mud pump replacement motors repair pricelist

As part of Experience 360, our Parts on Demand program lets you manage your replacement parts inventory at your regional location, pump site, or even via GD Energy Products Parts on Demand mobile trailers.

These Frac and Mud Pump Consumables are OEM-certified parts, designed, manufactured and tested by our Pump experts, and proven to maximize the performance on your operation. Our parts are always available, ensuring you have what you need, whenever and wherever you need it.

TR provides high quality Mud Pump replacement parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve & Seat etc. We are dedicated to assisting worldwide clients with most cost-effective and quality guaranteed mud pump liners, pistons and other mud pump replacement parts. Reducing the mud pump production cost is our priority so that significant saving can be achieved for our valuable clients and end users.

TR liners offer both ceramic mud pump liners and high-chrome mud pump liners (bimetal liner) with excellent resistance to abrasion, erosion and corrosion for most mud pumps in worldwide. Advanced anti-wear measures are adopted and highest-grade materials are selected in our mud pump liners production to increase their service life, which can reduce our clients’ investment cost of the project, and improve their production efficiency.Replacement Mud Pump Liners for Gardner Denver PZ 6/7/8/9/10/11

TR provides a wide series mud pump liners for all major brand mud pumps. We also offer custom design-built service per our clients’ drawings and specifications

TR also offers high quality replacement parts for all major brand mud pumps including valve module, piston/extension rods, pistons, valves and seats etc.

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

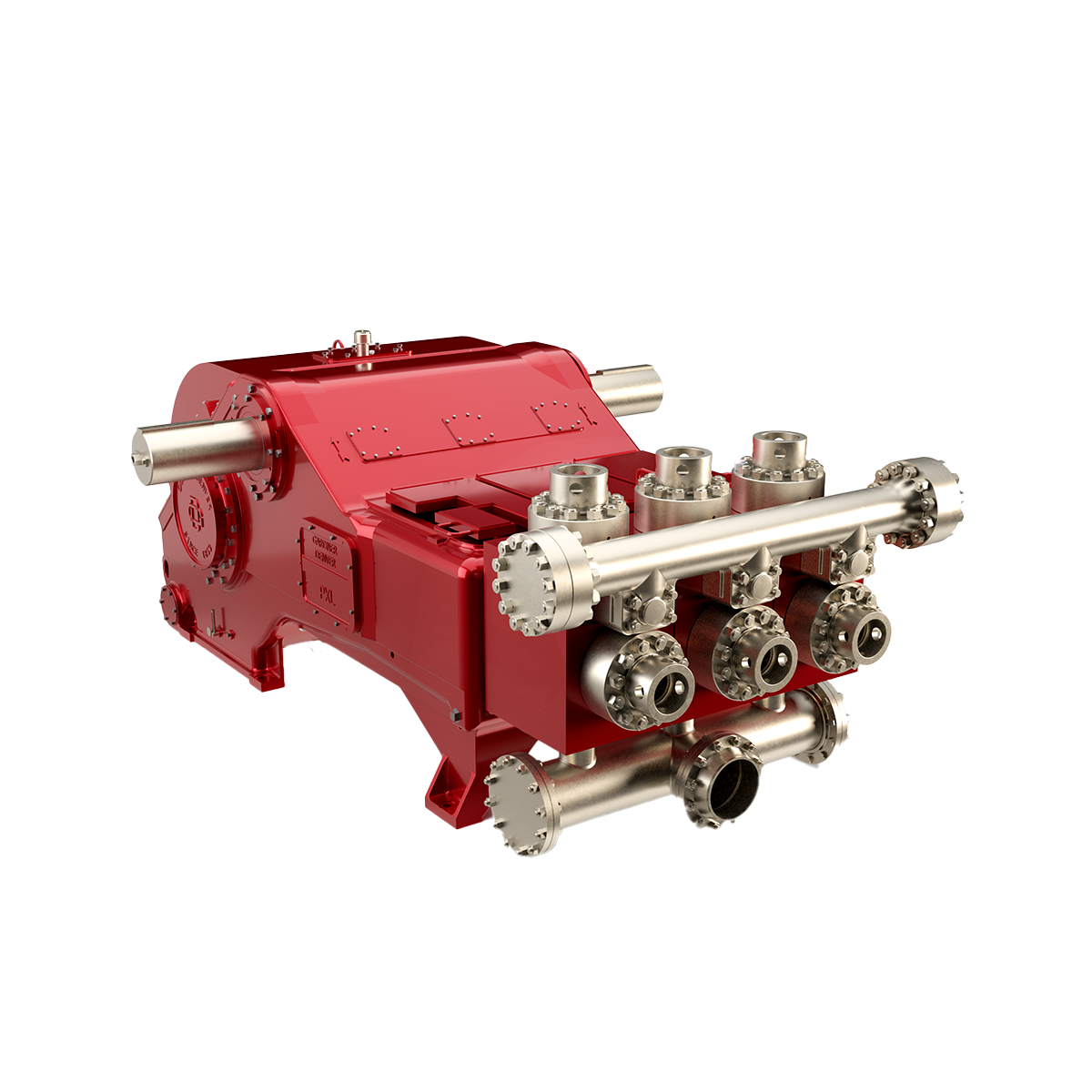

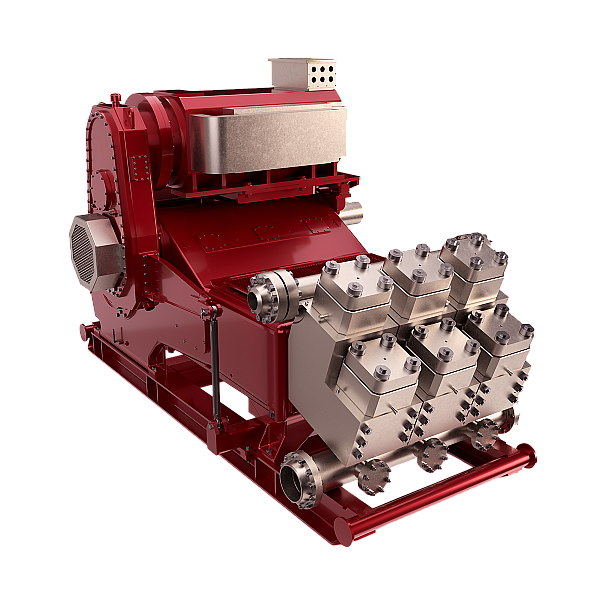

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Sump pump repair costs $200 to $870 on average, depending on the type. Emergency sump pump repairs cost $50 to $150 more after-hours. A sump pump maintenance plan costs $100 to $250 per year. Plumbers charge $45 to $150 per hour plus parts for sump pump service.

Submersible or sub-pump repair costs $200 to $1,000. Submersible pumps sit entirely underwater in the sump basin and are more difficult and expensive to repair.

Pump material – Plastic pumps are cheaper and lighter but not designed for high pressure. Metal pumps are stronger and last longer but cost twice as much as plastic.

Sump pump maintenance costs $100 to $250 per year for cleaning, testing, and weatherizing. Purchasing a multi-year service plan may reduce the annual cost. Routine maintenance extends the pump"s lifespan and improves its dependability.

Clearing – Annual maintenance should include clearing the check valve and float trigger. This check valve prevents water in the discharge pipe from emptying back into the sump pit. A float trigger turns the pump on or off, depending on the water level.

Filters – Sediment filters cost $10 to $30 and prevent clogs and debris from damaging the sump pump. Filters must be cleaned or replaced every six months to one year.

Reserve pumps – In flood-prone homes, a second reserve pump costs $1,000 to $4,500 and assists the main pump during heavy rainfall. Back-up pumps come in water-powered, battery-powered, and Wi-Fi-enabled models that alert the homeowner if the system stops working.

Sump pump replacement costs $500 to $1,200, depending on the location and pump type. Submersible sump pumps replacement costs $500 to $1,200 on average, while pedestal sump pump replacement costs $500 to $600.

Motor – The most common sump pump problem is typically a worn-out motor. A pump motor that constantly sucks up sediment may also get stuck. A filter helps prevent the problem but requires regular cleaning or replacement.

Long-running cycle– A long-running time indicates the pump has insufficient horsepower for the amount of water it must extract or the distance it must pump it.

Unfamiliar noises – Excessive pump motor noise may indicate a failed bearing. Rattling or grinding noises may mean the impeller fan is damaged or jammed.

Excessive vibration – A damaged or bent impeller causes the pump to wobble and vibrate. Fixing a bent impeller is complex, and a sump pump replacement is recommended instead.

Test the check valve – Pour water into the sump pit and confirm the pump removes the water from the pit. If the water returns to the pit, replace the check valve.

Clean the impeller – Unplug the sump pump and remove the screen from the bottom of the unit. Remove any debris that could block the impeller rotation.

Plumbers fix sump pumps, but repairs are not always cost-effective. Plumbers often recommend replacing a failed sump pump instead due to the comparable repair and replacement costs.

A sump pump needs annual servicing to avoid flooding and water damage. Homeowners can perform routine maintenance quarterly, like cleaning the filters and testing to ensure the pump functions properly.

Some basements stay dry without using a sump pump. However, homes in areas with excessive snow, rainfall, or high groundwater levels often need a sump pump or drainage system to prevent flooding or moisture damage.

Sump pumps last 7 to 10 years on average if properly maintained. A sump pump that runs frequently or must displace a large volume of water may only last five years.

Homeowners" insurance typically does not cover sump pump failure or water damage. Homeowners must purchase separate coverage for water backup and sump pump overflow.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

Is it time to replace the fuel pump? The fuel pump is responsible for transferring fuel from the gas tank to the vehicle’s engine. With a malfunctioning fuel pump, the engine won’t have fuel to keep the vehicle running. If this necessary component is failing, it can cause severe drivability and performance issues and has to be dealt with if you want a reliable, driveable vehicle. So how much will it cost to fix the fuel pump? As per yourmechanic.com, a completefuel pump replacement cost at a mechanic shop can land anywhere between $532.97 and $1,187.35 depending on factors such as the vehicle’s make and model and where the vehicle is fixed.

We will explain the types of fuel pumps, the signs of a bad fuel pump, and how a good mechanic will replace the fuel pump. We will also go through fuel pump repair cost breakdown.

As per repairpal.com data – “The average fuel pump replacement cost is between $834 and $874 with about 80% of the cost being the cost of the parts“.You may be able to find fuel pump parts for $50. Good quality fuel pump sets can cost between $200 to $1000. Labor costs are $150-$350. More expensive vehicles with complex designs can cost $2,500 to have a fuel pump replaced.

Here is a chart from YourMechanic.com that shows the average cost of fuel pump replacement for different vehicles. Cars Parts Cost Labor Cost Average Dealer Price

Automotive fuel pumps are either mechanically or electronically operated. Modern-day vehicles that require more pressurized fuel supply than mechanical fuel pumps can deliver will have an electronically operated fuel pump or fuel module that is mounted on or in the gas tank.

Fuel pumps have various components that work together to send fuel from the gas tank, through the fuel filter, to the fuel rail, distributed into the injectors, and sprayed into each engine cylinder combustion chamber. The pump must produce a certain pressure specified by the manufacturer.

Older vehicles that have a carburetor will have a mechanical fuel pump with either a diaphragm or plunger-type pump. Automobiles with engines rated under 450hp work well with them. Mechanical fuel pumps may be the more convenient and less costly of the pumps to choose from. They can be easier to access and would, in turn, have a lowered labor cost.

Mechanical fuel pumps use a pulling force to get the gasoline through the different components. They are normally mounted on the engine block with the engine’s camshaft operating the pump. The fuel is regulated with an inlet valve closing when fuel in the float bowl of the carburetor is filled and opening when more fuel is needed.

Common issues of mechanical fuel pumps includefuel leakage from the diaphragm into the crankcase, vapor lock in the pump, faulty diaphragm spring, and too low fuel pressure.

Modern vehicles with a fuel injection system have electric fuel pumps. These pumps do not have diaphragms or plungers that pull the gasoline but instead pushes gasoline through the different components with an electric motor.

Electrical fuel pumps can be mounted inside the fuel tank on a bracket that can be accessed from an access port on top of the tank. These pumps are designed to be submerged in gasoline. External electric fuel pumps sit outside the fuel tank.

Electric fuel pumps are powered and receive instructions from the Powertrain Control Module (PCM) and Engine Control Unit (ECU). It regulates fuel with pressure regulators.

Here are warning signs that can signify your vehicle needs a fuel pump repair and other culprits that cause the same symptoms. Rule out these other causes before paying for a fuel pump replacement that you may not need.

Sputtering– While trying to accelerate, the engine starts sputtering. Engine sputtering sounds like humming or purring from under the hood. This happens when there is not enough fuel pressure or inconsistent amount of fuel reaching the combustion chamber. Slow acceleration may be felt, too. This is a sincere sign there is something wrong with the fuel system. The fuel system includes the pump, fuel filter and injectors.

Low Gas Mileage – Less miles for your gas. If the relief valve in the fuel pump is not opening at the right time, your engine will be getting excess fuel and thus you will have lower fuel efficiency.

Driving regularly on a low tank of gas – While driving on an empty gas tank, the fuel pump can overheat and cause it to run dry. This stresses out the fuel pump and can cause it to malfunction.

Age– Time does not help rejuvenate anything, even fuel pumps. Over time there will be an accumulation of contamination and wear and tear. Fuel pumps can start hiccuping around 7 or 8 years old or after 100,000 miles.

Check the fuel pressure. Look up the figures for the year and model of the vehicle and connect the pressure gauge to the fuel system. First, measure the pressure with the vehicle turned on but the engine off. Then get a second pressure reading with the engine idling. For a healthy fuel pump, you should get a reading near specifications and then see a drop of 4 to 6 psi when you start the engine.

A good mechanic will go through a few extra procedures apart from just replacing the fuel pump. With other replacement parts, these extra charges are necessary for the new fuel pump to run efficiently. The mechanic will first ensure the fuel pump is actually malfunctioning.

Keep your gas tank at least a quarter full. This will cause less stress on the fuel pump. Ensure your gasoline has no impurities. Avoid getting dirt and debris in or around the gas tank opening. Less contamination equals less fuel filter blockage.

Pump Solutions #1 Corporation sells and services pumps, motors and replacement parts from top manufacturers. Buy centrifugal pumps, industrial water pumps, submersible pumps and pumping equipment online with low prices or contact us for expert service.

Pump Solutions #1 Corporation is a Scot Pump master distributor for the Midwest including Wisconsin, Illinois, Indiana, North Dakota and South Dakota.

Whether you need a price quote, help locating the right pump or part, or assistance with a new Scot Pump application, Pump Solutions #1 Corporation is your best resource for Scot Pump products and services.

We also provide pump repair, application assistance and pump system inspection. From our Racine headquarters we serve busineses & industries throughout the greater Milwaukee area including Kenosha, Pleasant Prairie, Oak Creek, Cudahy, Waukesha, West Allis and the surrounding areas.

We carry a wide selection of American-Marsh Pumps for use in fire protection, petro-chemical industries, power generation and many more commercial and industrial applications.

Shop our selection of American-Marsh Pumps products for details on the 480 series vertical turbine pump, pump manuals, bulletins & brochures including performance curves, specifications and replacement parts information.

Pump Solutions #1 Corporation has Wisconsin"s best prices and service for American-Marsh Pumps. Call or contact us online with questions or product requests.

WEGis the largest industrial electric motor manufacturer in North America, producing over 21 million high-quality, dependable electric motors annually.

WEG electric motors are specifically developed for a wide range of industrial and commercial pumping applications. Find the exact WEG pump motor you need by searching with required horsepower, phase, RPM, frame or enclosure type.

All-Flo air-operated diaphragm pumps deliver the performance and durability of larger pumps in a small, lightweight package. All-Flo’s non-stalling, rugged pumps ensure dependable continuous operation.

A new All-Flo pump or replacement part from Pump Solutions #1 Corporation will ensure your fluid handling system will exceed your expectations and provide the highest performance during operation.Pump Solutions #1 Corporation will help you find the perfect All-Flo pump or replacement part.

Baldor electric motors are built with Baldor’s commitment to quality and the safety of their customers. Baldor designs and manufactures industrial electric motors such as AC Motors, DC Motors, Servo Motors, and Gearmotors.

Baldor motors provide solutions for many important industries including mining, water & wastewater, paper & forest, air handling, aggregate & cement, chemical, oil & gas, and more.

AMT designs and eningeers electric water pumps and pump components in Royersford, PA. View product information and a brochure for their gasoline & diesel-driven solids handling pumps or contact us for replacement parts and service.

We sell self-priming centrifugal pumps from Scot Pump, AMT & Calpeda. Self-priming centrifugal pumps are perfect for clear liquids, dirty water or limited solid handling and can be positioned above the water line. Learn more about our self-priming and standard centrifugal pumps or contact us today for a free quote!

Buy an immersible pump used for coolant, cutting oil or lubrication fluids. Pump Solutions #1 Corporation carries immersion pumps engineered for dry environments and should be installed where a vertical solid shaft motor has been previously used.

Our quality AMT immersible pumps are versatile, cost-effective and low-maintenance. Contact a pump specialist for help choosing the right pump, or get a free quote on an immersible pump today!

Our quality submersible pumps are able to discharge up to 10" and filter up to 2,2000 gallons per minute. Contact us for more information, submersible pump components, repair and pricing.

Pump Solutions #1 Corporation is a distributor for Scot Pump, American Marsh and Calpeda frame-mounted centrifugal pumps. Mounting your centrifugal pump increases durability and performance and is ideal for irrigation, mining and many more applications.

Pump Solutions #1 Corporation is a distributor for multi-stage centrifugal pumps from top manufacturers. Multi-stage centrifugal pumps are ideal for applications requiring high output or high pressure. Contact us to order a pump or get more information!

Close-coupled centrifugal pumps eliminate the separate couplings and frame mounts found in traditional centrifugal pumps. This makes close-mounted centrifugal pumps low-maintenance and fast, perfect for moving precise volumes of liquid.

Pump Solutions #1 Corporation pump repair and system evaluation experts have decades of experience in the field working with many kinds of fluid handling systems. Our team understands prompt service and professional pump solutions make all the difference.

Pump Solutions #1 Corporation provides expert pump repair, system diagnostics, pump motors and replacement parts with the best possible service to customers in many Wisconsin& Illinois locations including Milwaukee, Racine, Kenosha, Waukesha, Muskego, Burlington, Waukeganand the surrounding areas.

Pump Solutions #1 Corporation has a huge selection of high quality pumps and pump components from major manufacturers. We encourage customers to contact us to discuss having your fluid handling system inspected and evaluated by the best pump distributors and repair experts in the business. Call us anytime at 262-835-0774

Sump pumps1 come in two types: submersible and pedestal. The type you have directly impacts the cost of your repairs because each has unique features and characteristics. Different problems can occur with each type, and the costs vary accordingly.

The average cost of pedestal sump pump2 repairs is between $150 and $500. They have the motor at the top, where it stays dry, with the drawtube at the base of the sump pit. These types are less expensive to install and maintain, and there is less risk of motor issues. However, problems can still occur with these pumps, such as impeller faults and valve issues.

Homeowners pay between $175 and $550 for submersible sump pump repairs. They are designed to be submerged in water and sit right at the base of the sump pit. They are more expensive to purchase and repair because these pumps are usually complex and involve extra labor. Common problems include motor issues, float problems, and broken impellers.

Location is another factor impacting the cost of sump pump repairs. Pumps can be placed in various spaces around the home, such as crawl spaces, basements, and outdoor areas. Some areas are easily accessible, while others require more work to get to, leading to higher labor costs.

The average cost of basement sump pump repair is between $150 and $550. The basement is the most common location for nstallation. This is because the basement is the lowest point in the house, ideal for collecting water building in the sump basin and removing it. Repair workers are used to working in basements and should charge standard fees for working with this pump.

To repair a sump pump in a garage, expect to pay between $150 and $550 to have it fixed. Just like the basement, the garage is another common location to install them. The costs are generally identical to basement pump repairs because garages are easy to access and do not pose unique challenges.

If you have a sump pump in the bedroom, repairs range from $175 to $575. The bedroom is not common for installation, but you can have pumps in bedrooms, typically in a closet space. You may want to install one in your bedroom if it is on the ground floor or the basement due to the risk of flooding. Accessing these pumps can be a little harder because they are in the closet, leading to slightly higher repair costs.

Repairs for crawl space sump pumps average $200 to $600. Crawl spaces are common locations for installation, but the costs of repairing these are often higher because access can be restricted. This makes it harder for workers to do the repairs, leading to higher labor costs.

Homeowners pay between $200 and $600 for outdoor sump pump repairs. These pumps require special landscaping and usually must be installed in their own trenches under the surface. This means accessing outdoor units can be difficult. More problems can occur with them because they are exposed to the elements. Issues like freezing and rust are common.

Sump pumps have a range of components, including the motor, impeller, and discharge pipe. Issues can arise with each major component of your unit, and some repairs are much simpler and cheaper to complete than others. The table below shows common repairs and the average prices for each.

Expect to pay between $75 and $125 to fix a sump pump float switch. The float switch is the part that controls the pump’s function. The float rises as the water level rises, and at a certain height, the switch opens a circuit that starts the pump. Switches can fall out of position and may require repositioning.

Homeowners pay between $100 and $225 for sump pump impeller repairs. The impeller pushes the water out of the sump pit. It performs a lot of work and can be exposed to tough conditions, meaning the impeller may break or become stuck or dirty. This component may require cleaning, readjustment, or patching to repair minor damages.

The average cost of sump pump discharge pipe repair is between $125 and $300. The discharge pipe transports water from the sump basin and out of the home. Like other pieces of piping, it can become damaged with cracks or holes. It may also become clogged. Plumbers may need to patch superficial damages or flush the pipe to remove the blockages.

To repair a sump pump motor, expect to pay between $150 and $300. The motor is the workhorse of the unit, providing the power the system needs to drain water via the discharge pipe. Several issues can arise with motors, but some simple readjustments and rewiring can solve minor issues.

In some cases, the parts of your unit may be damaged or broken beyond repair and must be replaced with new components. The price of replacements depends on the parts because some are small and cheap to replace while others are more expensive. The table below shows examples of different replacement parts for sump pumps and the costs of each.

The average cost of sump pump float switch replacements is between $100 and $150. If it is not draining correctly and water is building in the pit, the float switch may be broken and must be replaced. Luckily, this is a simple and affordable job because replacement switches are inexpensive and easy to install.

Sump pump valve replacements range from $125 to $200. The check valve controls the flow of water and prevents the pump from re-pumping water that has already been discharged. Valves can be damaged and may need to be replaced if water flows back into the pit after being discharged.

The cost of sump pump impeller replacements averages $125 to $250. The impeller is a vital part of the system, and if yours is broken, you need to replace it as soon as possible. New impellers are relatively cheap, but it can take time to install them, so most costs are for labor.

The cost of replacing a sump pump discharge pipe is between $175 and $600. The total price of the replacement depends on how much piping must be replaced. Some units have short discharge pipes, but others have longer sections of piping. It mostly depends on the location. Longer pipes cost more and take longer to install.

Homeowners pay between $250 and $500 for sump pump battery replacements. Batteries are not always necessary, but it can be a good idea to have a battery as a backup power source for your pump if a storm knocks out the power. The price depends on the battery size and type, with higher-powered batteries costing more.

To replace a sump pump motor, expect to pay between $250 and $500. The motor is usually the most expensive component, so it can be an expensive part to fix. You may need a new motor if the existing one burns out or is seriously damaged and no longer works.

Many problems can arise with your unit. It might make a strange noise, spring a leak, or emit an unpleasant smell. The cost of repairs varies depending on the problem. The table below shows examples of problems and average repair costs for each.

Homeowners pay between $100 and $175 for sump pumps with the float stuck. If the float is stuck on, there are a few possible issues. The float may have become rusted or damaged or the switch may not be working correctly. There might also be dirt or debris interfering with the system, so it may need cleaning or the float might need replacing.

Fixing a sump pump that is making a loud humming noise averages between $100 and $250. They emit a humming noise naturally as they run, but you may have an issue with the check valve or a clog if the humming is unusually loud. The valve might need to be checked or replaced, the clog may need to be cleared, and the impeller might also need to be cleaned.

If your unit is not pumping, expect to pay between $100 and $250 for repairs. Your pump may not be pumping for a few reasons. It could be caused by a clog or issue with the impeller. The pipe may need flushing, or the impeller might need cleaning, readjusting, or replacing.

Sump pumps that smell of rotten eggs cost from $100 to $250 to repair. It is very unpleasant when a unit starts to smell, and it usually happens because the pit dried up and sulfur smells are rising from the sewer. Usually, the pipes may need cleaning, and water may need to be added to the pit to deal with this issue.

If you have mold in your sump pump pit, expect to pay between $125 and $250 to have it removed. Mold can build up in the sump pit if it is not maintained properly and cleaned regularly. This can be unsightly and unpleasant, and the mold spreads if left untreated, so you need to bring in professionals to remove it.

If your unit is clogged, repair costs range from $150 to $300. Theycan clog in several ways. Clogs can build in the pit, pipes, float switch, or other parts. Certain parts may need repair or replacement, and clogs must be flushed.

The average cost of repairing a rusted unit is between $150 and $450. Since they are constantly exposed to water, rust can occur. If rust is spotted early, it could be scrubbed away. However, the affected parts may need to be replaced if the rust is deeper and more extensive.

Leaking sump pump repairs range from $150 to $500. There are a few possible explanations behind a leak. A clogged or leaky pipe could be causing the issue or caused by cracks or loose parts in the system. Usually, a plumber must inspect the pump, find the leak source, and take action like tightening valves or patching the damaged pipe.

If your unit is constantly running after a period of heavy rain, expect to pay between $150 and $500 for repairs. They normally run during periods of heavy rain, so there might not be anything to worry about or any problem to fix. However, there could be an issue with the check valve or motor if the pump continues running, which might need to be repaired or replaced.

Frozen sump pump repairs average $200 to $400. It is usually only outdoor units that freeze. But this can also happen in those located in basements, and it can be a very serious problem to deal with. The pump must be defrosted as soon as possible, and the lines need to thaw. Debris and blockages must be removed to free the system and get it running again.

You need a plumber or sump pump repair specialist to fix your unit. Labor costs usually run between $50 and $100 per hour. Costs vary based on the location and worker experience. Some plumbers have set fees for certain repairs, while others charge by the hour. You need to pay extra for emergency repairs and travel if you live in a remote location. You may also need to pay a minimum fee or call-out fee of $50 to $75.

If you need your sump pump repaired urgently, you typically pay an extra $100 to $200 on top of the usual repair price. This is because plumbers and repair companies may have to adjust their schedules and delay other appointments to rush to your home and deal with the emergency. Emergency repairs may be needed in serious situations like when the pump is broken and water is collecting in your basement or another part of your home.

Sump pump inspections cost between $50 and $100. During an inspection, a sump pump specialist or plumber inspects your unit for damages, looking for things like cracks and clogs. They also check key components of the pump to ensure everything is working correctly. They provide a full report of their findings and recommendations for repairs or sump pump servicing you may require. It is best to get inspections once a year or after heavy rains and storms.

The average cost of professional sump pump maintenance is between $100 and $300. You can also do maintenance yourself to save money. Professional maintenance fees usually cover cleaning the unit, cleaning loose debris, checking the valve, and removing standing water in the sump pit.

If you prefer to do maintenance yourself, you can do several tasks to keep your pump in good condition. Clean the pit, removing debris and loose items. It is also a good idea to test the check valve by pouring water into the pit and checking that the pump responds. The impeller may need to be cleaned. It is also wise to check the float by pouring water into the pit and seeing if it rises.

In some cases, you may hesitate between having your unit repaired or replaced. Usually, the first thing to think about when making this decision is the cost. It typically costs between $700 and $1,600 to replace a sump pump, including the new pump and labor. This process can take a few hours but is simple. So if the estimated cost of your repairs is higher than the cost of a new pump or you have repeatedly paid for repairs, it may be a good idea to purchase a new one.

Also think about the age. Sump pumps last from 5 to 30 years. Submersible models are less long-lasting, with estimated lifespans of around 5 to 15 years. Pedestal pumps can run for around 15 to 30 years. If your pump is old and approaching the end of its lifespan, it may make sense to purchase a new one to save money and avoid problems.

Sump pump removal should cost around $100 to $200. This fee should cover uninstalling the pump and disposing of it. You may want to have a sump pump removed if you are planning on installing a new one in the same location later or want to install a new unit in a different location.

The cost of professional sump pump cleaning is between $100 and $200. This fee usually includes a range of cleaning processes, including cleaning the valve, getting rid of standing water in the pit, and cleaning loose dirt and debris from around the pump. It is a good idea to professionally clean your pump annually, or you can save money by cleaning it yourself.

The cost of sump pump freeze protection ranges from $125 to $250. It can be important to have freeze protection fitted to sump pumps at risk of freezing in areas like crawl spaces and backyards. Different freeze-protection accessories, such as overflow devices and drains, can fit to the pump to allow water to escape even if ice or snow builds up and blocks the main line. Insulation may also be installed around the line to reduce freezing.

Additional Considerations and CostsInsurance. You can have your unit insured, and some homeowner’s policies include sump pump coverage as standard, but others do not. Read the fine print and be aware of what your policy covers. You could customize your existing policy to add sump pump protection.

Permit. You do not usually need a permit for minor repairs and maintenance like fixing impellers and cleaning the unit. However, for more extensive jobs that involve alterations to the pipes, a permit may be needed. Consult with your local building authority for more information.

High bills. Sudden and unexpected rises in utility costs can often be a sign of problems. If you notice your utility bills are suddenly high, it may be a sign the sump pump has sprung a leak and must be repaired.

Lifespan. The lifespan depends on its type, location, and amount of maintenance. Pumps last from 5 to 30 years, with submersible pumps lasting around 5 to 15 years and pedestal pumps lasting 15 to 30 years.

DIY. You can do minor repairs and maintenance on your unit if you know what you are doing. Big issues like fixing broken motors and replacing components should always be left to the professionals.

Troubleshooting. There is a simple test you can do to troubleshoot your unit . Pour water into the pit and check that the float rises to ensure it is working. You should also check that the pump triggers and starts working to ensure the check valve is functioning.

Several things could cause a unit to stop working. The float switch or impeller might be jammed, the pump may not be getting power, a part might be broken, or dirt and debris could be interfering with the system.Does insurance cover sump pump failure?

It can, but it depends on the details of your specific policy. Some home insurance policies cover sump pump system failure, but others do not.How do you reset a sump pump?

There is usually a reset button on the motor you can press. Otherwise, you must turn the pump off or unplug it, clean and inspect it before plugging it back in, and switching it on.Do sump pumps need maintenance?

Yes, they require some maintenance to remain in good working order. They usually must be cleaned and inspected regularly.Is it normal for a sump pump to run every 15 minutes?

Yes, but it depends on the water level in the area. During rain and storms, sump pumps can run very regularly. They may also run frequently in the spring when the water table is higher from winter run-off.How often should you check your sump pump?

If your swimming pool pump is not functioning properly, the next step is to choose between a pool pump repair or replacement. First, identify the problem. Once you know what’s wrong, you can determine whether the parts should be replaced/repaired, or you need to buy a new pool pump.

We recommend avid do-it-yourselfers stay away from pool pump repairs outside of the most superficial clogs. Pool pumps are very powerful motors that can easily hurt you. The risk of damaging yourself or the pump is quite high, and a problem will only increase your total repair costs.

If your pool pump is not doing its job properly, you need to examine what is happening as soon as possible in order to maintain water circulation. If you can’t figure it out on your own, our experts are happy to provide assistance. Below, you’ll find a list of common problems and how we typically troubleshoot them.

If the pump is not pulling water through the system as it should, it means water will not reach the filter appropriately. This can cause your water to quickly become dirty and murky. A clog in the pipes or other pool systems is the most common cause of this issue. The impeller can also be clogged with debris. Air leakage in the suction line can be another potential cause.

A typical pool pump will produce a little noise. However, loud noises usually mean that something is not right. Common causes are structural vibrations in the pump itself, or inadequate/unstable water supply to the pump. High-pitched noises are usually caused by worn out bearings. The task of replacing bearings is painstakingly technical. The entire system must be shut down and disassembled first, so it’s usually best to call a pro to repair them.

A normal pump should not take in any air at all because even a small amount of air can cause the pump to overheat. Many pump systems may have small air leaks, but they can quickly become a major problem once they grow bigger. The most common causes include damaged thread sealant, a leaking valve stem, and bad plumbing. Give a professional a call to assist you if you suspect air is being sucked into the pump.

Given the many models of pool pumps that come at different prices, it can be difficult to choose the best for your needs. Therefore, here are the key things to consider when choosing a pool pump.

If you have a lot of people using the pool, there will be maintenance implications because you need to clean the water more often. You may want to have a larger residential pump (or even a commercial grade pump) if you have a busy pool in your home.

A dual speed pump can be perfect so you are saving energy during non-peak times. Most people leave the pump on the low-speed setting during normal operation. They typically adjust the power higher while cleaning the pool, or operating the pool heater. Similarly, a variable speed pool pump will provide even more control over water flow if you have large gatherings and need to circulate water quickly during short durations of time.

Most homeowners want to make an educated financial decision when buying a pool pump. They research their options and get a professional opinion, and may find themselves “on the fence” when it comes to choosing between value-priced and higher-priced models. It’s fine to be price-conscious, but we strongly recommend you consider your pool’s needs. Will saving a few hundred dollars today leave you wishing you had a better capacity pump model in the future? The last thing you want is to save a few bucks up front, only to end up with murky/dirty water, and high maintenance/repair costs for years to come.

Put simply, your pool pump’s only job is to circulate water. It draws water from the swimming pool through the main drain and skimmer, moves it through a filter (and chlorine generator, heater, etc. as necessary), and feeds it back to the pool using the main returns.

Above-ground units typically have a big filter basket (used for debris collection), and a high-capacity motor. The above-ground pool pump has a motor overload protector, efficient high flow action, quicker filtering cycles, and relatively few maintenance requirements.

Inground pool pumps are often cheaper and easier to operate compared to their above-ground counterparts. However, they may not be as energy efficient as above-ground pool pumps.

As the name suggests, single-speed pool pumps run at a constant speed. The pumping power cannot be changed. The pump is either on or off. Typical pumping speed is 3,450 rpm for almost all single speed models.

A single speed pump creates adequate pool water circulation because its speed is always ‘high’. They are also the easiest to find and the most affordable to buy.

Energy inefficiency is one of the key disadvantages of using single speed pumps. This is because they operate at a constant high speed, meaning they consume a large amount of energy throughout the day and night. It’s not cost-effective to run a single-speed pool pump for 24 hours. Also, single speed pumps are generally noisy due to the ‘high’ motor speed.

Unlike the single speed version, a dual pool pump’s speed can be adjusted. The standard low and high speed settings are at 1,725 rpm and 3,450 rpm respectively. A toggle switch or a frequency inverter is used to control the speeds. The low speed is used for a basic pool circulation while high speed is used for more demanding operations (like when you need to rapidly clean a murky pool).

A two-speed pool pump is more versatile than its single-speed counterpart. This means it can save energy when running at the low-speed setting. The low speed setting is also quieter. If you want a greater water circulation or suction (like on a hot sunny day prone to algae growth or during peak pool usage), you can tune to the high-speed setting.

It is not as energy efficient as the variable pool pumps even when running at the low speed. It is also more expensive to purchase than a single-speed pump. The low-speed setting is insufficient to run some pool heaters. It is also not reliable to circulate water in above-ground swimming pools due to low water flow. While a step up from single-speed pumps, we strongly recommend upgrading to a programmable variable speed pool pump to make use of the latest advances in pool pump efficiency.

A variable speed pool pump is more flexible because you can adjust speed across a wider range. This means the pumping speed can match the specific task you want to accomplish, and can be tuned to the optimal level for your swimming pool.

The ability to adjust motor speed to a wide range of options enhances energy saving. Some of the modern high-end units have integrated programmable smart features that can adjust the speed automatically. Those smart pumps can also detect blockage problems and shut down the pump system. Many variable pumps also utilize a sealed Permanent Magnet Motor (PMM), which run quieter and without overheating issues.

One of the major disadvantages is the high initial cost, which is more than single-speed pumps or two-speed pumps. However, given the long lifespan of pumps, you should evaluate all purchases based on total lifetime expenditure.Cost

The motor’s power usage may vary depending on pool pump model. Generally, motors over 2 horsepower (hp) will run on 230 volts while those with less hp will run on 115 or 230 volts. Electric motors are not completely sealed from environmental elements because they are air cooled. For that reason, it is crucial to prevent water or other debris from entering the motor through the cooling vents.

This is located at the end of the pool pump. It contains a basket through which water is pulled as the impeller turns. The hair and lint trap prevents clog in the impeller by stopping debris from entering through the small openings.

8613371530291

8613371530291