mud pump valve body insert made in china

A wide variety of mud pump valve inserts options are available to you, such as 1 year, not available.You can also choose from new, mud pump valve inserts,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump valve inserts is 1.5 years, 6 months, or 3 months.

2. The progressive cavity pump with stainless steel material & fluororubber stator could be used to transfer corrosive mud, slurry, dredge, sludge, slush, etc. 3. For customers" different requirements, p ump may be equipped with gear box motor, electric magnetic speed adjustable motor, CVT motor, frequency inverter motor, etc. 4. Widely used in petroleum industry, medicine & daily use chemistary, food industry, construction industry, printing and papermaking, etc.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

Mud pump valve body and mud pump valve seat were produced according to API Specs as well as ISO9001 quality system by our company, were used high quality alloy steel 40CrNiMo、20CrMnTi, processed with overall forging and carburizing, the surface hardness HRC≥60; They were produced under accurate calculation and numerical control lathe, which makes dimensions of valve body and seat perfectly match each other, also were used many times by land and offshore platforms. The service life of valve body and seat are 4-5 times more than ordinary ones, which improves the working efficiency and decrease the cost and working strength.

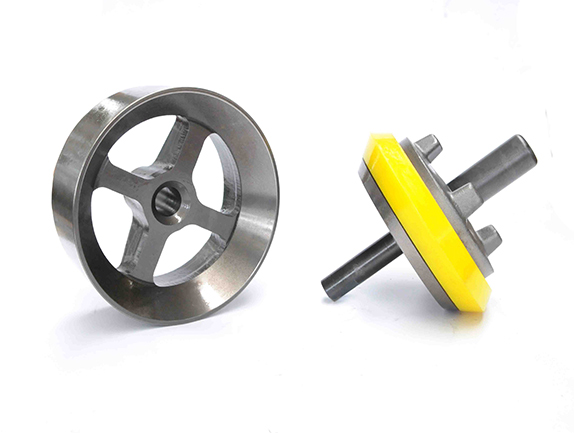

Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). As to valve insert (valve rubber) material, we can provide Nitrile rubber (NBR) valve insert, polyurethane (PU)valve insert, compound polyurethane and HNBR.

The valve assembly is composed of valve body, valve seat, valve insert, etc. The valve body and valve seat are made of alloy steel through strict and reasonable heat treatment process, so that the surface hardness of the workpiece is high, and the core has good toughness, fatigue resistance, impact resistance and tight angle fit. Valve insert is made of oil resistant rubber, epoxy resin glue and other wear-resistant sealing materials.

When the fluid passes through the valve, the valve ball leaves the valve seat, the flow channel is opened, and the fluid can pass through. When the fluid flows reversely, under the action of pressure (or other forces), the valve ball sits on the valve seat, the flow channel is closed, and the fluid cannot pass through the valve. The principle is basically like this. Valve is often used in pumps, especially in multi plunger pumps, to maintain the one-way flow of fluid. Valve assembly is the whole system (each part of the valve) that constitutes the valve.

Revata Engineering offers very high quality and precision machined sleeved bi-metallic liners finished to relevant API dimensions. They are available for various pumps, manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others.

Piston Assemblies are available both in single and double acting type. They are available for different models of pumps manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others. Piston rubber of piston assemblies are manufactured by using very high strength polymer with very tough fabric backing. Special care is taken for accurate dimensions of Piston body to ensure very long life. Revata Engineering"s piston assemblies give very long life even under extreme working conditions.

Valve Assemblies consisting of Valve Seat, Valve Body, Valve Spring & Valve Insert are available for different models of pumps manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others. Special care is taken for the dimensional matching of valve seat and valve body working angles for ensuring very high life even under extreme working conditions. Valve Inserts are made out of high quality polyurethane material.

Revata Engineering manufactures Valve Cover Gaskets & Packing out of special grade of rubber compounds for the specific applications. The rubber compound has been developed by our Research & Development team after intensive research and customer inputs. Packings, require skill-full manufacturing technique have also been developed after intensive application research and now they are rated as one of the best in the market.

Other items like Piston rod, Lantern Ring, Liner Wear Plate, Liner Gasket, Wiper Rod, Oil Seals, Valve Guide, Bushing, Liner Wear Plate Gaskets, are also available for different models of pumps of Oil Well, National, Gardner Denver, Omega, Ellis, Williums, Bournedrill and others.

Valve Seat, Valve Body and Valve Nut are manufactured by using forged carbon steel / stainless steel as per the requirement of the users, suitably hardened grounded finished and hard-coated, wherever required. Special care is taken for dimensional matching between Valve Seat and Valve Body working angles to ensure long-life under severest of working conditions. Inserts are available in polyurethane and other polymers to suit customers’ requirement.

Stem-guided valve &Tri-arm seat features greater fluid flow than four-arm seats, as well as it features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing.The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert.

Stem-guided valve & Cross-arm seat features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing.The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert.

Three-wing guided valves and full open seats features greater fluid flow than four-wing valves, the unibody forged valve features greater strength than traditional welded-wing valve. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation.

HNA makes two styles of Four-wing guided valves and full open seats which feature greater fluid flow through the full open seat. The full open seat provides easier valve maintenance and seat pulling, in valve-over- valve fluid ends.

Innovative unibody Four-wing guided valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation. This combination will handle lost circulation material better than most conventional style valves and seats while the seating angle greatly improves flow characteristics and the heavy-duty load bearing capacity greatly improves service life.

The unibody forged Four-wing guided valve & Full open seat features greater strength than traditional welded-wing valve. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Delian valve and seat are made of forged alloy steel with deep carburized wear surface. We offer a full range of valves and seats which include full open valve and seat, 3 web / 4 web design valve and seat.

The valve comes with full open seat features four guide wings. They are either inertia welded to the valve body or uniformly forged with valve body. The urethane insert can be easily snapped on.

We are offering mud pump valve body. shandong, china (mainland) brand name singho model number xl105 application mud pump material steel name mud pump valve body fininshing epd coating treatment carburizing and hardening certificate iso9001:2000 volume 28.6 cubic inch weight 7.5 lbs name: mud pump valve body full open plate type material: alloy steel, ductile iron, grey iron finishing: epd coating deep carburized wear surface heavy-duty valve design no welding dimensions and tolerances per ansi y14.5 1.these parts are used for mud pumps. We also make other parts for mud pumps like valve seat, piston, spring, pump plate, retainer etc. 2 they are made of alloy steel without any welding on the parts. 3. They are treated by carburizing and hardening. 4. Epd coating is made before packing. 5.dimensions and tolerances per ansi y14.5 6. All the parts are made according to customer’s requirements. 7. We mainly made the products as per customer’s drawings.

Valve assembly is composed of valve seats, valve body, valve spring & valve insert and valve guide.They are available for different models of pumps, such as Emsco, IDECO,Halliburton, Oil Well, National, OPI, Gardner Denver and others.Valve Seat,Valve Body and Valve Nut are manufactured by forged premium carbon steel,or according to the requirement of users. Valve Inserts are made of high quality polyurethane and other polymers to suit customers" requirement.

Our standard valve is offered with polyurethane inserts rated for 170° to 180°F (77° to 82°C) drilling-mud temperatures. We also offer a special high-temperature urethane compound as an option for high-temperature drilling conditions to 200°F (93°C) and higher.

4.The rubber sheet is made of polyurethane material which improves the service life of valve assembly, the operational use time is more than 300 hours.

8613371530291

8613371530291