newman's mud pump gpm in stock

pump gpm in stock"/>

pump gpm in stock"/>

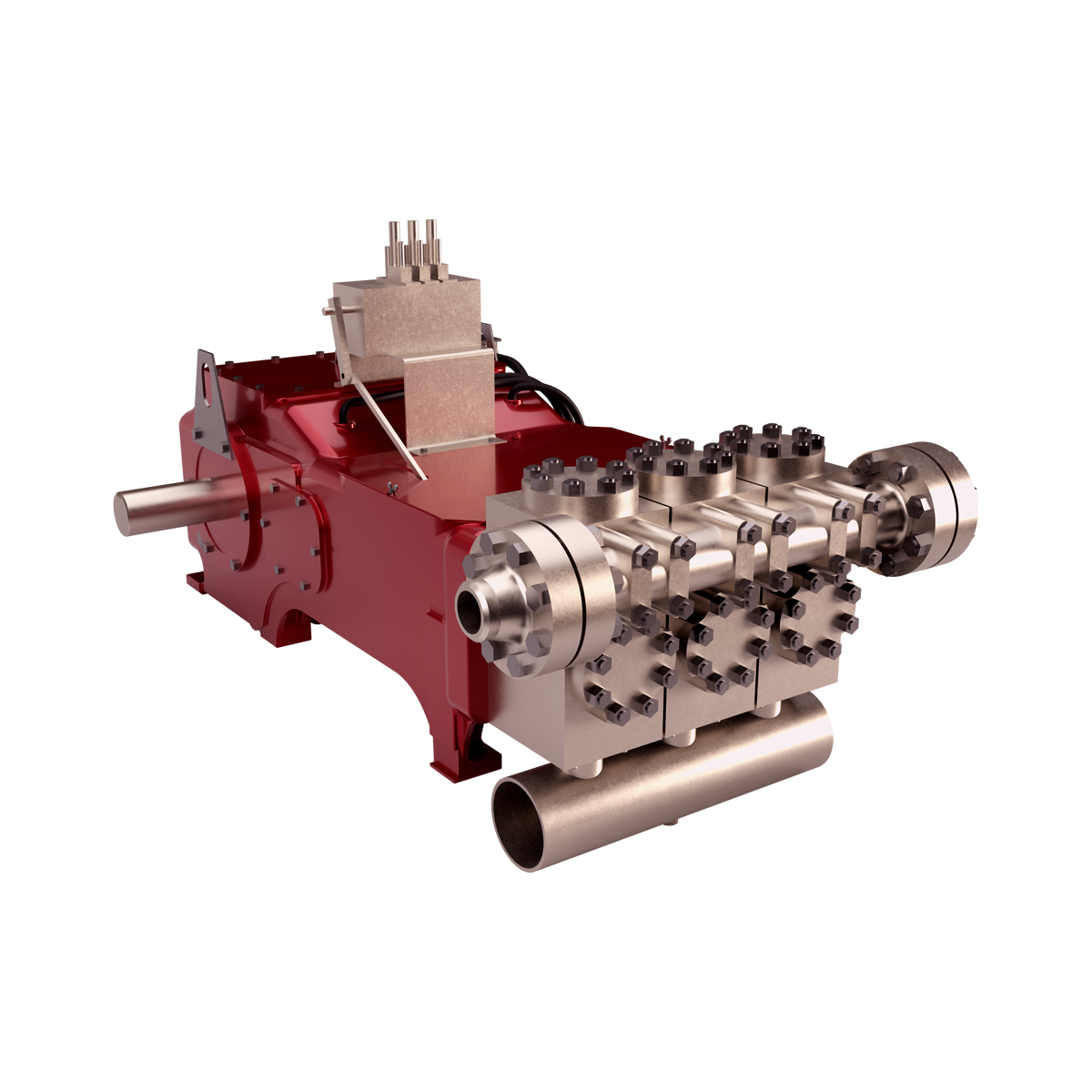

Single Acting Triplex pumps come with three cylinders and are commonly used for various applications requiring low to medium flow rates including mud pumping, cement pumping, salt water disposal, descaling, high pressure pumping, Frac pumping and pipeline systems for the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors. We have new, used and rebuilt API 674 triplex pumps of all leading manufacturers like Union, Gaso, Emsco, Apex and Wheatley.

pump gpm in stock"/>

pump gpm in stock"/>

Single Acting Triplex pumps come with three cylinders and are commonly used for various applications requiring low to medium flow rates including mud pumping, cement pumping, salt water disposal, descaling, high pressure pumping, Frac pumping and pipeline systems for the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors. We have new, used and rebuilt API 674 triplex pumps of all leading manufacturers like Union, Gaso, Emsco, Apex and Wheatley.

pump gpm in stock"/>

pump gpm in stock"/>

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

pump gpm in stock"/>

pump gpm in stock"/>

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

pump gpm in stock"/>

pump gpm in stock"/>

Our full-open valves and seats are designed for use in GD Energy Products PZ, F-Series, and National 12P lines of triplex drilling pumps. This gives you options to use these parts across your whole fleet of pumps.

pump gpm in stock"/>

pump gpm in stock"/>

FIG. 1 shows one configuration including the BHA 185, which may be rotated by a downhole motor driven by, for example, electrical power or a flow of drilling fluid. In some embodiments, the BHA 185 may include the downhole mud motor used to provide rotational power to the BHA 185. Drill collars may be used to add weight on the drill bit 190 and to stiffen the BHA 185, thereby allowing the BHA 185 to transmit weight to the drill bit 190 without buckling or experiencing a structural failure. The weight applied through the drill collars to the bit 190 may allow the drill bit 190 to cut material in the subterranean zone 195, thereby creating the wellbore 170 in the zone 195.

As the drill bit 190 operates, drilling fluid or “mud” is pumped from the terranean surface 147 through a conduit coupled to a mud pump to the kelly 160. The drilling fluid is then transmitted into the drill string 175, through the BHA 185 and eventually to the drill bit 190. The drilling fluid is discharged from the drill bit 190 and, typically, cools and lubricates the drill bit 190 and transports at least a portion of rock or earth cuttings made by the bit 190 to the terranean surface 147 via the annulus 172. The drilling fluid is then often filtered and reused by pumping it back through the drill string 175.

As illustrated in FIG. 2A, the mobile wellsite monitor 200 is in wireless communication with one or more wireless sensors 265. The wireless sensors 265 may be identical to or substantially similar to the wireless sensors 165 shown in FIG. 1. In other words, the wireless sensors 265 may be located on or adjacent the rig 155 and measure any number of wellsite variables, such as hydrogen sulfide concentration one or more distinct forces or loads on the hydraulic drilling equipment. In the illustrated embodiment, the mobile wellsite monitor 200 may be in wireless communication with the wireless sensors 265 through a Wi-Fi connection. Alternatively, any appropriate wireless communication protocol may be utilized. For example, the wireless communication protocol may be 802.11a, 802.11b, 802.11g, 802.11n, 802.20, WiMax, and many others. In the illustrated embodiment, the wireless sensors 265 may communicate via the wireless communication protocol to the antenna 245 located at a topmost portion of the mast 235. The data transmitted between the wireless sensors 265 and the mast 235 (e.g., H2S concentration, tong pressure, well pressures, flow/pump rates) may be communicated to the control module 230 as well. Such data may also be stored in the control module 230 prior to transmitting such data to one or more remote locations.

8613371530291

8613371530291