mud pump parts commissioning pricelist

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We"ve been striving to be an excellent business enterprise partner of you for Vertical Roller Mills, Horizontal Solid Slurry Pump, Centrifugal Centrifugal Pump, We warmly welcome all perspective inquiries from home and abroad to cooperate with us, and look forward to your correspondence.

Slurry pumps run as the key part in the mining process, power plant, metallurgy and other relevant industries are supposed to perform at an optimal standard. Atlas Pump guarantee to keep the slurry pumps at optimal performance throughout the entire working life by our highest quality spare parts. Atlas Pump promise to be the reliable back of the worldwide partners to provide the qualified and cost-effective spare parts to deal with the maintenance and emergency situations.

Atlas Pump manufacture multiple series slurry pumps and suitable spare parts (hard metals & rubbers). Including wet parts (impeller, volute, FPL insert, throat bush…), bearing assembly (shaft, bearing housing, ceramic coating shaft sleeve, end cover, cover shim…), and the seals (gland seal, mechanical seal and expeller seal) etc…

Aircraft Brake System Market Growth & Trends to 2023 Profiling Honeywell, Safran, United Technologies, Meggitt, Parker Hannifin, Crane Aerospace & Electronics – Press Release | High Pressure Diesel Water Pump

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Factory Price Mud Pump - SPARE PARTS – Tiiec , The product will supply to all over the world, such as: Poland, Puerto Rico, Zurich, Look forward to the future, we"ll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let"s develop market by fully utilizing our in depth advantages and strive for building.

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec is an experienced specialist supplier of overhaul, SPS, parts and service for rig and drilling equipment. We can provide Norwegian quality and decades of experience, while maintaning sensible prices and flexible solutions.

Tratec have delivered solid cost savings to our customers. This is due to our lower cost base, system with access to identical parts directly from manufacturer, and utilizing our experienced drilling equipment employees at very competitive rates.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

Mud Pumps are available for the different purposes of drilling and extracting of oil. In fact, the Unitized Pumps are a work of the hydraulic mechanical transmission. Unitized pump parts include 4 types of packages such as the air clutch transmission takes in the diesel engine, transmission (including card and shaft, decelerator, clutch, belt and pulley) and the Mud pump. The Mud Pumps are also inclusive of the hydraulic coupling transmission that consists of the diesel engine, hydraulic coupling and the Mud pump. It also includes the electric drive Mud pump and the chain transmission for apt design and assembling.

The Unitized design Pumps are built as well as licensed according to the specifications of the American Petroleum Institute where the master skid is the standard oilfield 3 runner skid. Mud Pumps like the F 1000 are driven by the diesel engine with the help of the narrow V belts. Pumps are complete with a bulk wheel, a set of V belts, a screw assembly, a belt guard and the screw devices for tightening the belts. Mud pump like the triplex liner single action pumps has an input power of 1000 horse power. The maximum stroke is all of 10 inches or 254 mm.

Mud parts also contain a maximum working pressure of 5000 PSI or 35 MPA. The Mud Pumps have a gear type made of integral herring bone with API 6 valve pots. The intake of the F 1000 Pumps is 12 inches or 305 mm and they have a discharge space of 4 inches or 102 mm. Mud pump also contain a pulsation dampener model that has a capacity of 75.7 liters or 20 gallons. The relief valve and pressure gauge are also an important part of the Mud pump as they help in various ways.

Mud pump like the diesel engine has a rated speed of about 1200 revolutions per minute and the movement takes place in an anticlockwise direction with the face output shaft end. For the purpose of testing and commissioning, the Mud pump needs to be installed and secured with machinery and different kinds of equipment. Furnish the lube products for testing and the diesel is required to be run for testing the transmission devices. To give you an idea, the Mud pump that is being discussed in this category is available at competitive prices and can be obtained for pneumatic clutch transmission that can be adjusted according to customer’s requirements.

KBL recently developed a large Vertical Turbine pumpset. It is a single-stage Horizontal Axial Flow Pump developed for use in the Circulation of Fermentation Broth. The pump has a

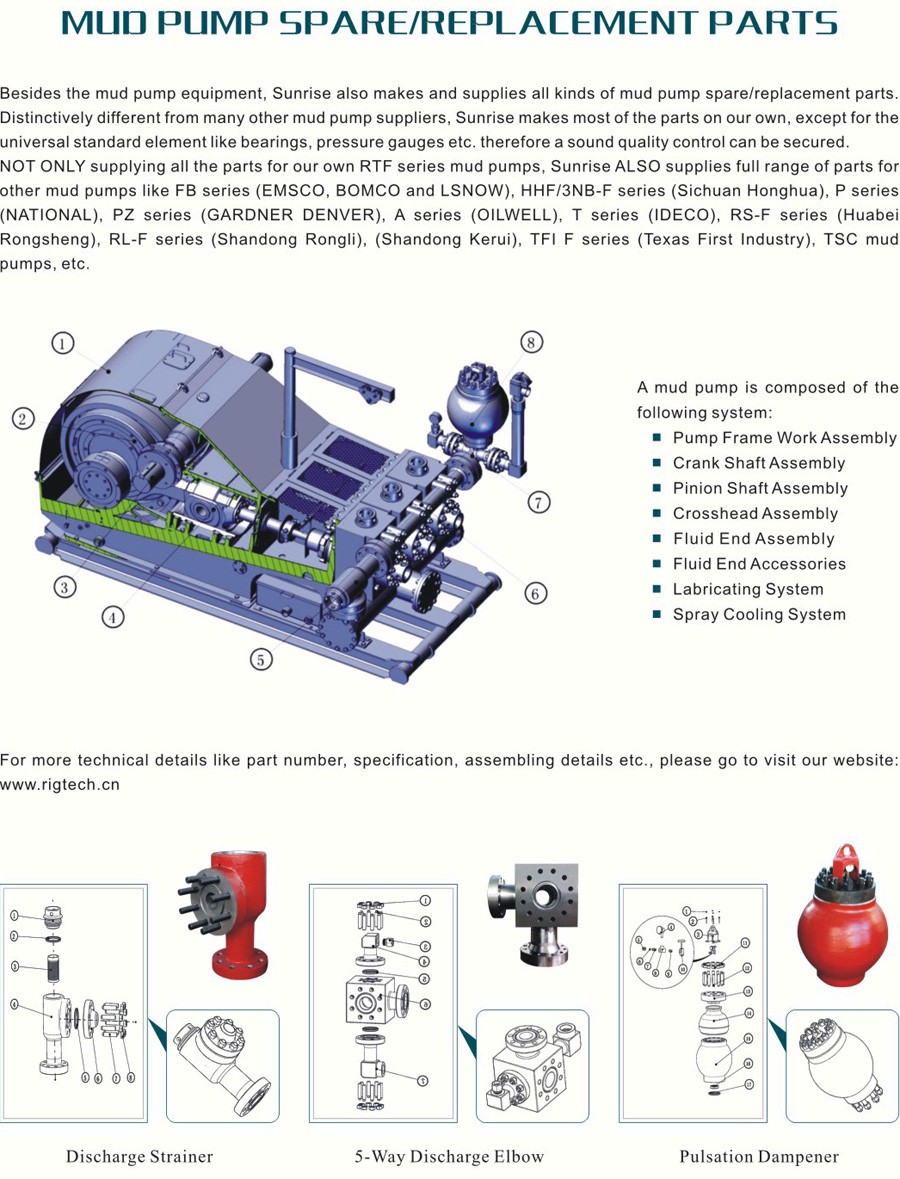

A mud pump is a reciprocating piston or plunger device designed to pump drilling fluid under high pressures and volumes down the drill string of a drilling rig. The main functions of drilling fluid are to provide hydrostatic pressure to prevent formation fluids from entering and to stabilize the bore, to keep the drill bit cool and clean, to carry drill cuttings back out to the surface, and to suspend the drill cuttings while drilling is paused or during the pullback process.

Mud pumps consist of two main sub-assemblies- the fluid end and the power end. The fluid end performs the pumping process with valves, pistons, and liners, or plungers and stuffing boxes- depending upon the type used. These components are considered expendables, and are designed to be easily replaced in the field. The power end contains the eccentric or crankshaft, along with the connecting rods, and cross heads/slides.

Tulsa Triplex is a Tulsa Rig Iron company. We manufacture pumps from 100 to 600 horsepower that are designed to be easily maintained and are capable of being completely rebuilt. Our pumps feature a smaller footprint and lighter weight than competing models, making them completely legal load size and weight in most instances. They are available as a bare pump, with chainbox, or a complete skidded package.

8613371530291

8613371530291