oil rig mud pump explosion supplier

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A wide variety of oil drilling mud pumps options are available to you, such as 1 year, not available and 2 years.You can also choose from new, used oil drilling mud pumps,As well as from energy & mining, construction works , and machinery repair shops. and whether oil drilling mud pumps is 1.5 years, 6 months, or unavailable.

During drilling in Oil and Gas exploration, drilling mud or Bentonite is pumped into boreholes for multiple reasons. Pumping drill mud into boreholes cools the drill bit as well as bringing drill cuttings to the surface as the way in which mud is pumped into boreholes forms a closed loop system. The use of drilling mud also provides hydrostatic pressure to prevent liquids such as oil and gas rising to the surface, as drilling mud is thixotropic meaning when it is not agitated it stiffens forming a mud which is an effective liquid and gas barrier.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

As a China top oil drilling rig solids control system manufacturer: GN Solids Control now list the top 10 oil drilling rig manufacturers for your reference.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

Lanzhou LS-National Oilwell Petroleum Engineering Co. Ltd. (LS-NOW for short) is a Sino-American Joint Venture established between Lanzhou Petrochemical Machinery Equipment and Engineering Group Corporation (LS Group) and National Oilwell International, Inc. (NOI). Scope of business: design, develop and manufacture complete land and offshore drilling rigs and workover rigs, and provide equipment package, components, fittings, parts and full services.

Main products: serial drilling rigs that are electrical or mechanical or electrical-mechanical compounded driven and suitable for different applications such as land, shallow, offshore and desert and meet the requirements of drilling and workover services. The drilling depth ranged from 1000 to 9000 meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is a subsidiary of Honghua Group which has been listed successfully in the Stock Exchange of Hong Kong. The company has been engaged in research, design, manufacturing and general assembly of oil drilling rig and equipments for oil exploration and development. Now it is the world’s second land drilling rig manufacturer, and China ‘s largest exporter of drilling rigs.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manufacturers for petroleum drilling rig equipment in China. It is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manufacturing Plant of National Petroleum Industrial Ministry of China). As a former national technical equipment production base, authorized by former national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product trial production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.

RG PETRO-MACHINERY (GROUP) CO. LTD, with its technical center, information center and quality inspection center at provincial level, has possessed 16 production plants for forging, metal machining, heat treatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

SJ Petroleum Machinery Co. , one of petroleum drilling rig and production equipment backbone manufacturers and Manufacturing Base for National Key Equipment (Workover, Cementing and Fracturing Equipment) recognized by National Economy and Trade Commission, has provided lots of advanced equipment to domestic customers in lieu of expensive imported equipment, and played an important role in increasing profits of petroleum industry and decreasing domestic oilfield development cost.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

(shanghai) petroleum equipment co., ltd. is established on august 2001. the 3h is the first rig manufacturer that introduces ship-building technology to the fabrication of petroleum equipment.

Shengli Oilfield Highland Petroleum Equipment Co., Ltd Established in 1992 was a private incorporated manufacturer of petroleum equipments located in Dongying city, Shandong province, the PRC. Through many years development, the company had been recognized and become well-known in petroleum industry achieved the superior position in the field of scale, product quality, technology ensuring and selling service and so on in petroleum equipment manufacturing in China. It possesses 3.5 billion RMB of total assets, owns more than 1,980 thousand square meters of plant area, China’s state-approved high-tech enterprise, China’s patent star enterprise, Shandong Province top 100 and excellent enterprise, Shandong Province unique petroleum equipment R & D center and over 370 engineers and technicians and 150 contracted noted specialists in ceeusro field.

Drilling Rig: Highland Company Drilling Rig Plant has advanced key facilities and assembly workshops for manufacturing rigs and it has enough test sites for assembling 12 sets of large scale drilling rigs at the same time,5 series (ZJ20~ZJ70, including 18 types) of drilling rigs have been developed and manufactured. These developed and manufactured products consist of mechanical drive, DC driven, AC VF drive and Electromechnical drilling rigs, which can handle the well with depth of 1500- 7000m in most of the large oilfields both at home and overseas.

Drilling and well control equipment that are not designed for hydrogen sulfide use could suffer a loss of structural integrity following exposure, which could impede their function and operation during an emergency. Hydrogen sulfide is extremely toxic to humans at minute concentrations. At higher concentrations it is flammable, as well as corrosive to metals. A surface breakout of this gas, if not responded to and controlled immediately, can result in injuries and/or fatalities, fire and explosion. Hydrogen sulfide should be anticipated in all areas of the rig where drilling fluid and associated equipment is present. Those areas include the rig floor, substructure, shale shakers, mud cleaners, mud pit room, mud pump room and well test equipment. Being heavier than air, hydrogen sulfide will settle in low-lying and poorly ventilated areas and will dissolve in oil and water present in those areas.

D) Flowing well testing. During well test operations involving flaring of formation fluids, hydrogen sulfideand sulfur dioxide should be anticipated around the rig.

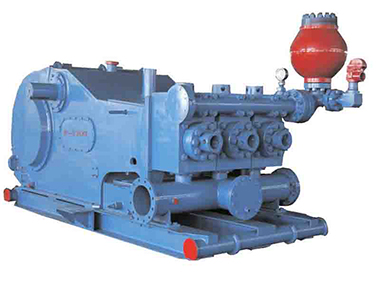

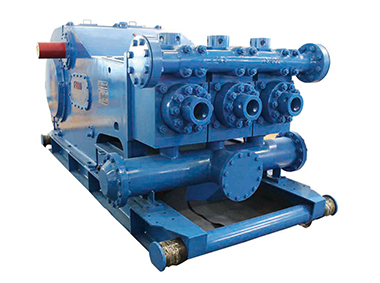

The Baoji/Bomco F1000 Triplex mud pump has a max. working pressure of 5,000PSI and a 6-3/4" liner size. This model is the first choice for the medium and deep dr... More Info

The Baoji/Bomco F1600HL Triplex mud pump has a max. working pressure of 7,5000PSI and a displacement of 46.5L/S with 6" liner size. This model is the f... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Emsco/Bomco 1600 Mud Pump, Unitized 1600 Mud Pump Powered by Two GE 752 Motors Charging Pump, Liner Flush Pump, Relief Valve, Mud Gauge, Etc. ....Call For Price More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - 1 - Rebuilt Gardner Denver PZ-9 Mud Pump Package, New Caterpillar C-27, 1050 HP diesel engine. Belt-driven. comes with pulsation dampener, discharge block, precharge, li... More Info

Mud Pumps - 1 of 3 used Gardner Denver PZ-8 triplex mud pumps. This would be a good rebuildable core. We also have new, rebuilt and good used pumps and packages available for sale ... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

While drilling a coal seam gas well at 28 m the power end covers of the mud pump exploded. Some side cover fragments were ejected up to 8 m away from the mud pump, while other fragments from the drive side of the mud pump damaged the drive belts and cage. The top cover was flipped off, coming to rest upside down at the rear of the mud pump.

Fires were ignited both inside the mud pump and on the exhaust system of the mud pump engine and were extinguished using hand held fire extinguishers.

The internal oil lubrication hose became disconnected from its fitting causing the lubrication pump to dump oil into the sump (Figure 2). Internal piping then failed to lubricate and cool the pump bearings, pistons and crossheads.

Insufficient lubrication within the power end of the mud pump created hot spots (Figure 3) and oil vapour resulting in a low pressure/high volume oil vapour explosion.

Four months prior to the incident problems were experienced with fluctuating oil pressure in the mud pump. Upon inspection it was found that the oil lubrication hose had disconnected from its fitting. This hose was reconnected and tightened by the Rig Manager.

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Fluid barrier of the flexible line. Protects the hose construction from corrosive and abrasive effects of the conveyed medium. The thickness of lining depends on the internal pressure, the inside diameter and the conveyed medium. The lining material is selected to withstand chemical and heat effects of drilling mud, well effluents, cement slurry, hydraulic fluid or whatever substance is conveyed through the hose.

Manufacturer of standard & custom industrial process tanks including garbage tanks & mud tanks used in pollution control applications. Types include aboveground storage tanks & underground storage tanks. Aboveground storage tank types include standard vertical tanks, horizontal tanks, fire resistant tanks, skid tanks, vertical basement tanks & generator base tanks. Underground tank types include oil water separator tanks, steel & fiberglass combination tanks, polyethylene & Mylar® wrapped steel tanks & double walled steel tanks. Tanks are available in different materials, sizes & styles & can be customized as per specifications. Industrial tanks meet UL®, ASME, ASTM, AWS, AWWA & API standards.

Oil tank is the major corollary equipment in oilfield drilling rig, it is mainly used to store and provide fuel to generator set.The oil tank designed and produced by our company is easy and convenient to use and maintain.

8613371530291

8613371530291