oil well drilling rig mud pump factory

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

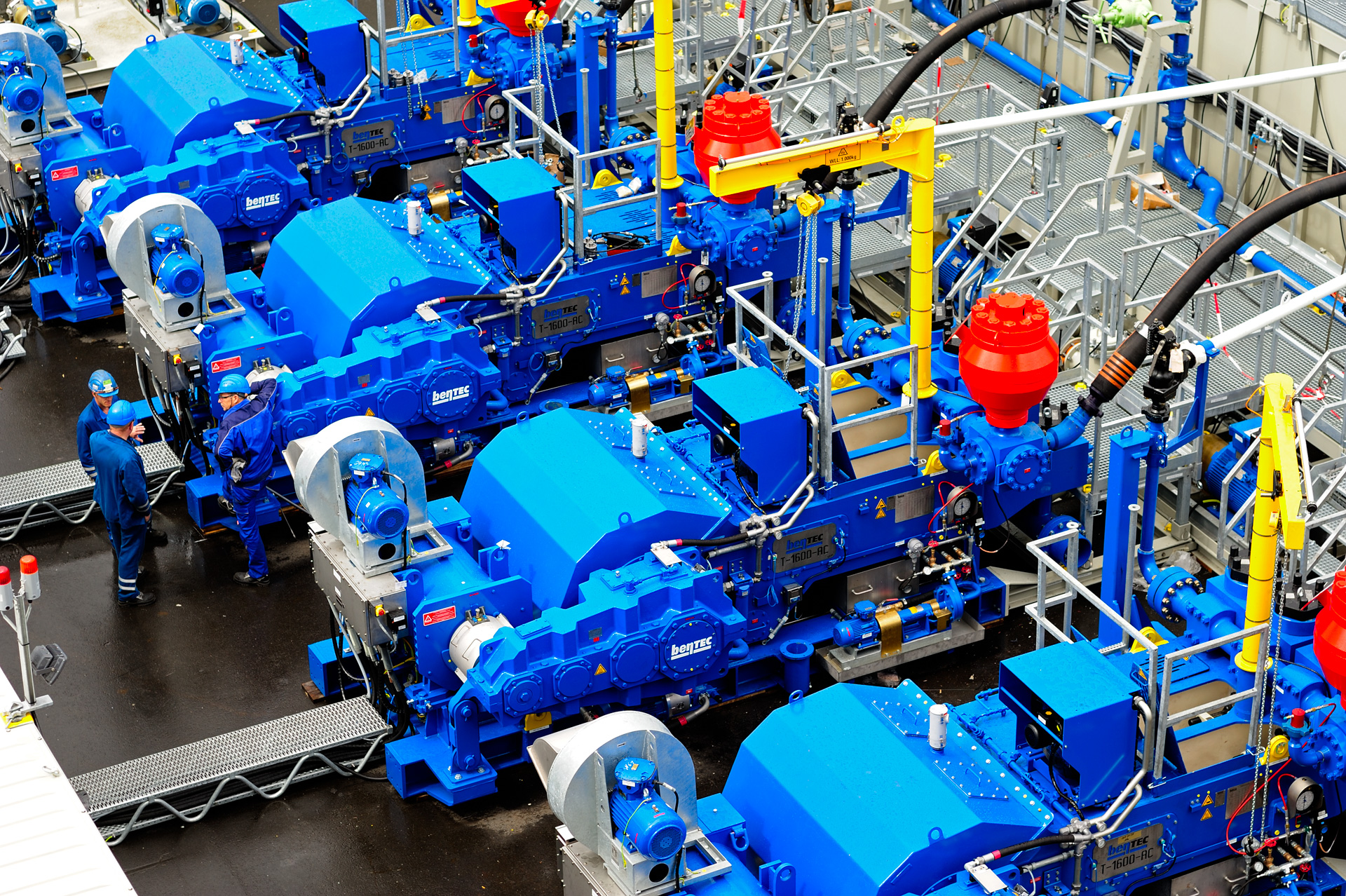

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A wide variety of oil drilling mud pump parts options are available to you, such as 1 year, not available and 2 years.You can also choose from new, oil drilling mud pump parts,As well as from energy & mining, construction works , and machinery repair shops. and whether oil drilling mud pump parts is 1.5 years, 6 months, or unavailable.

When choosing a size and type of mud pump for your drilling project, there are several factors to consider. These would include not only cost and size of pump that best fits your drilling rig, but also the diameter, depth and hole conditions you are drilling through. I know that this sounds like a lot to consider, but if you are set up the right way before the job starts, you will thank me later.

Recommended practice is to maintain a minimum of 100 to 150 feet per minute of uphole velocity for drill cuttings. Larger diameter wells for irrigation, agriculture or municipalities may violate this rule, because it may not be economically feasible to pump this much mud for the job. Uphole velocity is determined by the flow rate of the mud system, diameter of the borehole and the diameter of the drill pipe. There are many tools, including handbooks, rule of thumb, slide rule calculators and now apps on your handheld device, to calculate velocity. It is always good to remember the time it takes to get the cuttings off the bottom of the well. If you are drilling at 200 feet, then a 100-foot-per-minute velocity means that it would take two minutes to get the cuttings out of the hole. This is always a good reminder of what you are drilling through and how long ago it was that you drilled it. Ground conditions and rock formations are ever changing as you go deeper. Wouldn’t it be nice if they all remained the same?

Centrifugal-style mud pumps are very popular in our industry due to their size and weight, as well as flow rate capacity for an affordable price. There are many models and brands out there, and most of them are very good value. How does a centrifugal mud pump work? The rotation of the impeller accelerates the fluid into the volute or diffuser chamber. The added energy from the acceleration increases the velocity and pressure of the fluid. These pumps are known to be very inefficient. This means that it takes more energy to increase the flow and pressure of the fluid when compared to a piston-style pump. However, you have a significant advantage in flow rates from a centrifugal pump versus a piston pump. If you are drilling deeper wells with heavier cuttings, you will be forced at some point to use a piston-style mud pump. They have much higher efficiencies in transferring the input energy into flow and pressure, therefore resulting in much higher pressure capabilities.

Piston-style mud pumps utilize a piston or plunger that travels back and forth in a chamber known as a cylinder. These pumps are also called “positive displacement” pumps because they literally push the fluid forward. This fluid builds up pressure and forces a spring-loaded valve to open and allow the fluid to escape into the discharge piping of the pump and then down the borehole. Since the expansion process is much smaller (almost insignificant) compared to a centrifugal pump, there is much lower energy loss. Plunger-style pumps can develop upwards of 15,000 psi for well treatments and hydraulic fracturing. Centrifugal pumps, in comparison, usually operate below 300 psi. If you are comparing most drilling pumps, centrifugal pumps operate from 60 to 125 psi and piston pumps operate around 150 to 300 psi. There are many exceptions and special applications for drilling, but these numbers should cover 80 percent of all equipment operating out there.

The restriction of putting a piston-style mud pump onto drilling rigs has always been the physical size and weight to provide adequate flow and pressure to your drilling fluid. Because of this, the industry needed a new solution to this age-old issue.

As the senior design engineer for Ingersoll-Rand’s Deephole Drilling Business Unit, I had the distinct pleasure of working with him and incorporating his Centerline Mud Pump into our drilling rig platforms.

In the late ’90s — and perhaps even earlier — Ingersoll-Rand had tried several times to develop a hydraulic-driven mud pump that would last an acceptable life- and duty-cycle for a well drilling contractor. With all of our resources and design wisdom, we were unable to solve this problem. Not only did Miller provide a solution, thus saving the size and weight of a typical gear-driven mud pump, he also provided a new offering — a mono-cylinder mud pump. This double-acting piston pump provided as much mud flow and pressure as a standard 5 X 6 duplex pump with incredible size and weight savings.

The true innovation was providing the well driller a solution for their mud pump requirements that was the right size and weight to integrate into both existing and new drilling rigs. Regardless of drill rig manufacturer and hydraulic system design, Centerline has provided a mud pump integration on hundreds of customer’s drilling rigs. Both mono-cylinder and duplex-cylinder pumps can fit nicely on the deck, across the frame or even be configured for under-deck mounting. This would not be possible with conventional mud pump designs.

Centerline stuck with their original design through all of the typical trials and tribulations that come with a new product integration. Over the course of the first several years, Miller found out that even the best of the highest quality hydraulic cylinders, valves and seals were not truly what they were represented to be. He then set off on an endeavor to bring everything in-house and began manufacturing all of his own components, including hydraulic valves. This gave him complete control over the quality of components that go into the finished product.

The second generation design for the Centerline Mud Pump is expected later this year, and I believe it will be a true game changer for this industry. It also will open up the application to many other industries that require a heavier-duty cycle for a piston pump application.

Maintaining /monitoring the mud pumps and mud pits during operations. Notifying the Driller immediately of any unexplained pit level increases/decreases Verify and record drilling fluid properties at ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

Assist internal and external customers with troubleshooting of Rig Equipment (Top Drive, Catwalk, Wrench, Drawworks, VFDs, Generators, Mud Pumps, BOP) Expeditiously work to troubleshoot and resolve downtime ...

include but are not limited to safely and efficiently performing all tasks within the Rig Operations Areas of the Platform at the direction and under the supervision of the Crane Operator. Tasks may include ...

and special projects as may be directed. Additional functions N/A Qualifications Necessary qualifications, skills and abilities Able to identify and understand functionality of various rig equipment. ...

and special projects as may be directed. Qualifications Necessary qualifications, skills and abilities Able to identify and understand functionality of various rig equipment. Able to identify and understand ...

include but are not limited to: Safely and efficiently performing all tasks on the rig floor and B.O.P. area under the direction and supervision of the Driller. Operating the tongs, slips, and spinners ...

Assist higher level technicians, as well as work independently with minimal supervision. Promote a safe and quality environment in which to work Perform preventative maintenance requirements and maintain ...

The Driller must STOP the job if the situation is unsafe and report to Tool pusher. Conducts operations in a safe manner according to Policies and Procedures. Applies proper rig operating procedures, ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

as required by the Driller, Derrickhand or Rig Manage Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

Assists the Crew Pusher and/or TRS Lead in carrying out all routine, non-routine and emergency operational activities around the rig floor areas or any other area of the rig location as designated by ...

are prominent in every aspect of drilling the well, manual handling of tubular and tools, making up or breaking out during making connections or tripping pipe. The position is responsible for the processes ...

Rundong Company is a professional manufacturer of oil drilling equipment and drill rig components. In oil drilling, we need a pump to deliver water, mud and other drilling fluids, so the mud pump is an essential part of drilling equipment. Our core products are drilling mud pumps, offer duplex and triplex mud pumps and all mud pump components. We possess advanced expertise in quality mud pump production and our mud pump can be used as replacement parts for brands like Gardner Denver, Wheatley, National, Emsco, Ideco, Oilwell, FMC, OPI, etc. We have developed several series of mud pumps ideal for use on oil drilling rigs and well workover rigs.

8613371530291

8613371530291