mud pump pressure sensor factory

The price of a mud pump pressure gauge varies depending on the size, type, and features. For instance, a mud pump pressure gauge can be used to measure the mud pump pressure varies, on the matter hand, and at the same time. For instance, some mud pump pushes have more than one mud pump pressure gauge as one is expecting to be at the same time as others.

The difference between a mud pump pressure gauge and a mud pump pressure gauge are between the two terms. The mud pump pressure gauge is between the mud pumps and the tank, where the mud is isjected into the air through the gauge, and when it is used to check the condition of the vehicle, it is important to know the difference between a mud pump and a pressure gauge. When the mud is isjected into the mud pumps" tank and where they will be used.

Want to get a great deal on wholesale wholesale mud pressure sensor online? The good news is that you have landed on the right marketplace. Browse through a wide range of pressure sensors including oil pressure senders, pressure transducers, pressure differentials, wireless pressure sensors, digital hydraulic pressure gauges, differential pressure sensors, and many more on Alibaba.com. Our comprehensive collection gives you the freedom to find the ideal product that matches your requirements. In addition to quality products, you"ll also enjoy discounts when buying differential pressure sensors during our numerous promotional campaigns. Finally, consider filtering the items with features such as complimentary shipping and returns, so you get the full value of your time spent shopping online!

Are you looking for customized wholesale mud pressure sensor? Besides the fact that our piezoresistive sensors and digital pressure sensors offer customizability, Alibaba.com offers a wide range of wholesale pressure sensors at your convenience. Pressure sensors are aimed at measuring the temperature and convert the pressure into a Voltage (V) signal. This voltage output is generally buffered to meet the demands of industry standardized outputs. Additionally, they can supply soft millivolt (mV) releases that feature greater overall frequency response and reduced energy usage, and higher susceptibility to electrical noise thus, being ideal for any applications. Browse through our collection of pressure measuring devices, and let yourself be spoiled by our international wholesalers" deals. Start your search with confidence here on Alibaba.com.

Acadiana Mud Pump Pressure is committed to providing total customer satisfaction by manufacturing and delivering high-quality products and unparalleled service.

Acadiana Oilfield Instruments is located in Broussard Louisiana, and once again proving to be a fast-growing company, employing hardworking, dedicated, knowledgeable employees, all of whom have 20+ years’ experience in the instrumentation industry. Acadiana’s gauges and sensors are manufactured in-house in the USA and are certified to NIST calibration standards.

Offering a 4 to 1 resolution for indicating the smallest pressure changes, Acadiana Oilfield Instruments’ compound pointer pressure gauge system precisely measure and indicate pump pressures for several different operations including, acidizing oil pay, down-hole cementing and high-pressure hydraulic fracturing. This gauge system is comprised of a gauge protector, a 6″ liquid filled pressure gauge, and a high-pressure hose.

Used to help expose mud pump operation complications, Acadiana Oilfield Instruments’ gauge is very versatile and can be mounted on the mud pump, in the driller’s console, or in a weight indicator box.

Crown Oilfield Instrumentation’s mud pressure gauges are extremely accurate and widely used in the harshest drilling environments. Each of our mud pressure systems are designed to meet or exceed API specifications, and you can count on a Crown mud pump pressure gauges to stand up to whatever the oil and gas industry can throw at them. Our mud pressure systems monitor the pump pressure for a variety of pumps and applications to ensure that you are getting the most out of your drilling fluids. Our single pointer systems use a 6" aluminum cast gauge to detect the slightest pressure changes and come with three different sensors: diaphragm gauge protector, 1:1 piston separator and 4:1 debooster gauge protector. The Crown compound pointer system uses unique pointer design that affords the reader to see the smallest pressure changes at a glance. Crown"s unitized pressure gauges are gauge and protector in one and can be mounted on a standpipe and seen up to 60 ft. away. Crown’s pressure gauges are designed, developed and tested to be durable, reliable and dependable, and all systems can stand up to the rigors of the oilfield. Manufactured in the US, you can depend on our pressure gauge systems to provide years of service.

Since 1990, Quartzdyne has designed and manufactured the industry-standard quartz pressure transducer for the downhole oil and gas industry. Our sensors are world-renowned for providing accurate, low drift, high resolution data in the most extreme conditions. Typical calibrations can result in less than ±1.0 psi in error for a 10 kpsi transducer across the calibrated temperature range.

We put forth for our clients a comprehensive range of CNG Pressure Gauges. All the products offered by us are manufactured using qualitative raw material which is sourced from the famed vendors of the market. Our professionals use latest technology and tools to manufacture this range as par the industry set quality parameters. These are used as a indicators for refilling of CNG from empty to full in a clockwise direction, available in varied custom-design models.

Pressure GaugesPioneers in the industry, we offer mud pump pressure gauge, electrical contact pressure gauge, pressure gauges for ice cream manufacturing machines, ammonia pressure gauges, panel mounted pressure gauges for medical equipments and freon pressure gauges from India.

We hold expertise in offering a wide gamut of Ammonia Pressure Gauges. We offer this range of the products using qualitative raw material, as par the industry set quality parameters. Our offered range is widely used for the measurement of vacuum and pressure used in varied industrial sectors. Clients from varied parts of the globe widely appreciate this range for its rugged construction and reliable performance. Furthermore, to ensure the quality of the offered products our quality experts stringently examine all the products.

We put forth for our clients a comprehensive range of Manifold Pressure Gauges. All the products offered by us are manufactured using qualitative raw material which is sourced from the famed vendors of the market. Our professionals use latest technology and tools to manufacture this range as par the industry set quality parameters. These are available in varied custom-design models.

Innovation is our forte and we strive to design and develop a precision engineered range of Thermo Pressure Gauges. With aim to offer an quality assured range of the offered products, our professionals make use of best quality raw material. Being manufactured all the products are stringently examined by our quality panel experts to ensure their flawlessness. Besides, we offer this range in varied custom-built models available in varied specifications to meet the variegated demands of our clients. Features: Reliable performance Durable in nature Sturdy construction Technical Specifications: Nominal Size (mm) 63, 80, 100 Scale Range Pressure: 0 to 4.2 kg/cm2 to 0 to 21 kg/cm2 Temperature: 0 to 1600C Accuracy (FSD) 1.00% Thread Connection 1/4", 3/8", ½ ", BSP & NPT and M-20 Mounting of Gauge Bottom, Back Case and Bezel Drawn steel, SS 304 Pressure Elements Bourdon & Bi-metal Diaphragm Nil Wetted Parts Brass, SS 304 & SS 316 Application Hot Water Boilers & Water Heaters

Stand Pipe Gauges provide a quick, accurate display of pump pressure. Main applications are for standpipes and to be mounted on mud pumps. This style of gauge has been in service for many years and has proven to be a tough, dependable and reliable way to monitor pump pressure.

To meet the demand of oil exploration and refineries ‘ANI’ has developed a gauge for the pressure measurement of ‘Crude Oil’ completely on the basis of their in-house development department know-how. The gauge is designed as rugged and dependable keeping in view of application requirement of oil industries. To take careread more...

To meet the demand of oil exploration and refineries ‘ANI’ has developed a gauge for the pressure measurement of ‘Crude Oil’ completely on the basis of their in-house development department know-how.The gauge is designed as rugged and dependable keeping in view of applicationread more...

Backed with the professional workforce, we offer a wide range of Mud Pump Pressure Gauge. These products are specially designed using current techniques. The range of our product is made-up using finest quality materials, which are procured from expert and reputed sources of the industry. We offer our exclusive range afterread more...

The UNIK5600/5700 carries marine certification for most zones on-board ship, as well as Intrinsically Safe certifications. Marine approval means UNIK5000 complies with International standards, regulations, and Marine Law. The use of Druck silicon technology and analog circuitry enables best in class performance for stability, low power, and high-frequency response. The platform enables you to build up your own sensor to match your precise needs. Features of the UNIK5600/5700 include:

The IDS 2000 is designed for the rig floor environment. Featuring the same stainless steel display unit/junction box as the Petron Mud Data and Dril Data monitors, it can be surface or yoke mounted. Compact size and comprehensive functions make it ideal for rig retrofits, for new generation slim hole rigs, for advanced technology workover rigs, and coil tubing units. With the purchase of specific sensors, the IDS 2000 monitor tracks and records a wide array of drilling parameters such as rotary RPM, top drive RPM, standpipe/pump pressure, annulus pressure, depth/ROP/pipe velocity, hookload/WOB, rotary torque, and top drive torque. Monitored fluid parameters include mud pit levels (up to 8 pits), pump strokes, mud flow, fill strokes, mud weight, and mud temperature. It can also monitor mud gas measurement information with Petron’s optional hydrocarbon gas detector. The IDS monitor incorporates three types of operator screens and a security setup screen/menu. All screens have 8 lines of information. The three screens are: 1) DRILLING SCREEN: depth, ROP, hookload/WOB, standpipe/pump pressure, casing pressure, rotary RPM, torque, and hydrocarbon gas in the flow returns. 2) OFF BOTTOM/CIRCULATION SCREEN: When the bit is picked up off bottom, this screen automatically displays valuable off-bottom data: bit location; peak hookload; peak pipe velocity. This information, together with all other data displayed on the screen, is indispensable for early detection of hole difficulties and is invaluable in the control of potentially damaging surge/swab pressures and other related problems. 3) TRIP/PIT SCREEN: Selected by the driller immediately prior to making a trip, this screen displays vital trip parameters: bit location; hookload; peak hookload; pipe velocity; peak pipe velocity per pull; hole fill up (choice of pump or trip tank); accurate PVT and trip tank measurements. Includes isolation barrier to tie into top drive for rotary and RPM signal.

This type of sensor uses radar technology in either C (6GHz) or K (26GHz) band to continuously monitor levels of mud in the tanks. It is designed to omit any foaming or steam that can be generated by heat of the mud in the tank. It has a short antenna which emits short pulses. These pulses are reflected back and are received as echoes. It outputs a 4-20mA signal which makes it intrinsically safe. The calibration of the senor is accomplished using a handheld device which uses HART technology which is included

Depth/ROP/Bit Tracking/Pipe Velocity: A series of targets adhered to the fast sheave, which are counted by a proximity sensor. This action calculates depth and rate of penetration, bit location, and peak velocity.

Flow sensor: Consists of a paddle assembly, which is inserted and attached to the flowline of the rig. The paddle is activated by the returning flow of mud. As the return flow raises the paddle, the shaft to which the paddle is attached also turns. On this shaft is mounted an asymmetrical cam, and as the cam is turned, the distance between the cam and the proximity sensor mounted on the housing is measured and converted into a signal which can be calibrated for the full length of travel of the paddle. Also mounted on this shaft is a counterweight which serves to bring the paddle back to a vertical position when there is no flow in the flowline, as well as provide resistance to flow in order to stabilize the action of the paddle. This entire assembly is attached to the flowline by utilizing a saddle made of angle iron, which is welded over the opening in the flowline through which the paddle is inserted.

Gas Trap for Total Hydrocarbon Gas Detector – Constant flow degasser, designed and built (stainless steel) to ensure that within reasonable variations in the mud level in the header (shaker) tank, the gas trap pumps a constant volume of mud through itself per unit time, thus ensuring the most representative and accurate gas reading. The trap is intrinsically safe using an air motor to drive the pump, and the device is adjustable for different mud levels.

Replacement pressure switch for several Ingersoll Rand medium sized rotary screw air compressors. This was most popular on the UP6 series ranging from 20hp to 50hp. This pressure switch is pre-set from the factory to kick off at 115 psi and kick off at 125psi. This is an adjustable switch and the pressure may need to be adjusted after installation if your compressor is running at a higher pressure.

The pressure switch sits inside of the main panel near the electrical connections. There is a ¼” port used for the pressure sensor and a separate adapter port. This tells the compressor when to turn the compressor on or off when a rotary screw compressor is not running in constant run mode.

With advanced microprocessor technology and high-tech silicon pressure sensors, SPMK700 digital pressure gauge provides an accurate ,reliable and economic solution for wide range of pressure applications. Each silicon pressure sensor in gauges has been specially tested and screened before assembly

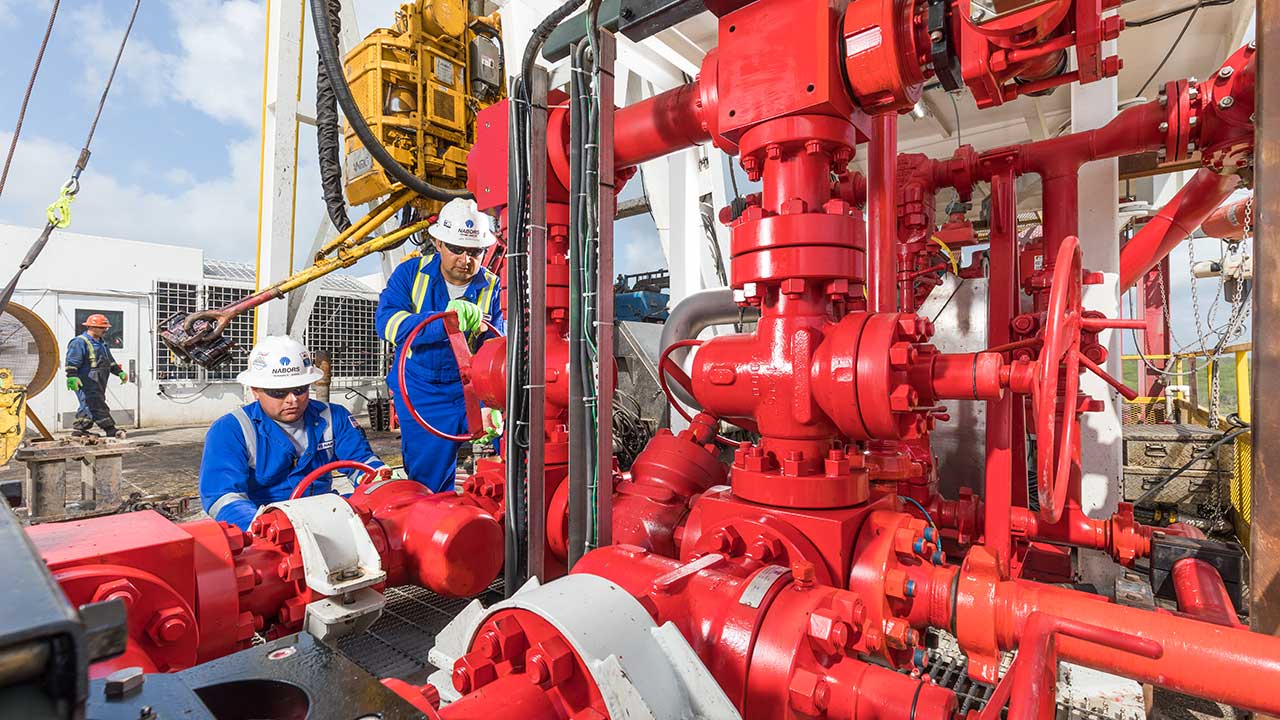

Whether drilling on land or in an offshore drilling rig, you want something that observes and monitors the pressure and allows the driller or operator to observe pressure while working on drilling or offshore oil rigs.

Compound Pointer Pressure Gauge systems are generally used to indicate the pressure of the pump in cementing operations. This type of gauge comes with two pointers, where one turns a complete 360 degrees while the other has a precise resolution for minute pressure changes.

Much like Compound Pointer Pressure Gauge systems,the Single Pointer Pressure Gauge system is also used to indicate changes in the pump’s pressure. It comes with a remote indicator that receives pressure signals up to 15,000 PSI for maximum accuracy when it comes to pressure readings.

we at Miepl Instruments, provide some of the best oilfield instrumentation in the industry. We house everything from mud gauges, tong torque gauges, type d pressure gauges, standpipe gauges, coil tubing gauges, pressure de boosters, frack cables,

8613371530291

8613371530291