi for well treatments and hydraulic fracturing. Centrifugal pumps, in comparison, usually operate below 300 psi. If you are comparing most drilling pumps, centrifugal pumps operate from 60 to 125 psi and piston pumps operate around 150 to 300 psi. There are many exceptions and special applications for drilling, but these numbers should cover 80 percent of all equipment operating out there.

The restriction of putting a piston-style mud pump onto drilling rigs has always been the physical size and weight to provide adequate flow and pressure to your drilling fluid. Because of this, the industry needed a new solution to this age-old issue.

As the senior design engineer for Ingersoll-Rand’s Deephole Drilling Business Unit, I had the distinct pleasure of working with him and incorporating his Centerline Mud Pump into our drilling rig platforms.

In the late ’90s — and perhaps even earlier — Ingersoll-Rand had tried several times to develop a hydraulic-driven mud pump that would last an acceptable life- and duty-cycle for a well drilling contractor. With all of our resources and design wisdom, we were unable to solve this problem. Not only did Miller provide a solution, thus saving the size and weight of a typical gear-driven mud pump, he also provided a new offering — a mono-cylinder mud pump. This double-acting piston pump provided as much mud flow and pressure as a standard 5 X 6 duplex pump with incredible size and weight savings.

The true innovation was providing the well driller a solution for their mud pump requirements that was the right size and weight to integrate into both existing and new drilling rigs. Regardless of drill rig manufacturer and hydraulic system design, Centerline has provided a mud pump integration on hundreds of customer’s drilling rigs. Both mono-cylinder and duplex-cylinder pumps can fit nicely on the deck, across the frame or even be configured for under-deck mounting. This would not be possible with conventional mud pump designs.

The second generation design for the Centerline Mud Pump is expected later this year, and I believe it will be a true game changer for this industry. It also will open up the application to many other industries that require a heavier-duty cycle for a piston pump application.

A chopper pump is a centrifugal pump which is equipped with a cutting system to facilitate chopping or maceration of solids that are present in the pumped liquid. The main advantage of this type of pump is that it prevents clogging of the pump itself and of the adjacent piping, as all the solids and stringy materials are macerated by the chopping system. Chopper pumps exist in various configurations, including submersible and dry-installed design and they are typically equipped with an electric motor to run the impeller and to provide torque for the chopping system. Due to its high solids handling capabilities, the chopper pump is often used for pumping sewage, sludge, manure slurries, and other liquids that contain large or tough solids.

The chopper pump was invented in 1950 by the Danish company Landia. The pump manufacturer, Christian Ølgaard, developed a pump with a special knife system to meet the need for macerating and pumping manure in agricultural applications. Manure with high solids content, containing straw and sawdust, would clog up other types of pumps, causing unstable operation in an environment which required high reliability.

As the need for the pumping of difficult media expanded to other industries, so did the use of the chopper pump in both dry and submersible applications and in various industries, including meat, paper and food processing, as well as the automobile industry, biogas, chemical plants, municipal wastewater and prison lift stations.

A chopper pump is operated by a drive unit (e.g. electric motor, hydraulic motor, power takeoff (PTO)), which turns the impeller and the cutting system. An open impeller design is used to successfully pass the macerated solids or thick slurry. A set of hardened steel cutters is installed externally to the pump suction in order to macerate all solids prior to entering the hydraulic parts of the pump. A chopper pump should not be confused with a grinder pump, which uses its impeller as part of the cutting mechanism. Grinder pumps are typically used for light weight sewage applications, whereas chopper pumps are used for tough solids handling applications.

The chopping system consists of a set of rotating cutters that are keyed to the shaft and work in conjunction with the stationary cutters, which are bolted to the suction plate. A system of mechanical seals are used to prevent the pumped liquid from entering the motor. The pump can either be connected to a pipe, flexible hose or lowered down a guide rail so that the pump sits on a coupling foot (aka base elbow), thereby connecting it to the discharge pipe.

8613371530291

8613371530291