mud pump pulsation dampener function pricelist

At Sigma Drilling Technologies, we utilize out-of-the-box thinking and cutting edge innovation. From our revolutionary pulsation control systems, to our one of a kind performance boosting solutions, Sigma delivers unsurpassed technology. Helping businesses succeed by getting the most out their equipment investment is our goal. Let us partner with your team to help maximize your production output, enhance equipment investment, and place you at the forefront of industry advancements.

The Charge Free Dampening System™ is the first and only complete dampening system designed for maximum performance and cost savings. With the highest pressure rating at 10,000 psi, the CFD System far surpasses any pulsation control equipment in the drilling market today. Sigma’s system utilizes both appendage and flow-through technologies and yet still maintains the most compact design.

This multistage system utilizes several of Sigma’s advanced products that are proven to maximize efficiencies and upgrade operations of any reciprocating pumping system by themselves.

By protectively coating both inside and outside the system’s Charge Free Stabilizer™ and the Charge Free Dampener™, the system is entirely corrosion-resistant. The Charge Free Dampening System™ is easily the most protected pulsation equipment available.

The Charge Free Dampening System™ is categorically the most sophisticated pulsation control available for your rigs’ pumping operations. With the introduction of the CFD System, Sigma Drilling Technologies proves to be the authority on state-of-the-art advancements in pulsation control technologies.

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/User%20Manuals/MECLINE/MEC%20ACCUMULATOR%20USER%20MANUAL.pdfPDF1NAME : Accumulator User ManualProduct Page Product Code : 603-2100-30Brand : MeclineProduct Code : 603-2100-30Weight : 1kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7Brand : Interpump GroupProduct Code : A7Weight : 2.055kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A4X%20TECH%20DATA.pdfPDF1NAME : A4X Technical InformationProduct Page Product Code : A4XBrand : Interpump GroupProduct Code : A4XWeight : 2.89kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7/30Brand : Interpump GroupProduct Code : A7/30Weight : 2.055kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7/45Brand : Interpump GroupProduct Code : A7/45Weight : 2.055kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7/50Brand : Interpump GroupProduct Code : A7/50Weight : 2.055kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7/60Brand : Interpump GroupProduct Code : A7/60Weight : 3kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7/90Brand : Interpump GroupProduct Code : A7/90Weight : 2.055kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7/120Brand : Interpump GroupProduct Code : A7/120Weight : 1kg

PDF1 : https://www.dualpumps.co.uk/files/pdf/products/Technical%20Data/Pratissoli/PRA%20A7%20TECH%20DATA.pdfPDF1NAME : A7 Technical InformationProduct Page Product Code : A7/130Brand : Interpump GroupProduct Code : A7/130Weight : 1kg

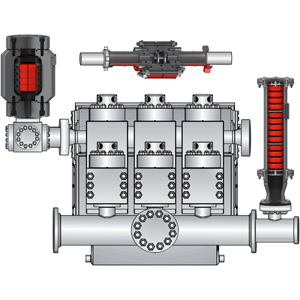

A quintuplex pump has a crankshaft supported in the pump by external main bearings. The crankshaft has five eccentric sheaves, two internal main bearing sheaves, and two bull gears.

A quintuplex pump is central to oil drilling and exploration due to the nature of operations. This pump circulates the mud to and from the surface, supporting the process for oil well operations.

The quintuplex pump is designed to circulate mud or drilling fluid under great pressure down the drill hole and back up. The pump is a reciprocating model that features five pistons, hence the name quintuplex mud pump. The right degree of pressure and precision is crucial for efficient well operations.

Despite the fact that all mud pumps have pulsation dampeners, noise levels are likely to be high and require modifications to keep noise pollution levels low. This is important, considering the long-running hours of equipment and the need to protect personnel from constant and high noise levels. With a quintuplex mud pump, the pulsation noise and the mud telemetry noise come down by as much as half, making operations less noisy.

Quintuplex pumps can be used in various applications including salt water disposal, descaling, high pressure pumping, Frac pumping, pipeline transfers in the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors.

Mud pumps comes in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pumps are the pump of choice. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers.

Duplex, triplex and quintuplex pumps all have an enviable history of sound engineering, designed to exceed the rigorous requirements of API 674 and customer satisfaction.

It is very natural for diaphragm pumps to have some pulsation. The pulsation generated is caused by sudden changes in piston direction. Pulsation Dampeners serve one function in the pumping system, which is to reduce pulsation by providing a cushion of air to bump against. These Udor Pulsation Dampeners use a rubber bladder that separates the air cushion from the solution being pumped.

Pulsation dampeners are used to improve pump system efficiency by removing pulsating flows from positive displacement pumps, insuring a smooth and continuous fluid flow and meter accuracy, eliminating pipe vibrations and protecting gaskets and seals. The result is a longer lasting and safer system. Pulsation dampeners are installed on the discharge side of positive displacement pumps to remove the pulsating flow caused by the start and stop action of the pump. Dampeners ensure a smooth and continuous flow, eliminate pipe vibration and protect in-line instrumentation.

When the drill tool is lifted out of the hole, a blowout could happen due to suction. In event of a blowout, the open position of the IBOP valve allows backflow, easing the installation process. Upon successful installation, the valve can be promptly closed with a relief rod to prevent further backflow. Fluid can then be pumped in from the surface to discharge the IBOP and drill string. The purpose of blowout prevention can be achieved by the following generic steps: discharging the relief sub; regulation of fluid; commence pump circulation.

Pulsation dampeners (also called pulsation dampers) are used for stabilizing the flow and the pressure in circuits with volumetric or dosing pumps. They are used in a wide range of applications.

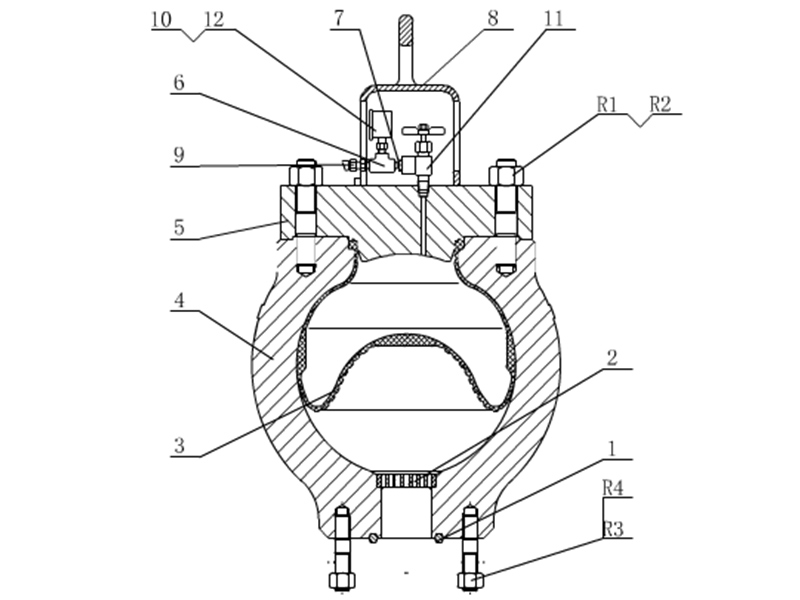

In every pulsation dampener there is a separator element between the gas it is charged with and the liquid of the circuit; its basic function being to avoid the leaking of the gas into the circuit. This separator element is basically made of two kinds of materials: Rubber (NBR, EPDM, FPM, butyl, silicone, etc…) or a thermoplastic material (normally PTFE); although it can also be made in stainless steel.

When a rubber separator element is used, the dampener is called bladder type. If the material is PTFE, we refer to membrane type and bellows type dampeners, depending on the shape of the separator element.

Choosing between different types of dampener depends on characteristics of the circuit like working pressure, temperature and chemical compatibility between the liquid and the material of the separator.

All our pulsation dampenersare made according to the European PED97/23/CE pressure vessels regulations, and their design meets the AD-2000 and ASME VIII Div.1 & 8 codes requirements (“U” stamp pending).

We can supply all of our dampeners with different circuit connection gauges as well as fitted with whatever flange, either screwed on, welded or integrated, to suit the customer’s needs.

8613371530291

8613371530291