mud pump saint louis manufacturer

Claypool Pump & Machinery was founded in 1946 by Ralph Claypool and has operated under family ownership in the St Louis area for the last 68 years. In that time Claypool Pump & Machinery (CPM) has been a trusted supplier of pumps and associated equipment for the commercial, industrial, municipal, and fire protection markets.

Claypool Pump & Machinery offer you pre-sales project design, a complete offering of equipment for all of your application needs, and a full service repair shop for any maintenance or St Louis pump repair you may require. Whatever your application: hot/chilled water systems, HVAC and cooling towers, fire pumps, industrial or process, and waste-water, we have a cost effective, timely, and informed solution. Our knowledgeable staff has over 100 years of combined experience in the commercial, fire, municipal, and industrial markets. Claypool Pump & Machinery’s large selection of products from the world’s best manufacturers, make us a leading St Louis pump distributor in custom pump sales in the Eastern Missouri and West Central Illinois areas.

With a working knowledge of almost every pump type and accessory for any pumping application, you can depend on our expertise and guidance to find solutions for your unique problems. If you need assistance to troubleshoot or to replacing a current installation our staff is ready to lend a hand. We wouldn’t be the best St Louis pump company without offering custom services either. For applications that require more complex pumping solutions (for example water solids pumping or fire department pumping projects), please don’t hesitate to contact us and we can work with you to identify the requirements, design a solution and select the right mix of pumping products that will help to deliver quality, long lasting performance.

With a complete selection of pumping equipment for any application, Claypool Pump & Machinery offers you pre-sale design, support and consultation backed by more than 65 years of experience in the industry, right from our St Louis, Missouri facility.

Mobile Mini delivers tank and pump solutions, secure storage containers, and ground-level offices to customers throughout the St. Louis area, including:

Mobile Mini is the country’s largest storage, mobile office, and jobsite solutions provider. When it comes to service, support, and reach, we’re unbeatable. No matter where you live, chances are there’s a Mobile Mini branch nearby. If you’re looking for tanks and pumps in St. Louis, you’ve definitely come to the right place.

St. Louis is a melting pot of food, culture, and some of the country’s best (and most sought-after!) beer. While the beer is a definite perk, our city has produced legends like Josephine Baker, T.S. Elliot, and William Burroughs. Our city streets and riverside parks have inspired greatness, and the spirit of creativity and innovation that launched these giants is still very much in the air. Oh, and our toasted ravioli is the stuff of legend.

At Mobile Mini St. Louis, we proudly serve the Central Missouri and Southwestern Illinois region, providing jobsite and water management solutions that are uniquely “Lou.” Our local branch is staffed by people who live and work in the area and who know this city’s needs backward and forward. At Mobile Mini, we would never dream of offering a College Hill solution for a Hyde Park jobsite.

Industrial Pumps for St. Louis: At Mobile Mini, we only carry the best diesel-driven centrifugal and electric submersible pumps. Our industrial pumps are designed to fit seamlessly with our selection of pipes, hoses, berms, and manifolds, and are durable, easily transferred across projects, and built to last. All pumps and accessories work quickly and efficiently to:

Roll-Off Boxes for St. Louis: Water isn’t the only jobsite needs that require equipment. We stock a range of roll-off boxes and other storage units that are designed to safely handle:

Pumps Sight flow windows, Flow computers or totalizers, Orifice plate, Oil gauges, Flow transmitters, Flowmeters, Rheometers, Rotameters, Water meters, Water meter spares, Venturis, Gas gauges, Air velocity and temperature monitors, Sight flow indicators, Metering or injection or proportioning pumps, Progressive cavity pumps

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

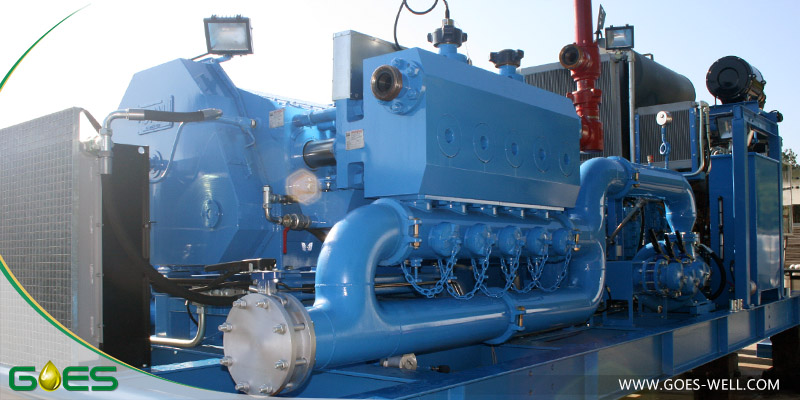

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

In May 1985, Jaeger left CME to pursue a career behind a drill rig. He went to work for an engineering firm in St. Louis as a member of the drill crew on a CME-45B rig. He moved on from there to a job in drilling equipment sales with Brainard-Kilman who, at the time, was an authorized distributor of CME equipment. He left there to become drill shop and fleet manager for a large engineering firm in the Southeast. Jaeger returned to CME in 1988, supporting the outside sales team before being assigned a sales territory in 1998.

The community’s search eventually led them to a trio of companies that combined their expertise to develop a three phase solution. Interactive Pipe Inspection (IPI), a Tumwater, Washington-based company that specializes in pipe inspections using advanced fiber-optic technology to CCTV long lengths of pipe, was first contracted to perform the initial under-lake pipe inspection of nearly 36,000 lf. For the second and third phases of the project, IPI partnered with Marion Hill Associates (MHA), a New Brighton, Pennsylvania-based commercial diving and marine construction company and SAK Construction (SAK), an O’Fallon, Missouri-based tunneling and pipe rehabilitation contractor, to create the plan. IPI hired several experts, engineers, and consultants to design subaqueous manhole structures, which MHA would construct. SAK, headquartered just miles from Lake St. Louis, joined the team to provide expert consultation, project management, and underwriting as well as pipeline rehabilitation when necessary.

The Lake Saint Louis Sewer Improvement Program called for the evaluation, upgrade and emergency access for approximately eight miles of sanitary sewer mains buried beneath Lake St. Louis and Lake St. Louise. Since the sewer system runs under the two lakes with no intermediate entry, very little information about the state of the pipe was available at the start of the project. With the pump stations no longer an option, the team of contractors needed a way to locate and gain access to the existing pipe in order to repair it now and in the future. The new design proposal consisted of 16 access manholes across the bottom of the lakes and further inspection of all the main lines, which IPI/MHA/SAK proposed in three phases. After the manhole was installed and the pipe inspected, any section of the pipe that required rehabilitation would be done by SAK using CIPP. Ultimately, this plan was accepted by both the homeowners and the Water District and resulted in only temporary disruption at a fraction of the original cost.

Getting the necessary equipment mobilized on the lake, figuring out the material and fittings of the pipe, and working 10 to 35 ft underwater with pipes buried 8 to 10 in. in the mud with zero visibility is a craft Maron Hill Associates has perfected.

Once the pipeline was located, manholes were introduced at varying intervals for access and to deploy inspection cameras. Conceptually, IPI developed the manhole installation idea, but Marion Hill Associates had the expertise when it came to water, diving, and marine construction. Getting the necessary equipment mobilized on the lake, figuring out the material and fittings of the pipe, and working 10 to 35 ft underwater with pipes buried 8 to 10 in. in the mud with zero visibility is a craft MHA has perfected – all with minimal disturbance to the recreational boating season.

Will I save money by mudjacking instead of replacing the concrete?Absolutely! Most mudjacking services cost half, if not a third, as much as replacing concrete.

Why has my concrete sunken / no longer level?Mother nature can do a number on the soil and ground beneath your concrete. Over time, soil settles, erosion happens, and nature takes its toll, causing your once level concrete to shift and settle. It’s a totally natural occurrence, and it’s most prevalent in areas of the country where there is an annual freeze-thaw cycle, like St. Louis. Through this shifting of earth, your concrete may sink, raise, and even crack. The good news is that mudjacking can help level your concrete once again.

Should I just replace my concrete instead of mudjacking it?Tearing out and replacing concrete slabs/patios/floors can be very expensive – usually far more than the cost of mudjacking. Mudjacking also takes a much shorter amount of time to complete. Once we’re done mudjacking, you’ll be able to walk on the area also immediately – no waiting for concrete to dry. And it’s a much less messy process than new concrete work.

How long does mudjacking take?Depending on the mudjacking service, you can expect mudjacking to take anywhere from 1 hour to most of the day. However, once finished, you can immediately walk on the concrete that has been fixed.

Do I have to be home while you mudjack?If the slabs you need mudjacked are on the exterior of your home, then, no, you don’t need to be home. We can fix sidewalks, patios, etc, while you’re away. However, if you need a slab in your garage or other interior area mudjacked, then we’ll need you there.

What exactly is the mudjacking process?If you are wondering how we fix uneven concrete, check out our What is Mudjacking page to see a video of how it works.

Will there be a lot of noise? What about dust and debris?Mudjacking pumps make about as much noise as a lawnmower. In terms of dust and debris, part of the process involves drilling small holes, which may make some dust. Occasionally, concrete needs to be sawed, which can make a lot of dust. If you’d like to manage the amount of dust, water can be used during this process.

Will mudjacking cause damage to my yard or sprinklers?In most situations, you will not see any damage from the mudjacking process. However, if your yard is wet and soft or sprinklers are running, there may be small ruts created by the pump.

Could my concrete crack during the mudjacking process?It is possible that your concrete will crack when being moved into place during the mudjacking process. Some concrete, when sunken, gets small cracks on the bottom that are not necessarily visible. When moved, this crack could become larger. However, these cracks are not caused by mudjacking. If you useexperienced, professional mudjackerswho use the correct process, cracking is highly unlikely.

What problems might I experience if I decide to mudjack?If you hire a mudjacking company that does not use the correct methods, your concrete may crack. That’s whySt Louis Mudjackingis a great choice!

Mud logging is the creation of a detailed record (well log) of a borehole by examining the cuttings of rock brought to the surface by the circulating drilling medium (most commonly drilling mud). Mud logging is usually performed by a third-party mud logging company. This provides well owners and producers with information about the lithology and fluid content of the borehole while drilling. Historically it is the earliest type of well log. Under some circumstances compressed air is employed as a circulating fluid, rather than mud. Although most commonly used in petroleum exploration, mud logging is also sometimes used when drilling water wells and in other mineral exploration, where drilling fluid is the circulating medium used to lift cuttings out of the hole. In hydrocarbon exploration, hydrocarbon surface gas detectors record the level of natural gas brought up in the mud. A mobile laboratory is situated by the mud logging company near the drilling rig or on deck of an offshore drilling rig, or on a drill ship.

Mud logging technicians in an oil field drilling operation determine positions of hydrocarbons with respect to depth, identify downhole lithology, monitor natural gas entering the drilling mud stream, and draw well logs for use by oil company geologist. Rock cuttings circulated to the surface in drilling mud are sampled and discussed.

The mud logging company is normally contracted by the oil company (or operator). They then organize this information in the form of a graphic log, showing the data charted on a representation of the wellbore.

The oil company representative (Company Man or "CoMan") together with the tool pusher, and well-site geologist (WSG) provides mud loggers their instruction. The mud logging company is contracted specifically as to when to start well-logging activity and what services to provide. Mud logging may begin on the first day of drilling, known as the "spud in" date but is more likely at some later time (and depth) determined by the oil industry geologist"s research. The mud logger may also possess logs from wells drilled in the surrounding area. This information (known as "offset data") can provide valuable clues as to the characteristics of the particular geo-strata that the rig crew is about to drill through.

Mud loggers connect various sensors to the drilling apparatus and install specialized equipment to monitor or "log" drill activity. This can be physically and mentally challenging, especially when having to be done during drilling activity. Much of the equipment will require precise calibration or alignment by the mud logger to provide accurate readings.

Mud logging technicians observe and interpret the indicators in the mud returns during the drilling process, and at regular intervals log properties such as drilling rate, mud weight, flowline temperature, oil indicators, pump pressure, pump rate, lithology (rock type) of the drilled cuttings, and other data. Mud logging requires a good deal of diligence and attention. Sampling the drilled cuttings must be performed at predetermined intervals, and can be difficult during rapid drilling.

Another important task of the mud logger is to monitor gas levels (and types) and notify other personnel on the rig when gas levels may be reaching dangerous levels, so appropriate steps can be taken to avoid a dangerous well blowout condition.

Because of the lag time between drilling and the time required for the mud and cuttings to return to the surface, a modern augmentation has come into use: Measurement while drilling. The MWD technician, often a separate service company employee, logs data in a similar manner but the data is different in source and content. Most of the data logged by an MWD technician comes from expensive and complex, sometimes electronic, tools that are downhole installed at or near the drill bit.

Mud logging includes observation and microscopic examination of drill cuttings (formation rock chips), and evaluation of gas hydrocarbon and its constituents, basic chemical and mechanical parameters of drilling fluid or drilling mud (such as chlorides and temperature), as well as compiling other information about the drilling parameters. Then data is plotted on a graphic log called a mud log. Example1, Example2.

Other real-time drilling parameters that may be compiled include, but are not limited to; rate of penetration (ROP) of the bit (sometimes called the drill rate), pump rate (quantity of fluid being pumped), pump pressure, weight on bit, drill string weight, rotary speed, rotary torque, RPM (Revolutions Per Minute), SPM (Strokes Per Minute) mud volumes, mud weight and mud viscosity. This information is usually obtained by attaching monitoring devices to the drilling rig"s equipment with a few exceptions such as the mud weight and mud viscosity which are measured by the derrickhand or the mud engineer.

Rate of drilling is affected by the pressure of the column of mud in the borehole and its relative counterbalance to the internal pore pressures of the encountered rock. A rock pressure greater than the mud fluid will tend to cause rock fragments to spall as it is cut and can increase the drilling rate. "D-exponents" are mathematical trend lines which estimate this internal pressure. Thus both visual evidence of spalling and mathematical plotting assist in formulating recommendations for optimum drilling mud densities for both safety (blowout prevention) and economics. (Faster drilling is generally preferred.)

Mud logging is often written as a single word "mudlogging". The finished product can be called a "mud log" or "mudlog". The occupational description is "mud logger" or "mudlogger". In most cases, the two word usage seems to be more common. The mud log provides a reliable time log of drilled formations.

Sample of drill cuttings of shale while drilling an oil well in Louisiana. For reference, the sand grain and red shale are approximately 2 mm. in dia.

The lime, gray/black = shale and yellow = sand. More yellow represents more sand identified at that depth. The lithology is measured as percentage of the total sample, as visually inspected under a microscope, normally at 10x magnification (Figure 3). These are but a fraction of the different types of formations that might be encountered. (Color coding is not necessarily standardized among different mud logging companies, though the symbol representation for each are very similar.) In (Figure 3) you can see a sample of cuttings under a microscope at 10x magnification after they have been washed off. Some of the larger shale and lime fragments are separated from this sample by running it through sieves and must be considered when estimating percentages. Also, this image view is only a fragment of the total sample and some of the sand at the bottom of the tray can not be seen and must also be considered in the total estimation. With that in mind this sample would be considered to be about 90% shale, 5% sand and 5% lime (In 5% increments).

P.W. Purcell "Chapter 16 Mud Logging" pp. 347-354 in L.W. Leroy, D.O. Leroy, and J.W. Raese, editors, 1977, Subsurface Geology, Colorado School of Mines, Golden, 941 pp. ISBN 0-918062-00-4

Chambre Syndicale de la recherche et de la production du petrole et du gaz naturel, 1982, Geological and mud logging in drilling control: catalogue of typical cases, Houston, TX: Gulf Publishing Company and Paris: Editions technip, 81 p. ISBN 0-87201-433-9

Exlog, 1979, Field geologist"s training guide: an introduction to oilfield geology, mud logging and formation evaluation, Sacramento, CA: Exploration Logging, Inc., 301 p. Privately published with no ISBN

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

8613371530291

8613371530291