mud pump supplier in malaysia factory

Soga SpA, Italy is a world-wide well-known manufacturer of synchronous alternators under the brand Sincro. Sincro has close collaborations with the main international gen-sets manufacturers.

Vikas Pumpis a growing Sludge Pump Manufacturers In Malaysiaengaged in offering a wide range of Industrial Pumps, Water Treatment Plant, Demineralisation Plant, Rain Water Harvesting Systems, Transfer Conveyors, Steel Tank, Industrial Chain, etc. to serve various purposes. By serving an excellent range at industry-leading prices, we have become a preferred choice of leading companies to get Sludge Pump In Malaysia. We stand behind our products with confidence, as all our products reflect the standard of quality we explain and we maintain.

As one of the leading Sludge Pump Manufacturers in Malaysia, we make sure to test all our products against several parameters before delivering it to our valuable clients. Our products are the best in the industry and are known for their smooth performance, innovation, excellence and affordability. Our efforts are always in the direction to meet and exceed client expectations. We offer the best Sludge Pump Manufacturers In Malaysia, Our pricing is not just competitive, but it matches the best in the industry. If you are looking for a reliable supplier and Manufacturers of Sludge Pump in Malaysia, you must contact us now.

Our company is managed to attain the position among the top Sludge Pump Exporters and Suppliers in Malaysia. If you want impeccable products, discuss your requirements with our experts. Call us or drop your enquiry to get our assistance today.

Roto Pumps is a leading High Pressure Slurry Pumps manufacturer and supplier. These kinds of pumps are built to transfer slurry- a semi- liquid combination of solid particles and fluid. The nature of these pumps makes them an ideal choice for various industries such as chemical, pharma, food, cosmetics, paper, paint etc. The robust quality of these pumps enables them to handle the transfer of varied kinds of liquids including mud, paints and crude oil. These kinds of pumps are extremely customer-friendly as they can are easy to clean and maintain.

Roto slurry pumps are a subtype of positive displacement pumps and work on the principle of progressive cavity pumps where cavities are from by rotary action of helix metallic rotor inside double helix elastomeric stator. The slurry is then transferred through these cavities from suction to discharge as a result of positive displacement. These pumps are ideal for liquids with varied viscosities, abrasiveness and other chemical compositions. These pumps can easily provide flow rate of 2200 GPM and pressure up to 696 PSI. Also, these pumps can be reversely operated and are non-clogging due to their unique design. Roto slurry pumps works fine in low NPSHR conditions as well.

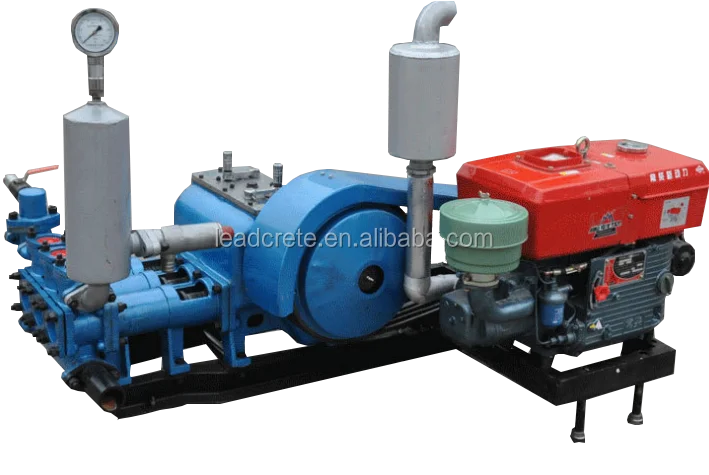

A wide variety of malaysia mud pump options are available to you, such as 1 year, 2 years and 3 years.You can also choose from new, used malaysia mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether malaysia mud pump is 1.5 years, 6 months, or unavailable.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

We manufacturer of mud pump, are presenting our range under “Vijay” Brand name. The offered mud pump is designed to circulate drilling fluid under high pressure and promote the variegated crude oil and mud slurry handling applications in oil & cement segments.

Handling of the mud during the drilling crude oil has become easy with the offered range of the mud pump, thanks to the ingenious configuration of thereof, wherein the inner curvatures of pump casing have been customized to reduce the load on the impeller, whereas raise the discharge volume. In order to prevent the corrosion and early aging, all the wet end parts of this mud pump are engineered using the considerably applauded PP (polypropylene) material attributing excellent corrosion resistance and hence is also perceived as the PP pump or polypropylene pump in the variegated industries.

The effectiveness of this mud pump ensures that drilling mud is circulated profoundly to the bottom of the home at sterling pressure and volume to bring drilling debris out of the well hole and thereby is immensely popular in the domestic as well as global market. Owing the fame of this mud pump (PP pump), we have made it available in the miscellaneous specifications as below.

Ramnath Industrial Park, Rajkot Ramnath Industrial Park, Kothariya Ring Road, Beside Murlidhar Way Bridge Aaji dem, Near Ramvan, Ramnath Industrial Park, Rajkot - 360002, Dist. Rajkot, Gujarat

Amraiwadi, Ahmedabad No. 16, Bankar Estate, Near Anup Estate, Behind Bharat Party Plot National Highway No. 8, Amraiwadi, Amraiwadi, Ahmedabad - 380026, Dist. Ahmedabad, Gujarat

Since 2001, TSC Manufacturing and Supply, LLC has been a leading global manufacturer and supplier of fluid end expendables, as well as mud pump spare parts for oilfield applications. Today, we continue to keep our proud tradition of excellence going, as we strive to better ourselves in order to better our customers" experience. Our global network of inventory locations provides unrivaled quality, customer service, on-time delivery, and unmatched technical integrity.

When it comes to mud pump fluid end expendable parts, TSC Manufacturing and Supply, LLC, has it all. TSC can, and will, match your needs, so that you won’t be lacking in anything. TSC mud pump liners are designed and manufactured to meet or exceed original equipment specification and API standards for almost all types of mud pumps in use today. With advanced technology, metallurgical control, and rigid inspection, we offer unmatched performance and durability, according to customer testimonies, in the most severe drilling conditions; both triplex and duplex liners are available in a wide range of sizes.

Our state-of-the-art repair facilities combine world-class equipment with over 150 years of industry leading expertise, to provide our customers with a comprehensive range of services. If you can’t come to us, we can bring our legendary expertise to you, using our full range of on-site repair and field service offerings.

8613371530291

8613371530291