oil and gas mud pump energy manufacturer

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

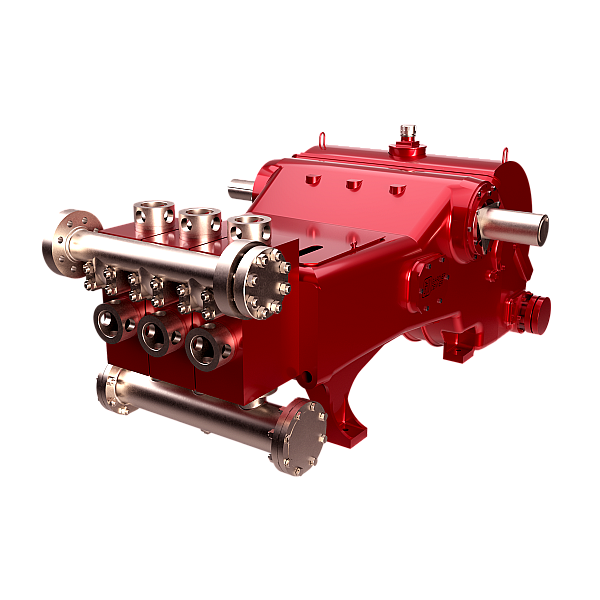

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Our state-of-the-art repair facilities combine world-class equipment with over 150 years of industry leading expertise, to provide our customers with a comprehensive range of services. If you can’t come to us, we can bring our legendary expertise to you, using our full range of on-site repair and field service offerings.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Shortly after founding White Star Pump Co. in 2002, Shaun White had a realization about the standard mud pumps offered by his and other companies to clients in the on- and offshore oil and gas drilling industries. At the time he started the company, White solely designed and manufactured three-piston – or triplex – pumps with interchangeable parts.

“[White] noted that all triplex pumps have the same design flaws,” says Bruce Suggs, vice president of sales and marketing for the Waller, Texas-based company. “He also realized that just about everything in the drilling industry and on rigs had changed in the last 50 years except for one thing – the mud pump.”

White set out in late 2003 to design a pump that did not have any of the flaws commonly found in triplex pumps. These flaws included unsupported crankshafts that bent and cracked, frames that stretched under load, fluid modules that were difficult to replace, rough fluid discharges with large pulses as opposed to a smooth even flow, and their weight and width made transport difficult.

The company in 2006 introduced the White Star Quatro, a four-piston, or quadraplex, mud pump it describes as a revolutionary step forward in technology. “We are the new guys suddenly getting a lot of attention in the industry,” Suggs says of the interest in the product, particularly among smaller oil and gas providers. “We think once companies try it, they will go completely Quatro.”

The Quatro pump features a number of design elements Suggs says distinguish it from the standard triplex pump. One of the main differences is the placement of bearings. In the triplex pump, the bearings are placed on the outside of the frame, with the all of the cylinders in the middle of the pump between the bearings. This design leaves a great deal of space or bending movement between the center piston and the supportive bearings. This generates a great deal of pressure on the pump’s crankshaft as the middle cylinder is firing, and creates a bend in the crankshaft on every rotation, eventually leading to a cracked crankshaft, Suggs says.

In the Quatro pump, the bearing is correctly placed in-between the cylinders, which reduces the load on the frame and crankshaft. This increases the life of the crankshaft exponentially and the bearings by as much as three times that of those in a triplex pump.

Other advantages of the Quatro pump include: lighter weight and a width, two-thirds that of a triplex pump; the ability for operators to replace fluid modules in 25 minutes versus six to 12 hours; the option to add a worm drive, which eliminates the need for belts, chains, right-angle drive and other moving parts; an optional two-cylinder shutdown system, which eliminates the need for a gear box; and a much smoother fluid discharge than triplex pumps.

Many of White Star’s pumps are powered by electric motors manufactured and supplied by Joliet Equipment Corp., an industrial motor and motor repair company headquartered in Joliet, Ill. “They’re a very good company to work with and very responsive to our requests,” Suggs says. “Joliet Equipment is a large company represented all over the world, but they’re just as responsive and supportive as a smaller player. They make a superior product and can get us the motors faster than many larger companies.”

White Star Pump Co. backs up its products with replacement parts and exemplary service. As an example, Shaun White is often on the phone in the middle of the night with new customers, helping them set up pumps and solving any problems they may have, Suggs says.

The company also offers a 10-year crankshaft warranty and a money-back guarantee. “We feel so strongly about the Quatro’s capabilities that we will offer customers their money back within the first six months,” he explains. EMI

During drilling in Oil and Gas exploration, drilling mud or Bentonite is pumped into boreholes for multiple reasons. Pumping drill mud into boreholes cools the drill bit as well as bringing drill cuttings to the surface as the way in which mud is pumped into boreholes forms a closed loop system. The use of drilling mud also provides hydrostatic pressure to prevent liquids such as oil and gas rising to the surface, as drilling mud is thixotropic meaning when it is not agitated it stiffens forming a mud which is an effective liquid and gas barrier.

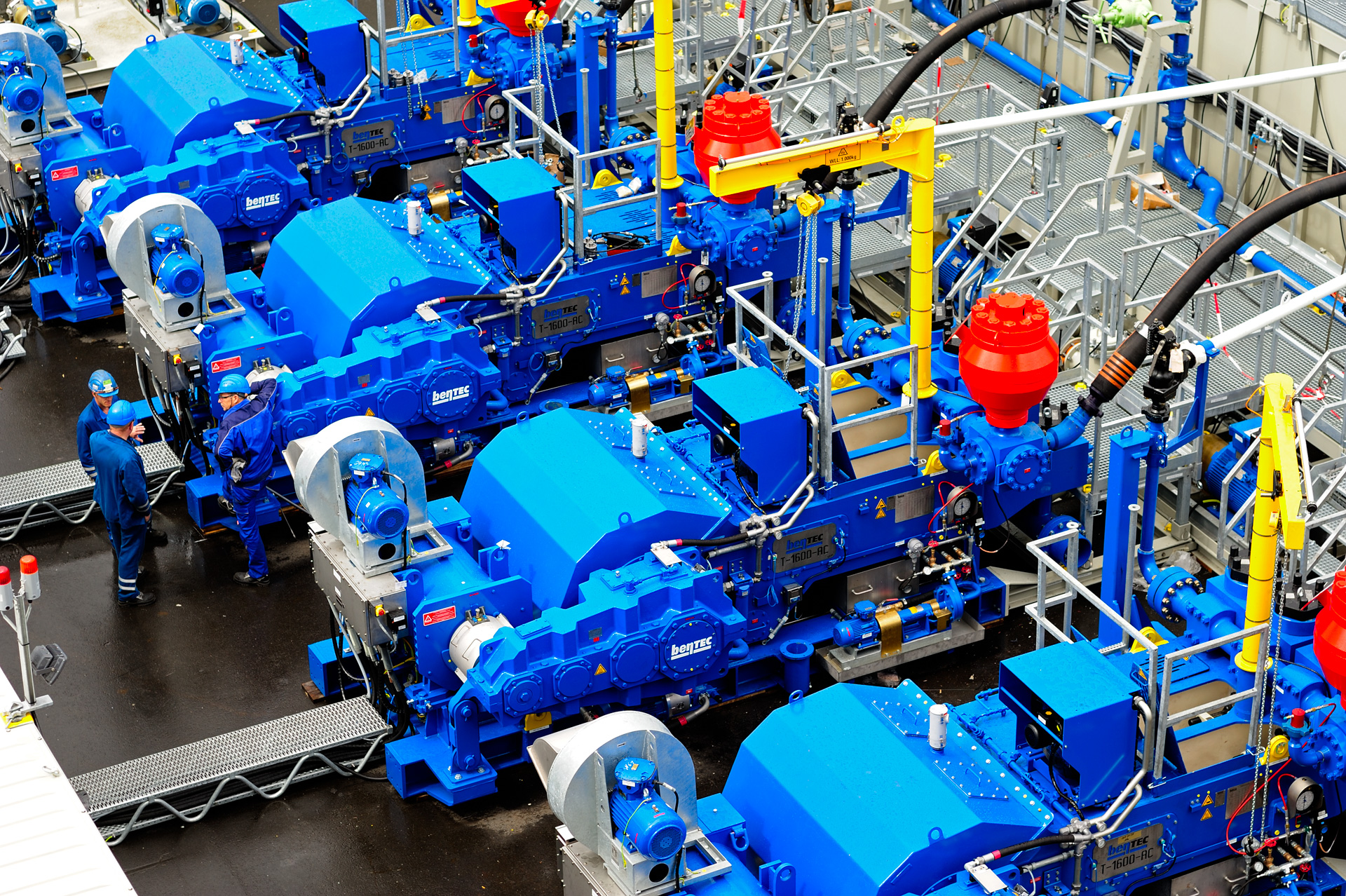

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

This design eliminates the need for chain or belt tensioning systems. The two-stage helical gear feeds directly into a forged/welded crankshaft, which is balanced and provides quiet and vibration-reduced operation.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

Mud pumps are the pumps deployed in the oil and gas industry, mainly to circulate drilling fluids and other kinds of fluids in and out of the drilled wells for exploration. The mud pumps transfer the fluids at a very high pressure inside the well using the piston arrangement. The number of pistons decides the displacement and efficiency of working of the mud pumps, originally only dual piston pumps and three-piston pumps were used, but the technological advancements have seen pumps with five and six pistons to come up. Currently the triplex pumps which have three pistons are used, but the duplex pumps having two pumps are still deployed in the developing countries.

Based on its types, global mud pump market can be segmented into duplex, triplex, and others. The triplex mud pumps will dominate the mud pump marking in the given forecast period owing to its advantages and ongoing replacement of duplex pumps with triplex pumps. Based on operation, the global mud pumps market can be segmented into electric and fuel engine.

The electric mud pumps will dominate the market during the given forecast period due to the advantage of eliminating the harmful carbon emission which is done in the case of fuel engine pumps. Based on its application, the global mud pumps market can be segmented into oil & gas, mining, construction, and others.

The major market driver for the global mud pumps market is the increasing exploration activities taking place in various regions of the world to satisfy the increased energy demand. The number of drilled wells has increased in recent years, which has certainly impacted the growth of the mud pumps market in both oil & gas and mining sectors.

Key market restraint for the global mud pumps market is the drift towards the cleaner sources of energy to reduce the carbon emissions, which will certainly decrease the demand for oil & gas and therefore will have a negative impact on the growth of the global mud pumps market.

Some of the notable companies in the global mud pump market are Mud King Products, Inc. Gardner Denver Pumps, Weatherford, Schlumberger, National Oilwell Varco, China National Petroleum Corporation, Flowserve Corporation, MHWirth, American Block, Herrenknecht Vertical Gmbh, Bentec GmbH Drilling & Oilfield Systems, Drillmec Inc, Sun Machinery Company, Shale Pumps, and Dhiraj Rigs.

The global mud pump market has been segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Owing to the well-established production sector and stable exploration industry North America holds the largest market for the mud pumps. The onshore exploration activities of oil & gas have increased at a good rate in the North America region, which has certainly boosted the growth of the mud pumps market in the region.

The demand from Europe and Asia Pacific has also increased due to exploration activities in both the regions owing to the increased energy demand. The energy demand specifically in the Asia Pacific has increased due to the increased population and urbanization. The Middle East and Africa also hold significant opportunities for the mud pumps market with increased exploration activities in the given forecast period.

In August 2018, Henderson which is a leading company in sales and service of drilling rigs, and capital drilling equipment in Texas signed a contract with Energy Drilling Company for the purchase and upgrade of oil field equipment’s which included three 1600hp × 7500psi mud pumps. This will be the first refurbishment completed at Henderson’s new service center and rig yard.

In January 2018, Koltek Energy Services launched the 99-acre facility for the testing of the oil field equipment in Oklahoma. This will allow the oil field equipment manufacturers to test their equipment at any given time. The company has deployed the MZ-9 pump which has a power rating of 1000Hp.

FET (Forum Energy Technologies) is a global company, serving the oil, natural gas, industrial, and renewable energy industries. FET provides value-added solutions that increase the safety and efficiency of energy exploration and production. We are an environmentally and socially responsible company headquartered in Houston, TX with manufacturing, distribution, and service facilities strategically located throughout the world.

After drilling many dry wells, George Strake Sr. struck oil on December 13, 1931 in Conroe, Texas, just 30 miles north of SWOP’s headquarters. By the end of 1932, his 8,500 acre oilfield was producing more than 65,000 barrels of oil a day.

One of the most expensive and troubling issues with drilling operations is the handling, processing, and circulation of drilling mud along with disposing of the unwanted drill cuttings. The drilling cuttings deposited in the half round tank and are typically removed with an excavator which must manually move the drill cuttings out of the waste bin or roll-off box and into the truck. The excavators are usually rented for this duty and the equipment charges can range from $200-300/day. Add in the cost for the day and night manpower and the real cost for a single excavator can be as much as $1800/day.

Using the excavator method explained above, the unloading of 50 barrels of drill cuttings from the half round can take as long as one to two hours. This task is mostly performed by the solids control technicians. The prime duty for the solids control technicians is to maintain the solids control equipment in good working order. This involves maintenance for the equipment, screen monitoring and changing, centrifuge adjustments, and retort testing to prepare a daily operational summary of the solids control program.

Operating the excavator takes the technician away from these tasks and can lead to poorly performing equipment. Additionally, the excavator has the potential for abuse as some solids control technicians use the climate-controlled cab as a break area or refuge from the elements. Many times, these guys are found asleep on the job.

One solids control company reported the idle time for the excavator can be more than 8 hours for a 24-hour period with 8 hours of operation and 8 hours of shut down time. Fuel and time lost can cause an economic drag on rig operations. And lastly, there have been several accidents on each rig causing a potential for injury, loss of production, and lost revenue as the excavator must be repaired.

Offshore drilling rigs follow a similar process in which the mud is loaded into empty drums and held on the oil platform. When a certain number of filled drums is met, the drums are then loaded onto barges or vessels which take the drilling mud to the shore to unload and dispose of.

Maintaining /monitoring the mud pumps and mud pits during operations. Notifying the Driller immediately of any unexplained pit level increases/decreases Verify and record drilling fluid properties at ...

Perform daily inspections and maintenance on electrical equipment. Comply with the permit to work and isolation systems. Carry out periodic maintenance according to the guidelines Maintain, troubleshoot ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

Assist internal and external customers with troubleshooting of Rig Equipment (Top Drive, Catwalk, Wrench, Drawworks, VFDs, Generators, Mud Pumps, BOP) Expeditiously work to troubleshoot and resolve downtime ...

include but are not limited to safely and efficiently performing all tasks within the Rig Operations Areas of the Platform at the direction and under the supervision of the Crane Operator. Tasks may include ...

and special projects as may be directed. Additional functions N/A Qualifications Necessary qualifications, skills and abilities Able to identify and understand functionality of various rig equipment. ...

and special projects as may be directed. Qualifications Necessary qualifications, skills and abilities Able to identify and understand functionality of various rig equipment. Able to identify and understand ...

Our Technical Sales Representative (TSR) is responsible for building on a very high level of product line & operational knowledge and experience to proactively and strategically sell specific tools, technologies ...

include but are not limited to: Safely and efficiently performing all tasks on the rig floor and B.O.P. area under the direction and supervision of the Driller. Operating the tongs, slips, and spinners ...

Assist higher level technicians, as well as work independently with minimal supervision. Promote a safe and quality environment in which to work Perform preventative maintenance requirements and maintain ...

and special projects as may be directed. Qualifications Necessary qualifications, skills and abilities A High School diploma is required. Should have at least 2 years of specific work experience. Must ...

The Driller must STOP the job if the situation is unsafe and report to Tool pusher. Conducts operations in a safe manner according to Policies and Procedures. Applies proper rig operating procedures, ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

as required by the Driller, Derrickhand or Rig Manage Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

Assists the Crew Pusher and/or TRS Lead in carrying out all routine, non-routine and emergency operational activities around the rig floor areas or any other area of the rig location as designated by ...

as assigned Essential Functions: Attention span to stay alert and attentive for up to 12 hour tour while performing sometimes repetitive and monotonous tasks Able to work 14 days on and ...

are prominent in every aspect of drilling the well, manual handling of tubular and tools, making up or breaking out during making connections or tripping pipe. The position is responsible for the processes ...

Gardner Denver, Lewco, NOV, Oilwell, National, Varco, Woolley, Baash-Ross, Demco, Bomco, Oteco, Brown & Sharpe, Ideco, P-Quip, and Continental Emsco, and the product models referenced on this website are trademarks or registered trademarks of their respective companies. Premium Oilfield Technologies is not authorized by or affiliated with any of these companies, and no business relationship, affiliation, or endorsement is claimed or implied.

8613371530291

8613371530291