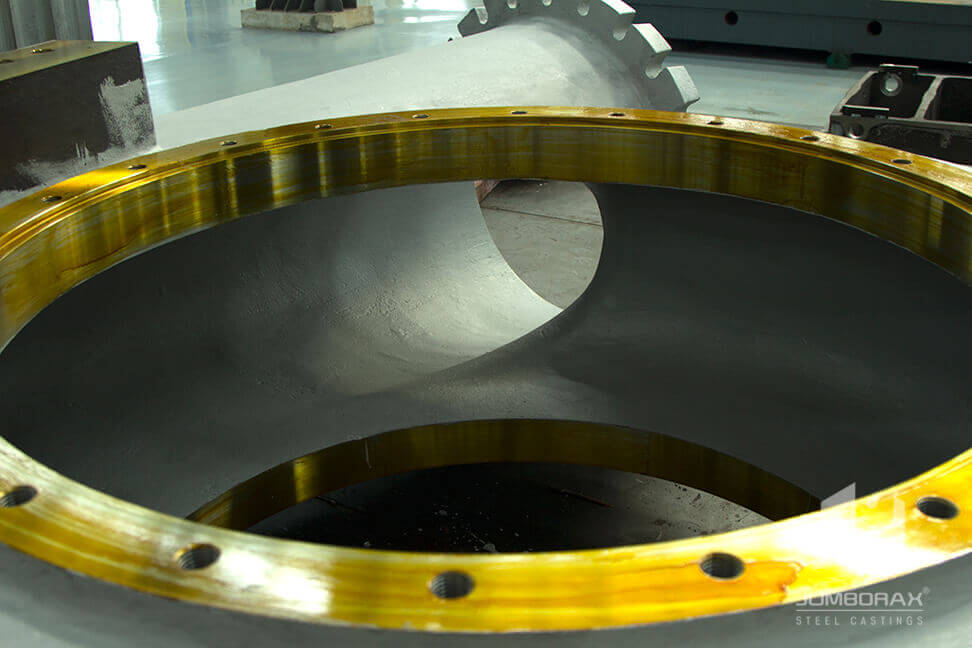

mud pump series steel castings quotation

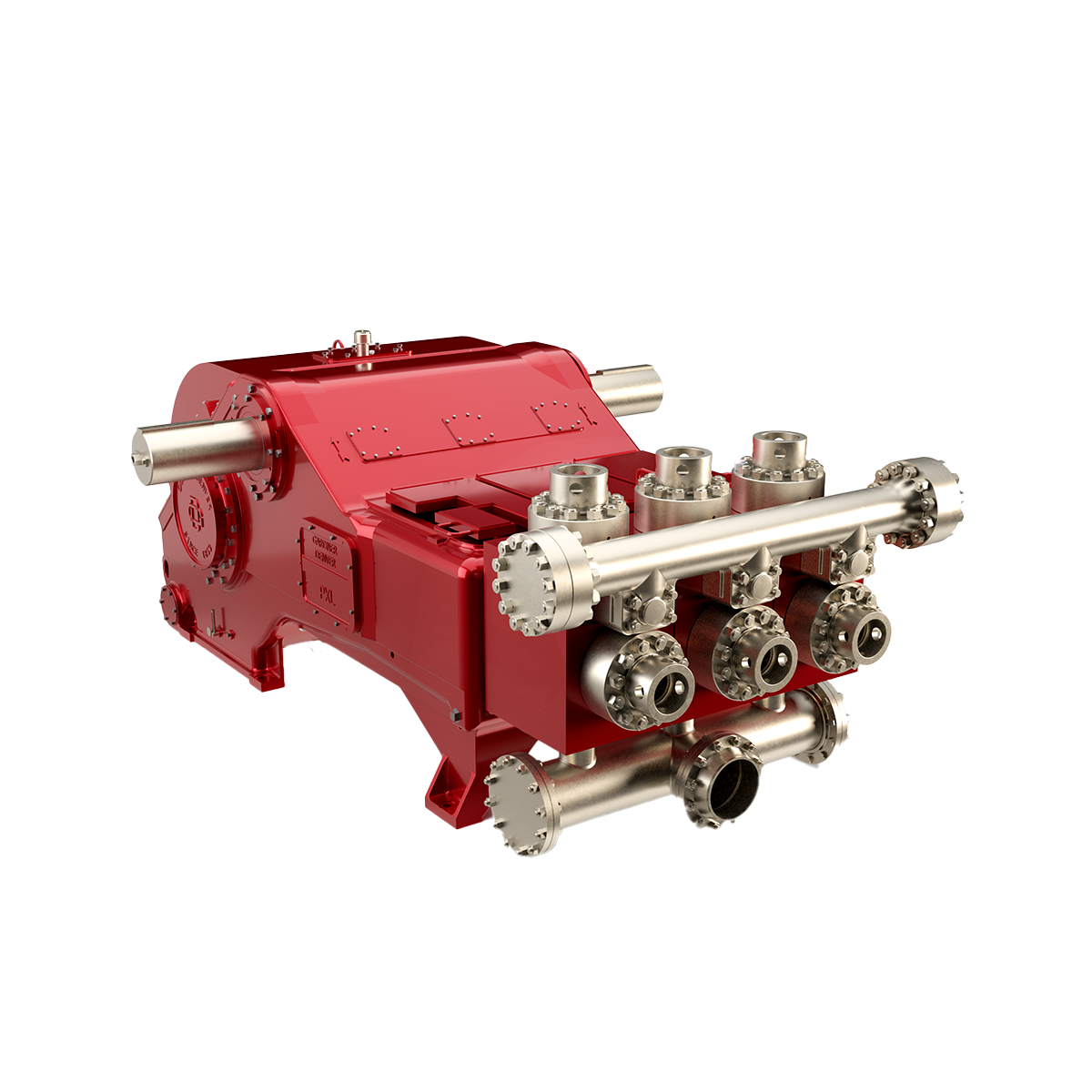

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

F-Series pumps are rated at long stroke length and relatively low strokes per minute, thus they improve the suction performance and increase the service life of the expendable parts on the fluid end.

Our F-Series Mud Pumps feature an advanced and durable design with interchangeable suction and discharge valves, and dual lubrication system.◆Features

The crankshaft, a casted alloy steel eccentric shaft, is furnished with herringbone ring gear, connection rods and bearings. The ring gear bore and the crankshaft surface is of interference fit and fastened with bolts and lock nuts.The big end of each connection rod is mounted on each eccentric strap of the crankshaft via the single row short cylindrical roller bearing. The small end of each connection rod is mounted on the crosshead pin via the double row long cylindrical roller bearing. Double row radial spherical roller bearings are mounted on either end of the crankshaft.

The crankshaft, a casted alloy steel eccentric shaft, is furnished with herringbone ring gear, connection rods and bearings. The ring gear bore and the crankshaft surface is of interference fit and fastened with bolts and lock nuts.The big end of each connection rod is mounted on each eccentric strap of the crankshaft via the single row short cylindrical roller bearing. The small end of each connection rod is mounted on the crosshead pin via the double row long cylindrical roller bearing. Double row radial spherical roller bearings are mounted on either end of the crankshaft.

Gears. Continuous to Sykes herringbone construction. Main gear is heat treated high-grade ductile iron. Pinion gear is cut from forged alloy steel and hardened.

Power Frame. Alloys stocked are Molybdenumâs cast iron and cast steel. Fluid ounce can be trimmed out for pumping various liquids. Ductile iron can be furnished upon request.

Liners. All pumps are available with interchangeable pipe liners. Standard materials available are Molybdenums alloyed iron, file hard steel and special corrosion resistant liners.

Valves. Valves and seats are available as follows: hardened and ground steel wing guided, bronze wing guided, steal or bronze insert type, direct blood valves for use on cast iron or bronze seats. McClatchie and mission can also be furnished.

Stuffing Box Lubrication. Furnished by use of regulated flow of oil from a force-feed lubricate or mounted on the pump, with a separate oil line to each stuffing box.

Explore a wide variety of cast iron mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These cast iron mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these cast iron mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right cast iron mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of cast iron mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

*Note: The Mud Pump Shell we displayed are not Standard Producing Unit. JUMBORAX is an OEM/ODM service & manufacture plan solution provider, all the products we displayed are samples just helping us to show our production capabilities. All the designs belong to our customers that we can not sell the products to others. If you wish to make your products, please Contact Our Customer Service with your ideas or drawings for further cooperation. Thank you very much.

Mud Sucker Pro Series air driven diaphragm pumps use check ball technology in the suction and discharge valve chambers to pump slurries, abrasive fluids, solids and general wastewater. Access to both the suction and discharge areas is available within seconds.

The Mud Sucker 4B-EC includes a standard emergency pressure relief valve. Since a diaphragm pump is also a positive displacement pump, a pressure relief valve reduces the chances of damage in an over pressurization event.

The only diaphragm pump in the industry with an exclusive pump body designed to enhance the flow of slurries and debris laden liquids to prevent clogs.

Ships complete with safety guards. Pump operator does not come into contact with moving components when guards are in place (removed in illustration above for clarity).

4. The pump can be installed with agitator or cutter device according to the requirement from customer. Agitator, which rotates with motor shaft, produces very strong agitation force, makes sediment become sestons to discharge. Cutter, which cuts the long fibers, plastic, paper bag, straw into pieces to discharge..

ISO 9002 certified distributor of a wide range of pumps & related process equipment including: diaphragm, progressive cavity, Leakproof canned motor centrifugal, Hastelloy C process centrifugal, corrosion resistant gear, epoxy, internal gear, Hydra-cell high pressure diaphragm, centrifugal, Iwaki centrifugal, modular drum and container, centrifugal, side channel & vertical inline, centrifugal & multi-stage centrifugal. Custom manufacturer of fiberglass sump & spill-stop pumps. Services include pump repair, re-building industrial mechanical equipment to factory standards & dynamic balancing. UL certified for rebuilding Class I, Group C & D, Division I, XP equipment. Factory authorized service for most products.

Stainless steel casting involves creating an original wax model, building the image with plaster and successive layers until a strong shell surrounds the model. After melting the wax, pour the molten stainless steel into the mold to create a perfect replica of the original wax pattern. Stainless steel casting provides economical undercutting, high resolution, sophisticated detail and smooth surface finish compared to machining separations.

We are a three-decade-old company that manufactures and supplies high quality pumps, for a range of industrial sectors and purposes. Our products are revered for their finesse and integrity which has been honed by our expert engineers. Moreover, as we understand the diverse needs of the dynamic industries we cater to, our products are highly customizable.

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacture of rotary Positive Displacement Pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry—from military, to food and beverage, to chemicals, fuels, and plastics—reliably pumping materials that are thin, thick, hot, cold, liquid, solid, etc.

8613371530291

8613371530291