mud pump maintenance training supplier

Graduates of the program have found that their newly improved maintenance skills have extended the life of the fluid ends on their site. Beyond increasing lifespan, customers have also seen benefits in the form of lower repair costs, decreased production costs and a reduction in workplace hazards.

Pump University’s knowledgeable instructors teach customers valuable maintenance tips through workbooks, visual presentations and hands-on training. Each three hour class can accommodate 10 to 15 employees. The classes are designed for drilling hands, but engineers and other employees have found value in the courses. Many participants find that these courses teach them about expendables as well as fluid ends.

Pump University participants receive a certificate upon completion of the program. The certification verifies Pump U graduates are equipped with the most up-to-date knowledge of fluid end maintenance practices.

Pump University is just one part of GD Energy Products’ continually growing service options. GD Energy Products makes the most durable pumps and fluid ends in the industry, and proper maintenance training ensures customers can maximize the life of their GD Energy Products products while minimizing costly downtime.

DAC Worldwide’s Surge Suppressor Model (295-403) depicts a high-fidelity, precision to-scale model of a pulsation damper, otherwise known as a surge absorber. The industrial model supports training in the operation and maintenance of mud pumps, and mud pumping systems found within oilfield facilities and other applications incorporating large reciprocating pumps.

Learners will explore design, construction, operation, and control of surge suppressors using these learning tools. The model features a clear acrylic shell, component cutaways, color coding, and realistic detail, which combine to make this a useful tool in both operations and maintenance training.

The construction of this realistic mechanical model is based on a variety of well-known pulsation dampener. Based on a unit manufactured by Hydril Corporation, this training aid is a complete to-scale replication of one of the most common dampeners in use today. Molded from urethane plastics using silicone rubber molds, all salient and important equipment details are shown and enhanced.

Its convenient size, detail, color-coding, and multiple cutaways combine to allow the device to be useful in courses covering surge suppressors, flexible diaphragm stabilizers, valve guards, and much more. This teaching aid complements courses in oilfield production activities, oil & gas production operations, and maintenance training.

This Surge Suppressor Model features a clear acrylic, 4.5-inch diameter shell, including a 120-degree sectioned area, that allows complete visibility of both internal and external components. To ensure an ideal training experience, the model also includes a durable PVC base, with provisions for tabletop mounting. All of the construction throughout the model is to-scale, and the perfect 3-dimensional solution for study, promotion, and training.

The Surge Suppressor Model is only one of DAC Worldwide’s expansive mechanical training models and cutaways, which includes a Gas Turbine Model (295-301), a Pumpjack Package Model (295-408), a Composite Crude Oil Desalter Training Model (295-501), and many more!

Many things go into getting the most life out of your mud pump and its components — all important to extend the usage of this vital piece of equipment on an HDD jobsite. Some of the most important key points are covered below.

The most important thing you can do is service your pump, per the manufacturer’s requirements. We get plenty of pumps in the shop for service work that look like they have been abused for years without having basic maintenance, such as regular oil changes. You wouldn’t dream of treating your personal vehicle like that, so why would you treat your pump like that.

Check the oil daily and change the oil regularly. If you find water or drilling mud contamination in the oil, change the oil as soon as possible. Failure to do so will most likely leave you a substantial bill to rebuild the gear end, which could have been avoided if proper maintenance procedures would have been followed. Water in the oil does not allow the oil to perform correctly, which will burn up your gear end. Drilling mud in your gear end will act as a lapping compound and will wear out all of the bearing surfaces in your pump. Either way it will be costly. The main reasons for having water or drilling mud in the gear end of your pump is because your pony rod packing is failing and/or you have let your liners and pistons get severely worn. Indication of this is fluid that should be contained inside the fluid end of your pump is now moving past your piston and spraying into the cradle of the pump, which forces its way past the pony rod packing. Pony rod packing is meant to keep the oil in the gear end and the liner wash fluid out of the gear end. Even with brand new packing, you can have water or drilling fluid enter the gear end if it is sprayed with sufficient force, because a piston or liner is worn out.

There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components.

Liner wash fluid can be comprised of different fluids, but we recommend just using clean water. In extremely cold conditions, you can use RV antifreeze. The liner wash or rod wash system is usually a closed loop type of system, consisting of a tank, a small pump and a spray bar. The pump will move fluid from the tank through the spray bar, and onto the inside of the liner to cool the liner, preventing scorching. The fluid will then collect in the bottom of the cradle of the pump and drain back down into the collection tank below the cradle and repeat the cycle. It is important to have clean fluid no matter what fluid you use. If your liners are leaking and the tank is full of drilling fluid, you will not cool the liners properly — which will just make the situation worse. There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components. Ensure that the water is spraying inside the liner and that any overspray is not traveling out of the pump onto the ground or onto the pony rod packing where it could be pulled into the gear end. If the fluid is spraying out of the cradle area and falling onto the ground, it won’t be long before your liner wash tank is empty. It only takes a minute without the cooling fluid being sprayed before the liners become scorched. You will then need to replace the pistons and liners, which is an avoidable costly repair. Make a point to check the liner wash fluid level several times a day.

Drilling fluid — whether pumping drilling mud, straight water or some combination of fluid — needs to be clean. Clean meaning free of solids. If you are recycling your fluid, make sure you are using a quality mud recycling system and check the solids content often throughout the day to make sure the system is doing its job. A quality mud system being run correctly should be able to keep your solids content down to one quarter of 1 percent or lower. When filling your mud recycling system, be sure to screen the fluid coming into the tanks. If it is a mud recycling system, simply make sure the fluid is going over the scalping shaker with screens in the shaker. If using some other type of tank, use an inline filter or some other method of filtering. Pumping out of creeks, rivers, lakes and ponds can introduce plenty of solids into your tanks if you are not filtering this fluid. When obtaining water out of a fire hydrant, there can be a lot of sand in the line, so don’t assume it’s clean and ensure it’s filtered before use.

Cavitation is a whole other detailed discussion, but all triplex pumps have a minimum amount of suction pressure that is required to run properly. Make sure this suction pressure is maintained at all times or your pump may cavitate. If you run a pump that is cavitating, it will shorten the life of all fluid end expendables and, in severe cases, can lead to gear end and fluid end destruction. If the pump is experiencing cavitation issues, the problem must be identified and corrected immediately.

The long and the short of it is to use clean drilling fluid and you will extend the life of your pumps expendables and downhole tooling, and keep up with your maintenance on the gear end of your pump. Avoid pump cavitation at all times. Taking a few minutes a day to inspect and maintain your pump can save you downtime and costly repair bills.

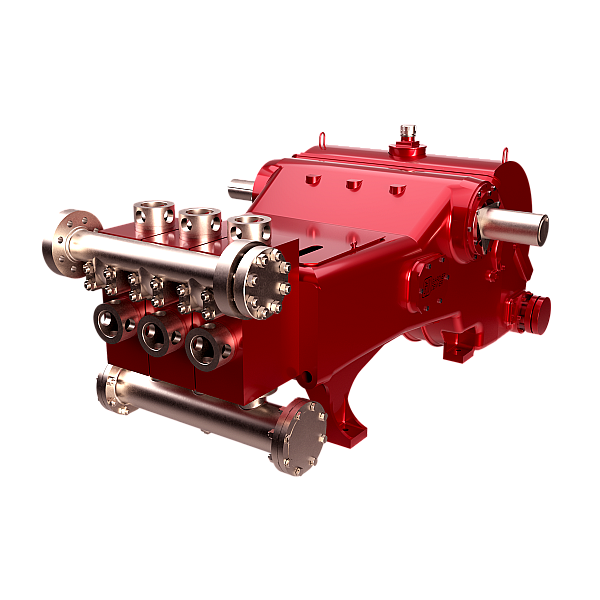

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

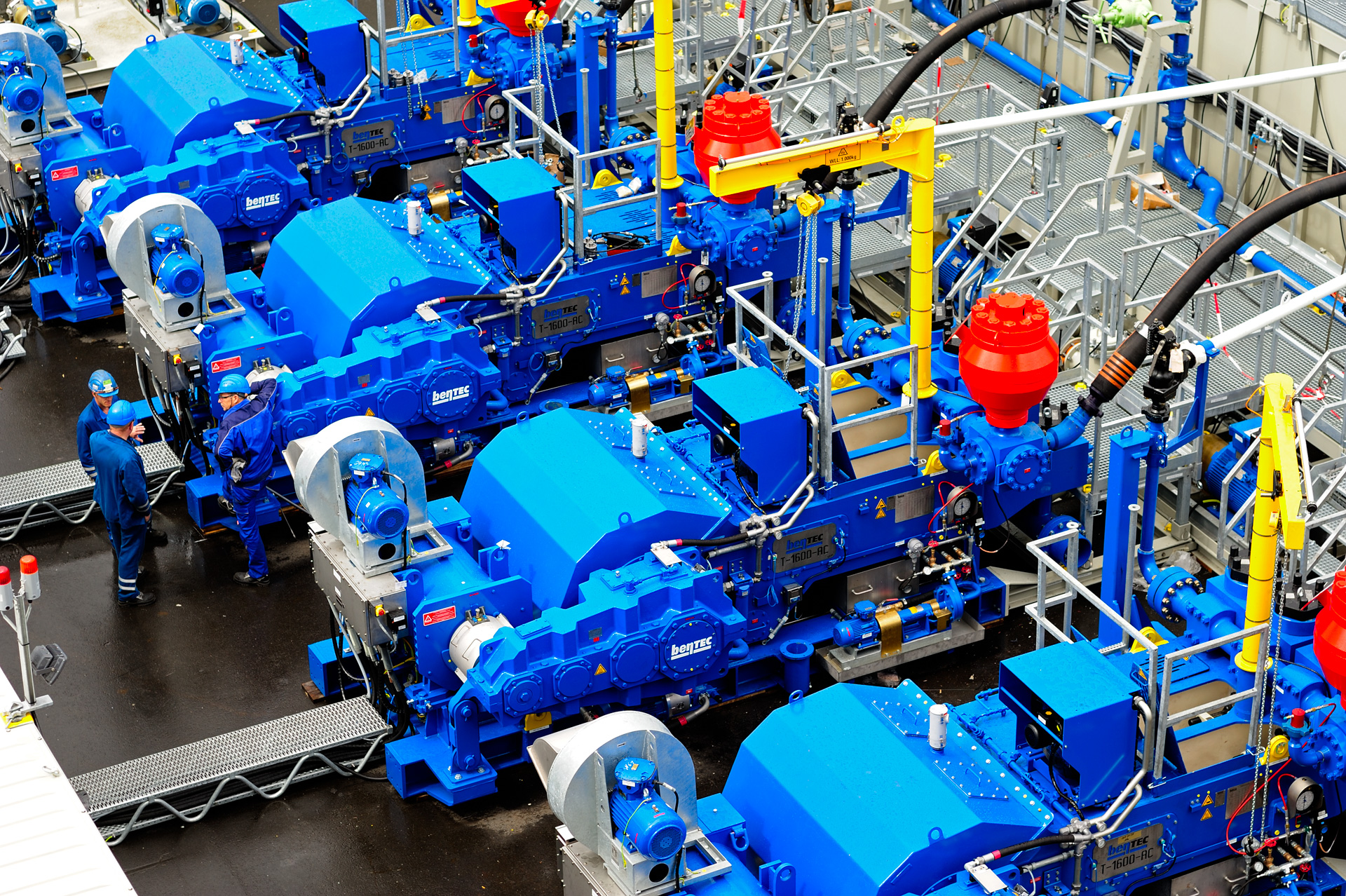

A comprehensive range of mud pumping, mixing, and processing equipment is designed to streamline many essential but time-consuming operational and maintenance procedures, improve operator safety and productivity, and reduce costly system downtime.

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

This unit covers the operation of mud pumps in the drilling industry. It includes planning and preparing for operation, monitoring mud pumps, and maintaining and repairing mud pumps. Licensing, legislative, regulatory and certification requirements that apply to this unit can vary between states, territories, and industry sectors. Relevant information must be sourced prior to application of the unit.

Specific skills are required to achieve the Performance Criteria of this unit, particularly for its application in the various circumstances in which this unit may be used. This includes the ability to carry out the following, as required to operate mud pumps:apply legislative, organisation and site requirements and procedures for operation of mud pumps

Specific knowledge is required to achieve the Performance Criteria of this unit, particularly for its application in the various circumstances in which this unit may be used. This includes knowledge of the following, as required to operate mud pumps:mud pumps

The evidence guide provides advice on assessment and must be read in conjunction with the performance criteria, required skills and knowledge, range statement and the Assessment Guidelines for the Training Package.

The evidence required to demonstrate competency in this unit must be relevant to worksite operations and satisfy all of the requirements of the performance criteria, required skills and knowledge and the range statement of this unit and include evidence of the following:knowledge of the requirements, procedures and instructions for operation of mud pumps

consistent achievement of required outcomesfirst hand testimonial evidence of the candidate"s:working with others to undertake and complete the operation of mud pumps

The range statement relates to the unit of competency as a whole. It allows for different work environments and situations that may affect performance. Bold italicised wording, if used in the performance criteria, is detailed below. Essential operating conditions that may be present with training and assessment (depending on the work situation, needs of the candidate, accessibility of the item, and local industry and regional contexts) may also be included.

Learning about the operation and maintenance of any important asset is the first step in optimizing its performance and reliability. This task is made easier when the participants have the opportunity to get a hands-on training for pumps and inspect the components in person. Sulzer’s training courses give customers the opportunity to gather essential information and knowledge from industry experts.

Pump training courses can include many aspects, from operation and maintenance to design and rerates; every aspect can be tailored to individual requirements. As a major pump original equipment manufacturer (OEM) and independent maintenance provider, Sulzer combines expertise and experience in its flexible and dynamic training courses.

The training seminars focus on the issues and concerns that are prominent in many industrial sectors. They can help companies to meet the demands for increased efficiency and availability as well as addressing any safety matters.

Typically planned over four days, the Sulzer Academy delivers training seminars that can include participants from different employers but with similar backgrounds and operational environments. Discussing many topics from basic principles to root cause analysis and operational challenges, courses are designed to share knowledge and expertise to the benefit of all involved.

Companies send operators and maintenance engineers to Sulzer locations for training by experts in pump design and operation. Through better understanding of pumps and their role in the wider process operations, it is possible to improve the availability, efficiency and costs associated with pump performance.

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 50 world-class manufacturing facilities and 100 service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2018, our 15’500 employees delivered revenues of CHF 3.4 billion.

Triplex plunger-type mud pumps feature a reciprocating, positive displacement pump design utilizing three plungers to safely transfer high-viscosity fluids under high pressure over an extended depth. Although they have many industrial applications, these pumps have become an essential part of oil well drilling rigs where they’re used to provide smooth discharge of mud and debris from oil wells.

In addition to their use in drilling and well service operations, mud pumps are also frequently used to handle corrosive or abrasive fluids, as well as slurries containing relatively large particulates, in applications like commercial car washes, wastewater treatment, cementing, and desalination operations.

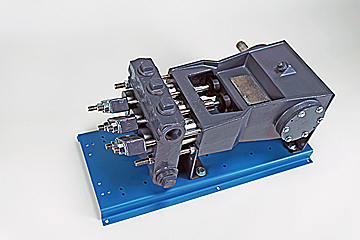

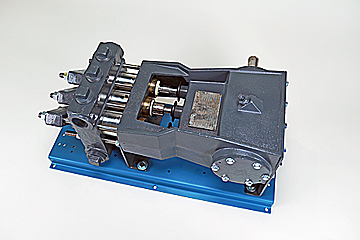

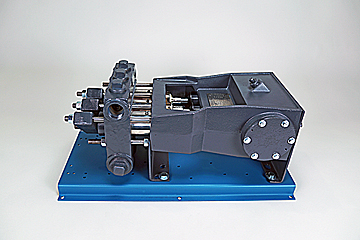

DAC Worldwide’s Representative Triplex, Plunger Mud Pump Dissectible (295-418) is an economical, conveniently-sized triplex plunger-type mud pump assembly that teaches learners hands-on maintenance activities commonly required on larger mud pump assemblies used in upstream oilfield production operations.

For example, mud pump assembly is used on well sites maintain downhole backpressure, to lubricate the rotating drill bit, and to help recycle and remove rock debris resulting from drilling activities. These heavy-duty, high-pressure pumps require regular refurbishment, inspection, and repair in the field.

DAC Worldwide’s dissectible mud pump assembly is a realistic sample that’s similar in geometry, design, and operating characteristics to the larger varieties learners will encounter on the job. DAC Worldwide chooses popular name-brand pumps for its dissectibles to ensure industrial and oil and gas training relevancy.

Using the dissectible mud pump, learners will gain hands-on experience with the operating principles, regular maintenance activities, and nomenclature/parts identification at a more convenient scale in the classroom or lab.

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Representative Triplex, Plunger Mud Pump Dissectible features a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Representative Triplex, Plunger Mud Pump Dissectible is a sturdy unit with a complete triplex, reciprocating, 20+ bhp plunger pump with .75" plunger, 1.5" stroke, and 3" cylinder sleeve. The unit allows for complete disassembly, assembly, and inspection, including removal of plungers, packing, and valves.

The dissectible mud pump comes with a formed-steel, powder-coated baseplate. It can also be mounted on a compatible DAC Worldwide Extended Electromechanical Workstation (903). Each unit comes with the manufacturer’s installation and maintenance manual.

Predictronics" solution predicted mud pump seal failure at least one day in advance, allowing for proactive maintenance. This helped the company prevent unscheduled downtime and avoid hazardous leak events, which cost the business productivity, money and resources.

A global oil and gas contractor with a specialty in automated drilling equipment and rig components was looking to develop and validate health monitoring methods with the induced fault data collected on their test rig and use this knowledge to apply a health monitoring approach to their mud pumps in the field. At the time, the contractor was experiencing mud pump leak events, which are not only dangerous, but also environmentally hazardous. In addition, there was a need to distinguish between anomalies due to actual leak events and anomalies caused by sensor issues.

The customer provided Predictronics with data collected over the course of a year from test bed data sets and sensors located on the piston, suction and discharge sections of two pumps in the field. Predictronics team members utilized their experience in industrial applications and expertise in vibration-based analysis to pull crucial features from the provided data by considering vibration patterns in the frequency and time-frequency domain. These features were integral to the development of health assessment models. The models then helped determine key indicators of pump seal failure, as well as establish the accuracy and necessity of the utilized sensors.

From Predictronics’ analysis, the contractor was able to ascertain the best sensor locations and identify possible sensor health issues that could occur in the field. The health and prediction models developed by Predictronics enabled the customer to predict mud pump failure at least one day in advance, allowing for proactive maintenance. This maintenance prevents hazardous leak events and unscheduled downtime, which cost the company productivity, money and resources.

Black-Jack Grout Pumps, Inc. offers more than 50 years of combined experience in Slabjacking, Mudjacking, Foundation Pier Repair, grout mixing, and grout pumping.

Through our experience and technical expertise within the grout pump and mortar pump industry, we offer the latest solutions in Grout Pumping, Mud Pumping, and Concrete Pumping across a large variety of applications.

From the most versatile grout pumping system on the world-wide market, “The Black-Jack Grout Pump,” to all the necessary training and advice to make your company successful in the industry, Black-Jack Grout Pumps, Inc. has the equipment, supplies, and training you need.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

The Positive Displacement Pump Training Course covers a large range of pump types like Gear Pump, Lobe Pump, Vane Pump, Screw Pump, Peristaltic Pump, Metering Pump, Power Pump, Diaphragm Pump, Piston Pump, Variable Displacement Pump, Beam Pump, Sucker Rod Pump, Hydraulic Pump, etc. with detailed pump classification.

The primary focus on graphics/animations in the training software course helps in very clearly understanding pump maintenance procedures, pump operating/working principle, and aids in pump repair. Included are animated explanations on all types of pumps like Gear Pump, Lobe Pump, Vane Pump, Screw Pump, Peristaltic Pump, Metering Pump, Power Pump, Diaphragm Pump, Axial Piston Pump, Swash Plate Piston Pump, Wobble Plate Piston Pump, Bent Axis Piston Pump, Radial Piston Pump, Variable Displacement Pump, Beam Pump, Sucker Rod Pump, Hydraulic Pump & Mud Pump. The positive displacement pump training program has a dedicated module to assist pump troubleshooting. Animated cut-sections gives a deep insight into pump operation and how pumps work.

Students, as well as maintenance and engineering personnel, and those who have not had formal training, will find that this computer-based training program on positive displacement pumps increases both their knowledge and confidence when performing maintenance. Those with previous training may find this program a good refresher and may learn some important information not covered in their original training.

The course on Positive Displacement Pumps is also available in a "Hardware Lock" licensing method. Many users have requested that they be able to use the software on multiple computers, i.e. when working with the program on the office computer and on the home computer. This Hardware Lock method allows users to install software on as many computers as they like. They need only enter the key on whichever computer they are currently wanting to use the software on. This copyright method also works great for the classroom environment.

Special Hardware Lock Bonus:For the hardware lock option, upon request, we will embed your company logo (replacing the BIN95 logo) in the compressor training software, both to give you a customized feel as well as for added protection of your new company software. (Please note the URL of the company logo in the comment area when ordering or email your logo to us, if you would like to take advantage of this new feature.)

Automated download system is powered by our preferred method of payment, secure PayPal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail order in, please click Training Software Order Form on our secure servers.

- The guide is customized to troubleshoot problems on individual pump types.Symptoms:Rotary Pumps:- No Liquid Delivery- Insufficient Discharge Pressure- Insufficient Capacity- Starts, but Loses Prime- Excessive wear- Excessive Heat- Excessive Noise and vibration- Excessive Power Demand- Motor Trips- Elevated Motor Temperature- Elevated Liquid TemperatureReciprocating Pumps:- No Liquid Delivery- Insufficient Capacity- Short Packing Life- Excessive wear at Liquid End- Excessive wear at Power End- Excessive Heat at Power End- Excessive Noise and vibration- Motor Trips6. Conventional and Interactive Skill Tests with Evaluation

Automated download system is powered by our preferred method of payment, secure PayPal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail order in, please click Training Software Order Form on our secure servers.

8613371530291

8613371530291