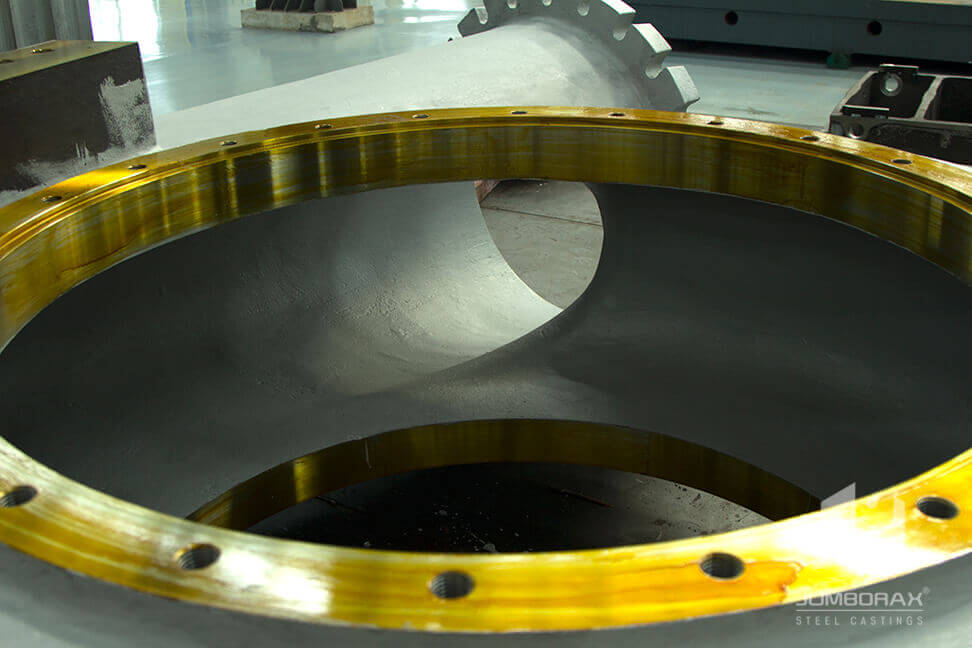

mud pump series steel castings made in china

*Note: The Mud Pump Shell we displayed are not Standard Producing Unit. JUMBORAX is an OEM/ODM service & manufacture plan solution provider, all the products we displayed are samples just helping us to show our production capabilities. All the designs belong to our customers that we can not sell the products to others. If you wish to make your products, please Contact Our Customer Service with your ideas or drawings for further cooperation. Thank you very much.

Steel is an alloy consisting of iron with carbon element less than 2%, and is usually added in other chemical elements in small amount like silicon, manganese, sulfur and phosphorus. So products made in steel casting can win good mechanical properties. Steel castings are used when iron castings are not available for excellent strength or shock resistance.

Alloy steel: Main grades of steel castings in alloy steel are 42CrMo, 35CrMo, 40CrNiMo, 4130, 4140 and 8630, etc. With alloy steel, it can obtain special properties for products like high strength, high toughness, wear resistance, corrosion resistance and good working performance. This kind of material is more likely to produce cast wear parts for mining & construction machinery.

Carbon steel: A steel with carbon content up to 2.1% by weight. Common grades of steel castings in carbon steel are ASTM 1020, ASTM 1030, ASTM 1045, ASTM 1080, etc. Carbon steel is choose to make steel castings which have strong lade or stress demands to ensure mechanical properties. Carbon steel could be divided into low carbon steel (WC≤0.25%), middle carbon steel (WC 0.25%-0.6%) and high carbon steel (WC>0.6%) according to different carbon content. The higher the carbon content is, the higher the hardness and strength will be.

Stainless steel: A steel alloy with a minimum of 10.5% chromium content by mass. It is highly corrosion resistant and wear resistant, provides excellent machinability, and is well-known for its aesthetic appearance. Main stainless steel grades for steel castings are SS304, SS316, PH17-4, etc. This type of material is commonly used for steel castings served for medical industry, food machinery, oilfield industry, etc.

Investment casting process is preferred when the steel part is not large, normally less than 60kg. Such technique can help to win close tolerance, high accuracy and less defects. Most important is that steel castings by investment casting can achieve good surface finish and nearly net shape.

Steel Sand Casting: Refers to steel castings made in sand casting process. Sand casting is an another process that utilizes non-reusable sand molds to form steel castings. It is a common production method for steel components of all sizes, from a few ounces to several tons. Sand casting isn’t only versatile in the size of its products – it can also create exceptionally complex or detailed steel castings, and can be used to cast nearly any metal alloy.

Sand Casting process is recommended when the steel parts are large or not required for perfect surface finish. Due to its low production cost, the price of steel sand castings will be much more competitive than steel investment castings. So if the budget is limited and not enough for investment casting, you can consider steel sand casting as the method.

There are lots of advantages using steel casting. After steel casting, we can not only improve the mechanical properties, especially strength, but also improve its wear resistance and corrosion resistance,sometimes even change magnetic response or thermal expansion. Steel casting makes designed products much more flexible in dimensions, which is not feasible in other manufacturing methods. Steel castings are produced by melting steel ingots into liquid status and pouring the liquid steel into ceramic shell mold, this allows products cast to shapes when other manufacturing ways can not meet.

Another point of steel is its weldable. The weldability of steel castings made it workable when a individual cast steel component need to work with another metal part. Besides, steel casting can replace welded fabrication parts when the capacity of welding fabrication can not meet the capacity of products.

Due to its reliability and strength, numerous industries rely on steel castings. Industries that use steel castings range from food processing and electronics to oil and gas. Some typical industries that using steel castings include the railroad, construction, drilling, transportation, and mining industries. Main examples of items that are steel casting are: gears, valve bodies, pump castings, mining machinery parts, agricultural wear parts, marine equipment parts, engine cylinder blocker, and railroad truck frames, etc.

In certain stainless steels, castings tend to have better corrosion resistance than equivalent forgings because of controlled amounts of ferrite present in castings.

As a specialized steel foundry, CFS Co.,Ltd is the manufacturer and exporter of high quality steel castings with our lost wax investment casting process up to 100kg in weight. After 30 years’ hard working, we are now becoming one of the largest steel casting companies in China. Currently, with a annual production capability 9,000t, our foundry has the ability to develop different kinds of custom steel castings for our customers in the shortest time, around 4-6 weeks. We have absolute advantages over other steel foundries for our ability of supplying steel castings in both short and high volume runs, machining, heat treatment, district inner quality control system, and other value-added services.

If you’re interested in using steel castings for your project, contact us today! As steel casting experts, we can provide you best design and manufacturing solution with the highest quality investment castings!

The crosshead supplied by lake petro is manufactured from high quality, cast steel and the guides are from a quality manganese bronze normally used in bearings. This combination of materials provides a low friction interface and generates very little heat, which indications no friction, which equates to no wear.

Lake petro has very rich experience in supplying spare parts of mud pump to the worldwide oil drilling industry.We stock and sell a wide selection of mud pump fluid end expendables and spares parts.

We have been OEM for many brands from Europe and our pumps has been used by famous brands from Middle east to apply for UL/FM Certificate. We can make pumps with the bearing housing as your own design.

• Four driving units cover complete range. The high tensile steel shaft accurately machined and groud is supported by antifriction bearings. The shaft is protected by shaft sleeve from wearing in the stuffing box area.

•City Water Supply •Irrigation •Fire Fighting •Air conditioning•Fresh water on the ship •Sanitary and cleaning installation •Power Sation•Mine Drainage•Spinkler system •Brine Pumping •Alkaline solution•Oil and Benzene

Professional China Mud Pump - BNA series Single Stage, End Suction Norm Centrifugal pumps – Beken, The product will supply to all over the world, such as: , , ,

Explore a wide variety of cast iron mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These cast iron mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these cast iron mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right cast iron mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of cast iron mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

The top management has an average experience in European high-alloy steel casting manufacturing of 30 years and can support customers both in material and design issues. They are also familiar with European standards and quality requirements.

AnWo produces high-alloy steel castings for pump casings, pump impellers, and components for hydro plants with a finished piece weight of up to 4 tons. The main products include pump casings, impellers, blades, and wicket gates. AnWo provides high-quality steel castings for the ANDRITZ GROUP on a continuous basis and develops new parts together with its customers.

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex:Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well"s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

Pump parts and accessories are components and devices used in the construction of pumps. A pump part may include an upstream and downstream bend element, sidestream, inlet guide vane, impeller, front and rear seals, diffuser, and an exit element such as a volute. Pump parts and accessories include gas pump parts, water pump parts, and sump pump parts. Other pump parts and accessories for water pumps include the shaft and impeller that spin on the sealed bearing, which is the part that usually wears out.

Pump is a machine that delivers fluid or pressurizes fluid. It transfers the mechanical energy of the prime mover or other external energy to the liquid to increase the liquid energy. The pump is mainly used to transport liquids such as water, oil, acid-base liquid, emulsion, suspension emulsion and liquid metal, as well as liquid, gas mixture and liquid containing suspended solids. The impeller is installed in the pump casing and fastened to the pump shaft, which is directly driven by the motor. There is a liquid suction pipe in the center of the pump housing. The liquid enters the pump through the bottom valve and the suction pipe. The liquid discharge port on the pump casing is connected with the discharge pipe.

Before the pump is started, the pump casing is filled with the liquid being transported; after starting, the impeller is driven by the shaft to rotate at a high speed, and the liquid between the blades must also rotate with it. Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and gains energy, leaving the outer edge of the impeller at a high speed into the volute pump casing. In the volute, the liquid decelerates due to the gradual expansion of the flow channel, and converts part of the kinetic energy into static pressure energy, and finally flows into the discharge pipe at a higher pressure and is sent to the place where it is needed. When the liquid flows from the center of the impeller to the outer edge, a certain vacuum is formed in the center of the impeller. Because the pressure above the liquid level of the storage tank is greater than the pressure at the inlet of the pump, the liquid is continuously pressed into the impeller. It can be seen that as long as the impeller rotates continuously, the liquid will be continuously sucked and discharged.

Pump valve is a collective term for pumps and valves. It is an industrial equipment used in liquid transportation. The reason why pumps and valves are often linked together is the occasion. In other words, there are usually valves where there are pumps, and pumps are often needed in some places. They are used in places where liquids are transported. Of course, valves are also used for gas. Vacuum pumps are also related to gas.

For pump-valve parts and products mass production manufacturing, MINGHE CASTING offers the highest degree of machining & casting service with a basis of 30+ years experience serving the pump-valve industry. Our pump-valve casting shop and experts deliver confidence. We have perfected the art of producing large component volumes with complete JIT reliability, backed by the quality and long-term reliability our customers expect.

MINGHE’s experience is unrivaled in the design, development, and manufacture of precision die cast and cnc machining solutions for a wide range of Pump Valve applications, including but not limited to:

Pump categories:water pumps, oil pumps, chemical pumps, diaphragm pumps, sewage pumps, screw pumps, submersible pumps, sewage pumps, submersible pumps, reciprocating pumps, air conditioning pumps, feed water pumps, multi-stage pumps, pipeline pumps, centrifugal pumps, three-screw Pumps, twin screw pumps, heat conduction oil pumps, scavenge pumps, corrosion-resistant pumps, high temperature and high pressure pumps, vacuum pumps, magnetic pumps, miniature electric pumps, mining pumps, slurry pumps, pulp pumps, non-clogging pumps, self-priming pumps, increase Pressure pump, fire pump, constant pressure tangent pump, clean water pump, thick slurry pump, mud pump, etc.

Minghe has over 30 years of experience assisting pump valve manufacturers design cost-effective mechanical components. When you partner with Minghe you can receive the following benefits from our die casting process:

Minghe’s die casting operation features 40 presses ranging from 250 to 3000 ton. We accommodate some of the most demanding pump valve part runs in terms of volume, part size, and complexity. Because of our engineering and modeling capabilities, we are known by our clients as a company that can reduce part complexity, and make the manufacturing process more efficient.

Minghe is an ISO Certified Die Casting Manufacturer and has extensive experience in designing and manufacturing zinc and aluminum parts to pump valve quality specifications.

Positive displacement pump/impeller pump/jet pump/vertical pump/horizontal pump/single suction pump/double suction pump/motor pump/steam turbine pump/diesel pump/diaphragm pump;

Currently, our pump valve casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Customchina die casting service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China"s top die casting service since 1995.

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.

Vacuum Casting is a casting process in which metal is smelted, poured and crystallized in a vacuum chamber. Vacuum casting can minimize the gas content in the metal and prevent metal oxidation. This method can produce very demanding special alloy steel castings and extremely easily oxidized titanium alloy castings. Minghe Casting has a vacuum casting sub-factory, which is enough to solve all the problems related to vacuum casting

Incepted as a Sole Proprietorship firm in the year 2007, in Ahmedabad (Gujarat, India), we “Maruti Inv Steel Cast are engaged in manufacturing, exporting and supplying of Aerospace Casting Parts, Agriculture Casting Parts, Automotive Casting Parts, Defense Castings, Architecture Casting Parts, Glass Fittings, etc. Due to features like durability, dimensional accuracy, corrosion resistance and easy installation, these products are highly acclaimed in the market. We export these products to European countries and Croatia.

The bimetal liner (composed of two housing parts and an insert). The outer part is made ??of round steel billets Article 20, 40,45,40 X, has a high tensile strength, toughness. By means of heat treatment the hardness of the inner surface of the liner is 59-64HRC and it has high wear material insert, cast iron with high chromium content of Cr 26-28%. At nominal operating conditions bimetal liner is capable of withstanding high pressure drilling fluid and provide a period of more than 800 hours of use. Guaranteed period is 400 hours.

Ceramic liner for drilling pumps are designed to operate in harsh geological conditions when working with large oil reservoirs depth, and are also used in offshore oil and gas deposits. Lifetime of ceramic liner is 5-10 times higher in comparison with the bimetallic liner and is more than 4000 hours.

Zirconia ceramic sleeve, developed with the help of technology and increase the phase transformation plasticity, characterized by high corrosive resistance, endurance, high strength and hardness, and the ability to perform work at a high pressure, high temperature. Using this liner reduce costs and drilling time. Compared with steel liners these ones have such properties as higher ductility, increased service life, reduced wear of pistons, etc.

Housing of chrome liner is made of round steel billets Article 20, 45.40 H. Using a special coating technology - the inner hole is coated with hard chrome thickness of 20 microns, through which, the surface hardness reaches 58-62HRC. Term of liners use is more than 400 hours.

Liner is made of round steel billets, st.20X, Article 70. With the technology of high-frequency current hardening, carburizing or quenched in bulk, purity inner hole becomes higher and reaches values of hardness 58-62HRC. Term of use is more than 200 hours.

8613371530291

8613371530291