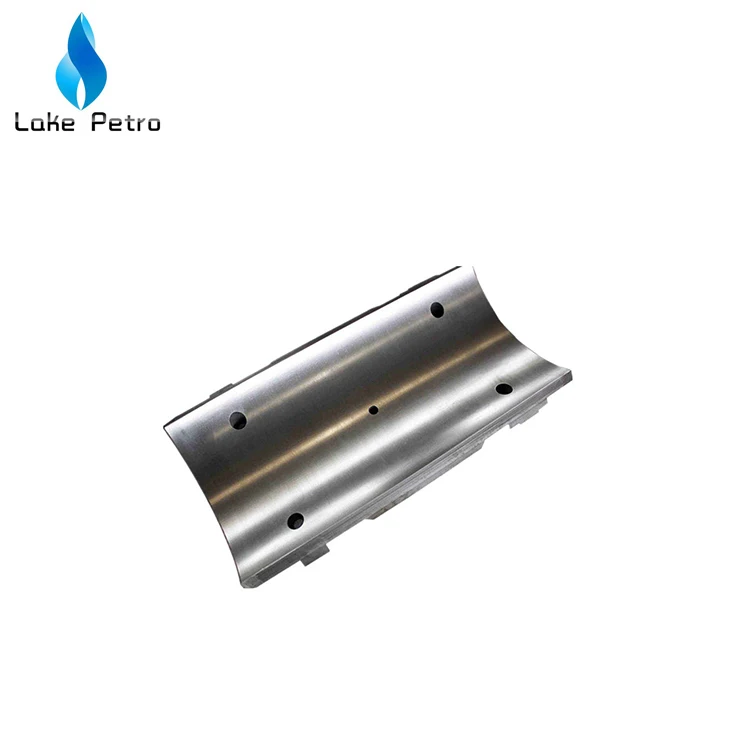

mud pump slide upper quotation

Browse through more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. EC Tool gives you a quote before your order, so you know what you’re getting for your money every time. While we primarily keep connecting rods for GA550 and GA750 models in stock, there are other options at your disposal as well. This includes custom connecting rods for most duplex and triplex mud pumps.

We now offer new crossheads and capsules for both EMSCO D-375 and DB-550 duplex pumps. You can also find slides and shoes for certain models. Available parts currently in our inventory include:

A top-performing solution for the oil and gas industries, our 10,080 gallon (240 BBL) open-top mud tank combines smooth interior walls with a sloped V-shaped bottom for easy drainage. Features include top-mounted sidewall support braces and durable one-quarter-inch steel-plate floors and walls make this tank an optimal choice for drilling and boring operations.

Since creating the first drilling mud pump more than 100 years ago, Gardner Denver Pumps has had a reputation for setting new industry standards for high-performance mud pumps for drilling rigs. Our customers prefer our drilling pumps because of the field-tested durability and ease of maintenance.

All Gardner Denver triplex pumps are machined for extreme applications and built for resilience. Our sub-assemblies, including our power ends and long-lasting fluid ends, maximize the efficiency and productivity of each Gardner Denver mud pump.

We know mud pumping requires durable drilling pumps built to withstand severe conditions. That’s why our fracturing hydraulic pumps are engineered with high-quality materials and tough construction for maximum resilience.

NexGen Manufacturing & Supply keeps a wide variety of replacement parts in stock for mud pumps, plunger pumps, swivels, top drives, handling tools, and much more! Additionally, we have more than 3,000 prints and drawings of oilfield equipment and

Designed to circulate drilling fluid under high-pressure up to 7500 PSI towards the drill string and backup the annulus, Mud pumps are workhorses that are crucial in drilling rigs. We, at Shalepumps have consistently aided oil and gas exploration with the most rugged and reliable mud pumps. One of the two distinct ends is mud pump fluid end modules, which plays an important role in the function of the pumps. We take a good look at the overall working of the mud pumps.

Operational parameters of displacement and pressure – The displacement is calculated on the basis of the diameter of the borehole, and the pressure mainly depends on the depth of the borehole. Deeper boreholes translate into higher resistance and higher pressure. The pump or the power end incorporates adjustable mechanisms that to adjust the pump displacement. The gearbox or hydraulic motor helps in adjusting the speed to meet requirements. At Shalepumps, we take great pride in the fact that the adjustable mechanism we put into the mud pumps offer greater flexibility in quickly adjusting the displacement.

Double acting reciprocating pumps – Inside a mud pump, pistons operate in cylinders to produce pressure. This pressure is used to suck mud and the suction valve is closed and moves to the left. When the pressure in the pipeline increases, the valve is forced open, and as a consequence, mud gets released. This, in a nutshell is the reciprocating action. The mud pump fluid end modules work in perfect unison and synchronization with the power end to produce harmonious reciprocating action and result.

Mud pumps comprise hydraulics such as hydraulic inlet, cylinders, outlet valve, cooling unit, pistons, pneumatic compressor, safety etc. The pump mechanics include casing, reduction, gear, slide crank mechanism, transmission shaft, drive pulley etc. At Shalepumps, each component is tested and rated to function with great efficiency, with longer runs in the most demanding conditions. The mud pumps that we manufacture at Shalepumps make good use of the suction and pulsation dampeners to keep vibration levels low. With lesser vibrations operations are unhindered by frequent maintenance or repairs.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

The Riserless Mud Recovery (RMR) System is a new and emerging technology for top hole/open hole drilling. The technology is planned to be used in Russia in 2006. The RMR Technology is applied for the open hole sections (no BOP installed), enabling return of fluid and cuttings in a closed system. A subsea mud pump is returning mud and cuttings to the drilling rig for treatment/recirculation instead of dispersal on the seabed. Since weighted mud is used the risk of shallow gas influx is reduced compared to conventional top hole/open hole drilling. However, since the return is routed to the platform, shallow gas is a cause of concern.

A new transient coupled reservoir-well two phase well control simulator for modelling drilling and well control scenarios with a dual pump drilling system has been developed.

Shallow gas scenarios during top hole drilling with the RMR System have been simulated and the results evaluated. The focus has been to detect a kick before gas reaches the return line. The evaluations have confirmed that the RMR System is a safe system, which can detect a shallow gas influx prior to gas reaching the return line, and also handle the influx in a safe manner. Modelling further shows that pit gain, sub sea power and RPM of subsea pump are the main parameters for kick indication. These results verify the feasibility of the RMR System related to safety and well control. In addition this System will reduce discharges to sea during top hole drilling, as well as significantly reduce the frequencies of shallow gas incidents.

Central lubrication manifold system with Stainless Steel tubing for feeding all main, eccentric, and pinion bearings. Pressurized lubrication is also provided to the upper and lower crosshead slide for longer crosshead life

The article presents selected technical issues relating to drilling performed by a drillship, one type of drilling rigs. Basic problems encountered in the main function of such rigs − drilling a well − are failures of mud pumps. The authors investigate these pumps in operational conditions, aiming at development of a system for monitoring the technical condition of these pumps. Work on a diagnostic system is in progress that will permit to predict the condition of mud pump valves well in…Expand

2. “There are only two kinds of women in the world, those who love shoes and those who had the misfortune to be born without the ability to experience total bliss on finding a pair of perfectly designed pumps in the right size at half price.” ― Jane Eldershaw

8613371530291

8613371530291