nabors drilling mud pump manufacturer

Managed Pressure Drilling (MPD) is an adaptive process used to more precisely control the annular pressure profile throughout the wellbore while drilling. Converting conventional atmospheric drilling to a closed circulating loop system enables the driller to optimize mud weight and rate of penetration (ROP), more quickly detect influx and fluid loss, and discriminate wellbore ballooning and breathing. This results in lower mud product cost, less stuck pipe, and potentially fewer casing strings.

The MPD process is executed by controlling flow conditions to maintain bottom-hole pressure according to a modeled pore pressure and fracture gradient drilling window. While the benefits of conventional MPD techniques are well known offshore, the economics of engineering, mobilization and rig-up, and additional specialized personnel requirements are not supported in cost-sensitive drilling programs such as unconventional land drilling.

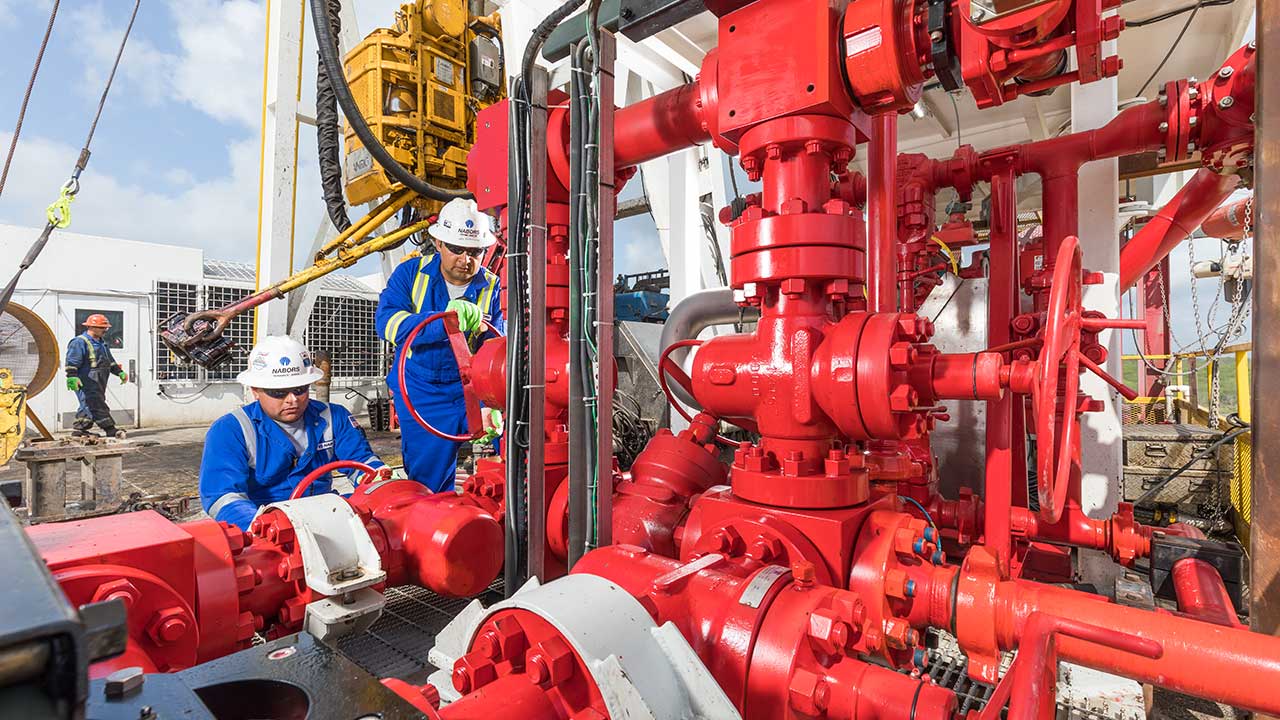

Nabors’ fit-for-purpose MPD equipment and integrated rig services enables a new concept to leverage today’s advanced land rig infrastructure including drives, manifolds, tanks, pumps, and gas handling equipment. Engineering and integrating MPD capabilities into the rig with unique automated workflows unlocks advantages in capital requirements, eliminates the need for pre-job surveys and engineering, and minimizes high mobilization and rig-up costs.

Through the advanced integration and automation of MPD services, the need for third-party service providers is also eliminated. Benefits include increased safety, less HSE exposure, lower cost, reduced pad footprint, more efficient rig moves, and more transparent performance analytics. For all of these reasons, scalability of MPD services is now more cost-effective for land drilling operations.

Designed to deliver maximum drilling performance, the PACE®-M800 rig further enhances drilling efficiencies and reduces flat time. Its simplified design enables faster, more advanced walking capabilities and quicker rig-up and rig-down times to reduce move times and lower drilling costs.

When drilling laterals at or greater than 7,500 feet, the PACE®-M800 rig’s racking capacity eliminates the need to lay down drill pipe between wells on the same pad.

It provides the required pressure to maximize rate of penetration (ROP) while running rotary steerable systems and during extended-reach laterals with conventional mud motors.

The PACE®-M800 rig also features faster, more advanced walking capabilities for multi-well pad drilling. It is ideal for drilling up to four wells per pad and moves twice as fast as the PACE®-X800 rig. Features include:

Jan. 25, 2023 -- Nabors’ recent acquisition of the engineering technology firm, MindMesh, includes the downhole simulation and modeling technologies that the MindMesh team has developed. Additionally, MindMesh co-founder and Chief Technology Officer Raju Gandikota...

A high percentage of mud motors are considered to be run out of spec by industry standards. The challenge has been to build a reliable motor that can withstand the stresses of more weight on bit, differential pressure, and rotary RPM.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Nabors owns and operates one of the world"s largest land-based drilling rig fleets and is a provider of offshore platform rigs in the United States and numerous international markets. Nabors also provides directional drilling services, performance tools, and innovative technologies for its own rig fleet and those of third parties. Leveraging our advanced drilling automation capabilities, Nabors" highly skilled workforce continues to set new standards for operational excellence and transform our industry.

Maintaining /monitoring the mud pumps and mud pits during operations. Notifying the Driller immediately of any unexplained pit level increases/decreases Verify and record drilling fluid properties at ...

Field Specialist - Directional Driller (DD)Have excellent Directional Driller experience?Do you enjoy working with cutting-edge energy equipment?Join our innovating Drilling Services Team!Our Drilling ...

Assist internal and external customers with troubleshooting of Rig Equipment (Top Drive, Catwalk, Wrench, Drawworks, VFDs, Generators, Mud Pumps, BOP) Expeditiously work to troubleshoot and resolve downtime ...

Field Specialist - Directional Driller (DD)Have excellent Directional Driller experience?Do you enjoy working with cutting-edge energy equipment?Join our innovating Drilling Services Team!Our Drilling ...

“Downhole motor technology, along with reaming-while-drilling and electromagnetic measuring-while-drilling (MWD) technologies have been critical for us in exploiting the Bakken,” said Mark R. Williams, senior vice president of exploration and development for Whiting Petroleum, one of the three most active operators in the Bakken and one of two companies that made the first commercial discoveries in the play back in 2005. Over the past six months, Whiting produced 90,000 bbls of oil from the Bakken and associated Three Forks play.

“The standardization of the 1,600-hp and larger mud pumps is allowing us to drill wells in as short a time as 12 days and increase our rates of penetration (ROP) dramatically,” Mr Williams said. “Reaming-while-drilling technology eliminates the need for us to spend two to three days cleaning out the hole when we finish drilling, and electromagnetic MWD tools allow us to measure various properties of the well while we’re drilling, which results in a savings of another one to two days.”

Encompassing much of North Dakota, parts of South Dakota and Montana and extending into Saskatchewan and Manitoba, Canada, the Williston Basin was deposited in the late Devonian and early Mississippian periods. The basin also includes the shallower Tyler play, where the first horizontal test using Bakken drilling technology is planned for Q4 this year; the deeper Mission Canyon and Red River plays; Duperow; Winnipegosis and Winnipeg Group. Operators also have conducted exploratory drilling in the Exshaw formation in northwestern Montana and Alberta, a region formed at the same time as the Williston Basin with very Bakken-like organic shale.

“From a reservoir engineering standpoint, the reservoir is very tight with low porosity and low permeability, requiring horizontal drilling and multi-stage fracturing to make it produce,” he explained. The Bakken formation also includes the underlying Three Forks interval, where a number of companies are producing, and the Lodgepole formation on top. A newly identified thin zone, the Pronghorn (formerly known as the Sanish), lies below the Lower Bakken and is being explored by some operators.

Whiting has drilled 140 wells in the play, initially drilling short laterals of 5,000 ft. The company quickly embarked on drilling longer single laterals with staged completions, which has proved to be a game-changer in the Bakken, Mr Williams said. “Over time, we began realizing that we got better results with more stages,” he said. “We are now typically running 40 stages per well.”

On average, Bakken wells feature a vertical section of 10,000 ft with laterals from 9,500 to 10,000 ft for a “perfect L shape,” Mr Williams continued. Operators can hold a 2-sq-mile lease space by drilling a single well and establishing production, then return several months later, put a pad at one end of the unit and drill several wells, often alternating between the Middle Bakken and the underlying Three Forks zone.

Rigs that can move long distances from county to county are optimum for drilling the initial held-by-production (HBP) wells, Mr Williams explained. “These rigs need to be able to break down into as few truckloads as possible because trucking in the region is hard to get and expensive. For the subsequent pad drilling, we need rigs that can skid easily from well to well.”

Whiting is also doing some production in the Red River and Mission Canyon pools, located near the southern end of the basin and in some areas, extending over the Montana-North Dakota state line. “For the most part, this is conventional drilling, and we’re using older, vertical-style rigs to find the reserves. However, the rigs need to be mobile and, ideally, truck-mounted,” Mr Williams said. Operators also are testing horizontal drilling applications for drilling the 11,000-ft vertical wells in these plays.

Globe Energy Serviceshas designed a five-axle land rig providing quick rig-up/rig-down operations, a mast with 116 ft of clearance and an adjustable drilling floor. Two of the new Mustang 600 Class rigs have been deployed to the Permian Basin for unconventional oil shale wells, and a third is working in the Kilgore gas field in East Texas. A fourth rig will be added this fall, also to the Kilgore field. Opportunities to deploy additional rigs to the Bakken and Eagle Ford are possible as well, according to Johnny Slaughter, vice president of well services. “The taller mast is a key element of this new rig, because the operator can rig up and clear the wellhead control equipment from the ground instead of a ramp,” Mr Slaughter said.

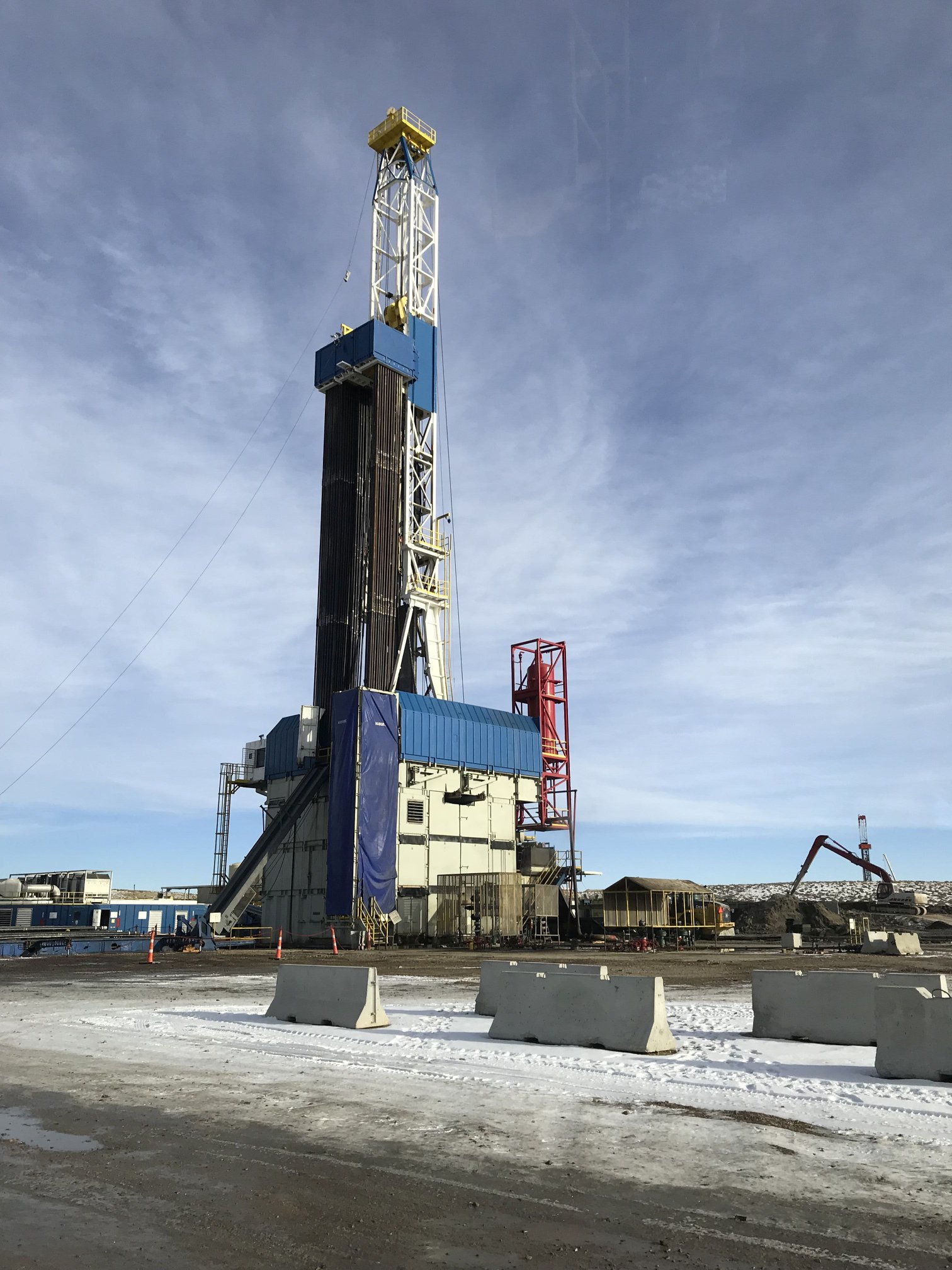

For drilling contractors, the Bakken has served as a catalyst for designing rigs that deliver the horsepower, mobility and automation that are driving production. With 57 active rigs out of a total Bakken rig count of 230, Nabors Drilling USA (NDUSA) is the largest contractor in the play. The company’s PACE-B (programmable AC electric) Series rig, a box-on-box, 1,500-hp model with a walking system, was built specifically for the Bakken and has consistently drilled 21,000-ft wells in less than half the time of most rigs in the basin, said Joey Husband, senior vice president and general manager of NDUSA.

Nabors currently has 25 PACE-B Series rigs in the region and will add four more later this year. “This rig is well suited for the Bakken, which is unique because the local infrastructure is under a lot of pressure,” Mr Husband said. “Drilling generates a lot of other activity, such as trucking and transportation, water delivery, fuel consumption, and delivery of parts and supplies.”

The pump horsepower and hydraulic torque specifications of the rig’s top drive system are designed with enough capacity to reach 21,000-plus ft well depths with long horizontal sections. The box-on-box design is climate-controlled with an enclosed system to allow for drilling in the winter. Dual fuel power systems take advantage of the natural gas available on site, reducing diesel fuel requirements.

“The beauty of this rig is that the walking system allows it to line up perfectly over each well, which allows for more efficient drilling,” Mr Husband said. “This precludes problems sometimes seen with conventional rail systems where conductor pipes are pre-set prior to the rig arriving on location and slightly off center from each other.”

For multi-well pads, the walking system allows a full setback of pipe to be left in the derrick, with stands made up, so the rig can walk to the next well and immediately start drilling. “This saves time and allows for simultaneous operations on the rig, he added. “For our customers who are drilling pads with up to seven or eight wells, we can quickly and efficiently walk down the well row as we drill.”

“Like most unconventional plays, the Bakken features tight oil or gas formations, and every operator has a different way of drilling the hole – some are vertical, some horizontal and some are S curves,” said Jay Thiessen, onshore global business development manager. “In many cases, operators are going into areas where transportation is difficult or road conditions don’t allow wide loads. Sometimes the formations require higher-than-than usual horsepower, more hydraulics for pumping or have high-pressure zones that require a higher-pressure blowout preventer (BOP) stack. In cases of pad drilling, the spacing is often very tight.”

But while drilling plans vary, a common theme in the Bakken is that operators are drilling long, extended laterals, which is why pad drilling is so prevalent, saidNiels Meissner, product technical manager for NOV. “For any unconventional tight oil or gas formation, in order to maximize the productivity of the well, an operator must maximize contact of the borehole with the productive part of the formation,” he said.

The company is designing rigs and equipment packages that are increasingly automated. “We’re looking at more drilling solutions that minimize personnel and that translate to more automation,” Mr Thiessen said. Features are currently still more semi-automatic in nature, keeping a person in charge versus relying on robotics. “For example, we’re developing a program for one customer where the driller pushes a button to initiate both the tripping and drilling cycles. More autonomous control systems, like our NOVOS system, will be coming onto the scene in the next few years, in the Bakken and elsewhere.”

From a drilling performance perspective, the company has two top drive software enhancements that can be installed on any rig equipped with an NOV top drive, Mr Meissner explained. SoftSpeed is a top drive control software upgrade that reduces or eliminates stick-slip, which often occurs when drilling extended-reach or long lateral wells. Another top drive enhancement, Twister, enables the top drive to put minor oscillations in the drill string to reduce friction when slide drilling.

“The technology also aids the directional driller in maintaining tool face, or orientation of his directional drilling tools,” he said. “For example, the driller can input a certain desired rotational angle into the system, and Twister will automatically compute and rotate the top drive a specific degree to achieve the desired angle of rotation downhole.”

In line with the trend toward multi-well pads, Marathon Oilis drilling on more two-well and four-well pad locations and plans to go as high as six to eight wells per pad, or more, using modern rig technology such as Helmerich & Payne’s (H&P) FlexRig 3s, said Jim Thompson, Marathon’s drilling and completions manager for the Bakken. “The multi-well pads limit the footprint and the impact on the infrastructure and communities,” he explained. “In some areas, especially the Badlands, the topography is such that the only way we can effectively develop certain acreage is to drill from a multi-well pad.”

Marathon Oil is seeing average measured well depths of approximately 20,500 ft; however, in the Badlands around the Missouri River and Lake Sakakawea, operators are drilling longer, 2 ½-section wells and looking at three-section wells for depths from 22,000 to 26,000 ft. “The geography of the area necessitates the need for longer laterals,” Mr Thompson said. “There also are ranges where we need extended lengths to drill under the lake.”

H&P has 35 rigs operating in the Bakken, approximately 65% of which are FlexRig3s, which is designed to accommodate a single-direction skid system that allows the rig to drill either a single-well pad or a single row of wells on a pad, said David Millwee, H&P’s vice president for performance solutions. The company has yet to venture into the basin’s experimental formations. “When we first arrived in the Bakken in 2006, we were drilling 16,000- to 18,000-ft measured depth wells with laterals of 6,000 to 8,000 ft,” he said. “We’re now drilling 10,000- to 12,000-ft laterals and recently extended to 14,000-ft laterals.”

H&P is also running its Flex4S rigs in the area. These rigs have similar design features as the Flex3 but are built specifically for pad drilling and incorporate an X/Y skidding system to be used for multi-well pad drilling in the Bakken.

Introduced in 1998, the FlexRig is now in its fifth generation. “The Flex3 has been a workhorse for H&P since 2002, improving drilling times and reducing costs for operators,” Mr Millwee said. “The characteristics of the rig are set up very well to drill the 22,000-ft and greater measured well depths we’re now seeing in the Bakken.”

PACE is a registered term of Nabors Industries. IDEAL, NOVOS, SteelToe, Twister and SoftSpeed are trademarked terms of National Oilwell Varco. FlexRig is a trademarked term of Helmerich & Payne.

* During daily rig visits, utilizes the Safety Checklist developed by the HSE department. The checklist documents deficiencies in Fall Protection, Safety Equipment, Best Practices, JSA"s and daily safety paperwork. Assist drill crew and rig manager with correction of the deficiencies. Report to Drilling Superintendent and HSE Supervisor those areas where assistance is needed to correct deficiencies.

* Perform incident investigations to find corrective actions for Near Misses, IFO"s, FSA"s and FAP"s. Report corrective actions to the Drilling Superintendent, HSE Supervisor and Operator, if requested.

* Utilizing the DSAIL (Drill Site Action Item Log), record items needing correction resulting from investigations, checklists and audits. Email Rig DSAIL to Drilling Superintendent and HSE Supervisor to monitor completion of action items.

8613371530291

8613371530291