mud pump module inspection in stock

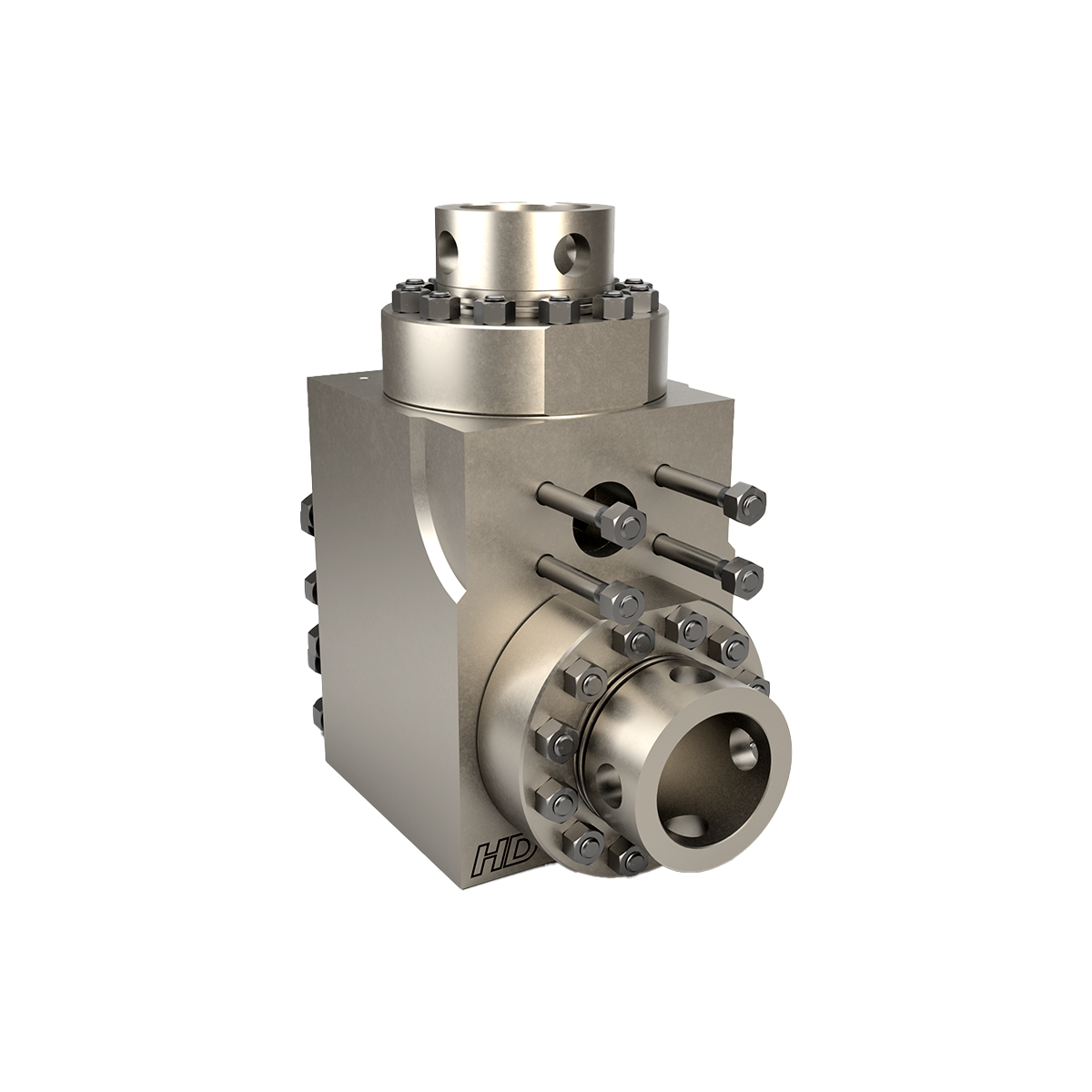

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

GPM International is a supplier of durable oilfield replacement parts for a wide variety of drilling mud pumps. Inventory products including mud pump fluid end parts, handling tool, etc. All of our products are fully exchangeable with O.E.M. standards.

All GPM products are API specification certified. All products will go through quality inspection at our manufacture facility as well as at our headquarters to assure our customer get qualified products.

Cavitation is an undesirable condition that reduces pump efficiency and leads to excessive wear and damage to pump components. Factors that can contribute to cavitation, such as fluid velocity and pressure, can sometimes be attributed to an inadequate mud system design and/or the diminishing performance of the mud pump’s feed system.

Although cavitation is avoidable, without proper inspection of the feed system, it can accelerate the wear of fluid end parts. Over time, cavitation can also lead to expensive maintenance issues and a potentially catastrophic failure.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump “knocking,” which typically sounds like marbles and stones being thrown around inside the equipment. However, the process of cavitation starts long before audible signs reveal themselves – hence the name “the silent killer.”

Mild cavitation begins to occur when the mud pump is starved for fluid. While the pump itself may not be making noise, damage is still being done to the internal components of the fluid end. In the early stages, cavitation can damage a pump’s module, piston and valve assembly.

The imperceptible but intense shock waves generated by cavitation travel directly from the fluid end to the pump’s power end, causing premature vibrational damage to the crosshead slides. The vibrations are then passed onto the shaft, bull gear and into the main bearings.

If not corrected, the vibrations caused by cavitation will work their way directly to critical power end components, which will result in the premature failure of the mud pump. A busted mud pump means expensive downtime and repair costs.

As illustrated in Figures 1 and 2, cavitation causes numerous pits to form on the module’s internal surface. Typically, cavitation pits create a stress concentration, which can reduce the module’s fatigue life.

Washouts are one of the leading causes of module failure and take place when the high-pressure fluid cuts through the module’s surface and damages a sealing surface. These unexpected failures are expensive and can lead to a minimum of eight hours of rig downtime for module replacement.

To stop cavitation before it starts, install and tune high-speed pressure sensors on the mud suction line set to sound an alarm if the pressure falls below 30 psi.

Accelerometers can also be used to detect slight changes in module performance and can be an effective early warning system for cavitation prevention.

Although the pump may not be knocking loudly when cavitation first presents, regular inspections by a properly trained field technician may be able to detect moderate vibrations and slight knocking sounds.

Gardner Denver offers Pump University, a mobile classroom that travels to facilities and/or drilling rigs and trains rig crews on best practices for pumping equipment maintenance.

Severe cavitation will drastically decrease module life and will eventually lead to catastrophic pump failure. Along with downtime and repair costs, the failure of the drilling pump can also cause damage to the suction and discharge piping.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump ‘knocking’… However, the process of cavitation starts long before audible signs reveal themselves – hence the name ‘the silent killer.’In 2017, a leading North American drilling contractor was encountering chronic mud system issues on multiple rigs. The contractor engaged in more than 25 premature module washes in one year and suffered a major power-end failure.

Gardner Denver’s engineering team spent time on the contractor’s rigs, observing the pumps during operation and surveying the mud system’s design and configuration.

The engineering team discovered that the suction systems were undersized, feed lines were too small and there was no dampening on the suction side of the pump.

Following the implementation of these recommendations, the contractor saw significant performance improvements from the drilling pumps. Consumables life was extended significantly, and module washes were reduced by nearly 85%.

Although pump age does not affect its susceptibility to cavitation, the age of the rig can. An older rig’s mud systems may not be equipped for the way pumps are run today – at maximum horsepower.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

TSM Modules are forged using superior materials with characteristics that exceed the typical 4130 forged products in the industry. Characteristics include: through hardness, fatigue/crack resistant properties and low temperature ratings. These features combined with smooth inside surfaces/radii result in a high quality product.

.jpg)

NOV 12-P-160 Mud Pump is rated at 1600 input horsepower (1193 kw) at 120 strokes per minute, with a 12-inch (304.8 mm) stroke. Multiple liner sizes allow pressures and volumes to handle circulation requirements in deep drilling applications.

Flexibility: Compact engineering provides higher efficiency in less space. The NOV 12-P-160 Triplex Mud Pump light weight and flexible design make it easily adaptable to a variety of rig configurations. This provides flexibility as drilling requirements and conditions change.

Fluid End Modules: NOV offers a choice of fluid end modules and valve covers for every P Series pump model to select the fluid end module that exactly matches drilling requirements. All pump models can be equipped with either the standard or premium forged, two-piece interchangeable fluid modules

During the production cycle, these Fluid Ends have strictnon-destructive testing, as ultrasound inspectionsandpenetrant tests to ensure the ultimate suitability.

14 P-220 Mud Pumps 3 available completely overhauled. The pumps have been machine inspected and all data will be provided. These 2200 HP pumps complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. The drives can be set up for AC or DC power. All Master Rig equipment meets or exceeds O.E.M. standards and a complete data pack is furnished with purchase. Please call if you have any questions.

READY TO SHIP - Three (3) completely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation dampener, 75 HP charge pump, two (2) GE 752 1000 HP rear mounted motors, 10 HP blower, mounted on a 3 runner skid with loading hitches and much more. Units come with complete data books and have been tested. MRI is a API facility and units comply with API standards.

Duplex mud pump package completely refurbished and never operated. Tri-Services Manufacturing TSM-500 pump, CAT engine. Data book provided with complete refurbishment details.

You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex Mud Pumps for sale by Pickett Oilfield, LLC. These National 12-P-160 Mud Pumps are Rebuilt and Ready to go to work.

Some refurbishments include: Fully reconditioned mud pump assembly. Pinion shaft assembly complete with new SKF bearings and new seals. Pump internals painted with Oil Resistant 2 Part epoxy Jotun Tank guard. MPI inspection of all critical areas of pump frame. MPI of all load path components of Crankshaft and Pinion shaft assemblies, and all new Southwest Premium “L” Shape 6,000 psi Fluid End Modules. A full Data Pack with all dimensional control & MPI reports will be furnished.

Warranty on National 12-P-160 Triplex Mud Pumps: All new parts fitted come with a 12 month warranty or such as offered by the part manufacturer; The refurbished GE-752 traction motors come with an 18 month warranty.

Pickett Oilfield, LLC offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Drilling Equipment at competitive prices, including Triplex Mud pumps.

Setembro/17 MUD PUMPS ACCEPTANCE METHOD Pág. 1 de 4

Date 1.0 Documentation, Certification and Performance Data Check that all relevant instruction manuals, workshop manuals and spare parts manuals are on file with the installation.1.1 COMMENT: Not Received Check the volumetric performance is as listed in the documentation. Not1.2 Received2.0 Mechanical Installation Verification Ensure all relevant personal protection equipment and procedural requirements have been satisfied prior to accessing the equipment. This2.1 may include, but is not limited to, lock-out/tag-out, ventilation, work permits and safety barriers. Check the installation of the mud pump on the skid. Check that the mud pump is2.2 well secured with locating blocks and bolted foundations.

2.3 Check the liner cooling water tank for proper capacity for the pump. COMMENT: Check that the liner cooling water pump is correctly piped in with pressure gage2.4 installed on the discharge side. COMMENT: Check that a screen element is fitted on the mud pump block end closest to2.5 the discharge end. Discharge dampener to be placed at the end where the HP discharge line2.6 starts. Pressure gage to be installed in a position upstream of the screen, to ensure2.7 that the pressure is sensed, even if the screen is blocked COMMENT:

Verify that the oil of correct grade is filled in the power end. Check the dip stick2.8 to ensure that the correct volume of oil is filled Check the rotation of the oil pump motor and verify that 40 psi2.9 pressure is building up in the system. COMMENT:

Sistema Integrado de Gestão de Saúde, Segurança, Meio Ambiente, Qualidade e Responsabilidade Social - IMS Pág. 1 de 4 FORMULÁRIO FORM-123-COM Setembro/17 MUD PUMPS ACCEPTANCE METHOD Pág. 2 de 4

Sistema Integrado de Gestão de Saúde, Segurança, Meio Ambiente, Qualidade e Responsabilidade Social - IMS Pág. 2 de 4 FORMULÁRIO FORM-123-COM Setembro/17 MUD PUMPS ACCEPTANCE METHOD Pág. 3 de 4

Date2.14 Discharge line of the relief valve should be anchored in secure manner Verify that the belt is installed correctly and does not interfere with the guards2.15 Check if strainer plate is installed in the suction strainer pot2.16 COMMENT : Visually Check the suction and discharge connections on the mud pump2.17 modules and manifolds to ensure that all bolting is correctly installed

2.18 Check that covers are installed on the pony rod wells 3.0 Electrical Installation Verification Inspect the motor connections for the main AC Drive motors, blower motors;3.1 lube oil motor, liner wash pump motor, super charging pump motor.3.2 Verify that all motors are good for 55 deg C ambient temp service3.3 Verify that all cables are sufficiently protected against damage3.4 Check that AC Motor lock out switches have been installed Check that all openings in the junction box for each AC motor have been3.5 used or properly plugged back.3.6 Verify that each AC motor has a spark arrestor that is installed3.7 Check each AC motor for correct rotation direction3.8 Verify grounding cable is fitted for all AC Motors. Install the stroke counter, check that the cables are properly routed3.9 COMMENT:4.0 Maintenance and Repair Equipment Assessment4.1 Equipment Fail Description

ACCEPTANCE METHOD Date FORMULÁRIO FORM-123-COM Setembro/17 MUD PUMPS ACCEPTANCE METHOD Pág. 4 de 4

Accepted by 5.0 Performance Acceptance testing 5.1 Check that the tension of the belt is adequate 5.2 Check that pressure gages are installed that are liquid filled 5.3 Check that guards are installed on all the shafts & couplings Check the skid for proper containment bunding to be provided to control 5.4 spills. COMMENT : NO 5.5 Check the precharge of the pulsation dampeners. Verify that only nitrogen has been filled in the dampeners. Use a gas tester. 5.6 5.7 Check that pressure relief valve is set to correct pressure. Hook up the suction and discharge lines. Fill the pump with water to 5.8 displace air Carry out running tests of the mud pumps under pressure. Endurance test of 4 hours continuous running is recommended. Flow thru the HP5.9 piping and back to the suction tank using a choke to create back pressure in the system. COMMENT: Verify that the stroke counter is working with display at rig floor DCR cabin5.10 as well as at the Automatic Choke control panel. Check the AC motor and blowers for abnormal sounds / noises while the5.11 pump is running. Trouble shoot any noises 6.0 COMMENTS & REMARKS 6.1 Need to improve the installation for the liner spray system. 6.2 6.3

8613371530291

8613371530291