mud pump packing manufacturer

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

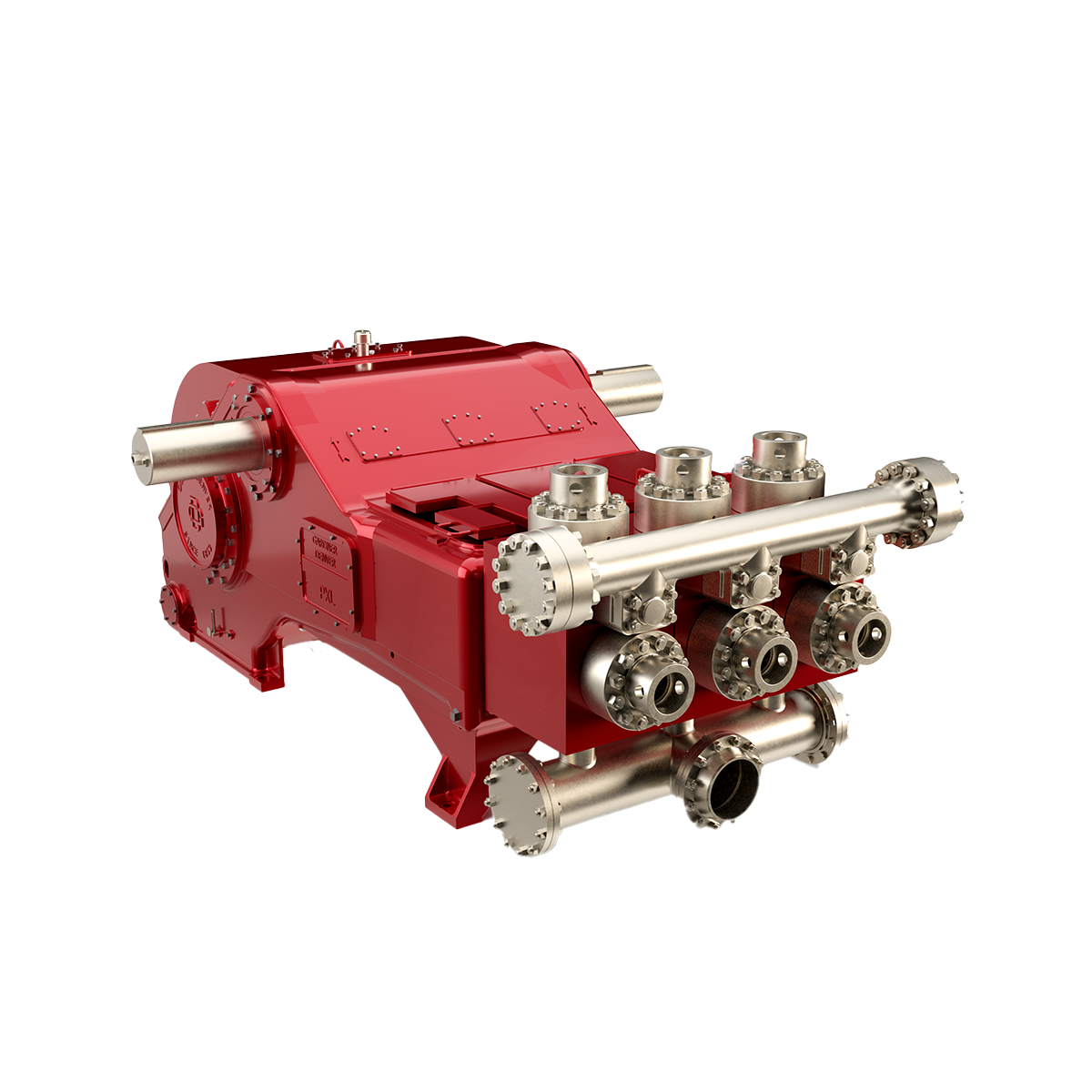

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Standard Industrial Manufacturing started in 1979. Our mission was to manufacture and supply pump parts to a few select pump retailers and OEMs. During the 1980s the company expanded its customer base to include all pump retailers and OEMs. Today, Standard has broadened its product lines to include most fluid-end expendables for all major pump brands.

JST provides high-performance well service packing, which is suitable for high-pressure and abrasive media in drilling, cementing and fracturing services. With our unique and innovative materials, the wear of plunger and fluid end is significantly reduced, therefore the well service packing can be used for long term, which reduces the pump maintenance cost. JST has patent for its well service packings.

A kit of replacement packings for high pressure "MUD" pumps from General Pump. Compatible with KF50MA and KF5M pumps. This is an OEM kit of packings to ensure a proper fit and material compatibility. Packing diameter measures 50 millimeters.

Then we collaborated with customers located throughout North America for more than a year to test Redline Packing and ensure its success across a variety of challenging environments. The results are remarkable, showing almost a two-fold increase in life vs the top competitor. Redline Packing is available today for GD Energy Products frac and well service pumps, and most competitor’s pumps as well.

Seal Well Packingis a leading manufacturer, supplier and retailer of highly specialized cotton graphite gland packing rope for the industry. The company was founded in the year 1985 as a Sole Proprietorship firm. We are involved in offering a wide range of Gland Packing Rope, Packing Rope, Cotton Rope, Asbestos Ropeand more.

Since 2001, TSC Manufacturing and Supply, LLC has been a leading global manufacturer and supplier of fluid end expendables, as well as mud pump spare parts for oilfield applications. Today, we continue to keep our proud tradition of excellence going, as we strive to better ourselves in order to better our customers" experience. Our global network of inventory locations provides unrivaled quality, customer service, on-time delivery, and unmatched technical integrity.

When it comes to mud pump fluid end expendable parts, TSC Manufacturing and Supply, LLC, has it all. TSC can, and will, match your needs, so that you won’t be lacking in anything. TSC mud pump liners are designed and manufactured to meet or exceed original equipment specification and API standards for almost all types of mud pumps in use today. With advanced technology, metallurgical control, and rigid inspection, we offer unmatched performance and durability, according to customer testimonies, in the most severe drilling conditions; both triplex and duplex liners are available in a wide range of sizes.

8613371530291

8613371530291