mud pump rpm calculator price

The shaft power - the power required transferred from the motor to the shaft of the pump - depends on the efficiency of the pump and can be calculated as Ps(kW) = Ph(kW)/ η (3)

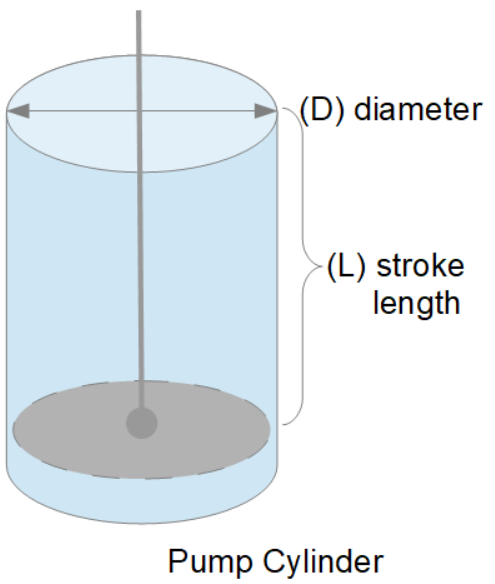

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

Pumps are an integral part of almost all industries today. From construction and mining to automotive and aerospace, pumps play a vital role in keeping these industries moving forward. While there are many essential parameters in pumps, one critical parameter is the pump flow rate which becomes a guiding factor for pump manufacturers.

The pump flow rate is one of the most important factors to consider when selecting a pump. It measures how much water the pump can move in a given period of time and is typically expressed in cubic meters/hour (m3/ h). If you’re looking for a pump to use in your home or business, it’s essential to know the flow rate needed to meet your needs. Otherwise, you may end up with a pump that isn’t powerful enough or one that uses more energy than necessary.

The first step is to determine what your needs are. For example, if you’re using the pump to provide water for irrigation, you’ll need to know the maximum flow rate that will be required. Once you know your needs, you can start looking for pumps that have the required flow rate, as you will now be able to give more precise directions to the pump manufacturers about your requirement.

To choose the right pump, it’s also important to consider other factors, such as pump size and efficiency. For instance, a large pump with a high flow rate may be more expensive to purchase and operate than a smaller pump with a lower flow rate. However, it may still be the better option if your water usage is consistently high or you have multiple zones in your irrigation system that need water simultaneously.

Overall, choosing the right pump for your home or business requires careful consideration of all aspects of pumping performance. With the right pump from reliable pump manufacturers, you can rest assured that you’ll always have an adequate supply of water on demand.

Pump flow rate simply refers to the volume of fluid that is moving through a pump in a given time period. There are various units through which it is measured, and they include cubic meter/hour (m3/h), litre/sec (l/s) or gallons per minute (GPM). Different pump manufacturers refer to different pump flow units.

The flow rate of a pump can be affected by several factors, including the size and type of pump, the speed at which it is operating, and the resistance of the system it is pumping into.

Pump Speed: This is the number of times the pump can complete an entire cycle in a minute and is measured in rotations per minute (rpm). The faster the pump speed, the higher the flow rate.

Pump Size: Larger pumps can move more liquid than smaller pumps. This is why it’s essential to choose an appropriately sized pump for your application.

Now that you know the basics of pump flow rate, you can begin to select a pump that is appropriate for your application. Keep in mind that the factors listed above will all affect pump flow rate, so it’s essential to consider each one when you give your requirements to the pump manufacturers.

Pump speed is measured in revolutions per minute (rpm). To convert from rpm to hertz, divide by 60. For example, if a pump operates at 1000 rpm, its frequency would be 16.67 Hz.

Let’s say you have a pump that is operating at 1000 rpm, has an impeller size of 6 inches, and is pumping water with a density of 62.4 lb/ft3. So the flow rate would be:

The good news is that there are many online flow rate calculators available for free, which you can consider using if you do want to get into too much mathematics.

There are a few key ways to increase the flow rate efficiency in pumps. One is to choose the right pump for the application. Another way is to ensure that the pump is sized correctly for the application. Additionally, regular maintenance can help keep a pump operating at peak efficiency.

When choosing a pump, it is vital to consider the application’s specific needs. For example, if a pump is handling a corrosive fluid, you should select stainless steel or other corrosion-resistant models. Similarly, if the fluid being pumped will be unusually viscous, then a positive displacement pump may be the best option.

Ensuring that a pump is appropriately sized for its application is also critical to maximizing flow rate efficiency. If a pump is too small for the task at hand, it will have to work much harder and will be less efficient. On the other hand, if a pump is too large for the application, it will not operate at peak efficiency.

Finally, regular maintenance is essential to keeping a pump operating at its best. This includes things like inspecting and cleaning the pump regularly and making sure that all of the moving parts are adequately lubricated. By taking these steps, it is possible to keep a pump running at peak efficiency for many years.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

We provide hydraulic components & repair services for industrial applications like paper mills, saw mills, steel mills, recycling plants, oil & gas applications and mobile applications, including construction, utility, mining, agricultural and marine equipment. This includes hydraulic pumps, motors, valves, servo/prop valves, PTOs, cylinders & parts.

Pumps tend to be one of the biggest energy consumers in industrial operations. Pump motors, specifically, require a lot of energy. For instance, a 2500 HP triplex pump used for frac jobs can consume almost 2000 kW of power, meaning a full day of fracking can cost several thousand dollars in energy costs alone!

So, naturally, operators should want to maximize energy efficiency to get the most for their money. Even a 1% improvement in efficiency can decrease annual pumping costs by tens of thousands of dollars. The payoff is worth the effort. And if you want to remotely control your pumps, you want to keep efficiency in mind.

In this post, we’ll point you in the right direction and discuss all things related to pump efficiency. We’ll conclude with several tips for how you can maintain pumping efficiency and keep your energy costs down as much as possible.

In simple terms, pump efficiency refers to the ratio of power out to power in. It’s the mechanical power input at the pump shaft, measured in horsepower (HP), compared to the hydraulic power of the liquid output, also measured in HP. For instance, if a pump requires 1000 HP to operate and produces 800 HP of hydraulic power, it would have an efficiency of 80%.

Remember: pumps have to be driven by something, i.e., an electric or diesel motor. True pump system efficiency needs to factor in the efficiency of both the motor AND the pump.

Consequently, we need to think about how electrical power (when using electric motors) or heat power (when using combustion engines) converts into liquid power to really understand pump efficiency.

Good pump efficiency depends, of course, on pump type and size. High-quality pumps that are well-maintained can achieve efficiencies of 90% or higher, while smaller pumps tend to be less efficient. In general, if you take good care of your pumps, you should be able to achieve 70-90% pump efficiency.

Now that we have a better understanding of the pump efficiency metric, let’s talk about how to calculate it. The mechanical power of the pump, or the input power, is a property of the pump itself and will be documented during the pump setup. The output power, or hydraulic power, is calculated as the liquid flow rate multiplied by the "total head" of the system.

IMPORTANT: to calculate true head, you also need to factor in the work the pump does to move fluid from the source. For example, if the source water is below the pump, you need to account for the extra work the pump puts in to draw source water upwards.

*Note - this calculation assumes the pump inlet is not pressurized and that friction losses are minimal. If the pump experiences a non-zero suction pressure, or if there is significant friction caused by the distance or material of the pipe, these should be factored in as well.

You"ll notice that the elevation head is minimal compared to the discharge pressure, and has minimal effect on the efficiency of the pump. As the elevation change increases or the discharge pressure decreases, however, elevation change will have a greater impact on total head.

Obviously, that’s a fair amount of math to get at the pump efficiency, considering all of the units conversions that need to be done. To avoid doing these calculations manually, feel free to use our simple pump efficiency calculator.

Our calculations use static variables (pump-rated horsepower and water source elevation) and dynamic variables (discharge flow and pressure). To determine pump efficiency, we need to measure the static variables only once, unless they change.

If you want to measure the true efficiency of your pump, taking energy consumption into account, you could add an electrical meter. Your meter should consist of a current transducer and voltage monitor (if using DC) for electrical motors or a fuel gauge for combustion. This would give you a true understanding of how pump efficiency affects energy consumption, and ultimately your bank account.

Up until this point, we’ve covered the ins and outs of how to determine pump efficiency. We’re now ready for the exciting stuff - how to improve pump efficiency!

One of the easiest ways to improve pump efficiency is to actually monitor pumps for signs of efficiency loss! If you monitor flow rate and discharge (output power) along with motor current or fuel consumption, you’ll notice efficiency losses as soon as they occur. Simply having pump efficiency information on hand empowers you to take action.

Another way to increase efficiency is to keep pumps well-maintained. Efficiency losses mostly come from mechanical defects in pumps, e.g., friction, leakages, and component failures. You can mitigate these issues through regular maintenance that keeps parts in working order and reveals impending failures. Of course, if you are continuously monitoring your pumps for efficiency drops, you’ll know exactly when maintenance is due.

You can also improve pump efficiency by keeping pumps lubricated at all times. Lubrication is the enemy of friction, which is the enemy of efficiency (“the enemy of my enemy is my friend…”).

A fourth way to enhance pump efficiency is to ensure your pumps and piping are sized properly for your infrastructure. Although we’re bringing this up last, it’s really the first step in any pumping operation. If your pumps and piping don’t match, no amount of lubricant or maintenance will help.

In this post, we’ve given you the full rundown when it comes to calculating and improving pump efficiency. You can now calculate, measure, and improve pump efficiency, potentially saving your business thousands of dollars annually on energy costs.

For those just getting started with pump optimization, we offer purpose-built, prepackaged solutions that will have you monitoring pump efficiency in minutes, even in hazardous environments.

I understand that John Blue Company is furnishing this calculator "as is" and that it is not covered by any warranty whatsoever, whether express, implied, or statutory, including, but not limited to, its freedom from errors, its fitness for any particular purpose, and/or its correct or incorrect use. I agree that by using this calculator, I am doing so at my own risk. I agree to hold John Blue harmless for any and all damages directly or indirectly related to the use of this calculator. In no respect shall John Blue Company incur any liability for any damages, including, but not limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or in any way connected to the use of this calculator, whether or not based upon warranty, contract, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of this calculator and its use.

Whether you operate an industrial pump or looking to purchase the right pumps in India for your needs, the flow rate of the system is a crucial parameter. In this guide, Sintech, the no.1 industrial

Flow rate is the amount of fluid that the pump can transport within a given time. Knowing the flow rate of your pump can help you achieve two key things:

You can figure out if your system is working efficiently. If you know the expected flow rate and the current flow rate, then you can identify if your system is underperforming. This helps you make the right action to improve the pump’s performance.

Before you approach multistage centrifugal pump manufacturers in India for your purchase needs, having an idea of the desired flow rate will help you plan the system design perfectly. If you calculate the required flow rate wrong, then you would install an oversized/undersized pump, which is not a good investment in the long run. So, you need to have a clear idea of the desired flow rate before ordering the best pumps in India from your preferred manufacturer.

You need to calculate three factors before ordering the right pumps:The type of fluid you need to pump – is it viscous or clear? What’s the temperature of the pumped fluid? Etc.

The volume of fluid that needs to be transported in a specific timeAll these three factors will vary based on your industrial needs. The volume of fluid that you want to transport determines the flow rate of the pump. The type of fluid and the distance transported both play a huge role in impacting the flow rate that you can achieve. Hence, all these three factors play a crucial role in determining the size and type of pump needed.

We highly recommend that you contact a pump sizing expert to help you decide the correct equipment to buy. At Sintech, we offer free pump sizing guidance for all our clients, to help them find the best pumps in India for their requirements.

Once you have installed the pump, you need to monitor the flow rate periodically to determine if your pump is performing efficiently. You can check the pump’s performance by monitoring several factors. Right now, we’ll just calculate the flow rate.

You can measure the flow rate of an operating pump using either one of the following two methods:Use a flow meter – A flow meter is a simple device that does exactly what it means – it measures the amount of fluid passing through the system. Attach the flow meter to the discharge outlet. The reading on the meter gives you the flow rate of the system.

Calculate flow rate manually by collecting fluid – You can collect the fluid at the output of the pump system using a bucket or vat. Measure the collected fluid, the time taken to collect it, and reverse engineer to find the flow rate. The formula for calculating the flow rate: Flow rate = Volume of Liquid Collected / Time Taken

If there is a significant difference between desired flow rate and the actual flow rate, you can then carry on an inspection of the pump system to determine what’s wrong. Or if it’s time for a pump replacement, then Sintech Pumps, the no.1 multistage centrifugal pump manufacturers in India has an excellent range of industrial pumps for all needs. Get in touch with our team to find the right pumps for your specific needs.

We commonly receive the call to help assist in properly sizing pulleys and sheaves for pump applications. Generally, this is in high pressure wash applications but we also run into a fair amount of agricultural applications where this knowledge can be leveraged. Pulleys or “sheaves” are commonly used for connecting pumps to motors or engines via drive belts. Most pulleys are cast iron or aluminum construction and are offered in either fixed-bore or tapered bushing styles.

For proper operation of any brand or pump type, it is critical to size pulleys and sheaves, correctly, in order to maintain correct RPM, (revolutions per minute). RPM speed is what determines the pump output flow rate – in gallons per minute, liters per minute, etc.

Incorrect pump RPM will adversely affect the pump performance. If the pump is turning too slow – it will not give full performance. Conversely, if the pump is turning too fast, it could cause premature mechanical failures (i.e. valve wear or elastomer failure).

Therefore, it is absolutely critical to ensure correct pulley sizing and analysis of the drive unit, (motor, engine, etc.) relative to the pump. For the sake of this discussion, we will assume standard electric motors at 1750 RPM and standard gas engines at 3400RPM. Do note, one must determine the rpm of their drive unit to be able to accurately calculate the pulley/sheave size.

If you start with an incorrect figure for RPM – you will size your equipment incorrectly. This could lead to shorter equipment lifespans and/or reduced output flow rates. Thus, ultimately a less efficient system which equates to more down time and added cost of operation. The scope of this post will be focused towards plunger pump applications. We assemble many units using this method in Omaha, NE. Dultmeier Sales is proud to display the Built in the USA logo on our products. Here are just a handful of the pulley-driven pump products that we offer.

There are complicated formulas for determining pulley ratios but in generic, layman terms, simply divide the driven component (pump) by RPM, the driver component (motor or engine) rated by RPM to get the required ratio. In the example below, the pump RPM is 1070, for full output, while the motor is 1750 RPM.

This means the pulley ratio must be .611 to drive the pump correctly. Hypothetically speaking, if we had a 4 inch pulley on the motor, we would require a 6.55” pulley on the pump. That mathematical equation is as follows: 4” divided by .611 = 6.55”

If the drive pulley on the engine is 4 inches in diameter, we need to calculate 4/.315 = 12.70. This means that the pump pulley must be 12.70 inches, in diameter, to run the pump at 1070 rpm. You can view a technical page from our catalog here – it will help to further explain the calculation process.

Most pulleys, or sheaves, are designed with either fixed shaft bores or tapered bushing hubs. Replaceable hubs fit the required motor or pump shaft size in either inch or mm sizes – depending on the application requirement. These hubs come with bolts to attach them to the pulley, or sheave.

Tapered style hubs simply fit into the pulley opening and then are tightened with two or three set screws, which draw the bushing and pulley together to make one assembly. The pulleys are then attached to the driver (electric motor or gas engine) and driven components (pump). The type of hub, H, SD, SH, etc. must match to a pulley with the same designation for proper fit.

As the information above shows, there are many things involved in order to determine the correct pulleys required to drive your pumps correctly. It is important to remember the larger the difference in pulley sizes, the larger the center distance required to maintain minimum contact with the smaller pulley. We would be glad to help with any sizing for your specific applications. Your Experts in Delivering Fluid Handling Solutions – We Know Flow!

The purpose of this article is to present some guidelines and simplified techniques to size pumps and piping typically used in mud systems. If unusual circumstances exist such as unusually long or complicated pipe runs or if very heavy or viscous drilling muds are used, a qualified engineer should analyze the system in detail and calculate an exact solution.

To write about pumps, one must use words that are known and well understood. For example, the label on the lefthand side of any centrifugal pump curve is Total Head Feet. What does this mean?

Total Head remains constant for a particular pump operated at a constant speed regardless of the fluid being pumped. However, a pump’s pressure will increase as the fluid density (mud weight) increases according to the following relationship:

Note that the pump pressure almost doubled. It follows that the required pump horsepower has increased by the same percentage. If the pump required 50 HP for water service, it will require the following horsepower for 16 lb/gal mud:

To summarize, a pump’s Total Head remains constant for any fluid pumped, only the pump pressure and pump horsepower will change. Therefore, a pump motor must be sized according to the heaviest weight mud to be pumped.

In our example problem, the required desilter pressure head is 75 ft. for any mud weight. However, the pressure would be 30.3 PSIG for water or 43.6 PSIG for 12 lb mud or 58.1 PSIG for 16 lb mud. A good rule of thumb is that the required pressure (PSIG) equals 4 times the mud weight (12 LB/GAL x 4 = 48 PSIG).

Determine the required pressure head and flow rate. If the pump is to supply a device such as a mud mixing hopper or a desilter, consult the manufacturer’s information or sales representative to determine the optimum flow rate and pressure head required at the device. (On devices like desilters the pressure head losses downstream of the device are considered negligible and are usually disregarded.)

Select the basic pump to pump the desired flow rate. Its best to refer to a manufacturer’s pump curve for your particular pump. (See example – Figure 3).

The pump’s impeller may be machined to a smaller diameter to reduce its pressure for a given application. Refer to the manufacturer’s pump curves or manufacturer’s representative to determine the proper impeller diameter. Excessive pressure and flow should be avoided for the following reasons:

The pump must produce more than 75 FT-HD at the pump if 75 FT-HD is to be available at the desilter inlet and the pump’s capacity must be at least 800 GPM. Therefore, we should consider using one of the following pumps from the above list: 4″ x 5″ Pump 1750 RPM – 1000 GPM at 160 FT-HD; or 5″ x 6″ Pump 1750 RPM – 1200 GPM at 160 FT-HD.

The pump suction and discharge piping is generally the same diameter as the pump flange diameters. The resulting fluid velocities will then be within the recommended ranges of 4 to 10 FT/SEC for suction lines and 4 to 12 FT/

SEC for discharge lines. Circumstances may dictate that other pipe diameters be used, but remember to try to stay within the above velocity guidelines. Smaller pump discharge piping will create larger pressure drops in the piping

and the pump may not be able to pump the required amount of fluid. (For example, don’t use a 4″ discharge pipe on a 6″ x 8″ pump and expect the pump’s full fluid flow.)

6″ pipe may be used for the suction pipe since it is relatively short and straight and the pump suction is always flooded. 6″ pipe is fully acceptable for the discharge pipe and is a good choice since the desired header is probably 6″ pipe.

8″ pipe may be used for the suction pipe (V = 5.13 FT/SEC) since V is still greater than 4 FT/SEC. 8″ pipe would be preferred if the suction is long or the suction pit fluid level is low with respect to the pump.

8613371530291

8613371530291