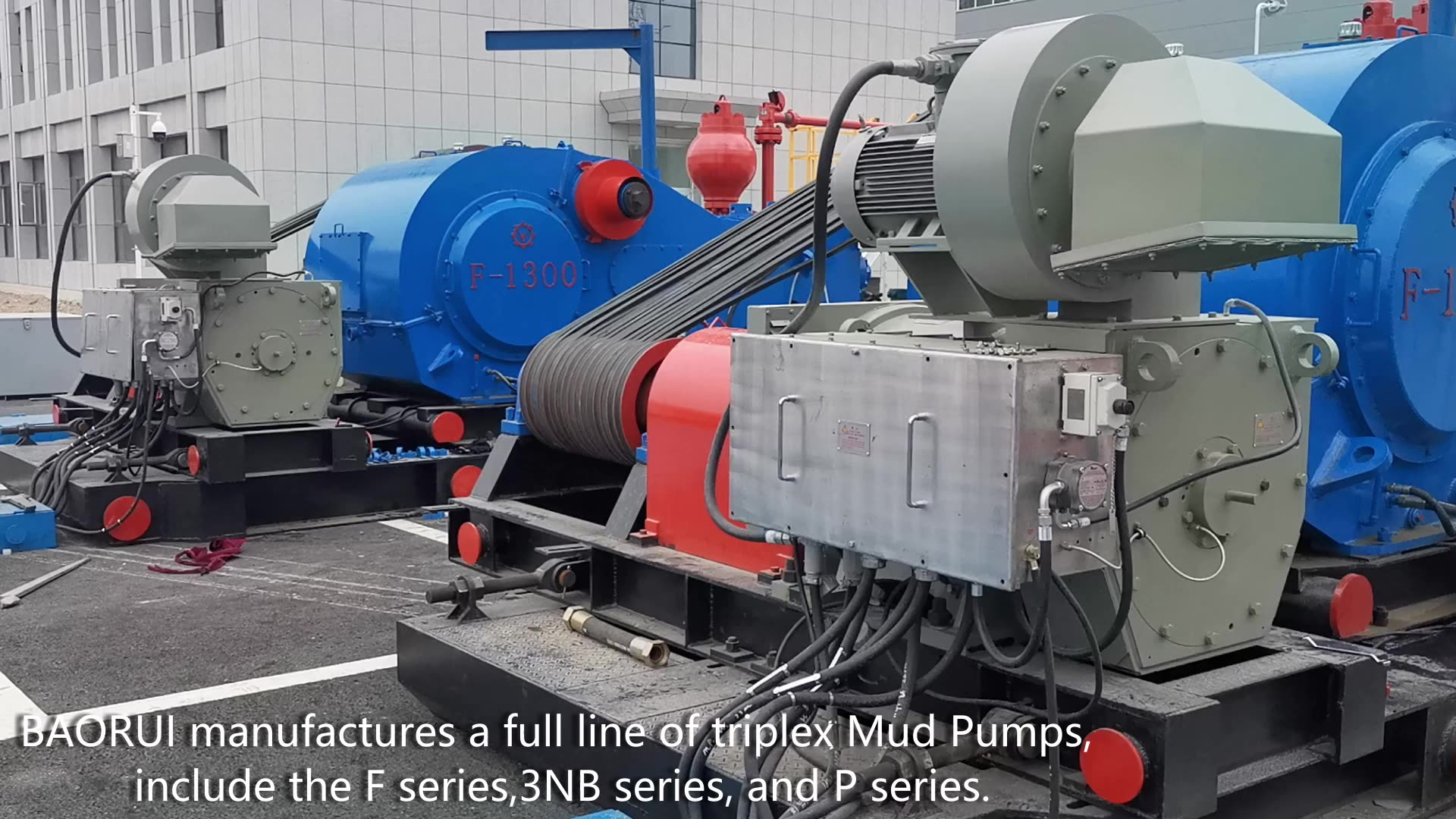

mud pump offshore drilling made in china

14/12 AH Head=40m, efficiency=76% Outlet horizontal on the top of the pump, fulley enclosed protection, CRz drive South Africa - Molybdenum Ore. 6/4 AH efficiency=66% Outlet horizontal on the bottom of the pump, fully enclosed protection, CV drive Canada Lead - Zinc Ore. 8/6 AH Head=34m, efficiency=70% Outlet vertical upward, fully enclosed protection, ZVz drive Russia - Copper Mine.

As a China top oil drilling rig solids control system manufacturer: GN Solids Control now list the top 10 oil drilling rig manufacturers for your reference.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

Lanzhou LS-National Oilwell Petroleum Engineering Co. Ltd. (LS-NOW for short) is a Sino-American Joint Venture established between Lanzhou Petrochemical Machinery Equipment and Engineering Group Corporation (LS Group) and National Oilwell International, Inc. (NOI). Scope of business: design, develop and manufacture complete land and offshore drilling rigs and workover rigs, and provide equipment package, components, fittings, parts and full services.

Main products: serial drilling rigs that are electrical or mechanical or electrical-mechanical compounded driven and suitable for different applications such as land, shallow, offshore and desert and meet the requirements of drilling and workover services. The drilling depth ranged from 1000 to 9000 meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is a subsidiary of Honghua Group which has been listed successfully in the Stock Exchange of Hong Kong. The company has been engaged in research, design, manufacturing and general assembly of oil drilling rig and equipments for oil exploration and development. Now it is the world’s second land drilling rig manufacturer, and China ‘s largest exporter of drilling rigs.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manufacturers for petroleum drilling rig equipment in China. It is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manufacturing Plant of National Petroleum Industrial Ministry of China). As a former national technical equipment production base, authorized by former national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product trial production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.

RG PETRO-MACHINERY (GROUP) CO. LTD, with its technical center, information center and quality inspection center at provincial level, has possessed 16 production plants for forging, metal machining, heat treatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

SJ Petroleum Machinery Co. , one of petroleum drilling rig and production equipment backbone manufacturers and Manufacturing Base for National Key Equipment (Workover, Cementing and Fracturing Equipment) recognized by National Economy and Trade Commission, has provided lots of advanced equipment to domestic customers in lieu of expensive imported equipment, and played an important role in increasing profits of petroleum industry and decreasing domestic oilfield development cost.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

Drilling Rig: Highland Company Drilling Rig Plant has advanced key facilities and assembly workshops for manufacturing rigs and it has enough test sites for assembling 12 sets of large scale drilling rigs at the same time,5 series (ZJ20~ZJ70, including 18 types) of drilling rigs have been developed and manufactured. These developed and manufactured products consist of mechanical drive, DC driven, AC VF drive and Electromechnical drilling rigs, which can handle the well with depth of 1500- 7000m in most of the large oilfields both at home and overseas.

This article is about onshore equipment for boring holes into the ground. For offshore oil rig, see Oil platform. For drilling tunnels, see Tunnel boring machine. For handheld drilling tool, see Drill.

A drilling rig is an integrated system that drills wells, such as oil or water wells, or holes for piling and other construction purposes, into the earth"s subsurface. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called augers. Drilling rigs can sample subsurface mineral deposits, test rock, soil and groundwater physical properties, and also can be used to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures (such as oil platforms, commonly called "offshore oil rigs" even if they don"t contain a drilling rig). The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth"s crust.

Small to medium-sized drilling rigs are mobile, such as those used in mineral exploration drilling, blast-hole, water wells and environmental investigations. Larger rigs are capable of drilling through thousands of metres of the Earth"s crust, using large "mud pumps" to circulate drilling mud (slurry) through the drill bit and up the casing annulus, for cooling and removing the "cuttings" while a well is drilled. Hoists in the rig can lift hundreds of tons of pipe. Other equipment can force acid or sand into reservoirs to facilitate extraction of the oil or natural gas; and in remote locations there can be permanent living accommodation and catering for crews (which may be more than a hundred). Marine rigs may operate thousands of miles distant from the supply base with infrequent crew rotation or cycle.

Antique drilling rig now on display at Western History Museum in Lingle, Wyoming. It was used to drill many water wells in that area—many of those wells are still in use.

Until internal combustion engines were developed in the late 19th century, the main method for drilling rock was muscle power of man or animal. The technique of oil drilling through percussion or rotary drilling has its origins dating back to the ancient Chinese Han Dynasty in 100 BC, where percussion drilling was used to extract natural gas in the Sichuan province.Edwin Drake to drill Pennsylvania"s first oil well in 1859 using small steam engines to power the drilling process rather than by human muscle.Cable tool drilling was developed in ancient China and was used for drilling brine wells. The salt domes also held natural gas, which some wells produced and which was used for evaporation of the brine.

In the 1970s, outside of the oil and gas industry, roller bits using mud circulation were replaced by the first pneumatic reciprocating piston Reverse Circulation (RC) drills, and became essentially obsolete for most shallow drilling, and are now only used in certain situations where rocks preclude other methods. RC drilling proved much faster and more efficient, and continues to improve with better metallurgy, deriving harder, more durable bits, and compressors delivering higher air pressures at higher volumes, enabling deeper and faster penetration. Diamond drilling has remained essentially unchanged since its inception.

Oil and natural gas drilling rigs are used not only to identify geologic reservoirs, but also used to create holes that allow the extraction of oil or natural gas from those reservoirs. Primarily in onshore oil and gas fields once a well has been drilled, the drilling rig will be moved off of the well and a service rig (a smaller rig) that is purpose-built for completions will be moved on to the well to get the well on line.

Mining drilling rigs are used for two main purposes, exploration drilling which aims to identify the location and quality of a mineral, and production drilling, used in the production-cycle for mining. Drilling rigs used for rock blasting for surface mines vary in size dependent on the size of the hole desired, and is typically classified into smaller pre-split and larger production holes. Underground mining (hard rock) uses a variety of drill rigs dependent on the desired purpose, such as production, bolting, cabling, and tunnelling.

In early oil exploration, drilling rigs were semi-permanent in nature and the derricks were often built on site and left in place after the completion of the well. In more recent times drilling rigs are expensive custom-built machines that can be moved from well to well. Some light duty drilling rigs are like a mobile crane and are more usually used to drill water wells. Larger land rigs must be broken apart into sections and loads to move to a new place, a process which can often take weeks.

Small mobile drilling rigs are also used to drill or bore piles. Rigs can range from 100 short tons (91,000 kg) continuous flight auger (CFA) rigs to small air powered rigs used to drill holes in quarries, etc. These rigs use the same technology and equipment as the oil drilling rigs, just on a smaller scale.

The drilling mechanisms outlined below differ mechanically in terms of the machinery used, but also in terms of the method by which drill cuttings are removed from the cutting face of the drill and returned to surface.

An automated drill rig (ADR) is an automated full-sized walking land-based drill rig that drills long lateral sections in horizontal wells for the oil and gas industry.Athabasca oil sands. According to the "Oil Patch Daily News", "Each rig will generate 50,000 man-hours of work during the construction phase and upon completion, each operating rig will directly and indirectly employ more than 100 workers." Compared to conventional drilling rigs", Ensign, an international oilfield services contractor based in Calgary, Alberta, that makes ADRs claims that they are "safer to operate, have "enhanced controls intelligence," "reduced environmental footprint, quick mobility and advanced communications between field and office."steam assisted gravity drainage (SAGD) applications was mobilized by Deer Creek Energy Limited, a Calgary-based oilsands company.

Baars, D.L.; Watney, W.L.; Steeples, D.W.; Brostuen, E.A (1989). Petroleum; a primer for Kansas (Educational Series, no. 7 ed.). Kansas Geological Survey. p. 40. Archived from the original on 8 November 2020. Retrieved 18 April 2011. After the cementing of the casing has been completed, the drilling rig, equipment, and materials are removed from the drill site. A smaller rig, known as a workover rig or completion rig, is moved over the well bore. The smaller rig is used for the remaining completion operations.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

Baoji Oilfield Machinery Co., Ltd (BOMCO), as a leading one in researching,designing, manufacturing and assembling Oil Drilling Rig and equipments for oilexploration and development since 1970s. It belongs to CNPC. Complete sets of onshore and offshore drilling rig and relating equipments could be produced. It produced most drilling rigs in 2005 in the world.

Main products: drilling rigs including AC VFD, DC, diesel engine and gear,chain, hydraulic and belt drive, truck-mounted and trailer-mounted series,ranging from 1,000 meters to 12,000 meters in drilling depth; a series of API7K-compliant mud pumps ranging from F-500 to F-2200; CGDS-I, a near-bitgeosteering system for well drilling, consists of the CAIMS (China AdjustableInstrumented Motor System), WLRS (Wireless Receiver System), CGMWD (ChinaGeosteering MWD), and the CFDS (China Formation/Drilling Software System).CGDS-I has three major functions: logging/measurement, transmission andsteering.

Scope of business: design and manufacture complete land and offshore drillingrigs and oil service rigs, and provide relating equipment package, components,parts and full services.

Main products: oil drill rigs that are electrical or mechanical orelectrical-mechanical compounded driven and suitable for different applicationssuch as land, shallow, offshore and desert and meet the requirements of drilling and oilfield services. The drilling depth ranged from 1000 to 9000meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is asubsidiary of Honghua Group which has been listed successfully in the StockExchange of Hong Kong. The company has been engaged in research, design,manufacturing and general assembly of Oil Drilling Rig and equipments for oil exploration and development. Now it is the world’s second land drilling rigmanufacturer, and China’s largest exporter of drilling rigs.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electricrig, mechanical drilling rig, composite drive rig, trailer mounted rig andindependent RT electric drive drilling rig, as well as their matchedequipments, i.e. drilling pumps, traveling block system, solid control system,electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum MachineryManufacturing Plant of National Petroleum Industrial Ministry of China in1969). RG has possessed 16 production plants for forging, metal machining, heattreatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigsas well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

RG could provide 12 series of products in 200 kinds, including skid-mounteddrilling rig, truck-mounted drilling rig, trailer-mounted drilling rig,workover rig, offshore drilling/workover equipment, solid control and mudcirculation equipment, oilwell logging equipment, petroleum special Vehicle,top drive drilling equipment, Hydraulic water drilling rig,mud pump,hoisting and rotaryDrilling equipment and related spare parts, etc.

It supply four major categories of products including drilling & workoverequipment, production equipment, offshore drilling & production equipmentand high pressure manifolds, 12 families and more than 200 types of products.

Its star products include pumping units, workover rigs, cementing units,fracturing packages, fracturing pump and high pressure fluid control products.

Shandong Kerui Holding Group, established in 2001, has become aninternational comprehensive enterprise with business scope covering: theresearch, development and manufacture of the petroleum drilling and wellservice equipment, oil production, wellhead & downhole tool and the specialoperation equipment in oilfield, manufacture and assemblage of natural gascompressor, R&D and manufacture of natural gas, coalbed methane & shalegas process equipment and oilfield energy saving electrical product, oilfieldexploration development comprehensive solution and technical service ofpetroleum engineering, etc.

The main products include oil drilling rig equipment, Oil pumpingequipment, Special equipment for oilfield, Oilfield tubing system and auxiliarymachines and tools. Kerui manufactures various workover rigs and drilling rigswith drill depth from 3000m to 9000m.

main business activity covers the design and manufacture of the followingseries of: electrical, mechanical drilling rigs, and electro-mechanic rigs withthe drill depth from 2,000 meters to 9,000 meters; module offshore drilling andworkover platforms, module offshore drilling rig, polar drilling rigs, andtruck mounted rigs; electrical driving control and system, and; main rig componentsof crown blocks, traveling blocks, hook, mud pump, swivel, and etc.

Now company has five classes of products/services: Drilling Equipments,Production Equipments, Tubular Goods, Oilfield Service and Chemicals, whichincludes dozens kinds of series products. We are able to design, manufactureand provide all these series of products, technical services and OEM parts.

The current product lines include workover & drilling rig series, oilfield environmental protection equipment series, oil recovery machinery seriesand water well & mineral drilling machinery series.

Shaanxi TEFICO Petroleum Mechanical And Electric New Technology Co., Ltd.(Tefico) located in Baoji, China biggest drilling rig manufacture center, andowning a strong technical expert team with nearly 30 years experience, has beendedicated to ensuring customers receive the highest quality land drilling rigsand drilling equipments for Oil, Gas , Geothermy, Shale Gas and Coal BedMethane since 2000.

TEFICO is provides complete land drilling rigs for sale and rental and majormechanical components, such as mast, substructure, crown block, rotary table,drawworks, travelling block, hook, mud pump, top drive. TEFICO is also aproject management company hence it can work as a subcontractor to join projector partner with clients in all relevant project.

The drilling industry has roots dating back to the Han Dynasty in China. Improvements in rig power and equipment design have allowed for many advances in the way crude oil and natural gas are extracted from the ground. Diesel/electric oil drilling rigs can now drill wells more than 4 miles in depth. Drilling fluid, also called drilling mud, is used to help transfer the dirt or drill cuttings from the action of the drilling bit back to the surface for disposal. Drill cuttings can vary in shape and size depending on the formation or design of the drill bit used in the process.

Watch the video below to see how the EDDY Pump outperforms traditional pumps when it comes to high solids and high viscosity materials commonly found on oil rigs.

Solids control equipment including shakers, hydro-cyclones, and centrifuges are utilized to clean the drill cuttings from the drilling fluid, which then allows it to be reused and recirculated. The circuit includes the mixing of the drilling fluid in the rig tanks.

The drilling fluid is prepared to control fluid loss to the formation by the addition of chemicals or mineral agents. Commercial barite or other weighting agents are added to control the hydrostatic pressure exuded on the bottom of the well which controls formation pressures preventing fluid or gas intrusion into the wellbore.

The fluid is charged into high-pressure mud pumps which pump the drilling mud down the drill string and out through the bit nozzles cleaning the hole and lubricating the drill bit so the bit can cut efficiently through the formation. The bit is cooled by the fluid and moves up the space between the pipe and the hole which is called the annulus. The fluid imparts a thin, tough layer on the inside of the hole to protect against fluid loss which can cause differential sticking.

The fluid rises through the blowout preventers and down the flowline to the shale shakers. Shale shakers are equipped with fine screens that separate drill cutting particles as fine as 50-74 microns. Table salt is around 100 microns, so these are fine cuttings that are deposited into the half-round or cuttings catch tank. The drilling fluid is further cleaned with the hydro-cyclones and centrifuges and is pumped back to the mixing area of the mud tanks where the process repeats.

The drill cuttings contain a layer of drilling fluid on the surface of the cuttings. As the size of the drill cuttings gets smaller the surface area expands exponentially which can cause rheological property problems with the fluid. The fluid will dehydrate and may become too thick or viscous to pump so solids control and dilution are important to the entire drilling process.

One of the most expensive and troubling issues with drilling operations is the handling, processing, and circulation of drilling mud along with disposing of the unwanted drill cuttings. The drilling cuttings deposited in the half round tank and are typically removed with an excavator that must move the contents of the waste bin or roll-off box. The excavators are usually rented for this duty and the equipment charges can range from $200-300/day. Add in the cost for the day and night manpower and the real cost for a single excavator can be as much as $1800/day.

Offshore drilling rigs follow a similar process in which the mud is loaded into empty drums and held on the oil platform. When a certain number of filled drums is met, the drums are then loaded onto barges or vessels which take the drilling mud to the shore to unload and dispose of.

Oil field drilling operations produce a tremendous volume of drill cuttings that need both removal and management. In most cases, the site managers also need to separate the cuttings from the drilling fluids so they can reuse the fluids. Storing the cuttings provides a free source of stable fill material for finished wells, while other companies choose to send them off to specialty landfills. Regardless of the final destination or use for the cuttings, drilling and dredging operations must have the right high solids slurry pumps to move them for transport, storage, or on-site processing. Exploring the differences in the various drilling fluids, cutting complications, and processing options will reveal why the EDDY Pump is the best fit for the job.

The Eddy Pump is designed to move slurry with solid content as high as 70-80 % depending on the material. This is an ideal application for pumping drill cuttings. Drill cuttings from the primary shakers are typically 50% solids and 50% liquids. The Eddy Pump moves these fluids efficiently and because of the large volute chamber and the design of the geometric rotor, there is very little wear on the pump, ensuring long life and greatly reduced maintenance cost for the lifetime of the pump.

plumbed to sweep the bottom of the collection tank and the pump is recessed into a sump allowing for a relatively clean tank when the solids are removed. The Eddy Pump is sized to load a roll-off box in 10-12 minutes. The benefit is cuttings handling is quicker, easier, safer, and allows for pre-planning loading where the labor of the solids control technician is not monopolized by loading cuttings. Here, in the below image, we’re loading 4 waste roll-off bins which will allow the safe removal of cuttings without fear of the half-round catch tank running over.

Mud cleaning systems such as mud shaker pumps and bentonite slurry pumps move the material over screens and through dryers and centrifuges to retrieve even the finest bits of stone and silt. However, the pump operators must still get the raw slurry to the drill cuttings treatment area with a power main pump. Slurry pumps designed around the power of an Eddy current offer the best performance for transferring cuttings throughout a treatment system.

Options vary depending on whether the company plans to handle drill cuttings treatment on-site or transport the materials to a remote landfill or processing facility. If the plan is to deposit the cuttings in a landfill or a long-term storage container, it’s best to invest in a pump capable of depositing the material directly into transport vehicles. Most dredging operations rely on multiple expensive vacuum trucks, secondary pumps, and extra pieces of equipment.

Using an EDDY Pump will allow a project to eliminate the need for excavators/operators to load drill cuttings, substantially lowering both labor and heavy equipment costs. The EDDY Pump also allows a company to eliminate vacuum trucks once used for cleaning the mud system for displacing fluids. Since the pump transfers muds of all types at constant pressure and velocity throughout a system of practically any size, there’s little need for extra equipment for manual transfer or clean up on the dredge site.

The EDDY Pump can fill up a truck in only 10 minutes (compared to an hour) by using a mechanical means such as an excavator. For this reason, most companies can afford one piece of equipment that can replace half a dozen other units.

This application for the Eddy Pump has the potential to revolutionize the drilling industry. Moving the excavator out of the “back yard” (the area behind the rig from the living quarters) will make cuttings handling a breeze. Trucking can be easier scheduled during daylight hours saving on overtime and incidences of fatigued driving. Rig-site forklifts can move the roll-off boxes out of the staging area and into the pump loading area. The operator can save money on excavators rental, damages, and keep the technician operating the solids control equipment.

The EDDY Pump is ideal for drilling mud pump applications and can be connected directly onto the drilling rigs to pump the drilling mud at distances over a mile for disposal. This eliminates the need for costly vacuum trucks and also the manpower needed to mechanically move the drilling mud. The reasons why the EDDY Pump is capable of moving the drilling mud is due to the hydrodynamic principle that the pump creates, which is similar to the EDDY current of a tornado. This tornado motion allows for the higher viscosity and specific gravity pumping ability. This along with the large tolerance between the volute and the rotor allows for large objects like rock cuttings to pass through the pump without obstruction. The large tolerance of the EDDY Pump also enables the pump to last many times longer than centrifugal pumps without the need for extended downtime or replacement parts. The EDDY Pump is the lowest total life cycle pump on the market.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Baoji Oilfield Machinery Co., Ltd (BOMCO), as a leading one in researching,designing, manufacturing and assembling Oil Drilling Rig and equipments for oilexploration and development since 1970s. It belongs to CNPC. Complete sets of onshore and offshore drilling rig and relating equipments could be produced. It produced most drilling rigs in 2005 in the world.

Main products: drilling rigs including AC VFD, DC, diesel engine and gear,chain, hydraulic and belt drive, truck-mounted and trailer-mounted series,ranging from 1,000 meters to 12,000 meters in drilling depth; a series of API7K-compliant mud pumps ranging from F-500 to F-2200; CGDS-I, a near-bitgeosteering system for well drilling, consists of the CAIMS (China AdjustableInstrumented Motor System), WLRS (Wireless Receiver System), CGMWD (ChinaGeosteering MWD), and the CFDS (China Formation/Drilling Software System).CGDS-I has three major functions: logging/measurement, transmission andsteering.

Scope of business: design and manufacture complete land and offshore drillingrigs and oil service rigs, and provide relating equipment package, components,parts and full services.

Main products: oil drill rigs that are electrical or mechanical orelectrical-mechanical compounded driven and suitable for different applicationssuch as land, shallow, offshore and desert and meet the requirements of drilling and oilfield services. The drilling depth ranged from 1000 to 9000meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is asubsidiary of Honghua Group which has been listed successfully in the StockExchange of Hong Kong. The company has been engaged in research, design,manufacturing and general assembly of Oil Drilling Rig and equipments for oil exploration and development. Now it is the world’s second land drilling rigmanufacturer, and China’s largest exporter of drilling rigs.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electricrig, mechanical drilling rig, composite drive rig, trailer mounted rig andindependent RT electric drive drilling rig, as well as their matchedequipments, i.e. drilling pumps, traveling block system, solid control system,electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum MachineryManufacturing Plant of National Petroleum Industrial Ministry of China in1969). RG has possessed 16 production plants for forging, metal machining, heattreatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigsas well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

RG could provide 12 series of products in 200 kinds, including skid-mounteddrilling rig, truck-mounted drilling rig, trailer-mounted drilling rig,workover rig, offshore drilling/workover equipment, solid control and mudcirculation equipment, oilwell logging equipment, petroleum special Vehicle,top drive drilling equipment, Hydraulic water drilling rig,mud pump,hoisting and rotaryDrilling equipment and related spare parts, etc.

It supply four major categories of products including drilling & workoverequipment, production equipment, offshore drilling & production equipmentand high pressure manifolds, 12 families and more than 200 types of products.

Its star products include pumping units, workover rigs, cementing units,fracturing packages, fracturing pump and high pressure fluid control products.

Shandong Kerui Holding Group, established in 2001, has become aninternational comprehensive enterprise with business scope covering: theresearch, development and manufacture of the petroleum drilling and wellservice equipment, oil production, wellhead & downhole tool and the specialoperation equipment in oilfield, manufacture and assemblage of natural gascompressor, R&D and manufacture of natural gas, coalbed methane & shalegas process equipment and oilfield energy saving electrical product, oilfieldexploration development comprehensive solution and technical service ofpetroleum engineering, etc.

The main products include oil drilling rig equipment, Oil pumpingequipment, Special equipment for oilfield, Oilfield tubing system and auxiliarymachines and tools. Kerui manufactures various workover rigs and drilling rigswith drill depth from 3000m to 9000m.

main business activity covers the design and manufacture of the followingseries of: electrical, mechanical drilling rigs, and electro-mechanic rigs withthe drill depth from 2,000 meters to 9,000 meters; module offshore drilling andworkover platforms, module offshore drilling rig, polar drilling rigs, andtruck mounted rigs; electrical driving control and system, and; main rig componentsof crown blocks, traveling blocks, hook, mud pump, swivel, and etc.

Now company has five classes of products/services: Drilling Equipments,Production Equipments, Tubular Goods, Oilfield Service and Chemicals, whichincludes dozens kinds of series products. We are able to design, manufactureand provide all these series of products, technical services and OEM parts.

The current product lines include workover & drilling rig series, oilfield environmental protection equipment series, oil recovery machinery seriesand water well & mineral drilling machinery series.

Shaanxi TEFICO Petroleum Mechanical And Electric New Technology Co., Ltd.(Tefico) located in Baoji, China biggest drilling rig manufacture center, andowning a strong technical expert team with nearly 30 years experience, has beendedicated to ensuring customers receive the highest quality land drilling rigsand drilling equipments for Oil, Gas , Geothermy, Shale Gas and Coal BedMethane since 2000.

TEFICO is provides complete land drilling rigs for sale and rental and majormechanical components, such as mast, substructure, crown block, rotary table,drawworks, travelling block, hook, mud pump, top drive. TEFICO is also aproject management company hence it can work as a subcontractor to join projector partner with clients in all relevant project.

Mud Pump is also a popular concept of a wide range of pumps. Different regions, habits, and ultimately the pump type will not be the same. The mud pump described in this entry is a pump type in most sense: Applied mud pumps in the field of oil drilling. In fact, some non-clean water pumps and mud pumps, such as sewage pumps and slurry pumps, are also commonly used when they are called.

Mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Mud pumps are an important part of drilling equipment.

In the commonly used positive circulation drilling, it is to send the surface flushing medium—clear water, mud or polymer rinsing liquid to the bottom end of the drill bit through a high-pressure hose, faucet and drill rod center hole under a certain pressure. Cool the drill bit, remove the cut debris and transport it to the surface.

The commonly used mud pump is a piston type or a plunger type, and the crankshaft of the pump is driven by the power machine, and the crankshaft passes the crosshead to drive the piston or the plunger to reciprocate in the pump cylinder. Under the alternating action of the suction and discharge valves, the purpose of pumping and circulating the flushing liquid is achieved.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

As a primary company in China manufacturing geotechnical equipment, we supply more than 60 kinds and 5 series of mud pumps, covering BW series mud pumps, cement grouting pumps, high pressure pumps, etc. and a number of drilling rigs, like core drilling rigs, engineering drillers, with the drilling depth reaching 100 to 3500 meters.

As a hi-tech company of Hunan province, we have established a professional R&D center. With over 50 years R&D experience, we have been granted 18 valid patents, and we are honored to become one of the national standard makers of mud pumps and drill rigs. We have also kept long-term cooperation with the technical center of China Geological Equipment Group Co., Ltd. and some primary higher education institutions to keep upgrading our technology and services.

Our mud pumps and drills rigs are awarded Famous Products of Hunan Province as well as National Silver Prize, Provincial High-quality Product and Technology Achievement Prize. We are certified by ISO9001: 2008 quality system and CE, and we also carry safety certificate of approval for mining products. In addition, our registered trademark is recognized as a famous trademark of Hunan province.

In oil drilling, high-pressure mud pump is the heart of drilling platform, and wear resistant cylinder liner is the main vulnerable part of mud pump. It need to withstand working conditions of high pressure, high wear and strong corrosion. At present, the mud pump cylinder liners are mainly bimetal cylinder liners and ceramic cylinder liners. The lining of the bimetal cylinder liner is made of high-chromium cast iron metal materials, the lining of the ceramic cylinder liner is made of alumina or zirconia structural ceramic material.

8613371530291

8613371530291