mud pump pulsation dampener explosion factory

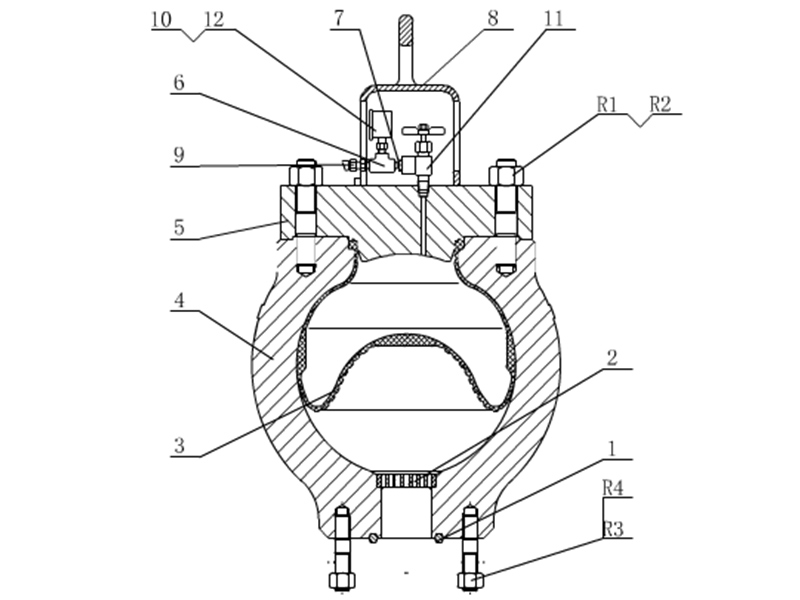

Mud Pump Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump.

Mud Pump Pulsation Dampener is a pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

Pulsation dampeners are made of forged steel rather than cast steel, improving reliability. All high pressure parts are hydrostatically tested. Internal components are changeable with off the shelf consumables.

The dampeners are available in explosion proof – ATEXmarked – execution. They are supplied with earth connection and conductive materials: conductive body, diaphragm in PTFE (conductive backing) or EPDM(conductive).

The dampeners are available in explosion proof – ATEXmarked – execution. They are supplied with earth connection and conductive materials: conductive body, diaphragm in PTFE (conductive backing) or EPDM(conductive).

The Tapflo pulsation dampener works actively with compressed air and a diaphragm, automatically setting the correct pressure to minimize the pulsations.

The aluminium dampeners are perfect to use for pH-neutral fluids. They have great resistance to corrosion and deterioration. They can be found in many applications from workshop, through paint industry to chemistry.

The sanitary series of Tapflo dampeners has been designed in particular for food, beverage, pharmaceutical and cosmetic industries where cleanliness and sterile environment is necessary.

Pulsation dampeners (also called pulsation dampers) are used for stabilizing the flow and the pressure in circuits with volumetric or dosing pumps. They are used in a wide range of applications.

In every pulsation dampener there is a separator element between the gas it is charged with and the liquid of the circuit; its basic function being to avoid the leaking of the gas into the circuit. This separator element is basically made of two kinds of materials: Rubber (NBR, EPDM, FPM, butyl, silicone, etc…) or a thermoplastic material (normally PTFE); although it can also be made in stainless steel.

When a rubber separator element is used, the dampener is called bladder type. If the material is PTFE, we refer to membrane type and bellows type dampeners, depending on the shape of the separator element.

Choosing between different types of dampener depends on characteristics of the circuit like working pressure, temperature and chemical compatibility between the liquid and the material of the separator.

All our pulsation dampenersare made according to the European PED97/23/CE pressure vessels regulations, and their design meets the AD-2000 and ASME VIII Div.1 & 8 codes requirements (“U” stamp pending).

We can supply all of our dampeners with different circuit connection gauges as well as fitted with whatever flange, either screwed on, welded or integrated, to suit the customer’s needs.

Closed loop pressurized freshwater liner wash system, complete with integral water cooling tank equipped with centrifugal pump and driven by explosion proof electric motor

Belt drive transmission: two each motor sheaves and QD mounted pump sheaves; banded Kevlar Vbelts; belt guards; for use with AC drive motors c/w 20HP blower assemblies

Pulsation dampeners are designed to absorb the excess pressure by up to 80% to prevent and limit these undesired outcomes acting similar to a car"s suspension. They are designed to either be pressurized by a compressed airline or via the same air connection to an Air Operated Diaphragm Pump to use pressure to counteract and limit the effect of overpressure. Pulsation dampeners require little maintenance and are often fit and forget. They should be fitted as close to the outlet of the pump as possible.

If you are experiencing issues with product foaming, inconsistent flow, water hammer, pipework vibrations and irregular readings from flowmeters discuss with us today to understand if a pulsation dampener will solve these issues.

8613371530291

8613371530291