mud pump maint pricelist

Explore a wide variety of mud pump price list on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump price list are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump price list is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump price list for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump price list to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

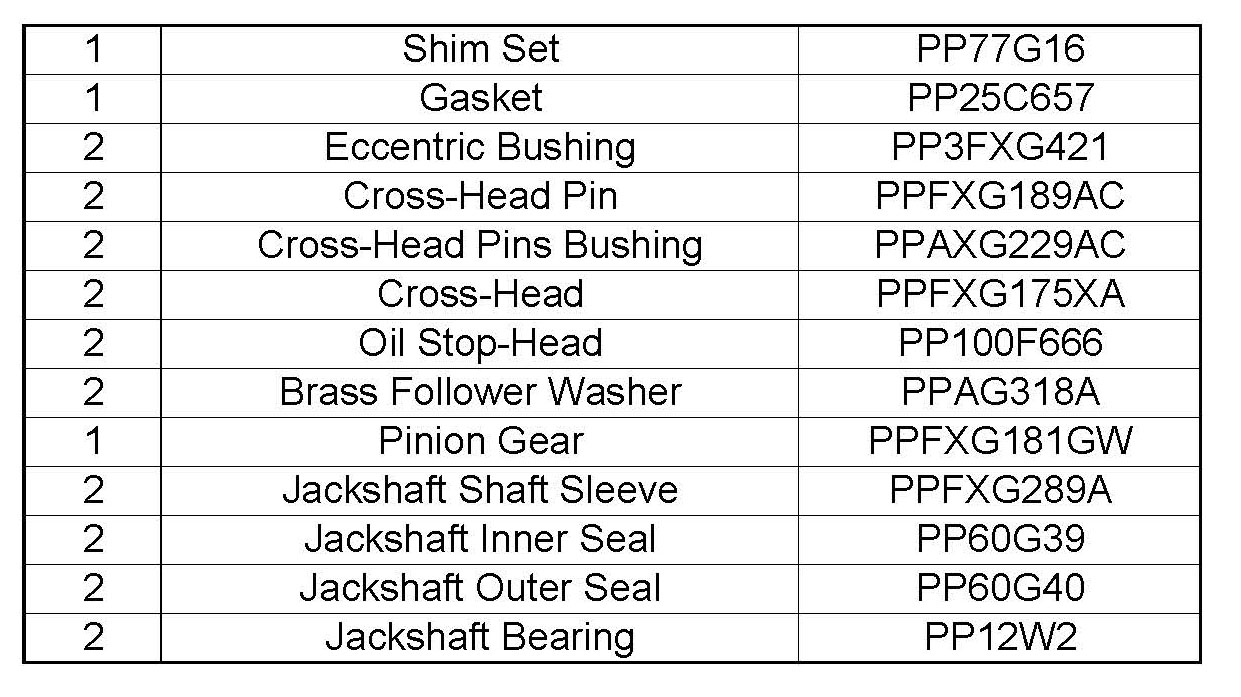

We stock fluid end parts for the5×6 mud pump, 5×6-1/4 FM45 mud pump, 5×8 mud pump, 5-1/2×8 mud pump, 5X10 mud pump, 4-1/2×5 mud pump, 7-1/2×8 mud pump, and 7-1/2X10 mud pump. The Gardner Denver mud pump model numbers for the above pumps are as follows: 5X6-FGFXG, 5X8-FDFXX, 5-1/2X8-FDFXX, 5X10-FDFXD, 4-1/2X5-FFFXF, 7-1/2X8-FYFXX, 7-1/2X10-FYFXD. We also handle Wheatley, Gaso, Worthington, Failing and Centerline parts and pumps. We also stock Foot Valve, Liner Puller, Valve Seat Puller, (4″ Inline Check Valve. Our Gardner Denver mud pump parts are not only competitively priced, they are also made in the USA. Oil Recommended by Gardner Denver. Call any of our experienced representatives to get the help and knowledge you deserve.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8613371530291

8613371530291